Fill Out Your Aws D11 Welder Qualification Form

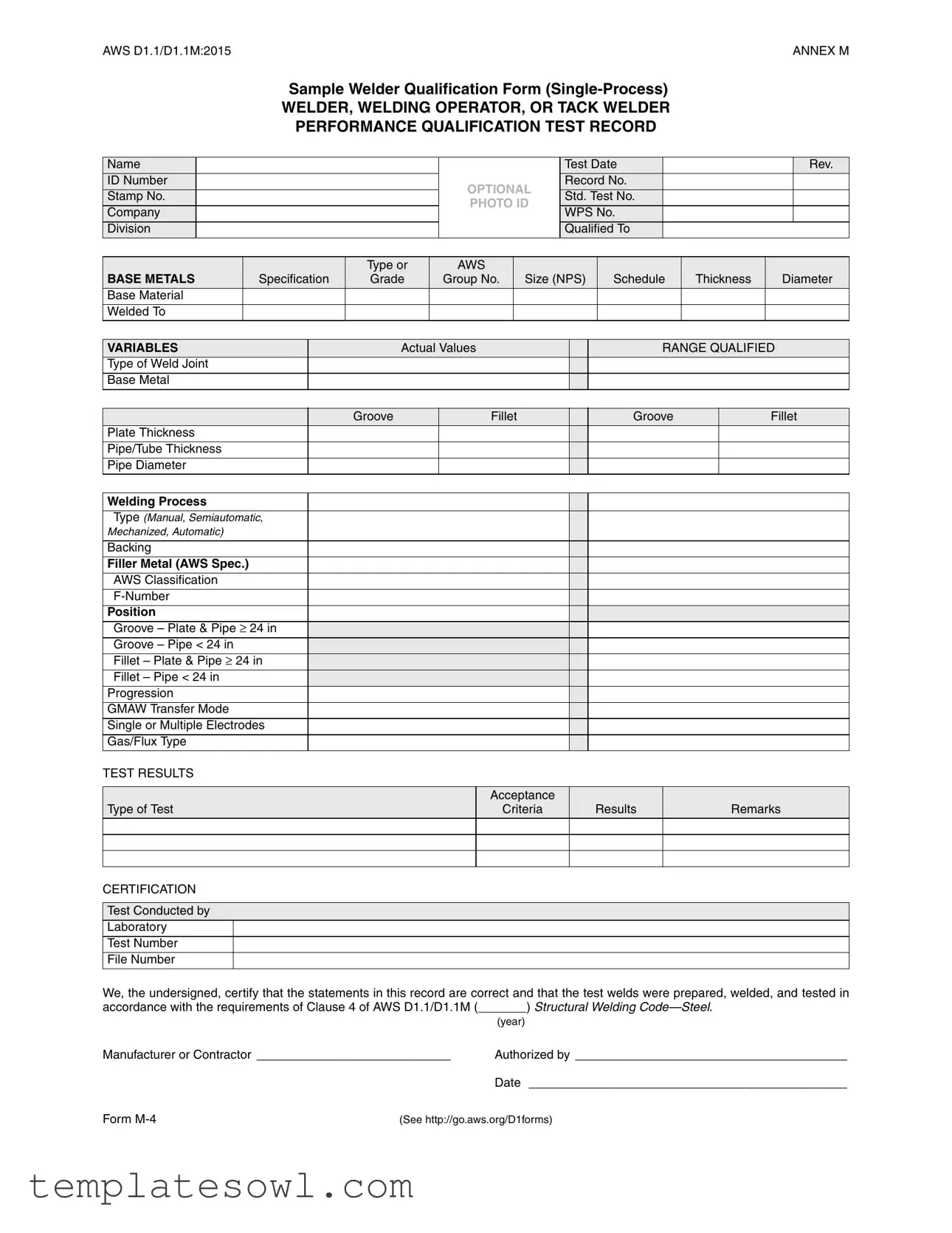

The AWS D1.1 Welder Qualification form plays a critical role in the assessment and recognition of a welder’s skills and capabilities. Within this comprehensive document, important sections capture essential details about the welder, including their name, ID number, and company information, alongside optional photo identification. The form outlines the specifics of the testing process, such as the test date, record number, and specifications for the welding procedure to ensure that all standards have been met. It emphasizes the variety of base metals, welding techniques, and joint types that the welder is qualified to handle, alongside variables like thickness and diameter. Also notably included are sections detailing the welding process and filler metal specifications, allowing for thorough documentation of the techniques employed during the test. The results section provides vital information on test outcomes, acceptance criteria, and any remarks from the testing process, creating a clear picture of the welder's proficiency. Ultimately, the certification section reinforces the validity, as it requires signatures from authorized parties, confirming that the welds were prepared per AWS standards. This form is a vital tool for both welders and employers, clearly outlining qualifications and ensuring adherence to industry standards.

Aws D11 Welder Qualification Example

AWS D1.1/D1.1M:2015 |

ANNEX M |

Sample Welder Qualification Form

WELDER, WELDING OPERATOR, OR TACK WELDER

PERFORMANCE QUALIFICATION TEST RECORD

Name

ID Number

Stamp No.

Company

Division

OPTIONAL PHOTO ID

Test Date

Record No.

Std. Test No.

WPS No.

Qualified To

Rev.

BASE METALS |

Specification |

Type or |

|

AWS |

|

Size (NPS) |

|

Schedule |

Thickness |

Diameter |

|||

Grade |

|

Group No. |

|

|

|||||||||

Base Material |

|

|

|

|

|

|

|

|

|

|

|

|

|

Welded To |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VARIABLES |

|

|

Actual Values |

|

|

|

RANGE QUALIFIED |

||||||

Type of Weld Joint |

|

|

|

|

|

|

|

|

|

|

|

|

|

Base Metal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Groove |

|

Fillet |

|

|

|

Groove |

|

|

Fillet |

|

Plate Thickness |

|

|

|

|

|

|

|

|

|

|

|

|

|

Pipe/Tube Thickness |

|

|

|

|

|

|

|

|

|

|

|

|

|

Pipe Diameter |

|

|

|

|

|

|

|

|

|

|

|

|

|

Welding Process

Type (Manual, Semiautomatic,

Mechanized, Automatic)

Backing

Filler Metal (AWS Spec.)

AWS Classification

Position

Groove – Plate & Pipe ≥ 24 in

Groove – Pipe < 24 in

Fillet – Plate & Pipe ≥ 24 in

Fillet – Pipe < 24 in

Progression

GMAW Transfer Mode

Single or Multiple Electrodes

Gas/Flux Type

TEST RESULTS

Type of Test

Acceptance

Criteria

Results

Remarks

CERTIFICATION

Test Conducted by

Laboratory

Test Number

File Number

We, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the requirements of Clause 4 of AWS D1.1/D1.1M (_______) Structural Welding

|

|

(year) |

Manufacturer or Contractor _________________________ |

Authorized by ___________________________________ |

|

|

|

Date _________________________________________ |

Form |

(See http://go.aws.org/D1forms) |

|

Form Characteristics

| Fact Name | Description |

|---|---|

| Purpose | The AWS D1.1 Welder Qualification form is used to document the qualifications of welders, welding operators, or tack welders according to AWS standards. |

| Testing Standards | This form complies with the AWS D1.1/D1.1M:2015 Structural Welding Code—Steel, ensuring that welders meet specific performance criteria. |

| Variables | It includes critical variables such as base metals, type of weld joint, welding process, and position, crucial for assessing weld quality. |

| Acceptance Criteria | Test results must meet defined acceptance criteria, which are clearly detailed in the form allowing for objective evaluation. |

| Certification | The form requires certification from an authorized representative, verifying that the test welds were completed according to AWS standards. |

| Test Results | Results of the qualification tests, along with any remarks, are documented for record-keeping and review purposes. |

| Photo ID | An optional photo ID can be included to enhance identification and verification of the individual being qualified. |

| Governing Laws | State-specific standards may apply, and it is essential to refer to local codes and regulations that govern welding qualifications. |

| Record Keeping | The form includes fields for record numbers, test numbers, and file numbers, ensuring proper documentation and tracking of qualifications. |

Guidelines on Utilizing Aws D11 Welder Qualification

Complete the AWS D11 Welder Qualification form to document a welder’s qualifications accurately. Ensure all required information is filled out clearly to avoid any issues with the certification process.

- Begin with the welder’s name at the top of the form.

- Fill in the ID number and stamp number, if applicable.

- Include the company name and division where the welder is employed.

- Attach an optional photo ID if desired.

- Date the test in the designated area.

- Record the test number and the standard test number as instructed.

- Specify the WPS number.

- In the base metals section, indicate the specification type or AWS size.

- Provide the schedule, thickness, or diameter as needed.

- Note the grade and group number for the base material.

- Document the actual values for each variable and ensure they are within the qualified range.

- Identify the type of weld joint (groove or fillet) and specify the required measurements.

- Indicate the welding process type (manual, semiautomatic, mechanized, or automatic).

- Fill in details for the backing and the filler metal according to the AWS specifications.

- Provide the AWS classification and F-number as required.

- Document the welding position and progression type in the appropriate areas.

- Record the type of test conducted and the acceptance criteria for results.

- Provide remarks for any additional information related to the test results.

- Identify the test laboratory and include their test number and file number.

- Finally, have the authorized personnel certify the statements with their signature, date, and title.

What You Should Know About This Form

What is the purpose of the AWS D1.1 Welder Qualification Form?

The AWS D1.1 Welder Qualification Form is designed to document the qualifications of welders, welding operators, or tack welders. It is an essential record that ensures individuals have completed a performance qualification test according to the standards set forth in AWS D1.1/D1.1M. By filling out this form, employers can verify that their welders possess the necessary skills and have adhered to the required specifications for various welding processes. Including details such as the type of weld joint, the welding process used, and the base metals involved, the form also serves as proof of compliance with industry standards.

What information is required on the form?

The form requires multiple pieces of information to comprehensively capture the welder's qualifications. Key fields include the welder's name, ID number, and company details. It should also include specifics about the test, like the date conducted, test number, and corresponding Welding Procedure Specification (WPS) number. Furthermore, details on the base metals, including their specifications, size, and any applicable AWS classifications, need to be filled in. The results section captures the type of test performed, acceptance criteria, and outcomes, ensuring a thorough overview of the welder’s capabilities.

Who can conduct the qualification test and complete the form?

The qualification test must be conducted by a qualified testing laboratory, ensuring that the procedure is executed in accordance with standard requirements. This laboratory is responsible for overseeing the process and validating test results. Upon completion, the form must be certified by the authorized personnel from the manufacturer or contractor. Their signature on the form attests to the accuracy of the information recorded, confirming that the test welds were prepared and evaluated as per AWS D1.1/D1.1M standards.

How long is the certification from the AWS D1.1 Welder Qualification Form valid?

The certification resulting from the AWS D1.1 Welder Qualification Form does not have a strict expiration date but is contingent upon the welder's continuous proficiency and adherence to welding procedures. If a welder changes processes, materials, or if significant time has lapsed since their last qualification test, they may need to retake the performance qualification test to remain compliant. Regular assessment and documentation help ensure that welders maintain their skills and meet the evolving demands of the industry.

Common mistakes

Filling out the AWS D1.1 Welder Qualification form is crucial for ensuring that welders meet necessary standards. However, many people make mistakes that can cause serious complications in the qualification process. Here are five common errors to avoid during this important task.

One significant mistake is failing to accurately complete personal identification details. This includes the welder’s name, ID number, and company affiliation. Omitting or misspelling any of these identifiers may lead to confusion or delays in processing. It’s important to double-check this information prior to submission.

Another frequent error occurs in the Base Metals section. Welders often misunderstand the specifications required. For example, failing to specify the appropriate material grades or groups can invalidate the entire qualification. Each entry must be clear and precise to ensure compliance with AWS standards.

A third mistake involves neglecting to fill in the Welding Process Type accurately. Whether the process is manual, automatic, or semi-automatic, this detail is critical. Selecting the wrong type may result in disqualification of test results, which can be costly and time-consuming.

Additionally, welders often overlook the importance of documenting the Test Results properly. This includes noting acceptance criteria and actual outcomes clearly. Ambiguities in this area can create confusion about the welder's qualifications and may lead to disputes later on.

Finally, one of the most overlooked aspects is the completion of the Certification section. All parties involved must ensure this part is filled out correctly, including signatures and dates. Without appropriate authorization, the entire qualification record could be deemed insufficient.

By being mindful of these common pitfalls, individuals can enhance the quality and accuracy of their AWS D1.1 Welder Qualification form submissions. Attention to detail can make a substantial difference in this certification process.

Documents used along the form

The AWS D11 Welder Qualification form is essential for documenting a welder's performance and qualifications. Along with this form, several other documents help ensure compliance and verify skills. Below is a list of these documents.

- Welding Procedure Specification (WPS): This document outlines the welding parameters and techniques required for specific types of welding. It serves as a guide for welders to ensure they meet industry standards.

- Procedure Qualification Record (PQR): A PQR verifies that a welding procedure can produce welds that meet required specifications. It documents the actual test results and variables used during welding.

- Welder's Qualification Test Record: Similar to the AWS D11 form, this record details the welder's qualifications and test results. It validates their ability to perform specific welding tasks according to industry standards.

- Certificate of Compliance: This certificate confirms that a welder or welding process adheres to certain standards or specifications. It often accompanies the qualification documents.

- Inspection Reports: These documents contain detailed assessments of weld quality and compliance. Inspections may be conducted during or after the welding process to ensure standards are met.

- Safety Data Sheets (SDS): SDS provide critical information on the safe handling of materials used in the welding process. Welders must be familiar with these materials to minimize health risks.

- Material Test Reports (MTR): MTRs verify the specifications and properties of base materials used in welding. They provide evidence that the materials meet required standards.

- Quality Control Plans: This document outlines procedures and responsibilities to ensure quality in welding processes. It helps organizations maintain consistency and compliance in their operations.

These documents work together to ensure that welders are qualified and that the welding processes adhere to industry standards. Proper documentation is crucial for maintaining safety and quality in the welding industry.

Similar forms

- Welding Procedure Specification (WPS): Similar to the AWS D11 Welder Qualification form, a WPS outlines the specific requirements for welding procedures. It includes details like material types, joint design, and welding techniques. Both documents ensure that welds are performed consistently and meet standards.

- Qualification Record for Welders (AWS D1.2): This document is used to record the qualifications of welders who are working on structural aluminum. Like the AWS D11 form, it includes information on the welder's performance and the parameters of the test, ensuring competency in welding procedures.

- Welder Performance Qualification Record (WPQR): The WPQR closely resembles the AWS D11 form as it provides a record of a welder's ability to produce welds that meet specified standards. It documents the tests performed and the criteria for acceptance, similar to the qualifications detailed in the AWS D11.

- Welding Certification Record (ANSI/AWS): This record certifies welders after they pass the required tests. It includes information on the welder's identity, type of welding performed, and associated tests, paralleling the structure of the AWS D11 qualification document.

- Fabrication Quality Control Plan: This document outlines the standards and procedures for ensuring quality in fabrication work, similar to how the AWS D11 form sets out the qualifications required for a welder. Both documents emphasize compliance and quality assurance in welding practices.

- Inspection Report (AWS D1.1): An inspection report documents the findings from a welding inspection, much like the AWS D11 Welder Qualification form records test results. Each ensures that the welding performed meets the established standards and requirements.

Dos and Don'ts

When filling out the AWS D1.1 Welder Qualification form, there are important do's and don'ts to consider. Here are some guidelines:

- Do ensure that all personal information is correct, including your name and ID number.

- Do carefully read the instructions provided in the form before starting.

- Do use the most recent version of the form, as specifications may change over time.

- Do check that all test results are complete and accurate before submission.

- Do maintain a copy of the completed form for your records.

- Don’t leave any sections blank; each part of the form is important.

- Don’t provide false information; honesty is crucial in this process.

- Don’t forget to sign and date the form; this validates your submission.

- Don’t ignore any additional requirements specified for your welding process.

Misconceptions

Misconceptions about the AWS D1.1 Welder Qualification form can lead to confusion regarding the welder qualification process. Below are eight common misconceptions clarified.

- The form is only for certified welders. Many believe this form is exclusively for certified welders. In reality, it is useful for all welders seeking to document their qualifications, whether they are new or experienced.

- Only specific welding processes can be recorded. While some may think the form limits itself to certain welding processes, it actually accommodates various processes, including manual, semiautomatic, mechanized, and automatic welding.

- The form is only applicable to large-scale projects. This misconception exists because it is often associated with industrial applications. However, the AWS D1.1 form is applicable to projects of all sizes, from small repairs to extensive constructions.

- Completion of the form guarantees employment. Many welders assume that filling out the qualification form automatically secures jobs. While it can enhance a welder's qualifications, employment is dependent on various factors beyond this form.

- The qualifications expire immediately after testing. There is a belief that qualifications are valid indefinitely. In fact, some companies may require retesting or requalification after a certain period, depending on their policies.

- The form is only relevant during initial training. Some think the AWS D1.1 Welder Qualification form is only necessary for new welders. Conversely, experienced welders may need to reevaluate and update their qualifications periodically.

- Only the welder's performance is assessed. It is a common assumption that the form evaluates solely the welder's skills. However, the overall welding process, including the materials and methods used, is also critically assessed.

- The form is not legally binding. Some may believe that the qualification form is merely a recommendation. However, it serves as an official record, documenting a welder's qualifications and compliance with industry standards.

Understanding these misconceptions can help clarify the importance and utility of the AWS D1.1 Welder Qualification form for both welders and employers alike.

Key takeaways

Filling out the AWS D1.1 Welder Qualification form is essential for maintaining proper records of welding qualifications. Here are some key takeaways:

- Accurate Information: Ensure that all personal details, including name and ID number, are filled out correctly. Mistakes can lead to complications down the line.

- Test Date: Clearly indicate the date when the test was conducted. This helps in tracking the validity of qualifications.

- Base Metals Specification: Provide accurate information about the base metals used, including their type, size, and thickness. This information is crucial for assessing qualifications.

- Welding Process: Specify the type of welding process used (manual, semi-automatic, etc.). Different processes have different qualification needs.

- Test Results: Clearly document the type of tests conducted and ensure they meet the acceptance criteria outlined in the AWS standards.

- Certification: Both the individual conducting the test and the authorized representative must sign the form. Their certifications attest to the accuracy of the recorded information.

- Use of Correct Form: Always use the current version of the form as provided by AWS. Keeping up with updates ensures compliance with the latest standards.

By following these guidelines, you can ensure that the AWS D1.1 Welder Qualification form is filled out correctly and is used effectively for maintaining welding qualifications.

Browse Other Templates

Bank Application Form - Ensure co-applicant signs where indicated, confirming joint application.

Florida Physical Form - If a student has experienced difficulty with exercise, such as dizziness or passing out, it must be reported in detail.

Property Condition Report Template Free - Owners complete this report to share knowledge of any existing defects or issues with the property.