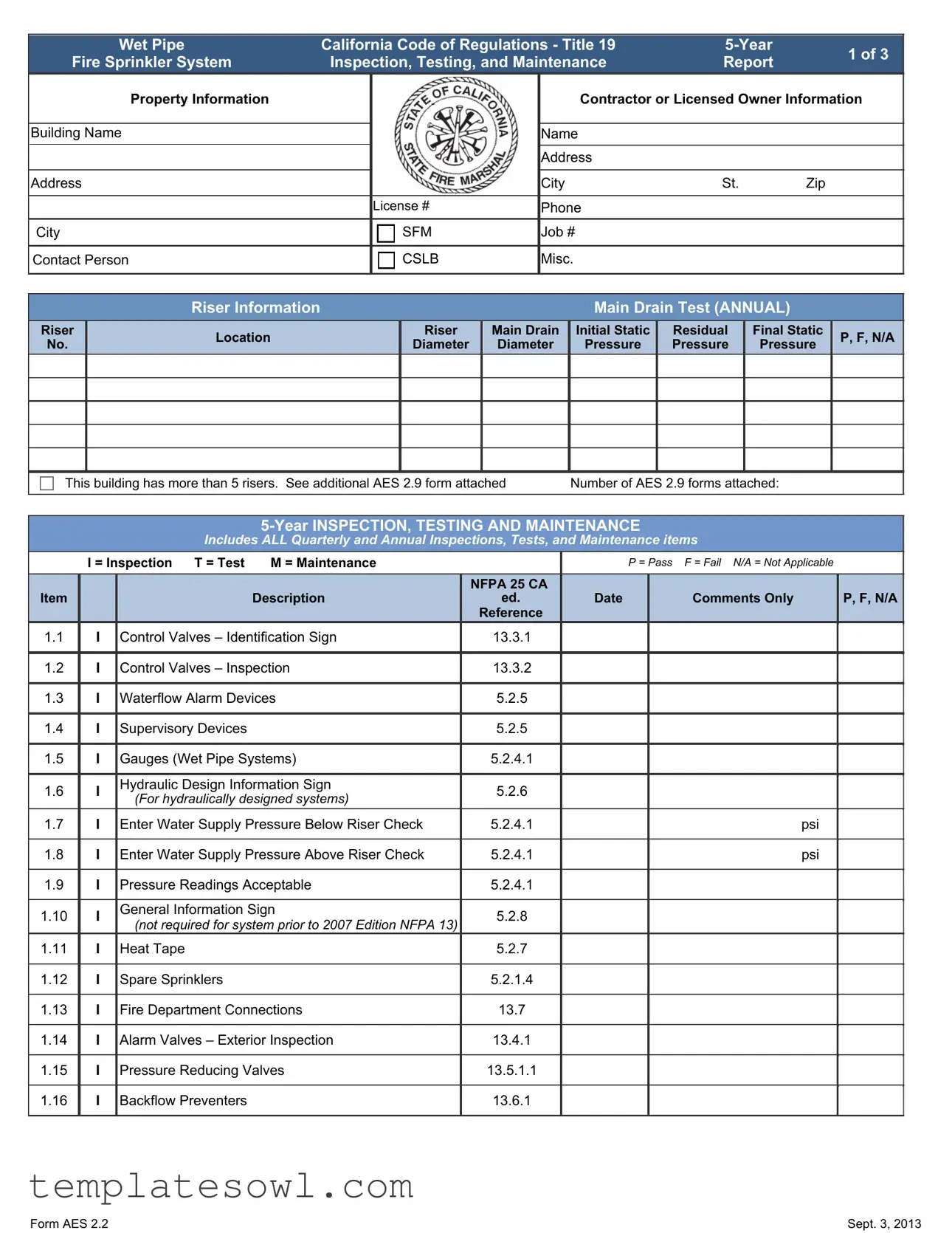

Fill Out Your 5 Year Fire Sprinkler Inspection Form

The 5 Year Fire Sprinkler Inspection form serves a critical purpose in ensuring the safety and operational effectiveness of fire sprinkler systems. This comprehensive document is designed for property owners, contractors, and certified inspectors to record vital information about the inspection, testing, and maintenance of these systems. Detailed sections include property information such as the building's name, address, and contact personnel, as well as contractor details that establish ownership and responsibility. Inspections cover a range of essential components, from control valves and waterflow alarms to backflow preventers and pressure gauges. Each item on the form specifies whether it passed, failed, or was not applicable, alongside references from the National Fire Protection Association (NFPA) standards. Additionally, the form includes provisions for annual inspections, documenting both routine checks and significant tests, such as main drain tests and control valve operations. Inspectors must also note deficiencies, comments, and any equipment found in need of repair or maintenance, underscoring the urgency of keeping fire safety systems fully functional. By adhering to the regulations outlined in the California Code of Regulations - Title 19, this form ensures that fire sprinkler systems meet the necessary safety standards, protecting lives and property.

5 Year Fire Sprinkler Inspection Example

Wet Pipe |

California Code of Regulations - Title 19 |

1 of 3 |

||||

Fire Sprinkler System |

Inspection, Testing, and Maintenance |

Report |

||||

|

||||||

Property Information |

|

|

Contractor or Licensed Owner Information |

|||

|

|

|

|

|

|

|

Building Name |

|

|

Name |

|

|

|

|

|

|

Address |

|

|

|

|

|

|

|

|

|

|

Address |

|

|

City |

St. |

Zip |

|

|

|

|

|

|

|

|

|

|

License # |

Phone |

|

|

|

City |

|

SFM |

Job # |

|

|

|

|

|

|

|

|

|

|

Contact Person |

|

CSLB |

Misc. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Riser Information |

|

|

|

|

|

Main Drain Test (ANNUAL) |

|

||||||

Riser |

|

Location |

Riser |

|

Main Drain |

Initial Static |

|

Residual |

|

Final Static |

P, F, N/A |

|||||

No. |

|

Diameter |

|

Diameter |

Pressure |

|

Pressure |

|

Pressure |

|||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This building has more than 5 risers. See additional AES 2.9 form attached |

Number of AES 2.9 forms attached: |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||||||

|

|

|

Includes ALL Quarterly and Annual Inspections, Tests, and Maintenance items |

|

|

|

||||||||||

|

|

I = Inspection T = Test |

M = Maintenance |

|

|

|

|

|

P = Pass |

F = Fail |

N/A = Not Applicable |

|

||||

Item |

|

|

|

Description |

|

|

NFPA 25 CA |

|

Date |

|

|

Comments Only |

P, F, N/A |

|||

|

|

|

|

|

|

ed. |

|

|

||||||||

|

|

|

|

|

|

|

Reference |

|

|

|

|

|

|

|

|

|

1.1 |

|

I |

Control Valves – Identification Sign |

|

|

13.3.1 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.2 |

|

I |

Control Valves – Inspection |

|

|

13.3.2 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.3 |

|

I |

Waterflow Alarm Devices |

|

|

5.2.5 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.4 |

|

I |

Supervisory Devices |

|

|

|

5.2.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.5 |

|

I |

Gauges (Wet Pipe Systems) |

|

|

5.2.4.1 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.6 |

|

I |

Hydraulic Design Information Sign |

|

|

5.2.6 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

(For hydraulically designed systems) |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.7 |

|

I |

Enter Water Supply Pressure Below Riser Check |

|

5.2.4.1 |

|

|

|

|

|

|

psi |

|

|||

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.8 |

|

I |

Enter Water Supply Pressure Above Riser Check |

|

5.2.4.1 |

|

|

|

|

|

|

psi |

|

|||

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.9 |

|

I |

Pressure Readings Acceptable |

|

|

5.2.4.1 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.10 |

|

I |

General Information Sign |

|

|

5.2.8 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

(not required for system prior to 2007 Edition NFPA 13) |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.11 |

|

I |

Heat Tape |

|

|

|

5.2.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.12 |

|

I |

Spare Sprinklers |

|

|

|

5.2.1.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.13 |

|

I |

Fire Department Connections |

|

|

13.7 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.14 |

|

I |

Alarm Valves – Exterior Inspection |

|

|

13.4.1 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.15 |

|

I |

Pressure Reducing Valves |

|

|

13.5.1.1 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.16 |

|

I |

Backflow Preventers |

|

|

|

13.6.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Form AES 2.2 |

Sept. 3, 2013 |

|

|

|

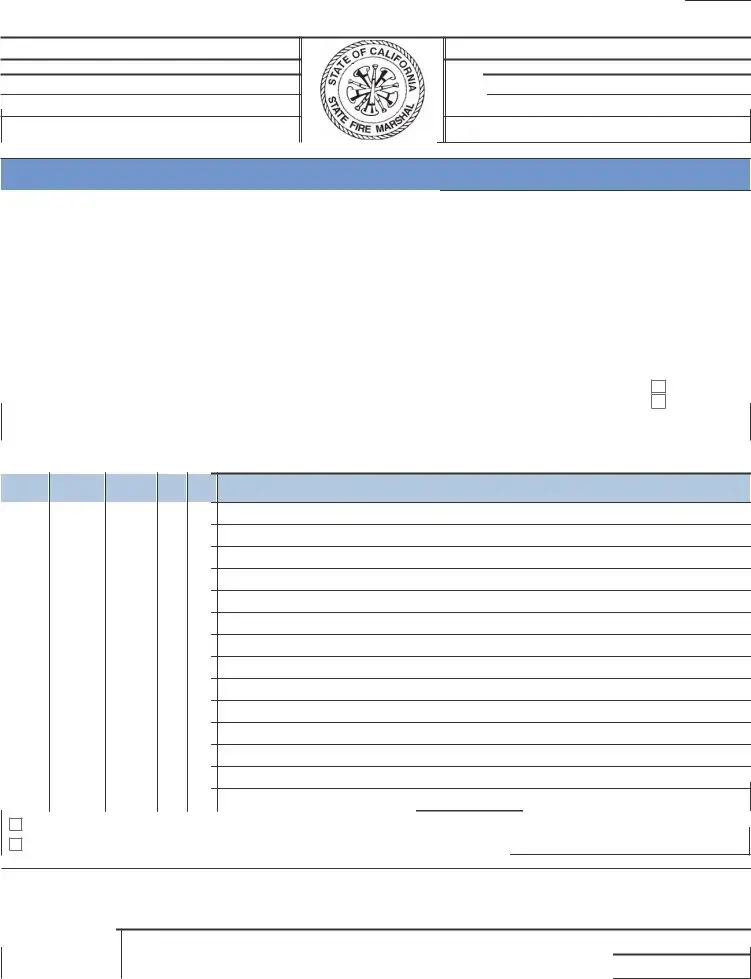

Wet Pipe |

|

California Code of Regulations - Title 19 |

|

5 Year |

2 of 3 |

||||||

|

Fire Sprinkler System |

Inspection, Testing, and Maintenance |

|

Report |

||||||||||

|

|

|

|

|||||||||||

|

|

|

Property Information |

|

|

|

|

Contractor or Licensed Owner Information |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Building Name |

|

|

|

|

Name |

|

|

|

|

|

||||

Address |

|

|

|

|

|

Job # |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

City |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

ANNUAL INSPECTION, TESTING, AND MAINTENANCE |

|

|

||||||||

|

|

|

|

|

Include ALL Quarterly Inspections (See AES 2.1) |

|

|

|||||||

I |

|

= Inspection |

T = Test |

M = Maintenance |

|

|

|

|

P = Pass F = Fail N/A = Not Applicable |

|

|

|||

Item |

|

|

|

Description |

NFPA 25 CA ed. |

|

Date |

|

Comments Only |

P,F,N/A |

||||

|

|

|

Reference |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.17 |

|

I |

Small Hose Connections - Hose Valve* |

5.1.6, 13.5.2 |

|

|

|

|

|

|

|

|||

|

13.5.5.1 |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.18 |

|

I |

PRV – Fire Sprinkler Systems |

13.5.1.1 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.19 |

|

I |

Buildings (Freeze Protection) |

4.1.1.1 |

|

|

|

|

Owner’s Responsibility |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.20 |

|

I |

Sprinklers |

|

|

|

5.2.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.21 |

|

I |

Sprinklers - Accessible Concealed Space |

5.2.1.1.6 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.22 |

|

I |

Pipe and Fittings |

|

|

5.2.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.23 |

|

I |

Pipe and Fittings - Accessible Concealed Space |

5.2.2.3 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.24 |

|

I |

Hangers |

|

|

|

5.2.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.25 |

|

I |

Hangers - Accessible Concealed Space |

5.2.3.3 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.26 |

|

I |

Seismic Braces |

|

|

5.2.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.27 |

|

I |

Seismic Braces - Accessible Concealed Space |

5.2.3.3 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.28 |

|

I |

Unsprinklered Areas |

|

|

CFC 901.4 |

|

|

|

|

Yes |

No |

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

2.1 |

|

T |

Field Service Test Required |

5.3.1 |

|

|

|

|

If REQUIRED, Enter 'F' until |

|

|

|||

|

Send Report to Fire Code Official |

|

|

|

|

results are returned from Lab |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

2.2 |

|

T |

Recalled Sprinklers |

|

|

Title 19 |

|

|

|

|

|

|

|

|

|

If not present = Pass; |

If present = Fail |

904.1(c) |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|||||

2.3 |

|

T |

Water Flow Alarm Devices |

5.3.3 |

|

|

|

|

sec. |

|

|

|||

|

90 secs max. Enter time |

13.2.6 |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

2.4 |

|

T |

Main Drain Test |

|

|

13.2.5 |

|

|

|

|

|

|

|

|

|

(Enter data on Page 1 of this form) |

13.3.3.4 |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||||

2.5 |

|

T |

Control Valve - Position |

|

|

13.3.3.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.6 |

|

T |

Control Valve – Operation |

|

|

13.3.3.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.7 |

|

T |

Supervisory Devices |

|

|

13.3.3.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

2.8 |

|

T |

Backflow Preventer Assemblies |

13.6.2 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.9 |

|

T |

Small Hose Connections* |

|

|

13.5.2.3 |

|

|

|

|

|

|

|

|

|

w/PRV Hose Valves – Partial Flow Test |

13.5.3.3 |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||||

2.10 |

|

T |

PRV – Fire Sprinkler Systems |

13.5.1.3 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||

2.11 |

|

T |

Pressure Gauges - Calibration |

5.3.2 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.12 |

|

T |

Small Hose Connections* |

|

|

13.5.6.2.2 |

|

|

|

|

|

|

|

|

* Small hose connections are hose valves and optional hose supplied by the fire sprinkler system. They do not include Class I, II, or III standpipe systems.

Form AES 2.2 |

Sept. 3, 2013 |

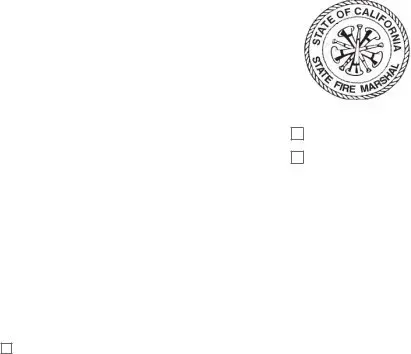

Wet Pipe |

California Code of Regulations - Title 19 |

5 Year |

3 of 3 |

Fire Sprinkler System |

Inspection, Testing, and Maintenance |

Report |

Property Information

Building Name

Address

City

Contractor or Licensed Owner Information

Name

Job #

ANNUAL INSPECTION, TESTING, AND MAINTENANCE

include ALL Quarterly Inspections (See AES 2.1)

I |

= Inspection |

T = Test |

M = Maintenance |

|

P = Pass |

F = Fail N/A = Not Applicable |

|

||||

Item |

|

|

|

Description |

NFPA 25 CA ed. |

Date |

|

Comments Only |

P,F,N/A |

||

|

|

|

Reference |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

3.1 |

M |

Check Valves - Internal inspection |

13.4.2 |

|

|

|

|

|

|

||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

3.2 |

M |

Control Valves |

|

13.3.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

3.3 |

M |

FDC - Backflush |

|

14.3.2.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

14.3.2.4 |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

3.4 |

M |

Internal Pipe Inspection - See Deficiencies and |

14.2 |

|

|

|

|

Yes |

|

||

|

|

|

|

|

|||||||

Comments Section for Results. |

|

|

|

|

No |

|

|||||

|

|

|

|

|

|

|

|

|

|

||

3.5 |

M |

Obstruction Investigation Required. If "Yes", see |

14.3 |

|

|

|

|

|

|

||

|

|

|

|

|

|

||||||

Deficiencies and Comments Section for Results |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||

3.6 |

M |

System Returned to Service |

4.5.3 |

|

|

|

|

Yes |

|

||

|

|

|

|

|

|||||||

|

|

|

|

No |

|

||||||

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||

D = Deficiency C = Comment (Indicate type ) |

|

|

|

|

|

|

|

||||

Item

Date

Riser

D C

Deficiencies and Comments

Indicate all equipment, devices and parts that were repaired or replaced

Check here if additional Deficiencies and Comments are listed on Form AES 9 |

Number attached: |

See Correction Form AES 10 for corrected deficiencies. |

Number attached: |

|

I hereby certify that the fire protection equipment listed above has been fully inspected, tested, and maintained on this date by the company indicated above, in accordance with CCR, Title 19, Sections 901 to 906 and that the equipment is fully operable except as noted in the “Deficiencies and Comments” section of this form.

Print Name

Signature

Date

Form AES 2.2 |

Sept. 3, 2013 |

Form Characteristics

| Fact Name | Description |

|---|---|

| Governing Law | The inspection form is regulated by the California Code of Regulations, Title 19, which outlines safety and maintenance standards for fire sprinkler systems. |

| Inspection Frequency | Fire sprinkler systems must undergo inspections, tests, and maintenance every five years, including all quarterly and annual evaluations. |

| Document Requirements | In addition to the main form, any building with more than five risers requires the submission of the AES 2.9 form detailing additional inspection data. |

| Certified Personnel | The inspection must be conducted by a licensed contractor or owner, who certifies that the equipment is fully operable according to the established guidelines. |

Guidelines on Utilizing 5 Year Fire Sprinkler Inspection

Completing the 5 Year Fire Sprinkler Inspection form is a critical task that requires attention to detail. This document is essential for ensuring compliance with safety regulations and maintaining the integrity of your fire protection system. Follow the steps below to accurately fill out the form.

- Begin by entering the property information:

- Building Name

- Address

- City

- State

- Zip Code

- Fill in the contractor or licensed owner's information:

- Name

- License Number

- Phone Number

- City

- Job Number

- Contact Person

- California State License Board (CSLB) Number

- Address riser information by entering:

- Riser Location

- Main Drain Test results including Initial Static, Residual, and Final Static pressures

- Number of additional AES 2.9 forms if applicable

- Move on to the inspection, testing, and maintenance section. Fill out each item as follows, using the codes provided (I for Inspection, T for Test, M for Maintenance, P for Pass, F for Fail, N/A for Not Applicable):

- Check the boxes for Control Valves, Waterflow Alarm Devices, Gauges, and others as per the form.

- Record the date of inspection and comments as needed.

- Make sure to fill out any pressure readings in psi where required.

- Complete the section for additional tests and checks as indicated, such as:

- Main Drain Test

- Control Valve operations

- Spares and connections

- Check and fill out the maintenance items that include internal inspections and system operations. Address any deficiencies noted during the inspection.

- Once all sections are completed, certify the form by:

- Printing your name

- Signing the form

- Entering the date of certification

Make sure to double-check all entries for accuracy. Sending the completed form to the appropriate fire code official ensures compliance and maintains your facility's safety standards. Don’t delay—this documentation is vital for both regulatory compliance and the safety of all building occupants.

What You Should Know About This Form

What is the purpose of the 5 Year Fire Sprinkler Inspection form?

The 5 Year Fire Sprinkler Inspection form is essential for documenting the inspection, testing, and maintenance of fire sprinkler systems. This form ensures compliance with regulatory standards and helps maintain the safety and functionality of fire protection systems in buildings.

Who is qualified to fill out this form?

This form should be completed by a licensed contractor or a qualified individual responsible for inspecting fire sprinkler systems. Their expertise ensures that all tests and maintenance activities are performed correctly and that the system meets the necessary safety standards.

What information is required on the form?

Key pieces of information needed include property details like the building name, address, and city, along with the contractor’s contact information. The form also requires inspection results for various components of the sprinkler system, including control valves, water flow alarms, and backflow preventers.

How often should the inspection be performed?

The inspection should be conducted every five years. However, routine inspections and testing occur quarterly and annually. All findings and maintenance activities should be accurately recorded in the form to ensure ongoing compliance and safety.

What happens if a failure is noted during inspection?

If any component fails the inspection, it's crucial to address the issue immediately. The form allows for the documentation of deficiencies and the necessary corrective actions. Repairs or replacements must be conducted before the fire protection equipment can be deemed operable.

Is there a specified deadline for submitting the completed form?

While the form does not explicitly state a submission deadline, it is advisable to submit the completed inspection report promptly after the evaluation. This helps ensure that any issues are logged and addressed while they are still fresh in records, maintaining compliance and safety.

Can I attach additional comments or documentation?

Yes, if there are additional comments or documented deficiencies, you can attach extra sheets, like Form AES 9, to provide more detail. Ensure that all necessary documentation accompanies the submission so that complete records are maintained for future reference.

Common mistakes

When filling out the 5 Year Fire Sprinkler Inspection form, many individuals make common mistakes that can lead to significant issues. One prevalent error is failing to provide comprehensive property information. It is crucial to include the complete building name, address, and city. Incomplete details may delay processing or confuse inspectors about the location of the fire sprinkler system.

Another mistake often seen is the incorrect designation of inspection results. Respondents sometimes fail to use the appropriate Pass, Fail, or Not Applicable indicators. Each item listed requires a clear status to reflect the condition accurately. Using vague terms or omitting these indicators can mislead everyone involved regarding the system's safety and functionality.

People frequently neglect the comments section or provide unclear remarks. This section is vital for explaining any anomalies or special circumstances detected during the inspection. By omitting comments or being vague, crucial details about equipment conditions may be lost, hindering efficient addressing of future repairs or maintenance.

Additionally, individuals sometimes overlook entering accurate pressure readings during tests. Incorrect static or residual pressure entries compromise the reliability of the test results. Each pressure reading must be noted carefully, ensuring that they fall within acceptable parameters. Failing to do so can result in inappropriate maintenance actions or neglect of necessary repairs.

Lastly, individuals often forget to certify the inspection at the end of the form. Signature and date affirmation validate the completion of the necessary checks. Neglecting this step may render the form invalid and lead to compliance issues. A properly completed form reflects diligence and ensures that safety standards are met.

Documents used along the form

Regular inspections and maintenance of fire sprinkler systems are critical to ensuring safety and compliance. Alongside the 5 Year Fire Sprinkler Inspection form, several other documents play crucial roles in this process. Here’s a brief overview of these essential documents.

- AES 2.1 Quarterly Inspection Form: This form outlines the requirements for quarterly inspections of fire sprinkler systems, detailing specific tests and maintenance checks that must be conducted every three months.

- AES 2.9 Additional Inspection Form: Used when a building has more than five risers, this form supplements the main inspection form by providing additional space for documenting results related to the extra risers.

- AES 9 Deficiencies and Comments Form: This document captures any deficiencies discovered during inspections, along with notes on repairs or maintenance required. It helps maintain a clear record of issues and resolutions.

- AES 10 Correction Form: It is used to report and document any corrections made to deficiencies noted on earlier inspection forms. This ensures that all issues are tracked and resolved appropriately.

- Annual Fire Safety Report: This report compiles information from all inspections and tests conducted throughout the year. It is often submitted to fire code officials to demonstrate compliance with safety regulations.

These documents collectively help ensure that fire sprinkler systems remain reliable and effective in protecting property and lives from fire hazards. Proper documentation creates a transparent record for both maintenance staff and regulatory authorities.

Similar forms

Annual Fire Alarm Inspection Report: Similar to the 5 Year Fire Sprinkler Inspection form, an Annual Fire Alarm Inspection Report outlines the inspection, testing, and maintenance of fire alarm systems. It ensures that alarm devices are functioning properly and identifies any needed repairs.

Fire Extinguisher Inspection Record: This document tracks the inspection and maintenance of fire extinguishers on a property. Like the sprinkler inspection report, it provides essential information about compliance with safety regulations and equipment functionality.

Fire System Maintenance Log: This log records all routine checks and maintenance performed on fire protection systems. It serves a similar purpose to the 5 Year Fire Sprinkler Inspection form by documenting service history and compliance status.

Emergency Lighting Inspection Report: This document details inspections of emergency lighting systems, ensuring compliance with safety codes. It shares the same goal of verifying that life safety systems are operational, similar to the sprinkler inspection.

Smoke Detector Testing Form: This form records the testing of smoke detectors in a property. It highlights operational status and compliance, similar to how the fire sprinkler form indicates the condition of sprinkler systems.

Backflow Prevention Assembly Testing Report: Much like the 5 Year Sprinkler Inspection form, this report outlines the testing and maintenance of backflow prevention devices to prevent contamination in water systems.

Kitchen Hood and Fire Suppression System Inspection Report: This report ensures that fire suppression systems in cooking areas are maintained and functioning correctly, similar to how fire sprinklers are inspected in the 5 Year form.

Carbon Monoxide Detector Inspection Record: This document verifies the inspection of carbon monoxide detectors, ensuring they are operational and compliant with safety standards, akin to the function of the fire sprinkler inspection report.

Hazardous Materials Inventory and Inspection Form: This document tracks hazardous materials on a property and their safety measures. Just like the sprinkler inspection report emphasizes compliance, this form underscores compliance with safety regulations related to hazardous materials.

Building Fire Safety Audit Form: This comprehensive document includes assessments of fire safety features, including sprinkler systems. It promotes overall safety compliance, paralleling the detailed inspections conducted in the 5 Year Fire Sprinkler Inspection report.

Dos and Don'ts

When filling out the 5 Year Fire Sprinkler Inspection form, attention to detail is crucial. Here are some guidelines to help ensure the form is completed correctly.

- Do: Clearly print all information in the designated areas.

- Do: Use complete names for companies and contractors.

- Do: Double-check measurements for accuracy, especially pressure readings.

- Do: Include all required documentation, such as additional forms if there are multiple risers.

- Do: Sign and date the form to validate the inspection.

- Don't: Leave any section blank unless it is marked as not applicable.

- Don't: Use abbreviations that could lead to confusion.

- Don't: Submit the form without reviewing the comments and deficiencies section.

- Don't: Forget to inform stakeholders about the inspection results.

- Don't: Alter any information after the form has been signed unless properly documented.

Misconceptions

Misconception 1: The 5 Year Fire Sprinkler Inspection Form is not necessary for every building.

Many individuals believe that only large or commercial buildings require this inspection form. In reality, any building that has a fire sprinkler system must adhere to strict inspection and maintenance guidelines, regardless of its size. This includes residential properties and small commercial spaces. Compliance ensures that all sprinkler systems function correctly in emergencies.

Misconception 2: If the system passes the inspection once, it will be fine indefinitely.

Some might think that passing an inspection provides a long-term assurance of safety. This is misleading. Fire sprinkler systems require regular inspections, tests, and maintenance. Conditions change over time due to environmental factors, wear and tear, or modifications in building structures. Regular five-year inspections are vital for ensuring ongoing compliance and functionality.

Misconception 3: The 5 Year Fire Sprinkler Inspection Form is only a checklist and has no legal implications.

This form holds legal significance as it documents the inspection, testing, and maintenance of fire sprinkler systems. Failing to complete or properly maintain records can lead to legal liabilities, especially if issues arise during a fire. Insurance companies and regulators look for these forms to verify compliance with safety codes.

Misconception 4: Owners can self-certify their fire sprinkler systems.

While individuals may feel confident about inspecting their systems, the form requires that inspections be conducted by licensed professionals. This ensures that the evaluations are thorough and conducted per established safety standards. Self-certification can lead to potentially hazardous oversights, which could jeopardize safety.

Key takeaways

The 5 Year Fire Sprinkler Inspection form assesses the condition and functionality of fire sprinkler systems in compliance with state regulations.

Accurate completion of the form is essential, as it contains both property and contractor details which must be filled out correctly to ensure proper identification and contact.

An annual inspection is required as part of the 5-year cycle, including a detailed evaluation of components like control valves and waterflow alarm devices.

Each inspection and maintenance item is marked as Pass, Fail, or Not Applicable, providing clear insights into the system's operational status.

Pressure readings must be carefully noted during inspections. They are critical to confirm that systems are functioning within acceptable limits.

The form requires documentation of any deficiencies or repairs found during the inspection. This information is crucial for future maintenance planning.

All entries should be accompanied by dates and comments to provide context for the inspection findings, enhancing accountability and record-keeping.

Browse Other Templates

Conditional Lien Release - This waiver includes comprehensive language regarding the assumption of risk by the Subcontractor.

Sheltercare Pet Insurance - Take the time to fill out every section to ensure no information is missing.