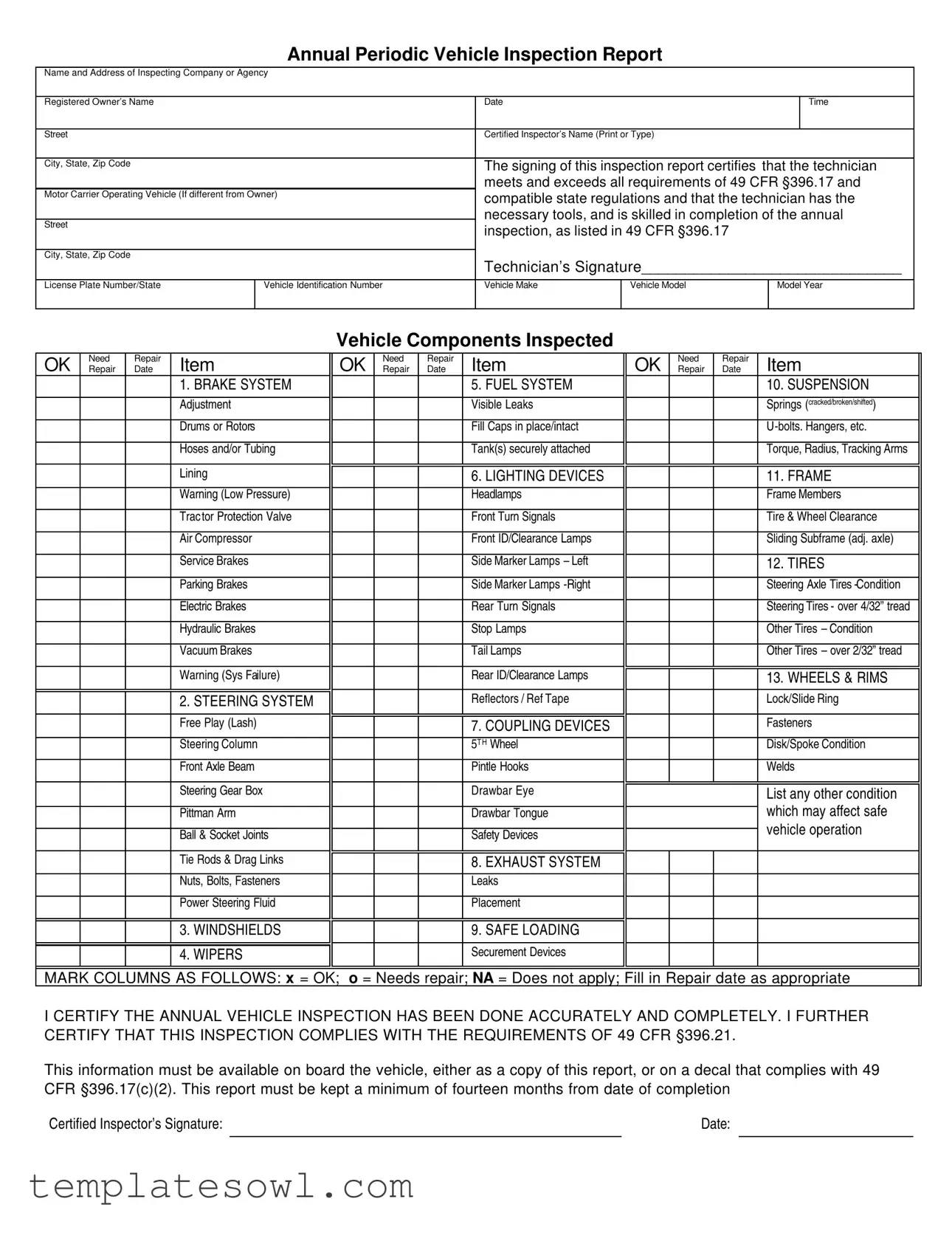

Fill Out Your Dot Vehicle Inspection Form

The DOT Vehicle Inspection form serves as a critical tool in ensuring the safety and compliance of commercial vehicles. Each year, fleet operators are required to carry out a thorough inspection of their vehicles, documenting crucial information that validates the vehicle's roadworthiness. This form captures essential details such as the name and address of the inspecting agency, the registered owner's information, and the date and time of inspection. It also features a section for the inspector’s signature, which attests to their qualifications and adherence to federal regulations. Through checks on various components, including brake and steering systems, tires, lighting devices, and more, the form helps identify both operational status and necessary repairs. Technicians must mark each item as either 'OK' or 'Needs repair,' ensuring transparency and accountability. The completed report must be kept on board for at least fourteen months, ready to demonstrate compliance with safety standards set forth in federal regulations. Consequently, this form is not merely a checklist but a comprehensive record that contributes significantly to the broader safety net for commercial transport on our roads.

Dot Vehicle Inspection Example

Annual Periodic Vehicle Inspection Report

Name and Address of Inspecting Company or Agency

Registered Owner’s Name |

|

Date |

|

|

Time |

|

|

|

|

|

|

Street |

|

Certified Inspector’s Name (Print or Type) |

|

|

|

|

|

|

|

|

|

City, State, Zip Code |

|

The signing of this inspection report certifies that the technician |

|||

|

|

meets and exceeds all requirements of 49 CFR §396.17 and |

|||

Motor Carrier Operating Vehicle (If different from Owner) |

compatible state regulations and that the technician has the |

||||

|

|

||||

|

|

necessary tools, and is skilled in completion of the annual |

|||

Street |

|

inspection, as listed in 49 CFR §396.17 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

City, State, Zip Code |

|

|

|

|

|

|

|

Technician’s Signature______________________________ |

|||

|

|

|

|

|

|

License Plate Number/State |

Vehicle Identification Number |

Vehicle Make |

Vehicle Model |

Model Year |

|

|

|

|

|

|

|

Vehicle Components Inspected

OK |

Need |

Repair |

Item |

OK |

Need |

Repair |

Item |

OK |

Need |

Repair |

Item |

|

Repair |

Date |

Repair |

Date |

Repair |

Date |

|

||||||

|

|

|

1. BRAKE SYSTEM |

|

|

|

5. FUEL SYSTEM |

|

|

|

10. SUSPENSION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adjustment |

|

|

|

Visible Leaks |

|

|

|

Springs (cracked/broken/shifted) |

|

|

|

|

Drums or Rotors |

|

|

|

Fill Caps in place/intact |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hoses and/or Tubing |

|

|

|

Tank(s) securely attached |

|

|

|

Torque, Radius, Tracking Arms |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lining |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6. LIGHTING DEVICES |

|

|

|

11. FRAME |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning (Low Pressure) |

|

|

|

Headlamps |

|

|

|

Frame Members |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tractor Protection Valve |

|

|

|

Front Turn Signals |

|

|

|

Tire & Wheel Clearance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Air Compressor |

|

|

|

Front ID/Clearance Lamps |

|

|

|

Sliding Subframe (adj. axle) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Service Brakes |

|

|

|

Side Marker Lamps – Left |

|

|

|

12. TIRES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parking Brakes |

|

|

|

Side Marker Lamps |

|

|

|

Steering Axle Tires |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electric Brakes |

|

|

|

Rear Turn Signals |

|

|

|

Steering Tires - over 4/32” tread |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hydraulic Brakes |

|

|

|

Stop Lamps |

|

|

|

Other Tires – Condition |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vacuum Brakes |

|

|

|

Tail Lamps |

|

|

|

Other Tires – over 2/32” tread |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning (Sys Failure) |

|

|

|

Rear ID/Clearance Lamps |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13. WHEELS & RIMS |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reflectors / Ref Tape |

|

|

|

Lock/Slide Ring |

|

|

|

|

2. STEERING SYSTEM |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Free Play (Lash) |

|

|

|

|

|

|

|

Fasteners |

|

|

|

|

|

|

|

7. COUPLING DEVICES |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Steering Column |

|

|

|

5T H Wheel |

|

|

|

Disk/Spoke Condition |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Front Axle Beam |

|

|

|

Pintle Hooks |

|

|

|

Welds |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Steering Gear Box |

|

|

|

Drawbar Eye |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

List any other condition |

|

||

|

|

|

|

|

|

|

|

|

|

|

which may affect safe |

|

|

|

|

Pittman Arm |

|

|

|

Drawbar Tongue |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

vehicle operation |

|

|

|

|

Ball & Socket Joints |

|

|

|

Safety Devices |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tie Rods & Drag Links |

|

|

|

8. EXHAUST SYSTEM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nuts, Bolts, Fasteners |

|

|

|

Leaks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power Steering Fluid |

|

|

|

Placement |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3. WINDSHIELDS |

|

|

|

9. SAFE LOADING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Securement Devices |

|

|

|

|

|

|

|

|

4. WIPERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MARK COLUMNS AS FOLLOWS: x = OK; o = Needs repair; NA = Does not apply; Fill in Repair date as appropriate

I CERTIFY THE ANNUAL VEHICLE INSPECTION HAS BEEN DONE ACCURATELY AND COMPLETELY. I FURTHER CERTIFY THAT THIS INSPECTION COMPLIES WITH THE REQUIREMENTS OF 49 CFR §396.21.

This information must be available on board the vehicle, either as a copy of this report, or on a decal that complies with 49 CFR §396.17(c)(2). This report must be kept a minimum of fourteen months from date of completion

Certified Inspector’s Signature: |

|

Date: |

|

|

|

INSPECTOR QUALIFICATIONS

Certification — 49 CFR §396.19

Motor carriers are responsible for ensuring that individual(s) performing an annual inspection under §396.17 are qualified as follows:

•Understands the inspection criteria set forth in Part 393 and Appendix G and can identify defective components

•Is knowledgeable of and has mastered the methods, procedures, tools and equipment used when performing an inspection

•Is capable of performing an inspection by reason of experience, training, or both, and qualifies in one of the following categories (check all that apply):

I.___ Successfully completed a State or Federal training program or has certificate from a State or Canadian Province which qualifies the person to perform commercial vehicle safety inspections.

Specify: _______________________________________

II.___ Have a combination of training or experience totaling at least one year as follows (check all that apply):

a.___ Participation in a truck

Where and Date: _____________________________________________________

b.___ (years) experience as a mechanic or inspector in a motor carrier maintenance program.

Name and Date: _____________________________________________________

c.___ (years) experience as a mechanic or inspector in truck maintenance at a commercial garage, fleet leasing company, or similar facility.

Name of Facility and Dates: ____________________________________________

d.___ (years) experience as a commercial vehicle inspector for a State, Provincial, or Federal Government.

Where and Dates: ____________________________________________________

I certify the above information is true and accurate to the best of my knowledge.

Employee ______________________________________ |

________________ |

Signature of Mechanic/Inspector |

Date |

Motor Carrier/Company ____________________________________ |

________________ |

Signature of Employer/Supervisor |

Date |

Evidence of Inspector Qualification is on file at:

_______________________________

BRAKE INSPECTOR QUALIFICATIONS

Certification — 49 CPR §396.25

“Brake Inspector” means any employee of a motor carrier who is responsible for ensuring all brake inspections, maintenance, service, or repairs to any commercial motor vehicle, subject to the motor carrier’s control, meet the applicable Federal standards.

No motor carrier shall require or permit any employee who does not meet minimum brake inspector qualifications to be responsible for the inspection, maintenance, service or repairs of any brakes on its commercial motor vehicles.

Minimum Qualifications

•Understands and can perform brake service and inspection

•Is knowledgeable of and has mastered the methods, procedures, tools and equipment necessary to perform brake service and inspection

•Is capable of performing brake service or inspection by reason of experience, training, or both, and qualifies in one of the following categories (check all that apply):

I.___Has successfully completed an apprenticeship program sponsored or approved

by a State, Canadian Province, a Federal agency or labor union, or has a certificate from a State or Canadian Province which qualifies the person to perform brake service or inspections.

Specify: ________________________________________________________________

II.___ Has

a.___Participation in a brake maintenance or inspection training program sponsored by a brake or vehicle manufacturer or similar commercial training program.

Where and Date:_______________________________________________

b.___ (years) experience performing brake maintenance or inspection in a motor carrier maintenance program.

Name and Date:_______________________________________________

c.___ (years) experience performing brake maintenance or inspection at a commercial garage, fleet leasing company, or similar facility.

Name of Facility and Dates:______________________________________

I certify the above information is true and accurate to the best of my knowledge.

Employee ______________________________________ |

________________ |

Signature of Mechanic/Inspector |

Date |

Motor Carrier/Company ____________________________________ |

________________ |

Signature of Employer/Supervisor |

Date |

Evidence of Inspector Qualification is on file at:

_______________________________

Form Characteristics

| Fact Name | Description |

|---|---|

| Form Purpose | The Dot Vehicle Inspection form is used to document the annual inspection of commercial vehicles to ensure they meet safety standards. |

| Required Components | This form includes information such as the inspecting agency's details, vehicle identification, and the inspections performed on various vehicle components. |

| Regulatory Reference | The inspection must comply with 49 CFR §396.17, outlining requirements for annual inspections of commercial motor vehicles. |

| Keeping Records | Inspection reports must be kept for a minimum of fourteen months from the date of completion to ensure accountability. |

| Technician Certification | Inspectors must be certified. They must comply with regulations stated in 49 CFR §396.17 and provide evidence of their qualifications. |

| Inspection Categories | The components inspected include brakes, steering, lights, tires, and more, each needing to be marked as OK or needing repair. |

| State Training Programs | The form acknowledges that inspectors can be certified through state or federal training programs, ensuring they meet necessary competency levels. |

| Brakes Inspection | Specific qualifications for brake inspectors are included, highlighting their responsibilities under 49 CFR §396.25. |

| Emergency Requirements | It is important that the form remains accessible on board the vehicle, either as a copy of the report or a compliant decal. |

| Technician Signatures | The report requires signatures from both the certified inspector and the vehicle's registered owner to ensure all details are authenticated. |

Guidelines on Utilizing Dot Vehicle Inspection

Filling out the DOT Vehicle Inspection form is essential for maintaining vehicle safety standards. It provides a comprehensive report on the vehicle's condition and ensures compliance with federal regulations. Below are the steps needed to complete the form accurately.

- Start by entering the Name and Address of the inspecting company or agency at the top of the form.

- Fill in the Registered Owner’s Name and the date of inspection.

- Indicate the Time, Street, City, State, Zip Code of the vehicle owner.

- Print or type the Certified Inspector’s Name and the relevant address details.

- Record the vehicle’s License Plate Number/State and Vehicle Identification Number (VIN).

- List the Vehicle Make, Vehicle Model, and Model Year.

- In the Vehicle Components Inspected section, mark whether each item is OK, needs Repair, or does not apply (NA) using the provided symbols.

- For each item that needs repair, fill in the Repair Date.

- Certify that the annual vehicle inspection has been done accurately and completely by providing the Certified Inspector’s Signature and the date.

- Complete the INSPECTOR QUALIFICATIONS section, checking all applicable criteria for qualifications.

- Signature of Mechanic/Inspector and Signature of Employer/Supervisor must be added to finalize the certification.

- Ensure that evidence of Inspector Qualification is indicated and filed correctly.

What You Should Know About This Form

What is the purpose of the DOT Vehicle Inspection form?

The DOT Vehicle Inspection form is designed to document the annual inspection of commercial motor vehicles. Its purpose is to ensure that vehicles meet safety standards outlined in federal regulations. The form provides details about the condition of various vehicle components and confirms compliance with safety requirements.

What information is required on the inspection report?

The report must include the name and address of the inspecting agency, the registered owner's name, the date and time of inspection, and the certified inspector’s name. It should also capture the vehicle's information, including the license plate number, vehicle identification number (VIN), make, model, and year. Additionally, the inspection results for various vehicle components must be recorded, indicating whether they are satisfactory or need repair.

How long must the inspection report be kept on file?

The inspection report must be retained for a minimum of fourteen months from the date it was completed. This requirement ensures that there is a documented history of the vehicle’s safety inspections, which may be reviewed by regulatory authorities if necessary.

What qualifies an inspector to perform DOT vehicle inspections?

An inspector must understand the inspection criteria and be knowledgeable about the methods and tools used during inspections. They can qualify through various means including completing an accredited training program or having substantial experience related to vehicle maintenance or operating procedures. The qualifications are crucial to ensure that inspections are performed accurately and safely.

What components of the vehicle are inspected?

The DOT Vehicle Inspection form requires the inspection of several key components, including the brake system, steering system, windshield wipers, lighting devices, tires, wheels and rims, exhaust system, and coupling devices, among others. Each component is assessed for safety to ensure the vehicle is roadworthy.

What does it mean if a component is marked as "Needs Repair"?

A component marked as "Needs Repair" indicates that it has been found deficient during the inspection. This designation implies that the identified issue could affect the vehicle's safe operation and should be addressed promptly before the vehicle is used on public roads.

Who is responsible for ensuring compliance with the inspection standards?

The motor carrier, or vehicle owner, is responsible for ensuring that all inspections are conducted by qualified personnel. This includes verifying that the inspector’s qualifications and training meet the standards established by federal regulations. Compliance is crucial for the safety of all road users.

Is the completed inspection report required to be carried in the vehicle?

Yes, the completed inspection report must be accessible on board the vehicle. It can be in the form of a copy of the report or as a decal that meets specific guidelines outlined in federal regulations. Having the report available is essential for inspections by law enforcement or regulatory agencies.

Common mistakes

Completing the DOT Vehicle Inspection form accurately is essential for ensuring road safety and regulatory compliance. However, many individuals make common mistakes that can lead to significant consequences. One mistake often seen is failing to provide complete and accurate information. Whether it’s the name of the inspecting company or the vehicle identification number, every detail matters. Incomplete entries can result in delays and complications if issues arise later.

Another frequent error is misunderstanding the inspection criteria. Each component listed on the form has specific requirements. Checking the wrong box, such as marking an item as "OK" when it actually needs repair, can have serious safety implications. It is vital to thoroughly understand each section before making any marks.

Failing to document repair dates can also cause problems. Each item that needs repair must include the date by which the work was completed. Leaving this space blank creates confusion and may lead to regulatory penalties. Maintaining accurate records shows diligence and thoroughness in vehicle maintenance.

People often overlook the qualifications of the inspector as well. The form requires certification and signature from a qualified technician. If anyone without the proper qualifications signs the form, it undermines the entire inspection’s validity. Ensuring that the inspector meets the required standards is critical.

Another mistake is neglecting to keep a copy of the inspection report on board the vehicle. The regulations mandate that this information be readily available, either as a physical copy or a compliant decal. Not having this documentation can lead to fines during roadside inspections.

Some individuals may also forget to mark items accurately. The form uses a simple marking system: “x” for OK, “o” for needs repair, and “NA” for not applicable. Misunderstanding or misusing these symbols can result in miscommunication about the vehicle’s condition. Remember, clarity is key.

People may also fail to review the entire form after completion. Before submission, taking a moment to double-check each section can prevent many of the common errors outlined. A thorough review helps catch mistakes before they cause issues down the line.

Finally, individuals often rush through the process. Proper vehicle inspection should never feel like a hurried task. Taking the time to inspect each component carefully and fill out the form accurately ensures compliance and promotes safety on the roads. By avoiding these mistakes, you can contribute to safer transportation for everyone.

Documents used along the form

The DOT Vehicle Inspection form is essential for ensuring the safety and compliance of commercial vehicles. However, other documents often accompany this form to help streamline the inspection and compliance process. Here’s a list of related documents that can play a vital role in maintaining vehicle safety and regulatory adherence.

- Equipment Maintenance Log: This document tracks all maintenance and repairs performed on the vehicle. It provides a history that can help identify recurrent issues, ensuring that all work meets safety standards.

- Driver Vehicle Inspection Report (DVIR): After each trip, drivers fill out this report to document any defects or problems found during their inspection of the vehicle. It ensures that issues are addressed before the next trip.

- Repair Orders: This form is used to detail any repairs conducted on the vehicle. It includes information on what repairs were made, when they were done, and who performed them, ensuring accountability and traceability.

- Certification of Inspection: This certificate confirms that the vehicle has passed inspection according to state and federal regulations. It is important for demonstrating compliance and may be requested during audits or inspections.

- Emission Test Results: For many vehicles, especially those in urban areas, emissions tests are required. This document shows that the vehicle meets environmental standards, which is crucial for regulatory compliance.

- Insurance Documentation: Proof of insurance is necessary for all commercial vehicles. This document verifies that the vehicle is covered for liability and damages, protecting the company from financial loss in case of an incident.

- DOT Registration Documents: These documents prove that the vehicle and the company operating it are registered with the Department of Transportation. This registration is a key requirement for legal operation on public roads.

By keeping these documents organized and up to date, vehicle operators can ensure they are in compliance with regulations and that their vehicles are safe for operation. Regular review of such documents can prevent potential issues and enhance overall safety on the road.

Similar forms

- CMV Driver’s Daily Vehicle Inspection Report - This document is completed daily by commercial vehicle operators to document the condition of their vehicle before use. Both reports assess vehicle safety and compliance according to established regulations, including noting any repairs needed.

- Annual Safety Inspection Checklist - Similar to the DOT Vehicle Inspection form, this checklist lists various vehicle components that need to be checked annually. Each provides a systematic approach for evaluating vehicle safety and compliance with legal standards.

- Pre-Trip Inspection Report - This report is filled out by drivers before departing on a trip. It outlines the same categories of inspections as the DOT Vehicle Inspection form, ensuring the vehicle is safe for operation and documenting any issues found.

- Vehicle Maintenance Log - This log tracks all maintenance and repairs performed on a vehicle. It parallels the DOT Vehicle Inspection by documenting the condition of specific vehicle components and noting when repairs were made or required.

- Brake Inspection Report - Dedicated to brake systems, this report focuses solely on the compliance and conditions related to vehicle brakes. Like the DOT Vehicle Inspection form, it ensures that vehicles meet safety standards for operation.

- FMCSA Compliance Review Report - This report is generated during compliance reviews conducted by the Federal Motor Carrier Safety Administration. It assesses company adherence to safety regulations, similar to how the DOT Vehicle Inspection evaluates individual vehicle safety.

Dos and Don'ts

When filling out the DOT Vehicle Inspection form, keep the following tips in mind:

- Do double-check the registered owner's name and address for accuracy.

- Do ensure that all inspection items are marked correctly with 'OK', 'Needs Repair', or 'Does Not Apply'.

- Do provide clear and legible signatures for the certified inspector and technician.

- Do include the repair dates where applicable.

- Do familiarize yourself with the inspection criteria before starting.

- Don't leave any sections blank unless they truly don't apply.

- Don't forget to keep a copy of the completed form on board the vehicle.

- Don't rush through the inspection; take time to check all components thoroughly.

- Don't pen your signature without first reviewing all the information for accuracy.

Misconceptions

Misconceptions about the DOT Vehicle Inspection form can lead to misunderstandings. Here are some common myths clarified:

- The inspection form is optional. Many believe the inspection is not mandatory, but all commercial vehicles must undergo annual inspections as per federal regulations.

- Only trucks need inspection. Some think only large trucks require these inspections, but all commercial vehicles—including buses and vans—must comply.

- The inspector's signature is not important. In fact, the technician’s signature certifies the inspection's validity and compliance with regulations.

- Inspections are the same in every state. While federal standards apply, specific state regulations may differ. Compliance with state laws is crucial.

- Completed forms can be discarded after a short time. The inspection report must be kept for a minimum of fourteen months after completion.

- Technicians can inspect any vehicle. Technicians must be qualified and certified to perform inspections on specific vehicle types, which varies from state to state.

- The inspection focuses mainly on safety. While safety checks are essential, the inspection also assesses compliance with various performance standards.

- Repairs are not required unless specified on the form. Repairs may be necessary even if they are not listed; vehicle safety should always be the priority.

- Inspecting companies do not have to be certified. Inspecting agencies must meet certain certification standards to ensure compliance with federal and state regulations.

- The form is for personal use only. This report must be available on the vehicle at all times, as it is subject to inspection by enforcement authorities.

Understanding the correct information helps to ensure compliance and safety in vehicle operations.

Key takeaways

Filling out the DOT Vehicle Inspection form is a vital step in ensuring vehicle safety and compliance with federal regulations. The following key takeaways can guide individuals in effectively using this form:

- Comprehensive Inspection Required: Each component of the vehicle must be thoroughly inspected, including but not limited to the brake systems, steering, tires, and lighting devices.

- Marking Conditions: Use designated marks to indicate the condition of each item: 'x' for okay, 'o' for needs repair, and 'NA' for items that do not apply.

- Documentation Is Key: Ensure that the completed inspection report is readily available on the vehicle, either as a copy of the report or as a compliant decal.

- Signature and Certification: An authorized inspector must sign and date the report, certifying that the inspection meets the standards required by federal regulations.

- Keep Records: Retain the inspection report for a minimum of fourteen months from the completion date, in accordance with federal guidelines.

- Inspector Qualifications: Inspectors must meet specific qualifications, including understanding the required inspection criteria and having extensive training or experience related to vehicle maintenance.

Browse Other Templates

Dea Form 41 Example - Compensation to the firm is based on a percentage of the sale price or other agreed terms.

Donor Profile - Opportunities for engaging the donor through personalized events.

Where Does Workers Comp Money Come From - Timely submission impacts the speed of authorization for treatment.