Fill Out Your Concrete Checklist From Form

The Concrete Checklist Form serves as an essential tool for supervising concrete pours on construction sites. Given that construction environments are often bustling and have multiple activities occurring simultaneously, it is easy for supervisors to overlook key details amidst the distractions. This form underscores the importance of a structured approach to inspections, ensuring that every critical aspect of a concrete pour is thoroughly evaluated. The checklist is designed to align with the specific project specifications, functioning as a condensed guide that highlights key areas such as formwork, reinforcing steel, and concrete delivery. Key features of the checklist include hold points, witness points, and tests that require sign-offs from supervisors, promoting accountability and quality control. Furthermore, it encourages the use of project-specific additions, allowing supervisors to customize the checklist based on prior experiences and common concerns at the site. Supervisors can benefit not only from the reminders provided by the checklist but also from peer insights shared through it. By taking the time to prepare and utilize this checklist effectively, supervisors can help mitigate the risks of oversight and enhance the overall quality of concrete work, leading to better project outcomes.

Concrete Checklist From Example

project check lists concrete pour

use in conjunction with the specification for the subject project

INTRODUCTION

It is difficult during a visit to a construction site to memorise all of the details that need to be checked and while the obvious ones stand out, many other items that should be checked are forgotten. Supervisors may get distracted or over extended due to time constraints and overlook items that may have more serious consequences later in the project.

These Check Lists provide a guide to the inspections that are required on site for a particular project. They are a précis of the full clauses in the project specification and can be referred back to the specification if the full text of the particular item is required. The Check Lists will remind you of virtually every potential problem in materials, workmanship and coordination between trades.

The Check Lists include a list of the Hold Points, Witness Points and Tests that are required to be signed off by the Supervisor on projects that include the Project Control section. The rest of the checks are simply dot points to jog the memory of the Supervisor.

Project specific checks may be added to the Check Lists for individual projects and the experience of Supervisors can be shared by the addition of particular checks on items or operations that are generally of concern on site. In this case less experienced Supervisors can use these Check Lists to provide them with the back up of more experienced officers.

Provide one copy of the Check Lists book to the Supervisor and one copy to the Contractor for the particular project.

HOW TO USE THESE CHECK LISTS

Take photocopies of the relevant Check List sections before going on site and study these. This book of Check Lists is spiral bound to allow pages to be photocopied easily.

Mark any items in the Check List that are of particular concern.

At the project site, check off the work against the Check Lists and make notes of any action required in the space provided.

When the work is completed and the final check has been made sign off and date in the box provided. There is also space to provide comments.

Keep a record of all of the completed Check Lists for future reference if required. These could prove to be valuable if disputes arise on the project.

There is no better way to document actual site conditions or details than by photographs, so don’t forget to take a digital camera on site and take images to go with particular items in the Check lists.

FURTHER DEVELOPMENT

If you have any suggestions to improve on these Check Lists or the system in general please contact Lawrie Foscaro, Manager, Specification Services, 3rd Floor Highway House, Palmerston. Tel; 8946 5021 or email DocumentationServices.DoI@nt.gov.au.

Doc ID |

Version |

Issued |

Printed |

Page |

2016.03 |

Sept 2016 |

19/09/2016 |

2 of 4 |

Comments from

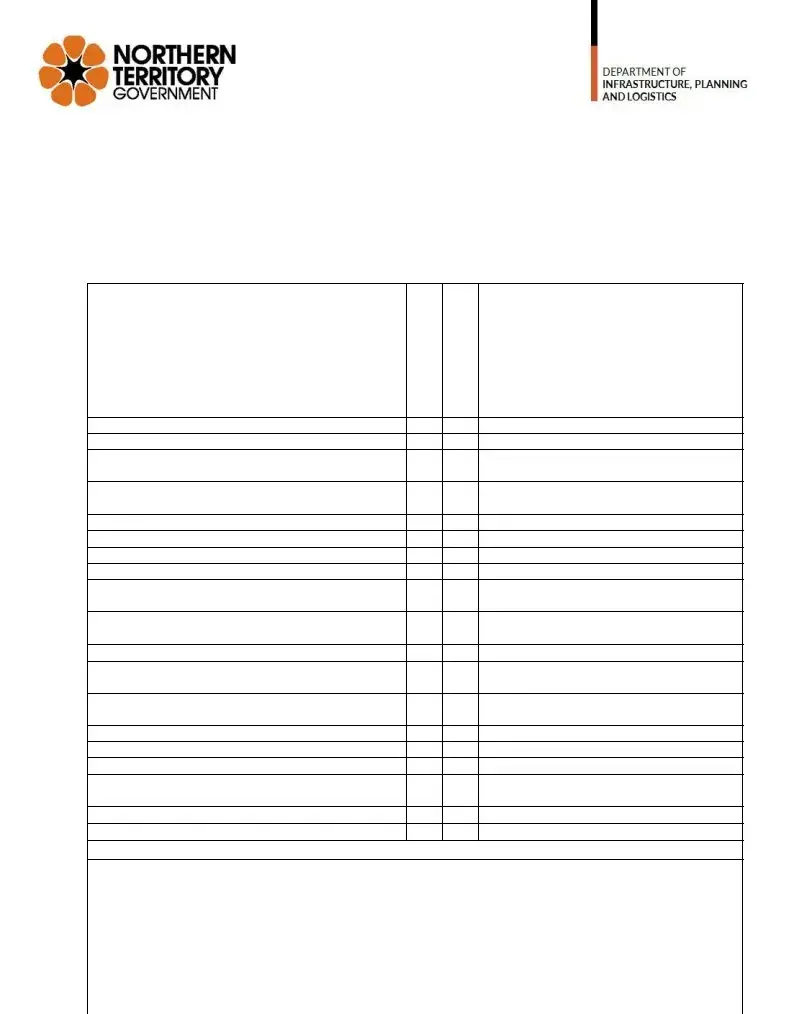

CONCRETE POUR CHECKLIST

Project/Job Name:

Contract No:

Audit Date:

Contractor:

Concrete Supplier:

Mix Design Approved/Not Approved

|

Audit Item |

Y |

N |

Comments |

|

1. Preliminary |

|

|

|

• |

Description |

|

|

|

• |

Lot Number/s |

|

|

|

• |

Previous Lots Conform |

|

|

|

• |

Casting Program Accepted |

|

|

|

|

|

|

|

|

• |

Curing Method |

|

|

|

|

(Stream) (Water) (Fog) (Other) |

|

|

|

2. Formwork and Falsework

• Formwork Dimensions in Accordance with Design, including void lengths

• Forms Clean, Smooth and Watertight and Free

of Deleterious/Extraneous/Foreign Materials

• Formwork within Dimension Tolerances

• Forms Meet Line and Level Requirements

3. Reinforcing Steel

• Steel Located/Fixed in Accordance with Drawings

• Reinforcing Clean and Free of Deleterious

Materials

• Critical Cover of 30mm Checked at all locations

• All Splices to Reinforcement at Approved Locations

• All Welds in Accordance with Australian Standards and RFT

4. Concrete Inclusions

• Embedded Dowels, Bolts, Conduits and Ducts

• Cored Holes, Weepholes, Block Outs, transverse stressing holes

• Lifting/Carrying Lugs etc

• Located as Shown on Drawings

Audit Results and Comments

Signature: |

|

|

Date |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Doc ID |

Version |

|

Issued |

Printed |

Page |

|

2016.03 |

Sept 2016 |

19/09/2016 |

3 of 4 |

|

||

|

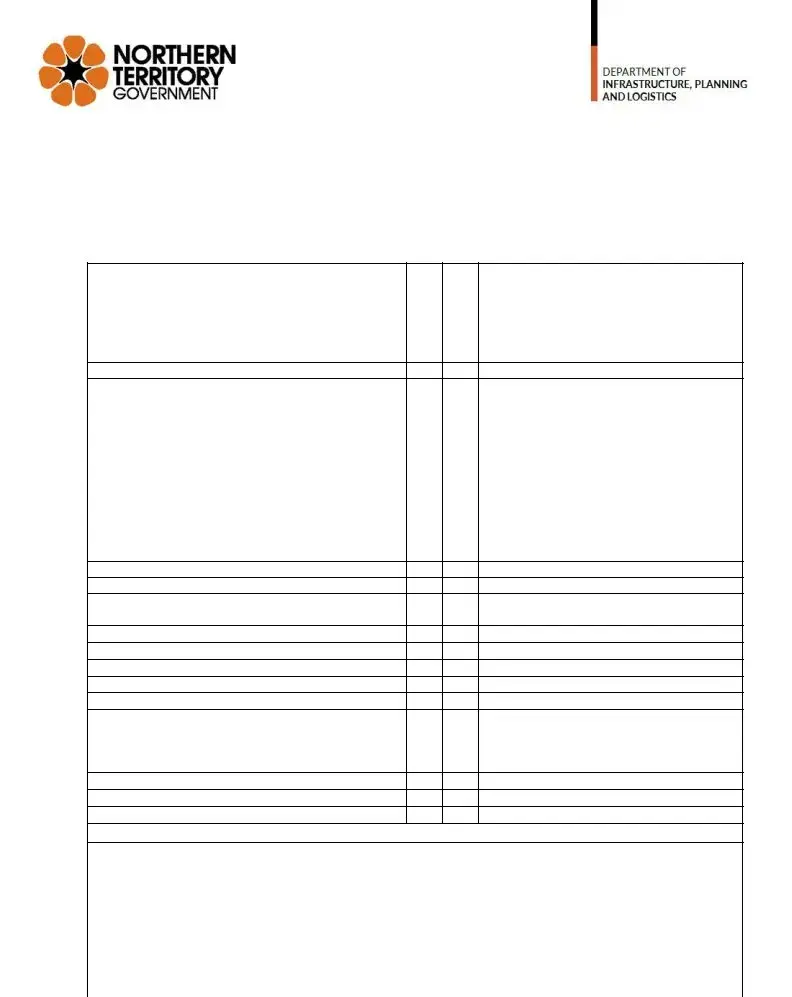

Audit Item |

Y |

N |

Comments |

|

|

5. Concrete Delivery |

|

|

|

|

• |

Number of Batches |

|

|

|

|

• Batch Time (From Delivery Docket) |

|

1. |

2. |

3. |

|

• Arrival Time at Site |

|

1. |

2. |

3. |

|

• |

Finish Time |

|

1. |

2. |

3. |

|

6. Concrete Testing |

|

|

|

• |

NATA Approved Testing Authority |

Name: |

|

|

• Ambient Temperature (Between 5oC and 35oC) |

|

|

|

|

• |

Actual Concrete Temperature |

1. |

2. |

3. |

• |

Target Slump 50 mm ± 10mm. Actual Slump |

1. |

|

|

|

|

2. |

|

|

|

|

3. |

|

|

• |

Amount of Admixture added |

1. |

2. |

3. |

• |

Amount of water added |

1. |

2. |

3. |

• Number of Cylinders Taken |

|

|

|

|

• |

Target Strength |

|

|

|

7. Concrete Placement

• Placement Method (Pump, Tremie, Chute,

Other)

• Sufficient Personnel for Finishing etc.

• Approved Vibration Method

• Back up Vibrators on Hand

• Reinforcement Cover Maintained During Pour

• Formwork Stable During Placing and Vibration

• Concrete Placed and Compacted Within: 25oC – 28oC = 75mins

28oC – 32oC = 60 mins 32oC – 35oC = 45 mins

• Provision for Closure of Access/Openings

• Forms Free of Foreign Matter Prior to Pouring

• Concrete Finished to Approved Tolerances

Audit Results and Comments

Signature: |

|

|

Date |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Doc ID |

Version |

|

Issued |

Printed |

Page |

|

2016.03 |

Sept 2016 |

19/09/2016 |

4 of 4 |

|

||

Form Characteristics

| Fact Title | Description |

|---|---|

| Purpose of the Checklist | The Concrete Checklist is designed to guide supervisors through necessary inspections during a concrete pour. It helps ensure that important details are not overlooked. |

| Importance of Inspection | During construction, distractions and time constraints can lead supervisors to miss vital checks. This checklist minimizes the risk of overlooking critical aspects that could impact the project later. |

| Project-Specific Additions | Supervisors have the flexibility to add specific checks tailored to individual projects. This allows for sharing valuable insights based on prior experience. |

| Record Keeping | It's recommended to keep completed checklists as a reference. They can serve as important documentation in the event of disputes related to the project. |

| Use of Photographs | Taking photographs during the inspections is encouraged. Visual documentation complements the checklist entries and adds clarity to site conditions. |

| Recommendations for Improvement | Feedback for improving the Concrete Checklist system is welcomed. Suggestions can be directed to the designated contact person for further enhancement. |

Guidelines on Utilizing Concrete Checklist From

Completing the Concrete Checklist From form involves gathering essential information and methodically checking off the various elements necessary for a successful concrete pour. The following steps provide a structured approach to ensure all critical aspects are reviewed and documented properly, helping to prevent issues on site and ensuring compliance with project specifications.

- Start by entering the Project/Job Name, Contract No, Audit Date, Contractor, and Concrete Supplier at the top of the form.

- Review the Mix Design and indicate whether it is Approved or Not Approved.

- For each Audit Item, check 'Y' for yes or 'N' for no, and write down any Comments as needed:

- Preliminary checks, ensuring details like Lot Number/s and Curing Methods are correct.

- Inspect Formwork and Falsework for dimensions, cleanliness, and tolerances.

- Verify Reinforcing Steel placement and cleanliness, and ensure critical cover requirements are met.

- Document any Concrete Inclusions, such as embedded dowels and block outs.

- Review Concrete Delivery information like batch details and arrival times.

- Check Concrete Testing, including compliance with temperature and slump targets.

- Examine Concrete Placement methods and conditions, ensuring stability and proper timing during pour.

- Once all checks are completed, carefully review your comments and ensure each section has been addressed.

- Have the Supervisor sign and date the form in the designated area.

- Take photographs of significant events or issues on-site that correspond to the checklist items, as this visual documentation can be invaluable.

- Keep a copy of the completed checklist for future reference, especially in case of disputes.

By following these steps carefully, you help ensure that all aspects of the concrete pour are thoroughly evaluated and documented, setting a clear path forward for the project’s success.

What You Should Know About This Form

What is the purpose of the Concrete Checklist Form?

The Concrete Checklist Form serves as a practical guide for supervisors to ensure that all essential aspects of a concrete pour are inspected. By using this checklist, supervisors can reduce the chances of overlooking critical items that could lead to issues down the line. It summarizes the specifications required for the project and is an easy-to-follow tool during onsite inspections.

How should I prepare before using the Concrete Checklist Form?

Before heading to the site, make sure to study the relevant sections of the checklist. Since the book is spiral-bound, you can easily photocopy the pages you need. Circle or mark any items that might be particularly important to your project. Familiarizing yourself with the checklist in advance will help ensure that you're ready to conduct thorough inspections when you arrive onsite.

Can additional project-specific checks be added to the checklist?

Yes, you can personalize the checklist by adding project-specific checks. This is particularly useful for unique aspects or challenges that might arise during your specific project. Sharing your past experiences can also benefit newer supervisors who may lack extensive onsite experience.

How do I document findings during the concrete pour using the checklist?

While reviewing the checklist onsite, you will find space provided for notes. As you check off each item, jot down any required actions or comments in the designated areas. This will create a valuable record of the inspection process. Once the work is completed, don't forget to sign and date the checklist.

Why is it important to take photographs during the concrete pour?

Taking photographs can be one of the best ways to document actual site conditions and specific details related to the project. These images can enhance your notes and offer visual evidence should any disputes arise later. So, always bring a digital camera to capture critical moments during the concrete pour.

What should I do if I have suggestions for improvements to the checklist?

If you have ideas or suggestions to enhance the Concrete Checklist Form, your feedback is welcomed. You can reach out to the Manager of Specification Services through the contact details provided. Your insights can help improve the effectiveness of the checklist for everyone involved in concrete projects.

What are Hold Points and Witness Points?

Hold Points and Witness Points are critical stages in the project where inspections must be conducted before proceeding to the next phase. These points are outlined within the checklist to ensure nothing is skipped and that all necessary approvals are obtained. They play a significant role in maintaining quality and compliance throughout the project.

How are concrete testing requirements addressed in the checklist?

The checklist includes specific items related to concrete testing, such as ambient and actual concrete temperatures, target slump, and the number of cylinders taken. These specifications are vital to ensure that the concrete meets the necessary standards and will perform well in the overall structure.

What should I keep in mind regarding concrete delivery?

The checklist prompts you to document various aspects of concrete delivery, such as the number of batches, arrival and finish times. Keeping accurate records of these details can help in managing the timeline of the project effectively and provide important data if there are any delivery issues or concerns about the concrete quality.

Common mistakes

Filling out the Concrete Checklist From form can be a daunting task, especially when there are numerous details to remember. One common mistake individuals make is neglecting to photocopy the relevant sections of the checklist before going on site. This oversight can lead to confusion during inspections and missed details. Having a physical copy allows for easy reference and ensures that important items do not get overlooked while on the job.

Another frequent error involves failing to mark items of particular concern. It’s crucial to highlight any sections that may require extra attention during the inspection. This step draws focus and reminds supervisors to thoroughly check those specific areas. Without this precaution, significant issues might be missed, leading to complications later in the project.

Many individuals also make the mistake of not making notes about necessary actions in the provided space on the form. Documentation is essential, as it creates a record of what needs to be addressed. These comments serve as valuable reminders for both the supervisor and the contractor, facilitating better communication and follow-up as the project progresses.

Another common oversight is not signing off on completed items. When tasks are finished, it’s important to officially acknowledge their completion by signing and dating the checklist. This act confirms that the work meets the required specifications and reinforces accountability among team members. Failing to do so might create disputes or confusion regarding the status of various tasks.

Furthermore, individuals often forget to take photographs to document site conditions aligned with the checklist. Visual records can clarify work processes and outcomes, providing crucial evidence should disputes arise. A picture speaks a thousand words, and in construction, it can prevent misunderstandings and support claims should they be necessary.

Lastly, some people skip the step of keeping a record of completed checklists for future reference. These documents could serve as vital assets if disagreements or questions about the project's execution emerge later on. By maintaining thorough records, you create a historical account of the project, serving everyone involved well in the long run.

Documents used along the form

In addition to the Concrete Checklist Form, several other forms and documents are commonly utilized to ensure that a concrete pouring project proceeds smoothly and adheres to required standards. Each of these documents serves a specific purpose, helping project managers, contractors, and supervisors to coordinate effectively and maintain quality control throughout the construction process.

- Concrete Delivery Docket: This document records the details of each concrete delivery, including batch numbers, delivery times, and quantities. It plays a critical role in tracking concrete supplied to the site and ensures that the delivered material meets project specifications. This information can assist in quality control and can be referred to in case of discrepancies.

- Concrete Mix Design Approval: Before any concrete is poured, the mix design must be approved to ensure that it meets specified performance criteria. This document outlines the proportions of materials in the concrete mix and any additives used. It ensures the concrete will perform as needed for load-bearing, durability, and environmental conditions.

- Concrete Test Results Report: This report provides the results of any tests conducted on the concrete prior to, during, or after the pour. It includes information such as slump tests, temperature readings, and compressive strength tests. Such data validates that the concrete delivered meets the necessary criteria and reinforces confidence in its structural integrity.

- Permit for Concrete Pour: A specific permit may be required from local authorities before commencing any concrete pouring activities. This document ensures compliance with local building codes and regulations. It often stipulates conditions under which the work can proceed, including noise control measures and scheduling restrictions.

These accompanying documents, when used in conjunction with the Concrete Checklist Form, help to create a comprehensive record of all project specifications and quality assurance checks. Together, they form an essential part of the construction documentation that guarantees projects meet their intended standards and reduces the risk of future disputes.

Similar forms

The Concrete Checklist Form shares similarities with several other important documents often used in construction projects. Each of these documents serves to ensure quality and compliance during various stages of a project. Here are nine documents that resemble the Concrete Checklist Form:

- Construction Daily Report: This document tracks daily activities on the construction site. It includes details like weather conditions, work performed, and labor used, similar to the way the checklist monitors various aspects of the concrete pour process.

- Inspection Request Form: Used to request a formal inspection of completed work, this form helps ensure that all requirements are met before proceeding. The checklist serves a similar purpose by outlining essential checks that need to be conducted prior to and during the concrete pour.

- Quality Control Plan: A comprehensive document that outlines quality standards and procedures for the entire project. Like the Concrete Checklist Form, it provides guidance to help teams identify and address potential issues before they impact the project.

- Change Order Form: This form documents any changes in the project scope, including adjustments to materials or processes. Both documents help keep the project on track by ensuring all details are accounted for, minimizing oversight.

- SITE Safety Inspection Checklist: A document designed to ensure safety standards are met throughout the construction process. Similar to the Concrete Checklist, it helps supervisors remember critical checks that could impact safety and compliance.

- Request for Information (RFI): Used to seek clarification on project details, an RFI helps avoid mistakes. The Concrete Checklist reduces the need for RFIs by preemptively addressing many common issues during concrete pours.

- Material Inspection Report: This document evaluates the quality of materials used in the project. Like the Concrete Checklist, it emphasizes the importance of verifying materials to ensure they meet project specifications.

- Testing and Inspection Schedule: This schedule outlines when inspections and tests are to occur throughout the project lifecycle. The checklist adheres to this concept by specifying critical inspection points during the concrete phase.

- Project Completion Checklist: A final checklist to confirm all project requirements have been met before completion. Like the Concrete Checklist Form, it ensures that every crucial item has been reviewed and ticked off before moving forward.

Dos and Don'ts

When completing the Concrete Checklist Form, careful attention to details is essential. Below is a list of actions to take and actions to avoid, ensuring a thorough and effective review process.

- Do take photocopies of the relevant Check List sections before heading to the site.

- Do mark any items in the Check List that particularly concern you.

- Do check off work against the Check Lists as tasks are completed.

- Do make notes of any required actions in the designated space provided.

- Do sign off and date the Check List once all checks are completed.

- Do document actual site conditions with photographs.

- Don't forget to review the project specification alongside the Check List.

- Don't overlook items that may appear minor but could have serious consequences.

- Don't neglect to keep a record of completed Check Lists for future reference.

- Don't hesitate to contact the project manager with suggestions for improvement.

Misconceptions

Misconceptions about the Concrete Checklist Form can lead to confusion and mistakes during the construction process. Here are ten common misconceptions along with clarifications.

- Checklists are Optional. Many believe that using checklists is not mandatory. In fact, they serve as essential tools to ensure all aspects of concrete pouring are addressed.

- One Size Fits All. It's often assumed that a general checklist is suitable for every project. However, projects can have specific requirements that must be incorporated into the checklist.

- Digital Checklists Are Just as Effective. Some think electronic checklists are sufficient substitutes. While they may be convenient, physical checklists allow for easier marking and comments on-site.

- Using the Checklist is Time-Consuming. Many feel that filling out checklists takes too much time. In reality, they streamline the inspection process and save time by ensuring nothing is overlooked.

- Site Conditions Don’t Change. It’s often thought that site conditions remain constant. Weather, material availability, and other factors can change quickly, making it essential to refer to checklists regularly.

- Only Supervisors Should Use the Checklist. Some believe that checklists are solely for supervisors. In truth, they can benefit all team members involved in the project.

- All Items are Equally Important. It's common to think every checklist item holds the same weight. However, certain points—like Hold Points—require immediate attention and should be prioritized.

- A Sign-Off is the End of the Process. People often view a signature as final. However, ongoing monitoring and documentation are critical even after the sign-off is completed.

- Photos Are Not Necessary. Some may feel documentation through photographs is optional. In fact, images support the written record and help clarify conditions and issues.

- Feedback on the Checklists is Not Required. Many assume the established checklists do not need improvement. However, input from users is crucial for the ongoing development of effective tools.

Understanding these misconceptions can lead to more effective use of the Concrete Checklist Form and contribute to the success of construction projects.

Key takeaways

The Concrete Checklist Form serves as an essential tool for ensuring the integrity of construction projects involving concrete pours. Here are some key takeaways to consider when filling out and utilizing this form:

- The checklist is designed to be used in conjunction with project specifications, offering a comprehensive guide for inspections.

- Supervisors should be proactive in utilizing the checklist to avoid missing critical details that can lead to significant issues later in the project.

- Copies of the checklist should be provided to both the supervisor and the contractor to promote accountability and collaboration.

- Before heading to the construction site, it is advisable to photocopy the relevant checklist sections for ease of use.

- Mark any items of particular concern on the checklist to ensure they receive proper attention during the inspection.

- Make sure to document actions required by noting them in the provided space on the checklist.

- After completing all checks, always sign and date the checklist to maintain a clear record of inspections.

- Keep a file of all completed checklists for potential future reference, as they can be invaluable in resolving disputes.

- Photographs are highly encouraged to document site conditions that correspond with specific checklist items; this adds a visual element to the records.

- Feedback and suggestions for improving the checklist process are welcome and can greatly enhance future versions.

By thoroughly engaging with the Concrete Checklist Form, supervisors can better ensure the quality and safety of concrete work on their projects.