Fill Out Your Auto Repair Checklist Form

When it comes to ensuring the safety and compliance of an auto repair shop, a well-structured Auto Repair Checklist can be an invaluable tool. Designed primarily for shop owners, this self-audit form lays out critical criteria that encompass federal environmental, health, and safety regulations alongside fire codes. By categorizing requirements into three sections, the checklist helps streamline the inspection process. Section A addresses the overall conditions at the site, focusing on crucial elements like materials and waste management, building standards, general equipment safety, and health practices. Section B dives deeper into specific auto shop operations, covering everything from routine car maintenance to battery storage practices. Lastly, Section C offers a space for noting deficiencies and tracking recommended corrective actions, allowing for continuous improvement. Beyond compliance, the checklist provides insightful tips for reducing pollution and enhancing workplace safety, emphasizing that a proactive approach is not only about meeting legal mandates but also about fostering a safe and efficient working environment.

Auto Repair Checklist Example

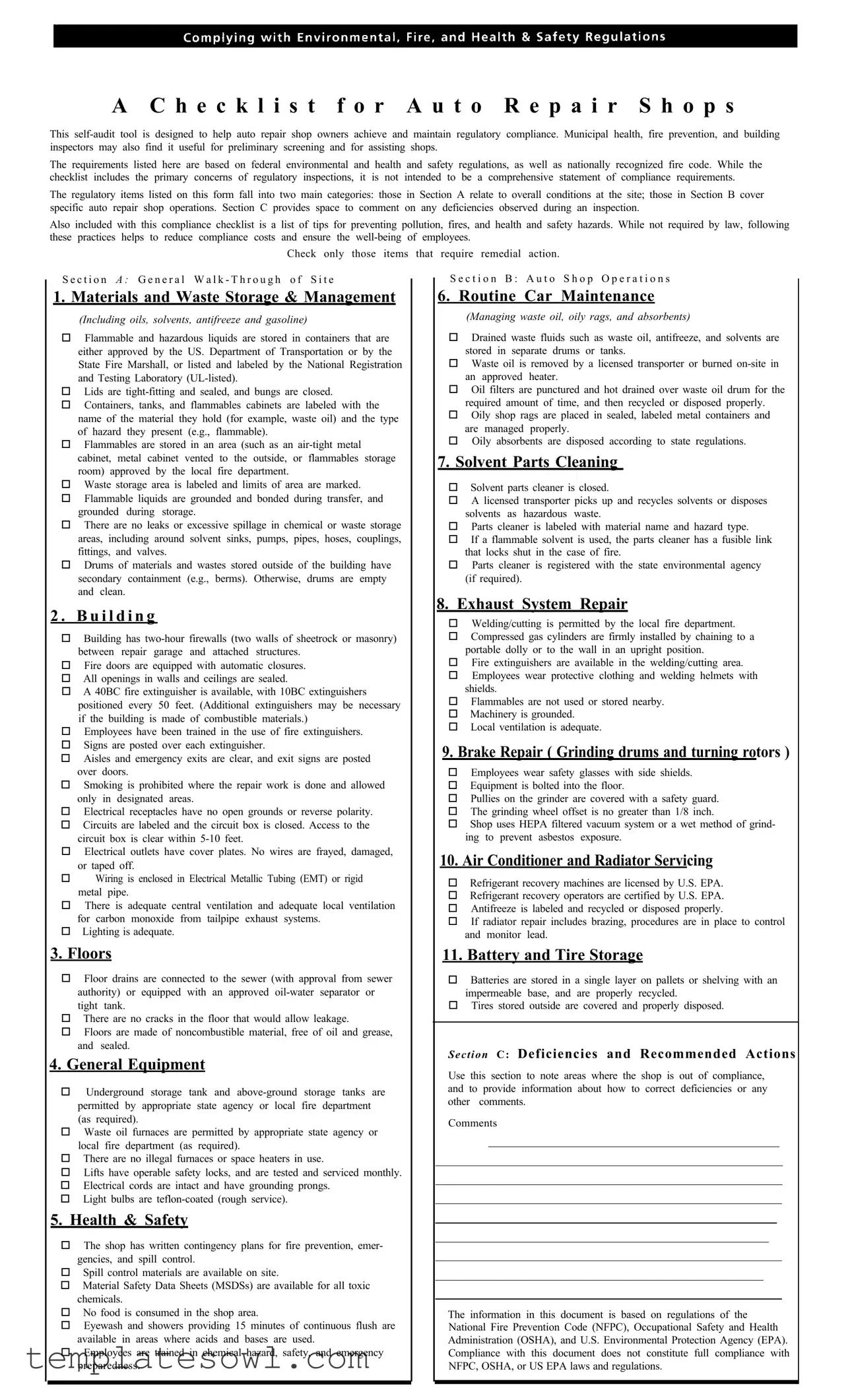

A C h e c k l i s t f o r A u t o R e p a i r S h o p s

This

The requirements listed here are based on federal environmental and health and safety regulations, as well as nationally recognized fire code. While the checklist includes the primary concerns of regulatory inspections, it is not intended to be a comprehensive statement of compliance requirements.

The regulatory items listed on this form fall into two main categories: those in Section A relate to overall conditions at the site; those in Section B cover specific auto repair shop operations. Section C provides space to comment on any deficiencies observed during an inspection.

Also included with this compliance checklist is a list of tips for preventing pollution, fires, and health and safety hazards. While not required by law, following these practices helps to reduce compliance costs and ensure the

Check only those items that require remedial action.

Section A : G e n e r a l W a l k - T h r o u g h o f S i t e

1. Materials and Waste Storage & Management

(Including oils, solvents, antifreeze and gasoline)

oFlammable and hazardous liquids are stored in containers that are either approved by the US. Department of Transportation or by the State Fire Marshall, or listed and labeled by the National Registration and Testing Laboratory

oLids are

oContainers, tanks, and flammables cabinets are labeled with the name of the material they hold (for example, waste oil) and the type of hazard they present (e.g., flammable).

oFlammables are stored in an area (such as an

cabinet, metal cabinet vented to the outside, or flammables storage room) approved by the local fire department.

oWaste storage area is labeled and limits of area are marked.

oFlammable liquids are grounded and bonded during transfer, and grounded during storage.

oThere are no leaks or excessive spillage in chemical or waste storage areas, including around solvent sinks, pumps, pipes, hoses, couplings, fittings, and valves.

oDrums of materials and wastes stored outside of the building have secondary containment (e.g., berms). Otherwise, drums are empty and clean.

2 . Building

oBuilding has

oFire doors are equipped with automatic closures.

oAll openings in walls and ceilings are sealed.

oA 40BC fire extinguisher is available, with 10BC extinguishers positioned every 50 feet. (Additional extinguishers may be necessary if the building is made of combustible materials.)

oEmployees have been trained in the use of fire extinguishers.

oSigns are posted over each extinguisher.

oAisles and emergency exits are clear, and exit signs are posted

over doors.

oSmoking is prohibited where the repair work is done and allowed only in designated areas.

oElectrical receptacles have no open grounds or reverse polarity.

oCircuits are labeled and the circuit box is closed. Access to the circuit box is clear within

oElectrical outlets have cover plates. No wires are frayed, damaged, or taped off.

oWiring is enclosed in Electrical Metallic Tubing (EMT) or rigid

metal pipe.

oThere is adequate central ventilation and adequate local ventilation for carbon monoxide from tailpipe exhaust systems.

oLighting is adequate.

3.Floors

oFloor drains are connected to the sewer (with approval from sewer authority) or equipped with an approved

oThere are no cracks in the floor that would allow leakage.

oFloors are made of noncombustible material, free of oil and grease, and sealed.

4.General Equipment

oUnderground storage tank and

oWaste oil furnaces are permitted by appropriate state agency or local fire department (as required).

oThere are no illegal furnaces or space heaters in use.

oLifts have operable safety locks, and are tested and serviced monthly.

oElectrical cords are intact and have grounding prongs.

oLight bulbs are

5.Health & Safety

oThe shop has written contingency plans for fire prevention, emer- gencies, and spill control.

oSpill control materials are available on site.

oMaterial Safety Data Sheets (MSDSs) are available for all toxic chemicals.

oNo food is consumed in the shop area.

oEyewash and showers providing 15 minutes of continuous flush are available in areas where acids and bases are used.

oEmployees are trained in chemical hazard, safety, and emergency preparedness.

S e c t i o n B : A u t o S h o p O p e r a t i o n s

6. Routine Car Maintenance

(Managing waste oil, oily rags, and absorbents)

oDrained waste fluids such as waste oil, antifreeze, and solvents are stored in separate drums or tanks.

oWaste oil is removed by a licensed transporter or burned

oOil filters are punctured and hot drained over waste oil drum for the required amount of time, and then recycled or disposed properly.

oOily shop rags are placed in sealed, labeled metal containers and are managed properly.

oOily absorbents are disposed according to state regulations.

7.Solvent Parts Cleaning

oSolvent parts cleaner is closed.

oA licensed transporter picks up and recycles solvents or disposes solvents as hazardous waste.

oParts cleaner is labeled with material name and hazard type.

oIf a flammable solvent is used, the parts cleaner has a fusible link that locks shut in the case of fire.

oParts cleaner is registered with the state environmental agency

(if required).

8. Exhaust System Repair

oWelding/cutting is permitted by the local fire department.

oCompressed gas cylinders are firmly installed by chaining to a portable dolly or to the wall in an upright position.

oFire extinguishers are available in the welding/cutting area.

oEmployees wear protective clothing and welding helmets with shields.

oFlammables are not used or stored nearby.

oMachinery is grounded.

oLocal ventilation is adequate.

9.Brake Repair ( Grinding drums and turning rotors )

oEmployees wear safety glasses with side shields.

oEquipment is bolted into the floor.

oPullies on the grinder are covered with a safety guard.

oThe grinding wheel offset is no greater than 1/8 inch.

oShop uses HEPA filtered vacuum system or a wet method of grind- ing to prevent asbestos exposure.

10. Air Conditioner and Radiator Servicing

oRefrigerant recovery machines are licensed by U.S. EPA.

oRefrigerant recovery operators are certified by U.S. EPA.

oAntifreeze is labeled and recycled or disposed properly.

oIf radiator repair includes brazing, procedures are in place to control and monitor lead.

11. Battery and Tire Storage

oBatteries are stored in a single layer on pallets or shelving with an impermeable base, and are properly recycled.

oTires stored outside are covered and properly disposed.

SECTION C: Deficiencies and Recommended Actions

Use this section to note areas where the shop is out of compliance, and to provide information about how to correct deficiencies or any other comments.

Comments

The information in this document is based on regulations of the National Fire Prevention Code (NFPC), Occupational Safety and Health Administration (OSHA), and U.S. Environmental Protection Agency (EPA). Compliance with this document does not constitute full compliance with NFPC, OSHA, or US EPA laws and regulations.

T i p s f o r A u t o R e p a i r S h o p s

The practices listed on this sheet provide specific ways to save on compliance costs by preventing environmental pollution and protecting the health and safety of workers.

S E C T I O N A :

G e n e r a l S i t e C o n d i t i o n s

Material Storage & Management

Purchasing

lOrder chemicals in appropriate amounts. Expired chemicals are costly to dispose and may pose a fire hazard.

lInspect materials immediately upon deliv- ery for leaks or other damage.

lPurchase

lAsk your supplier for the least hazardous materials suitable for the job. Review the Material Safety Data Sheets (MSDSs) prior to purchase.

Storage

lOrganize and label oils, chemicals, and haz- ardous materials in a single storage area.

lCreate an inventory system for oils, chemi- cals, and hazardous materials. Rotate your inventory.

lKeep unused materials in their original containers.

lInspect storage areas to identify points where spilled chemicals could enter the environment, such as floor drains, door ways, loading docks, catch basins, dirt or cracked floors. Avoid storing, dispensing or mixing chemicals in these areas.

lStore flammables in a location other than the building where people normally work, in a manner approved by local fire and health departments.

Usage

lUse

lAsk employees to return empty containers, such as, spray cans before they use new supplies.

lPour and mix chemicals in a

lUse only one spray can at a time of brake or carburetor cleaners, lubricants, grease, and sealants.

B u i l d i n g / F l o o r s

lContract with a fire extinguisher company to test and fill extinguishers once a year.

lRemove overhead items that could cause head injuries.

lKeep floors as dry as possible to prevent falls and potential electrical hazards.

lUse

lContract with a waste removal company to empty oil/water separators or tanks at least once a year.

lSeal floor drains, if approved by local authorities.

lUse magnetic covers for drains or dry wells.

O u t s i d e o f B u i l d i n g

lEnsure that catch basins have oil separators

lKeep catch basin sumps empty and clean.

lKeep wells locked and sealed.

S E C T I O N B :

A u t o S h o p O p e r a t i o n s -

Routine Car Maintenace

Reducing Spills

lBuild berms to contain 110% of the vol- ume of the largest container or tank in the storage area.

lPrevent waste oil spills by using drip pans. Place oily parts in the drip pan rather than on the floor.

lUse a resealable funnel to minimize spills from drip pans.

Cleaning Up Spills

lIf you do spill waste oil, use dry cleanup methods such as reusable absorbent pads, mops that absorb only oily liquids, or a bristle broom and dustpan. Drain excess oil into drip pans and then into a waste oil drum or tank.

lAfter using dry cleanup methods, remove any remaining waste oil with rags.

lUse clay absorbents or sawdust only as

a last resort. Check with your state environmental agency to find out how to properly dispose or recycle used absorbents.

Solvent Parts Cleaning

lUse aqueous cleaners instead of solvents.

lTo avoid drips, position the parts cleaner close to the work station.

lWear gloves and eye protection when handling solvents.

lUse a wire brush for cleaning before using solvents.

lFor very dirty parts, use a

lRemove cleaned parts slowly and allow them to drain over the sink.

B r a k e G r i n d i n g

lCapture metal filings in a bin under the brake grinder and dispose in trash.

Radiator Flushing and Repair

lReclaim antifreeze

lNever mix used antifreeze with used oil.

Batteries / Tires / Scrap Metal Parts

lWhen recharging batteries

lRecycle batteries, tires, and scrap metal parts.

lStore batteries inside the shop.

F O R

A d d i t i o n a l I n f o r m a t i o n -

L o c a l R e s o u r c e s

Contact your local Fire Department, Board of Health, Building Inspector, Code Enforcement Officer, or Local Emergency Planning Committee.

S t a t e R e s o u r c e s

Each state provides free, confidential techni- cal assistance for preventing pollution and meeting waste management and health & safety requirements.

Connecticut

Department of Environmental Protection

Hazardous Waste

Compliance Assistance

Office of Pollution

Prevention860-424-3022

Small Business

Assistance Program

State Fire Marshals Office

OSHA Consultation Program

Maine

Department of Environmental Protection

Office of Pollution |

|

|

Prevention |

|

|

Small Business |

Technical |

|

Assistance Program |

||

Fire Licensing and |

|

|

Inspections |

Unit |

|

OSHA Consultation Program |

||

Massachusetts

Department of Environmental Protection

Information Center |

|

|

|

Office of Technical |

|

Assistance |

|

Department of Fire Services |

|

OSHA Consultation Program |

|

New Hampshire |

|

Department of Environmental Services |

|

Pollution Prevention |

|

Program |

|

Small Business Technical |

|

Assistance Program |

|

Fire Marshals Office |

|

OSHA Consultation Program |

|

Vermont

Department of Environmental Conservation

Small Business Compliance |

|

Assistance |

|

Small Business |

|

Development Center |

|

Fire Prevention Division |

|

OSHA Consultation Program |

|

F e d e r a l R e s o u r c e s

U.S. EPA Region I |

|

New England |

Environmental |

Assistance Team |

For additional copies of this checklist call

Prepared by the Northeast Waste Management Officials’ Association, with Funding from U.S. EPA Region I

Form Characteristics

| Fact Name | Details |

|---|---|

| Purpose | The Auto Repair Checklist form serves as a self-audit tool, assisting auto repair shop owners in achieving and maintaining compliance with federal environmental, health, and safety regulations. |

| Content Structure | The form is divided into three sections: Section A addresses overall site conditions, Section B focuses on specific auto repair operations, and Section C allows for comments on deficiencies observed during inspections. |

| Compliance References | This checklist includes items based on regulations from major authorities such as the National Fire Prevention Code (NFPC), OSHA, and the U.S. EPA. |

| Utility for Inspections | Besides shop owners, municipal health, fire prevention, and building inspectors can utilize this checklist for preliminary screenings before formal inspections. |

| Additional Resources | Accompanying the checklist are tips for preventing pollution and health hazards, aimed at supporting shops in reducing compliance costs and protecting worker safety. |

Guidelines on Utilizing Auto Repair Checklist

To effectively fill out the Auto Repair Checklist form, follow these clear steps. This checklist can help identify areas needing attention to ensure compliance with safety and environmental regulations. Before starting, gather any necessary documents and take a moment to review the form layout.

- Section A: General Walk-Through of Site - Inspect the conditions at your repair shop. Check all aspects of materials storage, building integrity, floors, equipment, and health and safety. Mark the items that require action.

- Section B: Auto Shop Operations - Look at routine car maintenance procedures, solvent parts cleaning, exhaust system repair, brake repair, air conditioning and radiator servicing, and battery and tire storage. Check off items that need improvement.

- Section C: Deficiencies and Recommended Actions - This section is for noting any areas where compliance is lacking. Provide details on how you plan to address these issues or any other comments that might help with future inspections.

- Additional Tips - Review the tips section for best practices that can further enhance compliance and improve safety in the shop.

- Final Review - Go through the form to ensure all relevant sections are filled out accurately. Make sure you've marked only those items that need remedial action.

What You Should Know About This Form

What is the purpose of the Auto Repair Checklist form?

The Auto Repair Checklist is a self-audit tool designed for auto repair shop owners. Its primary aim is to help owners achieve and maintain compliance with various regulatory standards related to health, safety, and environmental practices. Municipal inspectors may also find it useful for preliminary screenings of auto repair shops.

What are the main sections of the checklist?

The checklist is divided into three main sections. Section A addresses general conditions at the site. This includes items related to materials and waste storage, building safety, and health and safety practices. Section B focuses on specific auto shop operations, such as routine car maintenance and solvent parts cleaning. Section C allows users to comment on observed deficiencies and recommended actions for improvement.

Who should use this checklist?

This checklist is intended for auto repair shop owners, municipal health inspectors, fire prevention officials, and anyone responsible for ensuring safety and compliance in auto repair operations. It serves as a guide to identify potential compliance risks and improve safety outcomes at the shop.

What types of regulations does the checklist address?

The checklist emphasizes compliance with federal regulations including those set by the Occupational Safety and Health Administration (OSHA), the Environmental Protection Agency (EPA), and the National Fire Protection Association (NFPA). These regulations cover a broad range of health, safety, and environmental issues that could impact auto repair operations.

Is the checklist comprehensive?

No, while the checklist includes vital compliance concerns, it is not exhaustive. Users should refer to specific regulatory guidelines for a complete understanding of compliance requirements applicable to their operations. The checklist serves as a starting point rather than a definitive source.

How can following the checklist benefit an auto repair shop?

By following the checklist, auto repair shops can reduce compliance costs, minimize the risk of accidents, and create a safer working environment for employees. Implementing recommended practices can also enhance the reputation of the business, leading to increased customer trust and satisfaction.

What should I do if my shop does not meet the checklist standards?

If deficiencies are identified during the inspection using the checklist, it is crucial to take action. Use Section C of the checklist to document the issues along with recommended actions for correction. Prioritize addressing significant safety and compliance shortcomings as soon as possible.

Are the tips provided in the checklist required by law?

The tips for preventing pollution, fires, and health hazards are not legally required. However, adhering to these suggestions can significantly enhance the safety and efficiency of your shop while also streamlining compliance efforts.

Where can I find additional resources related to compliance?

For local and federal resources related to environmental compliance and safety regulations, contact local health departments, fire marshals, or consult state-specific technical assistance programs. Many states offer free resources to help businesses meet their compliance obligations.

Common mistakes

Filling out the Auto Repair Checklist form can seem straightforward, but many people make some common mistakes that can lead to compliance issues. One frequent error is failing to check all relevant items in the checklist. Many users skip sections or neglect specific details because they assume everything is compliant. This oversight could lead to significant penalties during an inspection, especially if key safety measures are overlooked.

Another mistake often encountered involves incomplete information. Some individuals may not provide enough detail about each item checked. For instance, marking "compliant" but not including notes on maintenance or corrections can raise questions during audits. Detailed documentation is vital to showcase the actions taken to ensure compliance.

Using outdated information is also a common pitfall. People occasionally fill out the checklist without considering recent updates to regulations or safety standards. Regulatory compliance is not static; it evolves over time. Failing to use the most current guidelines can result in gaps that may expose the shop to legal vulnerabilities.

Lastly, many mistakenly assume that the checklist is a one-time task. Like routine maintenance on vehicles, compliance requires ongoing diligence. Regular reviews of the checklist and conditions in the shop are essential. This proactive approach helps identify potential issues before they become problems, ensuring a consistently safe work environment.

Documents used along the form

When managing an auto repair shop, having the right forms and documents can streamline processes and ensure compliance. In addition to the Auto Repair Checklist, several other forms and documents are often used to support operations and keep the shop running smoothly.

- Material Safety Data Sheets (MSDS) - These sheets provide detailed information about the hazards associated with chemicals used in the shop. They cover safe handling, risk of exposure, and what to do in case of an emergency.

- Waste Oil Storage Log - This log tracks the storage and disposal of waste oil. It includes details on the amount of waste collected, how it was handled, and the method of disposal. Keeping this log can help maintain proper waste management practices.

- Fire Safety Inspection Report - This document records the results of fire safety inspections conducted within the shop. It includes findings, recommended actions to rectify any issues, and the date of the inspection.

- Employee Safety Training Records - These records track the safety training provided to employees. It includes dates of training sessions, subjects covered, and employee signatures to acknowledge completion. Keeping these records helps ensure a compliant and safe work environment.

- Hazardous Waste Management Plan - This plan outlines the procedures for handling, storing, and disposing of hazardous waste produced in the shop. It is crucial for ensuring compliance with state and federal regulations regarding hazardous materials.

Utilizing these forms and documents aids in the smooth operation of the auto repair shop while promoting safety and compliance. By maintaining accurate records and following the recommended practices, shop owners can minimize risks and improve workplace conditions.

Similar forms

The Auto Repair Checklist form shares similarities with several other important documents related to safety and compliance within automotive repair facilities. Here’s a list of eight similar documents and how each aligns with the Auto Repair Checklist:

- Safety Data Sheet (SDS): Similar to the Auto Repair Checklist in its focus on chemical hazards, the SDS provides information about handling, storage, and emergency measures related to specific chemicals.

- OSHA Compliance Audit Checklist: Like the Auto Repair Checklist, this document guides businesses in assessing their adherence to Occupational Safety and Health Administration regulations, emphasizing workplace safety and hazard prevention.

- Hazardous Waste Management Plan: This document outlines procedures for the proper disposal and management of hazardous waste generated in an auto repair setting, mirroring the checklist's section on materials and waste management.

- Fire Safety Inspection Checklist: Both checklists address necessary fire safety measures, helping to identify hazards and ensure proper equipment is in place to prevent fire incidents.

- Environmental Compliance Checklist: Similar to the Auto Repair Checklist, this document assists in evaluating compliance with environmental laws, helping to identify practices that may lead to pollution.

- Personal Protective Equipment (PPE) Assessment: This assessment supports the safety protocols highlighted in the Auto Repair Checklist, specifically focusing on the required use of safety gear for employees in hazardous environments.

- Emergency Response Plan: Just like the Auto Repair Checklist, this document provides clear procedures for emergency situations, ensuring staff know how to respond effectively to workplace incidents.

- General Maintenance Checklist: This checklist oversees routine maintenance tasks in an auto shop, aligning with the Auto Repair Checklist by ensuring operational standards and safety practices are consistently upheld.

Dos and Don'ts

When filling out the Auto Repair Checklist form, certain practices can streamline the process and enhance accuracy, while others may lead to confusion or errors. Below is a list of nine things you should and shouldn't do.

- Do ensure that containers for flammable materials are properly labeled.

- Do check that all items requiring remedial action are marked clearly.

- Do review your Material Safety Data Sheets (MSDS) prior to making any purchases.

- Do organize your waste management system to facilitate easy inspections.

- Do provide comments in Section C to explain deficiencies and proposed corrective actions.

- Don’t fill out the form without reviewing the specific requirements for each section.

- Don’t leave items unchecked if they necessitate immediate attention.

- Don’t neglect to inspect your storage areas for potential leaks or spills.

- Don’t forget to inform employees about safety protocols and fire extinguisher usage.

By following these guidelines, you can ensure a smoother process in completing the Auto Repair Checklist and contribute to a safer, more compliant work environment.

Misconceptions

Misconception 1: The Auto Repair Checklist is a comprehensive compliance document.

While the checklist includes a range of important items, it is not intended to be exhaustive. It covers primary concerns related to regulatory inspections, but users should understand that additional requirements may exist outside the scope of this tool.

Misconception 2: Completing the checklist guarantees regulatory compliance.

Filling out the checklist does not mean that a shop is fully compliant with federal or state laws. This form serves as a self-audit tool, prompting users to identify areas in need of improvement, yet compliance ultimately depends on a broader understanding of relevant regulations.

Misconception 3: The checklist is only necessary for shop owners.

In reality, various stakeholders may find the checklist useful. Municipal health, fire prevention, and building inspectors can use it for preliminary screenings to assess compliance levels in auto repair shops, making it beneficial for a wider audience.

Misconception 4: The checklist is mostly about environmental regulations.

Though environmental issues are a significant part, the checklist also addresses health and safety concerns, fire prevention, and the overall condition of the workshop. This holistic approach ensures that multiple aspects of shop operations are considered, not just environmental compliance.

Key takeaways

When using the Auto Repair Checklist form, there are several important considerations to keep in mind:

- Purpose of the Checklist: This form serves as a self-audit tool for auto repair shop owners to remain compliant with various regulations related to health, safety, and environmental standards. It offers guidance for both shop owners and inspectors.

- Two Main Sections: The checklist is divided into two primary categories: Section A addresses overall site conditions, while Section B focuses on specific operational practices within the auto shop.

- Documentation of Deficiencies: Section C is dedicated to highlighting any deficiencies identified during inspections. This space allows for comments on compliance issues and recommendations for corrective actions, ensuring necessary steps are documented.

- Preventive Tips Included: The form contains valuable tips aimed at preventing pollution and hazards, which, while not legally required, can reduce compliance costs and enhance the safety of the working environment.

- Checklist Limitations: It's crucial to note that while the checklist encompasses main regulatory concerns, it is not exhaustive. Compliance with the checklist does not guarantee full adherence to all relevant laws and regulations.

Browse Other Templates

Philadelphia Special Inspections - It may include references to relevant building codes and standards.

Ds 160 Questions - Completing the Con 160 form is the first step to obtaining MyChart access for a child.

Isef Form - Investigated the influence of peer pressure on decision-making among middle school students, revealing critical social dynamics.