Fill Out Your Eyewash Station Log Sheet Form

The Eyewash Station Log Sheet form is a crucial component of workplace safety protocols, particularly in environments where hazardous materials are present. Designed to ensure that emergency eyewash fixtures are regularly checked, this form includes specific requirements that employees must follow to maintain readiness in the event of an accident. Each week, designated individuals must verify key aspects of the eyewash station, including ensuring that the path to the station remains unobstructed and that the eyewash fixture itself is free of obstructions. Additionally, the form requires that the nozzle dust caps are intact and functioning properly. Another critical task is to test the eyewash station by flushing water through the eyewash head to confirm that clear water flows without any leaks or contamination. If any issues arise during these inspections, personnel are instructed to contact the Physical Plant for maintenance while Safety Affairs is available for further inquiries. The log also provides space for monthly comments and designates a principal investigator along with their room number, ensuring accountability and traceability. This systematic approach to eyewash station maintenance underscores the importance of preparedness in promoting a safe workplace environment.

Eyewash Station Log Sheet Example

Safety Affairs

Safety Affairs

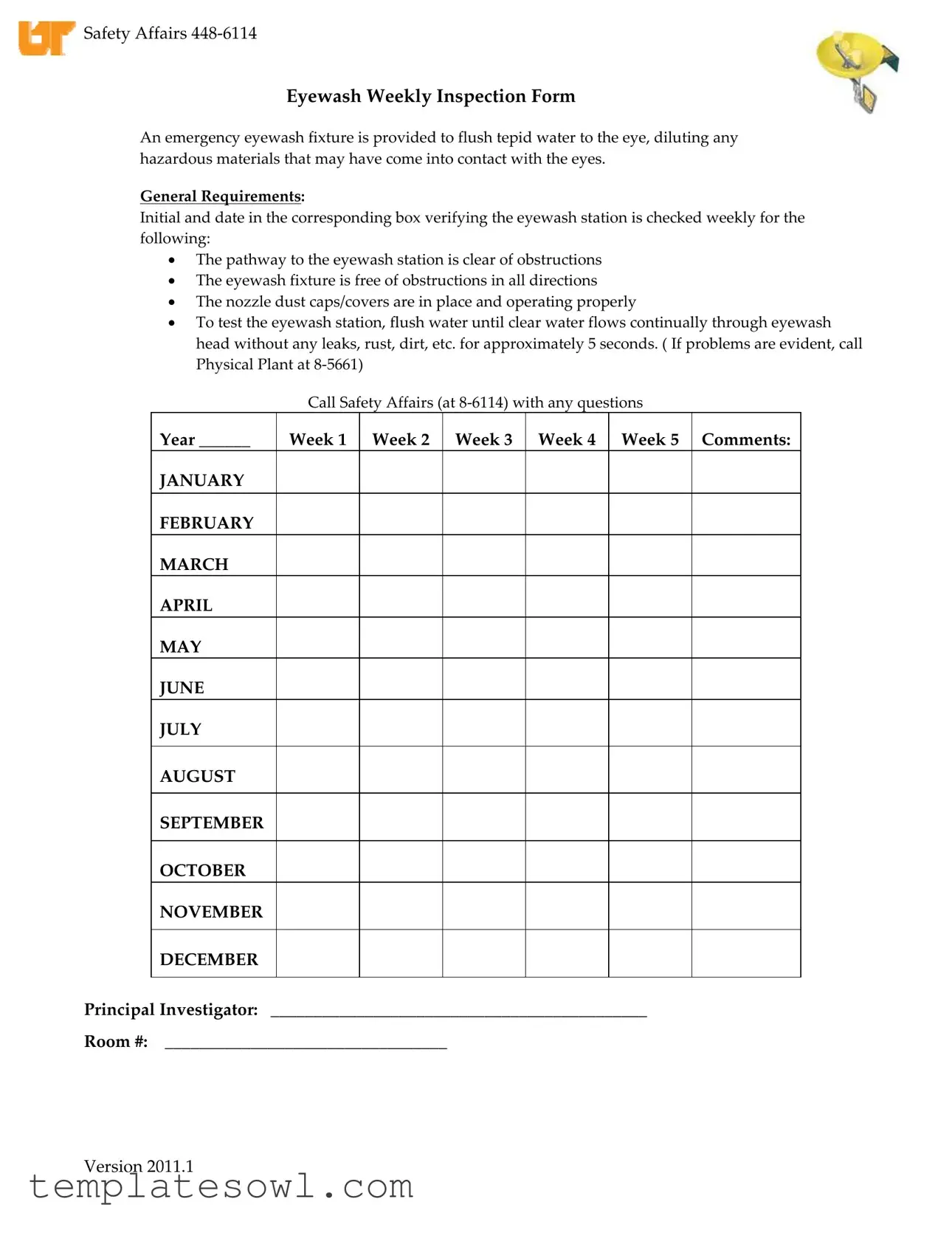

Eyewash Weekly Inspection Form

An emergency eyewash fixture is provided to flush tepid water to the eye, diluting any hazardous materials that may have come into contact with the eyes.

General Requirements:

Initial and date in the corresponding box verifying the eyewash station is checked weekly for the following:

•The pathway to the eyewash station is clear of obstructions

•The eyewash fixture is free of obstructions in all directions

•The nozzle dust caps/covers are in place and operating properly

•To test the eyewash station, flush water until clear water flows continually through eyewash

head without any leaks, rust, dirt, etc. for approximately 5 seconds. ( If problems are evident, call Physical Plant at 8‐5661)

|

|

|

Call Safety Affairs (at 8‐6114) with any questions |

|||||

|

Year ______ |

|

Week 1 |

Week 2 |

Week 3 |

Week 4 |

Week 5 |

Comments: |

|

JANUARY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FEBRUARY |

|

|

|

|

|

|

|

|

MARCH |

|

|

|

|

|

|

|

|

APRIL |

|

|

|

|

|

|

|

|

MAY |

|

|

|

|

|

|

|

|

JUNE |

|

|

|

|

|

|

|

|

JULY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AUGUST |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SEPTEMBER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OCTOBER |

|

|

|

|

|

|

|

|

NOVEMBER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DECEMBER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Principal Investigator: |

____________________________________________ |

|

||||||

Room #: _________________________________

Version 2011.1

Form Characteristics

| Fact Name | Details |

|---|---|

| Purpose of the Form | This form is designed to verify the weekly inspection of emergency eyewash stations. |

| Water Temperature | The water that flows from the eyewash station should be tepid, effectively flushing hazardous materials from the eyes. |

| Weekly Inspection Requirement | This form requires inspections to be logged weekly, ensuring safety in the workplace. |

| Clear Pathway | Inspectors must ensure that the pathway to the eyewash station is free from obstructions for easy access in an emergency. |

| Dust Caps | Nozzle dust caps or covers should be in place and functioning properly, maintaining the eyewash's hygiene. |

| Flush Test | The eyewash station must be tested by flushing water through the eyewash head for about five seconds, ensuring it's clear from leaks and debris. |

| Reporting Problems | Any issues found during the inspection, such as leaks or blockages, should be reported to Physical Plant at 8-5661. |

| Contact for Questions | For any questions regarding the eyewash station, Safety Affairs can be contacted at 8-6114. |

Guidelines on Utilizing Eyewash Station Log Sheet

Completing the Eyewash Station Log Sheet is essential for maintaining safety standards. This form helps ensure that all eyewash stations are regularly inspected and functioning correctly. Follow these steps to accurately fill out the form.

- Enter the year at the top of the form.

- Select the appropriate week for inspection (1-5) and circle it.

- Check each requirement listed under General Requirements:

- The pathway to the eyewash station is clear of obstructions.

- The eyewash fixture is free of obstructions in all directions.

- The nozzle dust caps/covers are in place and operating properly.

- Flush the eyewash station. Ensure clear water flows through the eyewash head without leaks or debris for approximately 5 seconds.

- If any issues are found, make a note to call the Physical Plant at 8‐5661.

- For questions, contact Safety Affairs at 8‐6114.

- Sign and date the form in the corresponding box to verify that the inspection has been completed.

- List any comments in the comments section at the bottom of the form.

- Fill in the Principal Investigator name and Room number at the end of the form.

What You Should Know About This Form

What is the purpose of the Eyewash Station Log Sheet?

The Eyewash Station Log Sheet is used to ensure that emergency eyewash stations are functioning properly. Regular checks are essential to guarantee that the equipment is ready for use in case of an emergency. It helps document the maintenance and inspection of the eyewash station.

How often should the Eyewash Station be inspected?

The eyewash station should be inspected weekly. Each inspection requires the person performing it to initial and date the log sheet, confirming that a thorough check was completed. This regular schedule helps maintain safety standards in the workplace.

What specific items need to be checked during an inspection?

During an inspection, several important items must be checked. The pathway to the eyewash station should be clear of any obstructions. The eyewash fixture must also be free of obstacles in all directions. Additionally, ensure that the nozzle dust caps or covers are securely in place and functioning correctly. Finally, test the eyewash station by flushing it for about five seconds to confirm that clear water flows without any leaks or dirt.

What should I do if I find a problem with the eyewash station?

If any issues are found during the inspection, such as leaks or obstructions, it is important to report them immediately. For repairs or maintenance, contact the Physical Plant at extension 8-5661. For any other questions related to safety, reach out to Safety Affairs at extension 8-6114.

How do I record inspection results?

Results of the inspection should be recorded on the Eyewash Station Log Sheet. Each week, fill out the appropriate week column and include your initials and the date. Add any comments regarding the condition of the eyewash station or actions taken as necessary.

Is training required for individuals inspecting the eyewash station?

While there may not be formal training for inspectors, it is important that anyone performing inspections is familiar with the eyewash station’s operation and the inspection checklist. Understanding each aspect of the checklist is crucial to identifying potential issues quickly and accurately.

What information is included in the log sheet?

The log sheet includes several key pieces of information. This includes the year, weeks of inspection, room number, and details about the principal investigator responsible for the eyewash station. It’s essential to have clear documentation of who is overseeing safety and maintenance.

How does this form contribute to workplace safety?

This form plays a significant role in workplace safety. By documenting regular inspections, it ensures that help is readily available if an employee is exposed to hazardous materials. Consistent checks promote accountability and help keep the eyewash stations in optimal condition for any emergencies that may arise.

Can I access a physical copy of the form?

Yes, physical copies of the Eyewash Station Log Sheet can typically be obtained from your safety department. If you need additional forms, contact Safety Affairs to ensure you have an adequate supply for ongoing inspections.

Common mistakes

When filling out the Eyewash Station Log Sheet, it is crucial to ensure accuracy and completeness. One common mistake people make is overlooking the importance of **initialing and dating** each inspection properly. Failing to do this not only undermines the integrity of the log but also can lead to confusion about when the last inspection took place. Each week should display a clear initial and date, confirming that the check has been completed.

Another frequent error is neglecting to check whether the **pathway to the eyewash station** is clear of obstructions. This aspect is vital for ensuring quick access during emergencies. If individuals skip this verification step, they may inadvertently create barriers that could delay response times in critical situations. This oversight could result in a significant safety risk for those needing immediate assistance.

Additionally, another mistake involves failing to **test the eyewash fixture** adequately. The inspection requires flushing the station until clear water flows without interference. If testers do not perform this step rigorously, issues like leaks or blockages may go unnoticed. As a result, the equipment could be rendered ineffective when it is most needed. Even if the water appears clear initially, the inspection demands a thorough approach.

Some may forget to **check the condition of the nozzle dust caps or covers**. These components serve an essential purpose by keeping contaminants at bay. If individuals overlook this aspect, the eyewash station could be compromised by dirt or debris that may have collected over time. Regular inspection of the dust caps is a few seconds of precaution that can significantly impact the station’s efficacy.

Finally, comments regarding the inspection are sometimes inadequately filled out or skipped entirely. This section serves to document any unusual observations or concerns during the inspection process. Ignoring it can lead to crucial information being lost, which may detrimentally affect future inspections or maintenance efforts. A well-documented log can help ensure continuous safety and compliance.

Documents used along the form

In workplace safety protocols, proper documentation is essential. Alongside the Eyewash Station Log Sheet form, several other forms and documents help maintain safety and regulatory compliance. Here is a list of commonly associated documents.

- Emergency Response Plan: This document outlines the procedures to follow in case of an emergency, including contact information for first responders and specific actions to take based on different types of incidents.

- Safety Data Sheets (SDS): SDSs provide detailed information about hazardous materials on-site. They include data about handling, storage, and emergency measures to take if exposure occurs.

- Inspection Checklist for Safety Equipment: This checklist is used to regularly verify that all safety equipment, including fire extinguishers, first aid kits, and eyewash stations, are in proper working condition.

- Incident Report Form: This form documents any safety incidents or near misses that occur. It captures details such as the nature of the incident, when and where it occurred, and the individuals involved, helping to improve future safety protocols.

Using these documents together aids in creating a comprehensive safety program. They provide vital information and establish clear procedures, fostering a safer workplace environment.

Similar forms

- Safety Data Sheet (SDS): Like the Eyewash Station Log Sheet, the SDS provides essential information regarding hazardous materials, including necessary procedures for emergency situations and safety measures that need to be taken during handling.

- Emergency Response Plan: This document outlines the procedures to follow during emergencies, ensuring that individuals know how to react. Similar to the Eyewash Station Log Sheet, it is a vital resource for safety preparedness and must be regularly updated.

- Incident Report Form: Both the Eyewash Station Log Sheet and the Incident Report Form track safety-related issues. The Eyewash Log records weekly checks, whereas the Incident Report Form logs occurrences of accidents or near misses in the workplace.

- Fire Extinguisher Inspection Log: Just like the Eyewash Station Log Sheet, this log tracks weekly inspections of fire extinguishers. It ensures that all emergency equipment is in working order, ready to be used when needed.

- Inspection Checklist for Personal Protective Equipment (PPE): Both focus on maintaining safety standards. The PPE checklist monitors required gear's condition and availability, while the Eyewash Sheet ensures the eyewash station is functional and ready for use.

- Safety Training Attendance Log: This log documents employees' participation in safety training sessions. Similar to the Eyewash Station Log Sheet, it serves as a record for compliance and indicates that safety protocols have been communicated.

- Equipment Maintenance Log: Like the Eyewash Station Log Sheet, this document tracks the maintenance and inspection of equipment. It ensures that tools and machines are serviced regularly, reducing the risk of accidents.

- Chemical Inventory List: This list keeps track of all chemicals present in a facility, similar to how the Eyewash Log monitors the functionality of emergency equipment. Both documents are essential for ensuring safety and compliance with health regulations.

Dos and Don'ts

When filling out the Eyewash Station Log Sheet form, it's important to follow certain guidelines to ensure accuracy and compliance. Here are ten things to consider:

- Do initial and date each inspection in the corresponding box.

- Do check that the pathway to the eyewash station is unobstructed.

- Do ensure that the eyewash fixture is free of any obstructions.

- Do verify that the nozzle dust caps and covers are properly in place.

- Do flush the eyewash station for at least 5 seconds to check for clear water flow.

- Don't skip any weeks or inspections on the log sheet.

- Don't ignore issues; promptly report problems to Physical Plant.

- Don't leave comments or questions regarding the inspection blank.

- Don't use the eyewash station if it is damaged or not functioning correctly.

- Don't forget to call Safety Affairs for any guidance needed.

Misconceptions

Many individuals may have misunderstandings regarding the Eyewash Station Log Sheet form. Addressing these misconceptions can help ensure that safety protocols are effectively followed. Below are eight common misconceptions:

- It is optional to complete the log sheet. Completing the log sheet is not optional; it is a vital part of maintaining the eyewash station. Regular documentation helps ensure compliance and safety.

- Only trained personnel should inspect the eyewash station. While training is beneficial, anyone can perform the inspection. It is essential that all staff recognize their responsibility in maintaining a safe environment.

- The inspection can be done infrequently. Inspections should occur weekly. Regular checks help identify issues before they become serious problems.

- If there are no visible issues, the log sheet doesn't need to be filled out. Even if the station appears operational, the log sheet must be filled out every week to document compliance and diligence.

- Flushing the station is a minor task and can be done quickly. Flushing the eyewash station properly requires at least five seconds of clear water flow. This ensures that any contaminants are adequately diluted.

- The log sheet is only for regulatory purposes. Although regulatory compliance is a factor, the primary purpose is to safeguard individuals' health. Keeping a well-maintained log enhances workplace safety.

- Problems do not need to be reported if they seem minor. Any issues identified during inspection should be reported immediately. Even minor problems can lead to more significant hazards if left unaddressed.

- Eyewash stations are foolproof and cannot fail. Eyewash stations, like any equipment, can malfunction. Regular inspections detect potential failures and ensure functionality when needed.

Understanding these misconceptions is essential for fostering a culture of safety in the workplace. By clarifying these points, individuals can be more proactive in ensuring compliance with vital safety standards.

Key takeaways

Filling out and utilizing the Eyewash Station Log Sheet is essential for ensuring workplace safety. Here are key takeaways to consider:

- The log sheet must be completed weekly to maintain compliance with safety regulations.

- Each inspection requires the initials and date of the individual conducting the check.

- Verify that the pathway to the eyewash station is free from obstacles.

- Ensure that the eyewash fixture itself is unobstructed from all directions.

- Check that the nozzle dust caps or covers are in place and functioning effectively.

- During testing, water should flow continuously for about five seconds without any leaks, rust, or dirt.

- If any issues are identified during the inspection, contact Physical Plant at 8-5661 for assistance.

- For any questions regarding the eyewash station's operation or maintenance, reach out to Safety Affairs at 8-6114.

- Document any observations or issues in the comments section of the log sheet for future reference.

These steps support a proactive approach to safety, ensuring that eyewash stations function properly when needed.

Browse Other Templates

Perc Mediation - All sections must be filled out; do not leave any blank unless marked.

T&lc - Being proactive about understanding law changes can mitigate the risk of application delays.

Public Information Report - The form emphasizes that all requests will be processed in the order they are received.