Fill Out Your Cf 1R Alt Hvac Form

The CF-1R Alt HVAC form is a critical document for anyone involved in HVAC alterations in California, specifically within Climate Zones 10 to 15. This form serves as a Certificate of Compliance, reflecting adherence to the 2008 Building Energy Efficiency Standards. Homeowners and contractors must understand when a permit is required, which includes several scenarios such as the installation of new HVAC systems, relocation of existing units, and alterations involving more than 40 feet of ducting. Failure to comply with the established building laws can result in severe penalties, including fines or the suspension of contractor licenses. The form mandates specific efficiency standards for heating equipment and air conditioning systems, ensuring that newly installed equipment meets minimum performance criteria. Additionally, it outlines requirements for duct insulation and sealing, thermostat installation, and HERS verification, which involve specialized inspections to confirm compliance with energy efficiency measures. The CF-1R Alt HVAC form thus plays a vital role in the construction process, ensuring that HVAC alterations are executed safely, efficiently, and in accordance with California regulations.

Cf 1R Alt Hvac Example

(ENFORCEMENT AGENCY CAN CUSTOMIZE WITH LETTERHEAD/SEAL)

2008 Building Energy Efficiency Standards Residential HVAC Alterations Climate

Zones 10 to 15

BUSINESS AND PROFESSIONS CODE, SECTION 7110

Willful or deliberate disregard and violation of the building laws, including the California Building Code, and local permit requirements constitutes a cause for disciplinary action from the Contractors State License Board working in conjunction with the local building department. This action may consist of fines up to $5,000 per violation or suspension/revocation of a contractor’s license.

WHEN IS A PERMIT REQUIRED?

A written construction permit shall be obtained from the enforcement agency prior to the erection, construction, reconstruction, installation, relocation, or alteration of any mechanical system, except as permitted in Appendix Chapter 1, Section 112.2 of the 2007 California Mechanical Code. Projects requiring permits include, but are not limited to:

• |

New HVAC installation |

• |

Relocation of an existing HVAC unit |

• |

HVAC Changeout |

• |

Adding or replacing more than 40ft ducting |

• Replacement of furnace, coil, FAU, or condenser |

|

in unconditioned space |

|

2008 BUILDING ENERGY EFFICIENCY STANDARDS (Title 24, Part 6) REQUIREMENTS INCLUDE:

1.Heating equipment must have a minimum 78% AFUE (Exception: Wall & floor furnaces; room heaters).

2.Central air conditioners & heat pumps less than 65,000 Btu/hr must have a minimum 13 SEER.

3.Newly installed or replaced ducts must have a minimum insulation value of

4.A setback type thermostat (24 hr clock with four set points) is required for all alterations.

5.New or replacement ducts must meet the mandatory requirements of Section 150(m):

•All joints and openings in the in the HVAC system must be sealed.

•Only UL 181, UL 181A, or UL 181B approved tapes or mastic shall be used to seal duct openings.

•Connections of metals ducts and the inner core of flex ducts shall be mechanically fastened. Flex ducts must be connected using a metal sleeve/coupling.

•Flex ducts that are suspended must be supported every 4ft. max for horizontal runs with no more than 2” of sag between supports and 6 ft. max for vertical runs.

WHEN IS HERS VERIFICATION REQUIRED AND WHAT FORMS ARE REQUIRED?

HERS verification is required for all HVAC alterations in Climate Zone

•

•

DESCRIPTION OF HERS TESTS BELOW (Full descriptions found in Residential Appendix RA3 and Residential Manual)

Duct sealing – The installer is to insure leakage of the HVAC system is less than 6% for new air conditioning system (new equipment and all new ducts) or 15%, 60% reduction, seal all accessible leaks, etc. for alterations to existing HVAC systems. When the contractor uses the option to seal all accessible leaks, all easily movable objects must be moved to seal existing ducting. New ducting installed by the contractor is not allowed to have any leaks even if it is no longer accessible. In example 3 of the

Cooling Coil Airflow (CCA) – There are two different minimum air flow requirements that must be met. These are 300 CFM and 350 CFM. The minimum 300 CFM per ton of cooling is required in order to conduct a refrigerant charge test. For new HVAC systems (new equipment and new ducts) the HVAC system must move a minimum 350 CFM of air for each ton of cooling.

Refrigerant Charge (RC) – The installer is required to verify the charge is correct. If the outside temperature is below 55 degrees then the weigh in method must be used by the installer. When the weigh in method is used the HERS rater must retest when the temperature is 55 and above. A charge indicator display (CID) can be used in place of conducting an RC, manufacturers are currently developing this device.

Temperature Measurement Access Holes (TMAH) – Installer must drill and mark holes to measure temperature split.

Hole for the placement of a Static Pressure Probe (HSPP) or Permanently installed Static Pressure Probe (PSPP) – Either the installer must drill and mark holes to measure static pressure or a permanently installed pressure probe must be installed and marked. Saturation Temperature Measurement Sensors (STMS) – Permanently installed type K thermocouple are installed on the indoor and outdoor coil so that the HERS rater can verify charge without attaching gauges. Instructions are found in Ch 4 of the Res. Manual. Fan Watt Draw (FWD) – Installer verifies that the furnace fan watt draw is less than 0.58 Watts/CFM.

NOTE: The

*For Final inspection ALL compliance forms

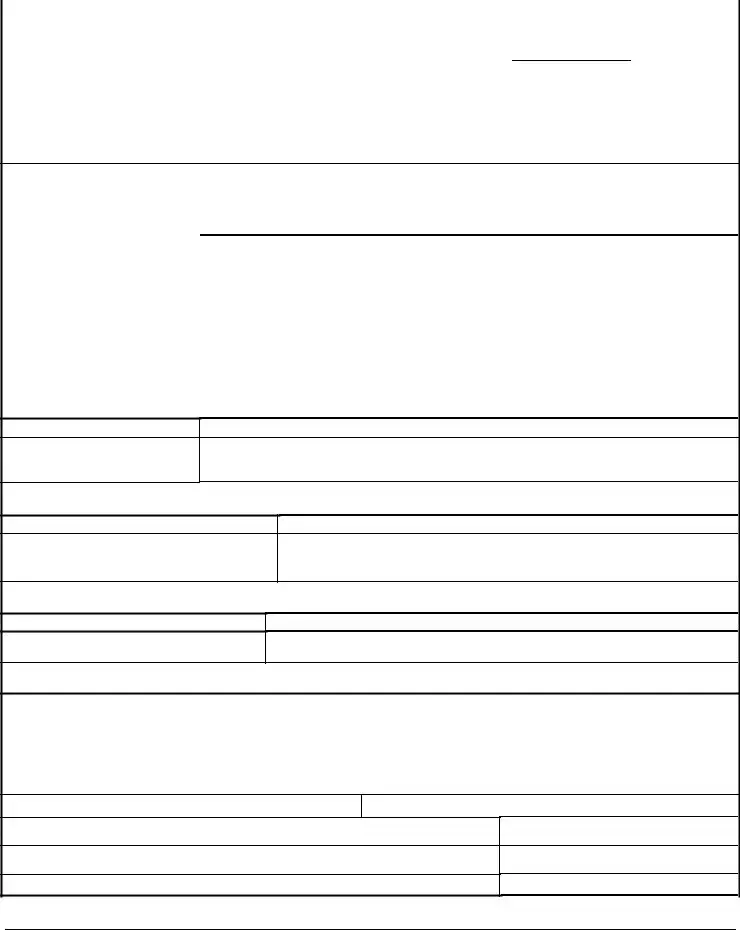

Simplified Prescriptive Certificate of Compliance: 2008 Residential HVAC Alterations |

||||||

Climate Zones 10 to 15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Site Address: |

|

|

Enforcement Agency: |

Date: |

|

Permit #: |

|

|

|

|

|

|

|

Equipment Type1 |

List Minimum Efficiency2 |

|

Conditioned Floor |

|

||

Duct insulation requirement |

Area |

|

Thermostat |

|||

Packaged Unit |

|

|

Over 40 ft of ducts added or |

|

|

Setback |

Furnace |

AFUE____ |

COP______ |

|

|

||

replaced in unconditioned space |

Served by system |

|

(If not already |

|||

Indoor Coil |

SEER_____ |

HSPF ____ |

|

|||

R 6 (CZ |

________ sf |

|

present, must be |

|||

Condensing Unit |

EER _____ |

Resistance |

|

|||

R 8 (CZ |

|

|

installed) |

|||

Other ________ |

|

|

|

|

||

|

|

|

|

|

|

|

1.Equipment Type: Choose the equipment being installed; if more than one system, use another

2.Minimum Equipment Efficiencies: 13 SEER, 78% AFUE, 7.7HSPF for typical residential systems.

HERS VERIFICATION SUMMARY Listed below are four HVAC alteration Options. The installer decides what work is being done and picks one of the appropriate Options. Each Option lists the HERS measures that must be conducted. A copy of the forms shall be left on site for final inspection and a copy given to the homeowner. At final, the inspector verifies that the work listed on this form was in fact the work completed by the installer. The inspector also verifies that each appropriate

1. HVAC Changeout |

Required Forms: |

|

• All HVAC Equipment replaced |

||

|

||

• Condenser Coil and /or |

||

• Indoor Coil and /or |

||

• Furnace |

||

|

For Split Systems: Duct leakage < 15 percent; RC, CCA ≥ 300 CFM/ton(Minimum Air Flow Requirement), TMAH

For Packaged Units: Duct leakage < 15 percent

Exempted from duct leakage testing if:

1. Duct system was documented to have been previously sealed and confirmed through HERS verification, or

2. Duct systems with less than 40 linear feet in unconditioned space, or

3. Existing duct systems are constructed, insulated or sealed with asbestos

2. New HVAC System

•Cut in or Changeout with new ducts: (all new ducting and all new equipment)

Required Forms:

For Split Systems: Duct leakage < 6 percent; RC, CCA ≥ 350 CFM/ton, FWD, TMAH, STMS, and either HSPP or PSPP.

For Packaged Units: Duct leakage < 6 percent

3. New Ducts with/or without Replacement

•Includes replacing or installing all new ducting and/or outdoor condensing unit and/or indoor coil and/or furnace. No or some equipment changed.

Required Forms:

For Split Systems: Duct leakage < 6 percent, RC, CCA ≥ 300 CFM/ton, TMAH

For Packaged Units: Duct leakage < 6 percent

4. New Ducting over 40 feet

• Includes adding or replacing more than 40

For split system or packaged units: Duct leakage < 15 percent

EXCEPTION: Existing duct systems constructed, insulated or sealed with asbestos.

Contractor (Documentation Author's /Responsible Designer's Declaration Statement)

•I certify that this Certificate of Compliance documentation is accurate and complete.

•I am eligible under Division 3 of the California Business and Professions Code to accept responsibility for the design identified on this Certificate of Compliance.

•I certify that the energy features and performance specifications for the design identified on this Certificate of Compliance conform to the requirements of Title 24, Parts 1 and 6 of the California Code of Regulations.

•The design features identified on this Certificate of Compliance are consistent with the information documented on other applicable compliance forms, worksheets, calculations, plans and specifications submitted to the enforcement agency for approval with the permit application.

Name:

Company:

Address:

City/State/Zip:

Signature:

Date:

License:

Phone:

2008 Residential Compliance Forms |

March 2010 |

Form Characteristics

| Fact Name | Details |

|---|---|

| Form Purpose | The CF-1R-ALT-HVAC form is used for compliance with the 2008 Building Energy Efficiency Standards for the alteration of HVAC systems. |

| Geographic Application | This form applies specifically to Climate Zones 10 to 15 in California. |

| Permit Requirement | A written construction permit must be obtained before making any alterations to mechanical systems, including HVAC systems. |

| Disciplinary Action | Violations of the building laws and codes, including non-compliance with this form, can result in fines or the suspension of a contractor’s license. |

| Efficiency Standards | Heating equipment must have a minimum Annual Fuel Utilization Efficiency (AFUE) of 78%, while central air conditioners must have a minimum Seasonal Energy Efficiency Ratio (SEER) of 13. |

| Duct Insulation | Newly installed ducts must have a minimum insulation value of R-4.2, with higher values required for ducts over 40 ft. |

| HERS Verification | HERS verification is needed for all HVAC alterations and specific documentation forms must be present at the job site for inspection. |

| Testing Requirements | Tests for duct sealing, airflow, refrigerant charge, and temperature measurements are mandated per the form instructions. |

| Effective Date | The CF-1R-ALT-HVAC form was adopted under the requirements set forth by the California Code of Regulations, Title 24. |

Guidelines on Utilizing Cf 1R Alt Hvac

After completing the CF-1R Alt HVAC form, submit it along with the required documentation to the enforcement agency before starting your HVAC project. This form ensures compliance with California Building Energy Efficiency Standards and outlines the specific alterations to be performed. Adhering to these guidelines can help avoid penalties and promote energy efficiency in your work.

- Begin by downloading or obtaining a copy of the CF-1R Alt HVAC form from the enforcement agency.

- Fill in the site address and enforcement agency details at the top of the form.

- Record the date and permit number in the designated areas.

- Specify the equipment type you are installing or replacing. Use a separate form for additional systems, if necessary.

- List the minimum efficiency ratings for the HVAC equipment. This may include AFUE, SEER, and EER based on the equipment type.

- Indicate the conditioned floor area affected by the installation.

- Fill in the duct insulation requirement based on climate zone regulations (R-6 or R-8).

- Check the box for the thermostat type you are installing, confirming if it is a setback type thermostat.

- Choose one of the four HVAC alteration options provided, based on your project type.

- Ensure all required forms, including CF-6R or CF-4R, are completed for final inspection.

- Sign and date the form, confirming your eligibility and accuracy of the information provided.

- Keep a copy of the form with supporting documentation on-site for inspection and provide a copy to the homeowner.

What You Should Know About This Form

What is the CF-1R ALT HVAC form used for?

The CF-1R ALT HVAC form is a simplified prescriptive certificate of compliance required for residential HVAC alterations in California’s Climate Zones 10 to 15. It ensures that HVAC installations meet the state's energy efficiency standards set forth in the 2008 Building Energy Efficiency Standards (Title 24, Part 6). The form must be completed by the installer based on the specific work being performed.

When is a permit required for HVAC work?

A written construction permit must be obtained prior to the installation, alteration, or relocation of any mechanical system, including HVAC. This requirement applies to new HVAC installations, HVAC changeouts, and the addition or replacement of more than 40 feet of ducting, among other projects. The enforcement agency determines the specific requirements for getting a permit.

What are the energy efficiency requirements for HVAC equipment?

The 2008 Building Energy Efficiency Standards stipulate that heating equipment must have a minimum Annual Fuel Utilization Efficiency (AFUE) of 78%. For air conditioners and heat pumps with a capacity below 65,000 BTU/hr, a minimum Seasonal Energy Efficiency Ratio (SEER) of 13 is required. Additionally, newly installed ducts must have a minimum insulation value of R-4.2, and higher values for longer duct runs depending on the climate zone.

What additional forms are necessary for final inspection?

For final inspection of HVAC alterations, it is necessary to complete and submit CF-6R forms. Additionally, if a HERS rater is involved, CF-4R forms must also be registered with an approved HERS Provider. HERS verification is mandatory for all HVAC alterations in specified climate zones, ensuring compliance with energy efficiency standards.

What does HERS verification involve?

HERS verification includes a series of tests to ensure the HVAC system operates efficiently. These tests evaluate duct sealing, airflow, refrigerant charge, and other performance metrics. The installer must ensure that leakage for new installations meets specified limits, and any alterations must achieve significant reductions in leakage. A HERS rater must verify these tests to receive approval from the enforcement agency during the final inspection.

What are the consequences of failing to comply with building laws?

Violating building laws, including the California Building Code and local permit requirements, can result in disciplinary actions from the Contractors State License Board. Penalties may include fines up to $5,000 per violation, as well as the suspension or revocation of a contractor’s license. Compliance is crucial to avoid these repercussions and ensure safety and efficiency in building practices.

How does the installer indicate the type of work being performed?

The installer selects one of four options on the CF-1R-ALT-HVAC form that best describes the work being performed. Each option details the required forms and measures necessary for compliance. It’s essential to provide accurate information on this form to ensure proper reporting and verification during inspections.

Common mistakes

Completing the CF-1R Alt HVAC form can be straightforward, but several common mistakes can lead to delays or complications. One prevalent error is failing to select the appropriate option for the HVAC work being conducted. The form requires you to choose one of the four options that best fits the work undertaken. Not doing so may confuse the inspector and can lead to issues during the final inspection.

Another common mistake involves inadequate documentation. For final inspection, all related forms, including CF-6R and CF-4R, must be completed and submitted. If the required forms are missing or incomplete, the inspector may reject the application. Double-checking that all documentation is present and properly filled out can help avoid such delays.

Individuals sometimes overlook the minimum efficiency requirements for equipment listed on the form. Specific standards, such as a minimum AFUE of 78% for heating equipment and 13 SEER for central air conditioners, are critical. Failing to include this information or using incorrect values can result in compliance issues, requiring resubmission of the form.

It’s essential to also pay attention to the thermostat requirement. The form mandates the installation of a setback-type thermostat. Not indicating this or mistakenly omitting it from the documentation can lead to compliance violations. Make sure to confirm that this detail is accurately represented on the form.

Additionally, many individuals make the mistake of not sealing joints and openings properly. The regulations specify that all joints and openings in the HVAC system must be sealed appropriately using approved materials. Failing to ensure this can result in performance issues and further complications during inspections.

Another oversight involves ignoring the HERS verification requirement. This verification is essential for all HVAC alterations in Climate Zones 10-15. Not indicating that a HERS rater will be involved or neglecting to register with an approved HERS provider can jeopardize project approval.

Lastly, it's not uncommon for applicants to misjudge the duct insulation requirements. The form must reflect accurate insulation values, as these play a critical role in ensuring energy efficiency. Miscalculating these values can have severe implications for project compliance and must be corrected before submission.

Documents used along the form

The CF-1R Alt HVAC form serves as a vital document for contractors engaging in HVAC alterations in specific climate zones. To ensure compliance with local laws and regulations, this form is often accompanied by several other essential documents. Each form plays a unique role in the overall project, helping to safeguard both contractor and homeowner interests while promoting energy efficiency and safety.

- CF-6R Form: This compliance form is crucial for final inspections. It provides evidence that all HVAC installations meet the required energy efficiency standards. The contractor fills out this form, detailing the work completed and ensuring that all performance measures have been adhered to.

- CF-4R Form: Required in conjunction with the CF-1R and CF-6R forms, the CF-4R is submitted by the HERS rater. This document certifies that all testing and compliance measures meet California's Title 24 energy standards. It cannot be filled out by hand and must be registered with a HERS provider.

- Compliance Certificate: This document certifies that all energy features and performance specifications meet legal requirements. It often accompanies the CF-1R form and acts as an assurance that the contractor has fulfilled their obligations under the California Building Energy Efficiency Standards.

- Inspection Checklists: Local enforcement agencies may provide checklists for inspectors to use during final inspections. These ensure that all necessary forms are present and that the installation complies with safety and efficiency standards.

- Energy Efficiency Reports: Depending on the installation's complexity, an energy efficiency report may be required. This document analyzes energy consumption following the HVAC alteration and outlines the expected benefits of improved efficiency measures.

By utilizing these forms and documents alongside the CF-1R Alt HVAC form, contractors can ensure a thorough compliance process. This not only supports adherence to energy regulations but also fosters positive relationships between contractors, homeowners, and regulatory agencies.

Similar forms

The CF-1R Alt HVAC form is an essential document for HVAC alterations, particularly in California. It shares similarities with various forms used in construction and maintenance. Below is a list of ten documents that are comparable to the CF-1R Alt HVAC form, along with a brief explanation of the connections between them.

- CF-6R Forms: These forms are also used during HVAC alterations. While the CF-1R details the compliance documentation for energy efficiency, the CF-6R focuses on the actual performance verification required during the final inspection.

- CF-4R Forms: Similar to the CF-1R, these forms are required for energy compliance, particularly for HERS verification. They track the various tests and inspections performed by HERS raters, much like how the CF-1R outlines work descriptions.

- Title 24 Compliance Forms: Compliance forms based on California's Title 24 standards address energy efficiency. These forms maintain similar purposes, ensuring that energy features abide by legal standards and technical requirements.

- Residential Manual: This document outlines procedures and standards related to HVAC systems. Like the CF-1R, it provides detailed guidelines for compliance, inspection, and performance testing essential to energy efficiency.

- HERS Verification Summary: This summary includes a collection of HVAC measures specific to HERS ratings. It operates similarly to the CF-1R as it requires installers to demonstrate compliance with energy standards.

- Construction Permit Application: Like the CF-1R, a construction permit application requires detailed information about the work to be undertaken. Both forms facilitate approval from the enforcement agency to ensure safe and compliant construction practices.

- Energy Use Disclosure Form: This form informs homeowners about a property's energy consumption and efficiency. Similar to the CF-1R, it aims to enhance understanding of energy standards and requirements within residential systems.

- Building Plans: When submitting building plans, compliance with energy standards is crucial. The details required in the CF-1R about HVAC efficiency can also be found in the energy-related sections of building plans.

- Inspection Reports: These reports document the results of routine and final inspections for HVAC systems. Like the CF-1R, they assess compliance with standards, ensuring all work meets regulatory benchmarks.

- HERS Rater Documentation: This documentation is necessary for verifying that HVAC installations meet California energy efficiency standards. It parallels the CF-1R by outlining the steps for ensuring all components fulfill energy performance expectations.

Dos and Don'ts

When filling out the CF 1R Alt HVAC form, proper attention to detail is crucial for compliance and successful processing. Here are eight important do's and don'ts:

- Do ensure that all information is accurate and complete before submission.

- Do keep a copy of all completed forms for your records.

- Do confirm that the necessary HERS verification forms are included.

- Do use the correct form for the specific type of HVAC alteration.

- Don't leave any fields blank on the form—provide all required details.

- Don't ignore the specific energy efficiency requirements outlined in the 2008 standards.

- Don't use handwritten entries on the CF-4R forms; these must be registered by HERS Raters.

- Don't forget to submit your forms before the final inspection to avoid delays in compliance.

By following these guidelines, you will facilitate a smoother process and ensure adherence to regulatory standards.

Misconceptions

When it comes to the CF-1R Alt HVAC form, there are several misconceptions that can lead to confusion. Understanding these can help ensure compliance and proper project management. Here are some common misunderstandings:

- All HVAC work requires the CF-1R form. Not every HVAC job requires this form. It is specifically for certain HVAC alterations in Climate Zones 10 to 15. Check the requirements before assuming it's necessary.

- Only large projects need a permit. Even small alterations, such as replacing a furnace in an unconditioned space, typically require a permit. This may come as a surprise, but permits are important for safety and compliance.

- You can do the inspection yourself. Inspections must be conducted by certified professionals, like a HERS rater or a building inspector. Trying to do this independently could risk project approval.

- This form is only about efficiency ratings. While efficiency is a significant component of the CF-1R form, it also encompasses proper installation practices, duct sealing requirements, and necessary documentation.

- It’s easy to skip HERS verification. HERS verification is required for all HVAC alterations in the designated climate zones. Neglecting this could halt your project and lead to penalties.

- All paperwork must be filled out by hand. There are specific forms, particularly the CF-4R forms, that cannot be completed manually and must be registered with an approved HERS provider. This is crucial for compliance.

Understanding these misconceptions can help clarify responsibilities and avoid unnecessary complications. Being informed allows for smoother interactions with regulatory agencies and ensures that your work meets established standards.

Key takeaways

Filling out the CF-1R Alt HVAC form accurately is essential for compliance with California’s Building Energy Efficiency Standards. Here are ten key takeaways to consider:

- The form is specifically for HVAC alterations in Climate Zones 10 to 15.

- A written construction permit is required before any major HVAC work begins, ensuring adherence to local building laws.

- The CF-1R Alt HVAC form must include details such as site address, equipment type, minimum efficiency, and duct insulation requirements.

- New equipment must meet stipulated efficiency ratings, such as a minimum 78% AFUE for heating equipment and 13 SEER for central air conditioners.

- HERS (Home Energy Rating System) verification is mandatory for all HVAC alterations, and specific forms are required for the final inspection.

- Consulting the required compliance forms (CF-6R and CF-4R) is vital for ensuring proper documentation and registration with an approved HERS Provider.

- Duct sealing requirements play a crucial role in achieving energy efficiency; leakage must be below specified limits for both new and altered systems.

- Different options on the form cater to HVAC changeouts, new installations, and situations involving more than 40 feet of ducting.

- Inspectors will verify that all work listed on the form was completed correctly, including checking signed compliance forms.

- Staying updated on all regulations and requirements related to energy efficiency standards is critical to avoid potential fines or disciplinary actions.

Being thorough and precise when filling out the CF-1R Alt HVAC form benefits both the contractor and the homeowner by ensuring compliance and improving energy efficiency.

Browse Other Templates

Form 14242 - Stay informed about abusive tax schemes to better understand what to report.

Dd1300 - The DD 1300 helps streamline communications during sensitive times of loss.