Fill Out Your Csd 1 Form

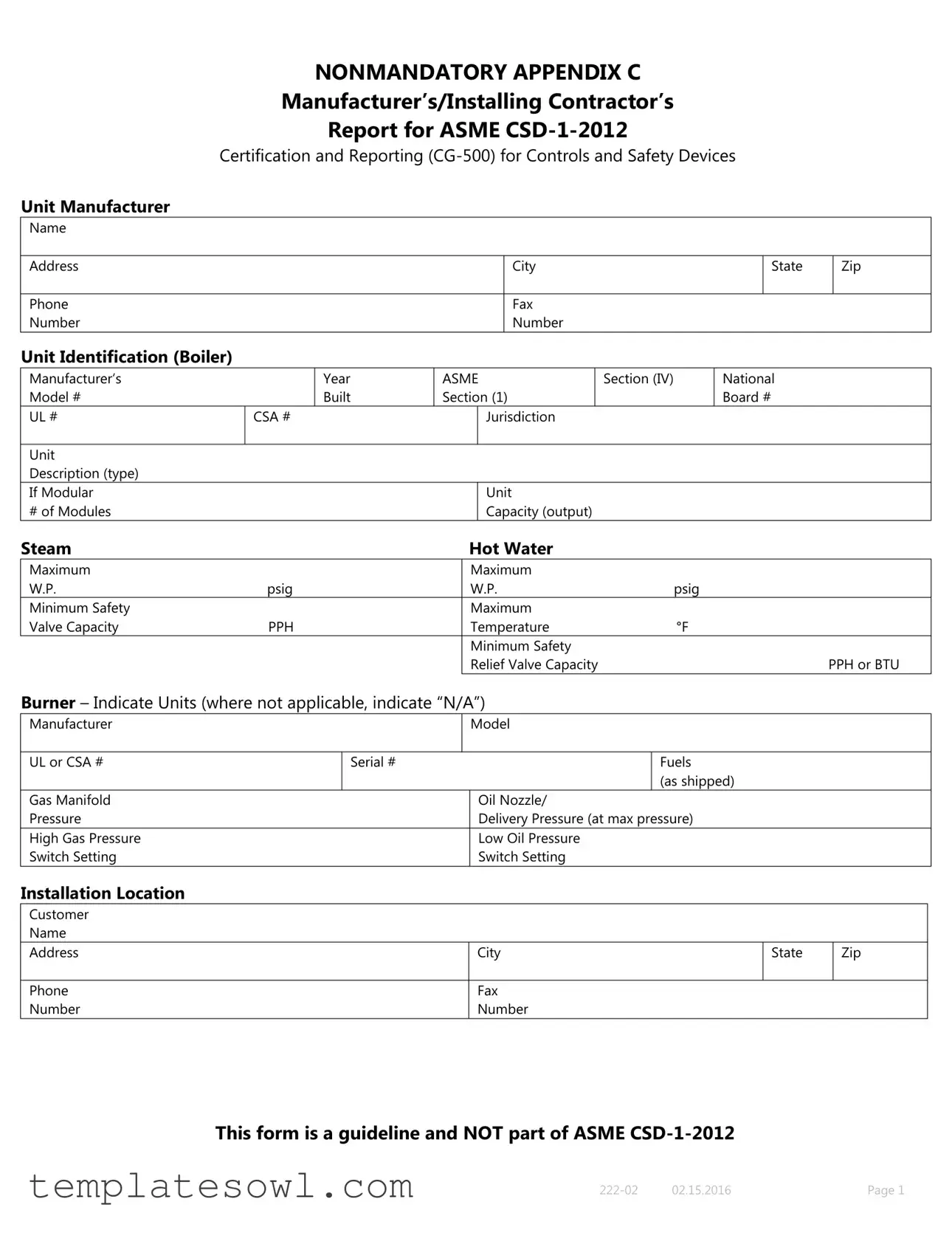

The CSD-1 form, officially known as the Manufacturer’s/Installing Contractor’s Report for ASME CSD-1-2012 Certification and Reporting, plays a crucial role in ensuring safety and compliance for controls and safety devices related to boilers. This comprehensive document is essential for manufacturers and contractors involved in the installation of these units, as it gathers key information that demonstrates adherence to safety standards. It prompts the user to provide details such as the manufacturer's name, address, and contact information, along with specific unit identification data including the model, serial number, and jurisdiction. Additionally, it encapsulates crucial operational information regarding various safety controls, including low-water fuel cutoffs, high-pressure limits, and safety shutoff valves, helping to verify that all devices are functioning correctly and safely. There is a section dedicated to operational tests performed, reinforcing accountability and ensuring that each component operates according to safety protocols. By compiling this data, the CSD-1 form facilitates a clearer understanding of each unit's operational status and prepares it for certification, ultimately aiding in the maintenance of safe boiler operating practices in compliance with established regulations.

Csd 1 Example

NONMANDATORY APPENDIX C

Manufacturer’s/Installing Contractor’s

Report for ASME

Certification and Reporting

Unit Manufacturer

Name |

|

|

|

|

|

Address |

|

City |

|

State |

Zip |

Phone |

|

Fax |

|

|

|

Number |

|

Number |

|

|

|

Unit Identification (Boiler) |

|

|

|

|

|

Manufacturer’s |

Year |

ASME |

Section (IV) |

National |

|

Model # |

Built |

Section (1) |

|

Board # |

|

UL # |

CSA # |

Jurisdiction |

|

|

|

Unit |

|

|

|

|

|

Description (type) |

|

|

|

|

|

If Modular |

|

Unit |

|

|

|

# of Modules |

|

Capacity (output) |

|

|

|

Steam |

|

Hot Water |

|

|

|

Maximum |

|

Maximum |

|

|

|

W.P. |

psig |

W.P. |

|

psig |

|

Minimum Safety |

|

Maximum |

|

|

|

Valve Capacity |

PPH |

Temperature |

|

°F |

|

|

|

Minimum Safety |

|

|

|

|

|

Relief Valve Capacity |

|

|

PPH or BTU |

Burner – Indicate Units (where not applicable, indicate “N/A”)

Manufacturer |

Model |

|

|

UL or CSA # |

Serial # |

Fuels |

|

|

|

(as shipped) |

|

Gas Manifold |

Oil Nozzle/ |

|

|

Pressure |

Delivery Pressure (at max pressure) |

|

|

High Gas Pressure |

Low Oil Pressure |

|

|

Switch Setting |

Switch Setting |

|

|

Installation Location |

|

|

|

Customer |

|

|

|

Name |

|

|

|

Address |

City |

State |

Zip |

Phone |

Fax |

|

|

Number |

Number |

|

|

This form is a guideline and NOT part of ASME

02.15.2016 |

Page 1 |

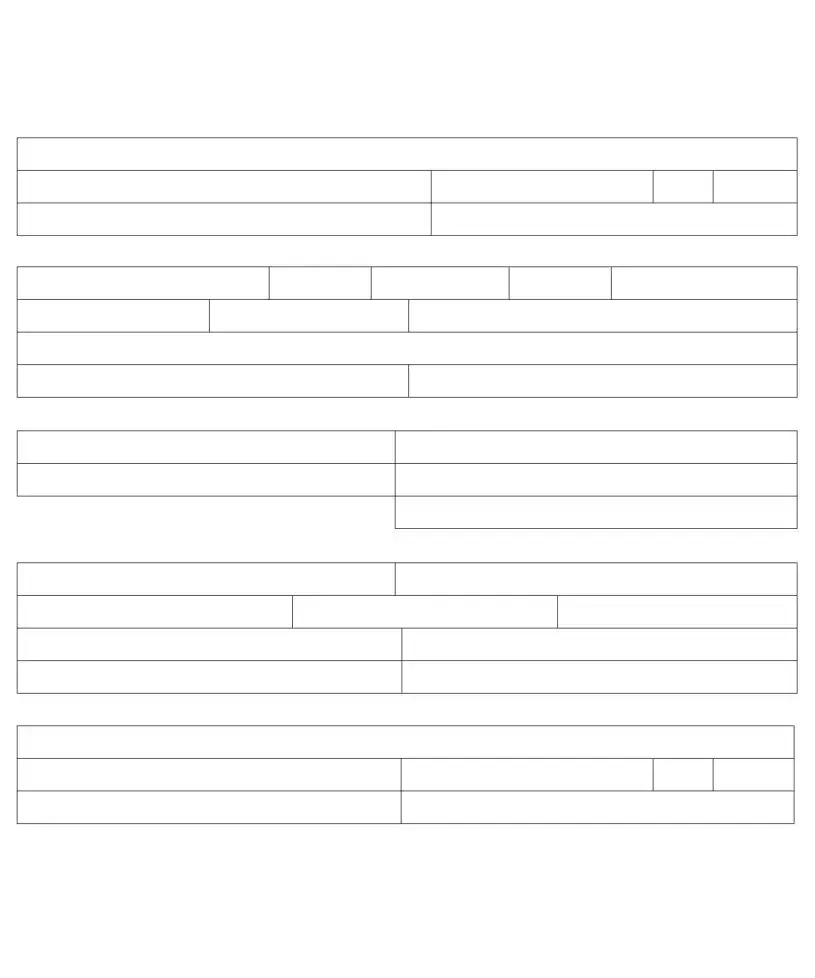

Certification and Reporting |

|

||

. |

|

Model |

Date Operational |

Control/Device |

Manufacturer |

Number |

Test Performed |

Operating Controls

Forced Circulation -

Steam Pressure -

Water Temperature –

Safety Controls

Forced Circulation -

High Steam Pressure Limit -

High Water Temperature Limit

Fuel Safety Shutoff Valve, Main

Pilot Safety Shutoff Valve -

Atomizing Medium Switch - |

|

|

Combustion Air Switch - |

|

|

High Gas Pressure - |

|

|

Low Gas Pressure - |

|

|

Low Oil Pressure - |

|

|

High Oil Temperature - |

|

|

Low Oil Temperature - |

|

|

Purge Air Flow - |

|

|

Flame Safeguard (Primary) |

|

|

|

|

|

Flame Detector – |

|

|

Low Fire Start |

|

|

|

||

Safety or Safety Relief Valve(s) |

|

|

|

|

|

Manufacturer |

Model |

|

Size |

Capacity |

Date of Operational |

|

PPH/BTU/hr |

Test Performed |

Representing Equipment Manufacturer |

|

|

|

|

|

Name |

Signature |

Date |

Representing Installing Contractor

Name |

Signature |

Date |

This form is a guideline and NOT part of ASME

Page 2

Form Characteristics

| Fact | Description |

|---|---|

| Form Purpose | The CSD-1 form is used for reporting on controls and safety devices related to boiler operations. |

| Regulatory Framework | This form aligns with ASME CSD-1-2012 standards, which govern safety device requirements. |

| Manufacturer Information | Details about the unit's manufacturer, including name, address, and contact information, must be provided. |

| Unit Identification | The form requires a unique unit identification number for the boiler, ensuring proper tracking and compliance. |

| Safety Valve Capacity | Information on the maximum and minimum safety relief valve capacity should be included in PPH or BTU. |

| Installation Location | The form mandates that the installation location and customer details be clearly stated. |

| Test Sections | Specific tests are outlined for various safety controls, including low-water fuel cutoff and high steam pressure limits. |

| Signatures Required | Representatives from both the equipment manufacturer and installing contractor must sign the form, confirming accuracy. |

| Operating Controls | The form details operational controls that must be tested and recorded, ensuring thorough safety assessments. |

| Not Mandatory | This form serves as a guideline and is not a mandatory part of ASME CSD-1-2012, providing flexibility for users. |

Guidelines on Utilizing Csd 1

Filling out the Csd 1 form is an important task that requires careful attention to detail. After completing the form, it will need to be submitted to ensure compliance with safety regulations. Make sure to gather all necessary information before you begin the process.

- Obtain the Csd 1 Form: Get a physical or digital copy of the form you need to fill out.

- Manufacturer Information: Enter the manufacturer's name, address, city, state, zip code, phone number, and fax number at the top of the form.

- Unit Identification: Fill in the unit identification details including the manufacturer's year, ASME section, model number, built section, board number, UL number, CSA number, and jurisdiction.

- Unit Description: Describe the type of unit you are reporting on. If it is a modular unit, indicate the number of modules.

- Capacity Information: Provide details about maximum and minimum safety valve capacities, output capacities in PPH, and maximum temperature.

- Burner Information: List the burner manufacturer, model, serial number, and UL or CSA number. If certain categories do not apply, indicate “N/A.”

- Fuel Information: Specify the fuels as shipped, including details for gas manifold, oil nozzle, and pressure settings for both gas and oil.

- Installation Location: Fill in the installation location along with the customer’s name, address, city, state, zip code, phone number, and fax number.

- Operational Devices Information: For each operational control or safety device, specify the manufacturer number and the tests performed.

- Safety Controls Information: List the same details for safety controls, including low-water fuel cutoff and high-pressure limits.

- Safety Relief Valve(s) Information: Provide the manufacturer’s name, model, size, capacity, and date of operational test performed.

- Signatures: Ensure that the equipment manufacturer and the installing contractor sign and date the form at the bottom.

Once the form is completed, check for accuracy and completeness before submitting it. Missing or incorrect information can lead to compliance issues down the line.

What You Should Know About This Form

What is the CSD-1 form and its purpose?

The CSD-1 form, formally known as the Manufacturer's/Installing Contractor’s Report for ASME CSD-1-2012 Certification and Reporting, serves as a standardized guideline for reporting on controls and safety devices for certain boiler and water heating equipment. Its main purpose is to document compliance with safety regulations and operational standards, ensuring the safe installation and performance of these units.

Who needs to fill out the CSD-1 form?

This form must be completed by manufacturers and installing contractors involved in the production and installation of boiler systems. Anyone responsible for the oversight of safety controls and operational devices in these systems should be familiar with the CSD-1 form.

What information is required on the CSD-1 form?

The CSD-1 form requires various details, including the manufacturer's name, contact information, and unit identification specifics. Additionally, it collects information about safety controls, operational devices, and the testing of these components. The unit's capacity, pressure ratings, and other specifications are also essential to include.

Is the CSD-1 form mandatory?

While the CSD-1 form is not mandatory, it is highly recommended for compliance with relevant safety codes. It acts as a helpful documentation tool that can facilitate inspections and certifications, particularly when modifications or installations occur.

What testing information is included in the CSD-1 form?

The form includes sections for documenting tests performed on various operating and safety controls. This includes tests for low-water fuel cutoff devices, pressure limits, and safety shutoff valves. Recording the outcomes and dates of these tests is crucial for demonstrating operational safety and compliance.

How does the CSD-1 form relate to ASME CSD-1-2012?

The CSD-1 form is designed to support compliance with the ASME CSD-1-2012 standards. It aligns with these regulations by providing a structured format for reporting on critical safety aspects of boiler operations. Completing the form helps ensure that installations meet the necessary codes and safety requirements.

What happens if the CSD-1 form is not completed?

Failure to complete the CSD-1 form can lead to compliance issues. It may result in penalties during inspections or delays in obtaining necessary certifications. It is advisable to maintain thorough documentation to uphold safety standards and avoid potential liabilities.

Who should sign the CSD-1 form upon completion?

Both the equipment manufacturer and the installing contractor must sign the CSD-1 form. This dual signature ensures shared accountability for adhering to safety protocols and regulatory standards related to the installation and operation of the equipment.

Where can I obtain a copy of the CSD-1 form?

The CSD-1 form can typically be accessed through industry associations, safety organizations, or relevant regulatory bodies. It is often available in both paper and digital formats to facilitate ease of use in reporting compliance.

Common mistakes

Filling out the CSD-1 form correctly is crucial for ensuring compliance with safety standards. However, many people make mistakes that can lead to delays or rejections. One common error is **omitting necessary information**. When individuals leave out key details, like the manufacturer’s name or the unit identification number, it can cause significant issues. Every section of the form is important, and missing information can prevent proper certification.

Another mistake is providing **inaccurate descriptions of the unit**. The unit description must be clear and precise. Errors in specifying whether the unit is for steam or hot water can lead to incorrect assessments of safety controls. Always double-check that the type of unit aligns with the applications and safety devices being reported.

Many people also overlook the **importance of listing the correct specifications** for safety relief valves. Incorrect values for maximum and minimum capacities can jeopardize the entire safety assessment. These specifications are essential since they directly impact the unit's performance under pressure. Failing to provide this information accurately can hinder the evaluation process.

Additionally, individuals sometimes forget to include **the contact details for the customer**. Including accurate names, addresses, and phone numbers is essential. This information ensures that the certification can be communicated properly. Missing or incorrect contact details can create confusion and complicate follow-up inquiries.

Lastly, submitting the form **without proper signatures can lead to rejection**. Both the equipment manufacturer and the installing contractor must sign the form. A missing signature sends the form back for correction, resulting in waste of time. Ensure that all parties involved have reviewed and signed the documents before submission to avoid unnecessary delays.

Documents used along the form

When completing the CSD-1 form for safety devices in boiler systems, it is often necessary to accompany it with several additional documents. Each document serves a specific purpose to ensure compliance with safety regulations. Below is a list of common forms and documents that may be used alongside the CSD-1.

- CE Marking Certificate: This document proves that the product meets the essential requirements of relevant European safety directives. It provides assurance to customers and regulators about the safety and quality of the product.

- Installation Manual: A guide that details the procedures for installing the corresponding equipment. It includes safety precautions and operational guidelines to ensure proper installation.

- Manufacturer's Safety Data Sheet (SDS): This sheet contains important information about the materials used in the equipment, including hazards, handling, and emergency measures for safety during installation and operation.

- Testing Reports: Documentation that verifies the operational efficacy of safety devices and controls. These reports detail the type of tests performed and their outcomes, which are crucial for regulatory compliance.

- Certificate of Compliance: Issued by a third-party inspection agency, this certificate indicates that the equipment meets all applicable safety standards and codes, ensuring peace of mind for both suppliers and users.

- Maintenance Logs: Records that track regular maintenance activities performed on the equipment. These logs ensure that safety devices are functioning optimally and may be required for ongoing compliance checks.

- Wiring Diagrams: Detailed illustrations showing the electrical connections within the boiler system. These diagrams assist in troubleshooting and ensure that safety controls are properly integrated into the system.

- Commissioning Report: This report summarises the initial setup and testing of the equipment to confirm it operates as intended. It often includes findings or issues encountered during the commissioning process.

- Manufacturer's Warranty: A document that outlines the terms of warranty coverage, ensuring that any defects or failures during the warranty period are addressed without extra costs for the buyer.

In summary, these supporting documents are essential for a thorough understanding of the safe operation of boiler systems and compliance with safety standards. Together, they contribute to a safer working environment and bolster confidence in the equipment's reliability.

Similar forms

The Csd 1 form serves crucial functions related to safety and compliance in the context of boiler and burner operations. Below are eight documents that share similarities with the Csd 1 form, each serving various roles in safety and operational reporting:

- ASME Form P-NGF: This form focuses on the certification of pressure vessels. Like the Csd 1 form, it includes technical specifications and operational parameters required for compliance.

- NFPA 85 Documentation: This pertains to boilers and combustion systems. Similar in that it emphasizes safety controls and operational tests to ensure proper functioning during use.

- Manufacturer’s Mandatory Report: This report outlines standards that manufacturers must follow. It shares the requirement for specific equipment details and testing performed before installation.

- Boiler Inspection Report: Conducted by certified inspectors, this report highlights safety compliance, akin to the Csd 1 form in verifying that all safety measures are met.

- Installation Verification Form: This document ensures that all equipment has been installed correctly. It resembles the Csd 1 form in its focus on installation specifics and component assessments.

- Operational Maintenance Log: This log records maintenance activities and safety inspections. Like the Csd 1 form, it serves to track the performance and safety of equipment over time.

- Fuel Safety Certification: This document confirms that all fuel systems are secure. It parallels the Csd 1 in detailing safety measures and testing results for fuel delivery mechanisms.

- Emergency Shutdown Procedure Form: This form outlines actions to take during a system failure. It shares a commitment to safety by providing clear guidelines, similar to those found in the Csd 1 form.

Dos and Don'ts

When filling out the Csd 1 form, here are some essential do's and don'ts:

- Do ensure all fields are completed accurately to avoid processing delays.

- Do double-check the contact information provided for the customer and manufacturer.

- Do verify the serial numbers and model numbers to maintain compliance with certification requirements.

- Do submit the form promptly, especially if your project timeline is tight.

- Do keep a copy of the completed form for your records.

- Don't leave any mandatory fields blank, as this can lead to rejection of the form.

- Don't use abbreviations that may cause confusion or misinterpretation.

- Don't neglect to include additional documentation if required.

- Don't forget to sign the form, as it is a crucial step in the submission process.

- Don't wait until the last minute to fill out the form to avoid unnecessary stress.

Misconceptions

Mispconceptions About the CSD-1 Form

- Misconception 1: The CSD-1 form is mandatory for all installations.

- Misconception 2: Only manufacturers need to fill out the CSD-1 form.

- Misconception 3: The form is a certification document.

- Misconception 4: The information is not reviewed after submission.

- Misconception 5: There is no deadline for submitting the form.

- Misconception 6: The CSD-1 form applies only to steam systems.

- Misconception 7: Any modifications to the equipment do not require an updated CSD-1 form.

This form is a guideline and is not required for every circumstance. Some situations may not require its use depending on local regulations.

Both manufacturers and installing contractors are responsible for completing this form. Ensuring accuracy is essential for compliance.

The CSD-1 form serves as a report rather than an official certification. Certification comes from separate testing and validation processes.

Regulatory bodies may review the form as part of their inspections. Providing accurate and complete information is vital.

Timely submission may be required by local jurisdictions or during inspections. Delays can lead to compliance issues.

This form is applicable to both steam and hot water systems. It's crucial to specify the type of unit being reported.

Any changes to the system or components may necessitate an updated form. Keeping records current ensures safety and compliance.

Key takeaways

When filling out and using the Csd 1 form, here are some key takeaways to keep in mind:

- The Csd 1 form is designed for reporting on controls and safety devices related to boilers and similar equipment.

- It is important to enter complete and accurate information for the manufacturer, installation location, and unit identification.

- Check that all components, like safety controls and operational controls, are listed with their corresponding model numbers and settings.

- Specify the type of fuel used; whether it’s gas, oil, or other options, to ensure correct operational information.

- Be thorough when describing the unit's capacity, including its output in pounds per hour (PPH) and temperature settings.

- Remember that this form serves as a guideline and is not an official part of the ASME CSD-1-2012 documentation.

- Ensure that both the equipment manufacturer and the installing contractor sign the form to validate the information.

- Review the form for any specific jurisdictional requirements that may apply to your region.

- All information should be completed prior to use to ensure compliance with safety regulations.

- Keep a copy of the submitted form for your records, as it may be necessary for future reference or inspections.

Browse Other Templates

Wt-6 Wisconsin - This form should be submitted in a timely manner to ensure the state receives tax payments promptly.

Superbill Template Pdf - This form provides detailed information about the attending providers involved in a patient's care.