Fill Out Your Jsa Form

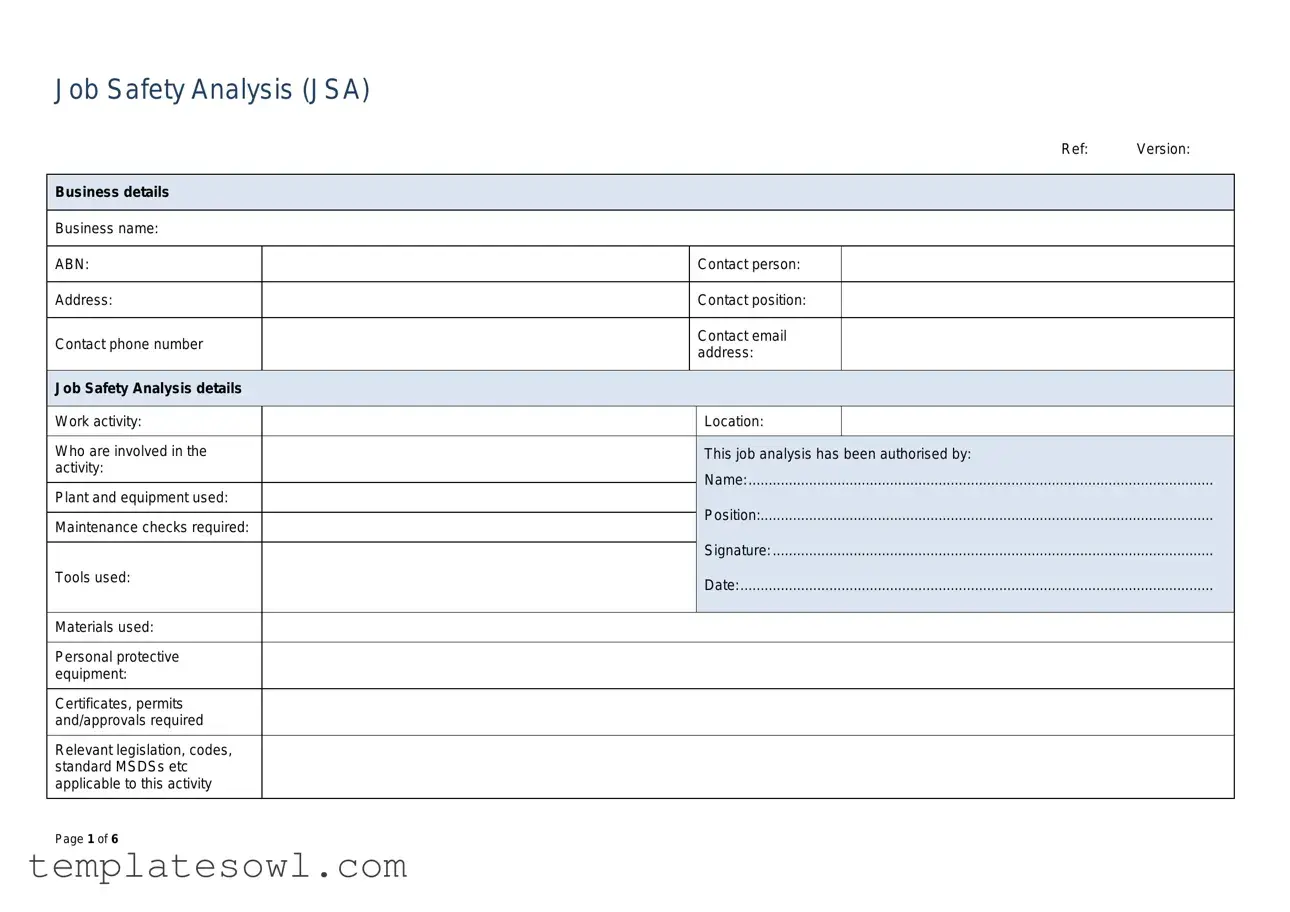

The Job Safety Analysis (JSA) form serves as an essential tool for workplaces aiming to ensure safety and mitigate risks associated with specific job activities. Designed to collect crucial information, the form requires details such as the business name, contact information, and the work activity being analyzed. Participants involved in the job must be identified, and an authorized person signs off on the analysis, indicating accountability. The JSA emphasizes the importance of recognizing potential hazards tied to plant and equipment, tools, materials, and personal protective equipment (PPE) used during the task. Each job step is scrutinized through a comprehensive risk assessment, which evaluates the likelihood and consequences of potential incidents. By employing a hierarchy of controls, the JSA outlines effective measures to eliminate or reduce hazards, guiding employers on the best practices for protecting workers. It’s not just about filling out forms; it's about fostering a culture of safety and awareness, making it vital for every organization to commit to this proactive approach. This introductory understanding of the JSA form lays the groundwork for a deeper exploration into its components, processes, and best practices for implementation in the workplace.

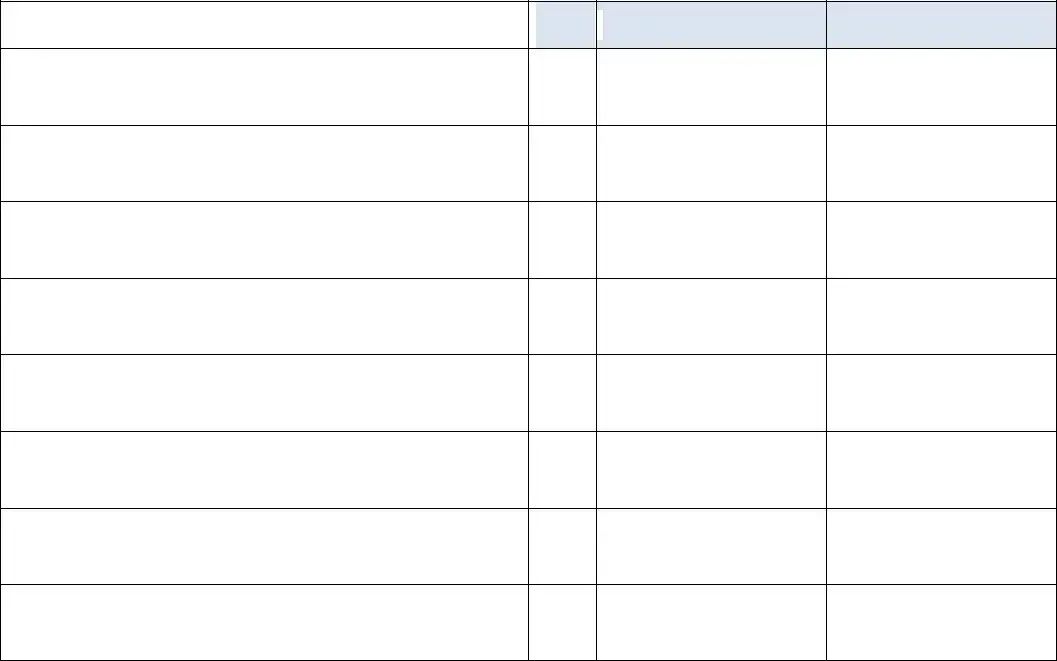

Jsa Example

Job Safety Analysis (JSA)

|

|

|

|

Ref: |

Version: |

|

|

|

|

|

|

Business details |

|

|

|

|

|

|

|

|

|

|

|

Business name: |

|

|

|

|

|

|

|

|

|

|

|

ABN: |

|

|

Contact person: |

|

|

|

|

|

|

|

|

Address: |

|

|

Contact position: |

|

|

|

|

|

|

|

|

Contact phone number |

|

|

Contact email |

|

|

|

|

address: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Job Safety Analysis details |

|

|

|

|

|

|

|

|

|

|

|

Work activity: |

|

|

Location: |

|

|

|

|

|

|

|

|

Who are involved in the |

|

|

This job analysis has been authorised by: |

|

|

activity: |

|

|

Name: |

||

|

|

|

|||

Plant and equipment used: |

|

|

|||

|

|

|

|

|

|

|

|

|

Position: |

|

|

Maintenance checks required: |

|

|

|||

|

|

|

|

|

|

|

|

|

Signature: |

|

|

Tools used: |

|

|

|||

|

|

Date: |

|||

|

|

|

|||

|

|

|

|

|

|

Materials used: |

|

|

|

|

|

|

|

|

|

|

|

Personal protective |

|

|

|

|

|

equipment: |

|

|

|

|

|

|

|

|

|

|

|

Certificates, permits |

|

|

|

|

|

and/approvals required |

|

|

|

|

|

|

|

|

|

|

|

Relevant legislation, codes, |

|

|

|

|

|

standard MSDSs etc |

|

|

|

|

|

applicable to this activity |

|

|

|

|

|

|

|

|

|

|

|

Page 1 of 6

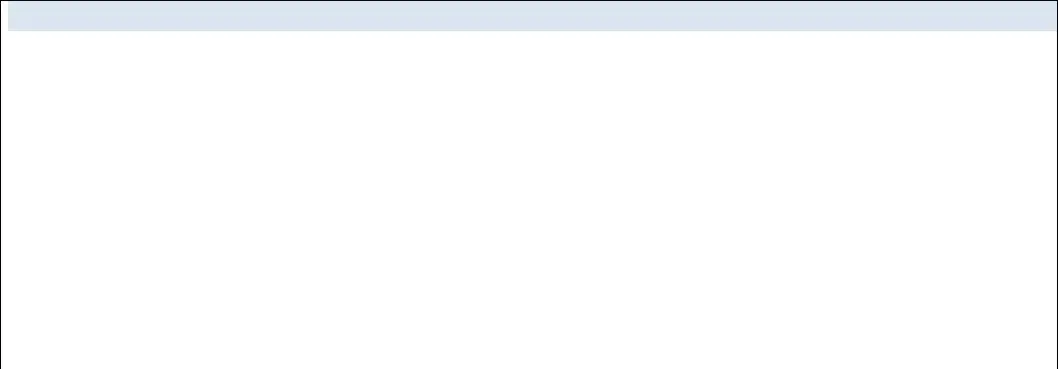

Risk assessment

**Use the risk rating table to assess the level of risk for each job step.

|

|

|

|

|

|

|

|

|

Likelihood |

|

|

|

|

|

|

|

|

|

1 |

|

2 |

|

3 |

|

4 |

|

5 |

|

|||||

|

Consequence |

|

Rare |

|

Unlikely |

|

Moderate |

|

Likely |

|

Almost Certain |

|||||

|

|

The event may occur in |

|

The event could occur |

|

The event should occur |

|

The event will probably occur |

|

The event is expected to |

||||||

|

|

|

exceptional circumstances |

|

sometimes |

|

sometimes |

|

in most circumstances |

|

occur in most circumstances |

|||||

1 |

Insignificant |

|

LOW |

|

|

LOW |

|

|

LOW |

|

|

LOW |

|

|

MODERATE |

|

|

No injuries or health |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

issues |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

Minor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

First aid treatment |

|

LOW |

|

|

LOW |

|

|

MODERATE |

|

|

MODERATE |

|

|

HIGH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

Moderate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Medical treatment, |

|

LOW |

|

|

MODERATE |

|

|

HIGH |

|

|

HIGH |

|

|

CRITICAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

potential LTI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Major |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Permanent disability or |

|

LOW |

|

|

MODERATE |

|

|

HIGH |

|

|

CRITICAL |

|

|

CATASTROPHIC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

disease |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

Extreme |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Death |

|

MODERATE |

|

|

HIGH |

|

|

CRITICAL |

|

|

CATASTROPHIC |

|

|

CATASTROPHIC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Risk rating:

Low risk:Acceptable risk and no further action required as long as risk has been minimised as possible. Risk needs to be reviewed periodically.

Moderate risk:Tolerable with further action required to minimise risk. Risk needs to be reviewed periodically.

High risk:Tolerable with further action required to minimise risk. Risk needs to be reviewed continuously.

Critical risk:Unacceptable risk and further action required immediately to minimise risk.

Catastrophic:Unacceptable risk and urgent action required to minimise risk.

Page 2 of 6

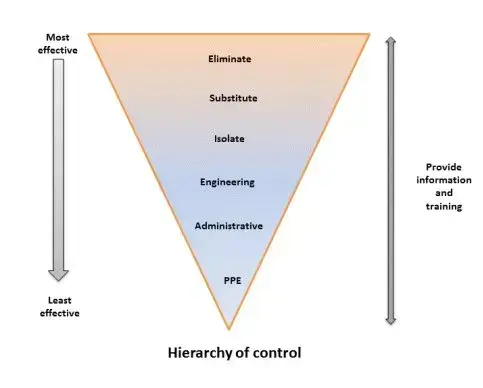

Risk controls

The hierarchy of control can be used as an effective tool to deal with health and safety issues at work. Use the type of control suggested as measures to deal with the hazard. Aim to use control measures from as high on the hierarchy of control list as possible. If that is not possible the next option down the list or a combination of the measures should be implemented. The least effective control measure is the use of personal protective equipment (PPE) and it should be used as a last resort or a support to other control measures. Information and training should be integrated with all levels of control to explain how controls work.

1.Eliminate – if it is possible, the hazard should be removed completely. For example, get rid of dangerous machines.

2.Substitute – replace something that produces the hazard with something that does not produce a hazard. For example, replacing solvent based paint with water based paint. Risk assessment on the substitution must be conducted to ensure that it will not pose another hazard.

3.Engineering control – isolate a person from the hazard by creating physical barrier or making changes to process, equipment or plant to reduce the hazard. For example, install ventilation systems.

4.Administrative control – change the way a person works by establishing policies and procedures to minimise the risks. For example, job scheduling to limit exposure and posting hazard signs.

5.Use personal protective equipment (PPE) – protect a person from the hazard by wearing PPE. For example, wearing gloves, safety glasses, hard hats and

Page 3 of 6

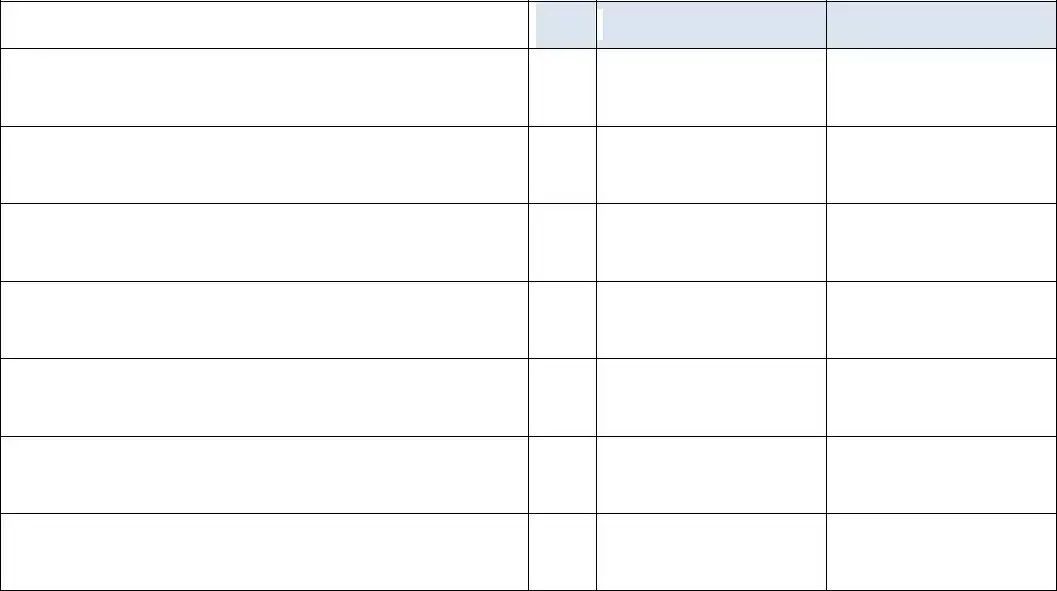

JSA – Action steps

|

Step No |

|

|

Job step details |

|

|

Potential hazards |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Risk rating**

How to control risks***

How to control risks***

Name of persons responsible for work

Review number: |

Version: |

Page 4 of 6

|

Step No |

|

|

Job step details |

|

|

Potential hazards |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Risk rating**

How to control risks***

How to control risks***

Name of persons responsible for work

Review number: |

Version: |

Page 5 of 6

This job safety analysis has been developed through consultation with our employees and has been read, understood and signed by all employees undertaking the works:

This job safety analysis has been developed through consultation with our employees and has been read, understood and signed by all employees undertaking the works:

Print Names: |

Signatures: |

Dates: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Review No |

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

|

|

|

|

|

|

|

|

|

|

Initial: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Date: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A10592057 |

|

|

|

|

|

|

|

|

|

Page 6 of 6

Form Characteristics

| Fact Name | Details |

|---|---|

| Purpose | The Job Safety Analysis (JSA) aims to identify and control hazards associated with a specific job task. |

| Governing Law | Applicable laws may vary by state; refer to OSHA regulations and relevant state-specific occupational health and safety laws. |

| Components | A JSA includes business details, work activity, involved personnel, equipment used, and risk assessments. |

| Risk Assessment | Each step of the job is rated for risk based on likelihood and consequences, using a defined scale from low to catastrophic. |

| Control Measures | The JSA outlines a hierarchy of controls to manage risks from elimination to the use of personal protective equipment. |

| Authorization | Each JSA must be authorized by a responsible person, indicating approval and accountability for the task. |

| Review Process | JSAs should be reviewed periodically to ensure they remain effective and reflect current working conditions. |

| Training | Training on controls and risk management is crucial and must be integrated at all levels of the organization. |

| Documentation | The JSA must be documented thoroughly to provide a record of the hazards, assessments, and controls implemented. |

Guidelines on Utilizing Jsa

Completing the Job Safety Analysis (JSA) form is an important step in ensuring workplace safety. After filling out this form, it will provide you with a comprehensive analysis of potential hazards associated with a specific job activity, alongside measures to control these risks. Follow the steps provided below for a systematic approach in completing the form.

- Business Details: Start by entering the business name, ABN, contact person, address, contact position, phone number, and email address.

- JSA Details: Fill in the work activity description, the location of the work, and list individuals involved in the activity.

- Authorization: Specify who has authorized the job analysis by providing their name and position. Include their signature and the date.

- Plant and Equipment: List all plant and equipment that will be used during the job. Mention any maintenance checks required, along with tools and materials to be used.

- Personal Protective Equipment (PPE): Specify all personal protective equipment needed for the job.

- Certificates and Permits: Identify any certificates, permits, or approvals required for the activity along with relevant legislation, codes, standards, or MSDSs.

- Risk Assessment: Use the risk rating table to evaluate each job step for potential hazards. Assign a likelihood and consequence rating to determine the overall risk.

- Risk Controls: Based on your findings, outline the control measures for each identified risk, following the hierarchy of control from elimination to PPE.

- Action Steps: Fill in details for each job step, including potential hazards, risk ratings, control measures, and the name of the person responsible for the work.

What You Should Know About This Form

What is a JSA form?

A JSA form, or Job Safety Analysis form, is a tool used to identify and analyze potential hazards associated with specific job tasks. It outlines safety measures to prevent accidents and injuries in the workplace. The form provides a structured approach to evaluating risks and implementing controls to ensure a safe work environment.

Why is a JSA important?

A JSA is crucial for maintaining workplace safety. It helps organizations systematically identify hazards associated with a task before work begins. By doing so, it minimizes the risk of accidents and injuries, enhances compliance with safety regulations, and promotes a culture of safety within the organization.

Who should complete the JSA?

The JSA should be completed by individuals familiar with the job or task at hand. This often includes supervisors, safety officers, and the workers who will be performing the task. Involvement from employees ensures that the analysis reflects real-world scenarios and hazards they may encounter.

How do you assess risk using the JSA?

Risk assessment in a JSA involves evaluating the likelihood of an incident occurring and the possible consequences of that incident. The risk rating table included in the JSA helps categorize risks into various levels: low, moderate, high, critical, or catastrophic. Each job step is assessed to determine its associated risks.

What controls can be included in a JSA?

Controls in a JSA follow a hierarchy that prioritizes eliminating hazards first, then substituting them, using engineering controls, implementing administrative controls, and, as a last resort, using personal protective equipment (PPE). Each type of control should aim to minimize risk effectively.

How often should a JSA be reviewed?

A JSA should be reviewed regularly, especially when there are changes in the work process, equipment, or any incidents occur. A review ensures that the information remains relevant and that the safety measures continue to protect workers effectively.

What happens if risks are identified as critical or catastrophic?

If risks are identified as critical or catastrophic, immediate action is required to mitigate those risks. This may include halting work until control measures are implemented. The goal is to eliminate or significantly reduce the hazard to an acceptable level before any work proceeds.

What are the responsibilities of employees regarding JSAs?

Employees must actively participate in the JSA process. They should report hazards, follow safety procedures outlined in the JSA, and wear the required personal protective equipment. Their engagement is key to ensuring a safer work environment.

Is training necessary when using a JSA?

Yes, training is essential. Employees should be trained on how to conduct a JSA, understand the risks associated with their tasks, and know the procedures and controls implemented to manage those risks. This knowledge empowers them to work safely and effectively.

What documentation should accompany a JSA?

A JSA should be accompanied by relevant documentation, such as safety data sheets (MSDS), permits, approvals, and any legislative requirements. Keeping comprehensive records helps ensure compliance with safety regulations and provides a reference for future analyses.

Common mistakes

Filling out the Job Safety Analysis (JSA) form requires attention to detail and care. However, individuals often make several common mistakes that can lead to incomplete or inaccurate submissions. One common error is leaving out essential business details, such as the business name and contact information. Omitting this information can delay communication and hinder the effectiveness of the safety analysis.

Another frequent mistake is failing to specify who is involved in the work activity. The absence of this detail can lead to misunderstanding of roles and responsibilities, potentially creating confusion during the job analysis process. Additionally, not completing the work activity and location fields accurately can affect the reliability of the risk assessment, as these elements are crucial in identifying applicable hazards.

Moreover, many individuals do not utilize the risk rating table effectively. They may skip this section entirely or provide vague ratings that do not truly reflect the potential risks associated with each job step. Proper evaluation of likelihood and consequence using the defined scale ensures that risks are adequately recognized and addressed.

Additionally, another common oversight is neglecting the hierarchy of control measures. Some individuals might list only one or two controls instead of exploring multiple levels of safety options available to mitigate risks. Without a thorough consideration of elimination, substitution, and engineering controls, the JSA may fail to provide the safest outcome.

It is also not uncommon for people to forget to list any personal protective equipment (PPE) required for the job. This oversight places workers at unnecessary risk. Furthermore, failing to designate responsible personnel for each risk control measure can lead to a lack of accountability and follow-through on safety actions.

Another mistake is not reviewing or updating the JSA periodically. The work environment may change, and so should the safety analyses. Leaving the document unchanged may result in outdated information that no longer applies to current working conditions.

Finally, neglecting to include relevant certificates, permits, and approvals required for specific activities can bring about compliance issues. Ensuring all necessary documentation accompanies the JSA not only helps maintain legal adherence but also promotes a culture of safety within the workplace.

Being mindful of these common mistakes can significantly enhance the quality of a completed JSA form, ultimately ensuring a safer work environment for everyone involved.

Documents used along the form

The Job Safety Analysis (JSA) form is an essential tool used to identify hazards associated with specific work tasks and to outline measures to mitigate those risks. In practice, several other forms and documents are commonly utilized alongside the JSA to enhance workplace safety and compliance. Below is a brief description of these documents.

- Safety Data Sheet (SDS): This document provides information about the properties of a particular substance. It includes details on handling, storage, and emergency measures related to the substance, ensuring employees understand the potential hazards of materials they may encounter on the job.

- Risk Assessment Form: This form assists in evaluating the level of risk associated with work tasks. It requires identifying potential hazards, determining who may be harmed, and outlining measures to control the risks, thus complementing the JSA process.

- Permit to Work (PTW): A PTW is required for specific tasks that are hazardous, such as hot work, confined space entry, or work at height. It details the scope of work, precautions that must be taken, and the persons responsible for ensuring safety during the task.

- Incident Report Form: This form is used to document any accidents, injuries, or near-misses that occur in the workplace. It captures important details such as what happened, who was involved, and what actions were taken, contributing to future safety improvements.

Each of these forms plays a crucial role in promoting safety within the workplace. Together with the JSA, they help to foster a culture of safety and facilitate compliance with relevant regulations.

Similar forms

- Safety Data Sheet (SDS): Like the JSA form, the SDS provides vital information about the hazards of chemicals used in the workplace. Both documents aim to enhance safety by identifying risks and outlining control measures.

- Workplace Hazards Assessment: This document evaluates potential hazards associated with various tasks. Similar to the JSA, it identifies risks and suggests ways to mitigate them, focusing on worker safety.

- Job Hazard Analysis (JHA): The JHA shares similarities with the JSA in its purpose of identifying job-related hazards, assessing their risks, and providing mitigation strategies in a structured format.

- Safety Inspection Checklist: This checklist assesses workplace safety conditions and hazards. Like the JSA, it helps ensure compliance with safety standards and identifies areas needing improvement.

- Emergency Response Plan: This plan outlines the steps to take during an emergency. It shares the JSA's focus on safety, frequently addressing hazards that could arise during the job.

- Permit to Work: This document grants authorization to carry out specific work, often under hazardous conditions. It includes risk assessments similar to those found in the JSA.

- Environmental Risk Assessment: This assessment evaluates risks to the environment during work activities. Like the JSA, it emphasizes the importance of identifying potential hazards and implementing control measures.

- Health and Safety Policy: This policy outlines a company's commitment to workplace safety and health. It relates to the JSA by establishing general safety guidelines that inform specific JSA processes.

- Training Records: Training records document employees' safety training and qualifications. They support the JSA by ensuring that all personnel involved are aware of safety protocols and hazards.

- Accident/Incident Report Form: This form captures details of workplace accidents and near misses. It is similar to the JSA in that both aim to improve safety by understanding past hazards to prevent future incidents.

Dos and Don'ts

When filling out the Job Safety Analysis (JSA) form, it's essential to follow specific guidelines to ensure accuracy and efficiency. Here are some important dos and don'ts:

- Do provide accurate business details, including the business name, ABN, and contact information.

- Do clearly outline the work activity and the location where it will take place.

- Do identify all individuals involved in the job, including their roles and responsibilities.

- Do thoroughly assess risks using the provided risk rating table for each job step.

- Don't leave any sections blank; incomplete forms may lead to misunderstandings or safety oversights.

- Don't underestimate the potential hazards associated with a job step; always err on the side of caution.

- Don't forget to review and update the risk controls regularly to ensure they remain effective.

- Don't ignore the importance of personal protective equipment; it should be considered as part of the overall safety plan.

Misconceptions

Many people have misunderstandings about the Job Safety Analysis (JSA) form, which can lead to improper use and confusion. Here are six common misconceptions along with clarifications:

- JSA is only for high-risk jobs. Many think that a JSA is only necessary for jobs considered dangerous. In reality, a JSA is beneficial for all types of work activities, regardless of their perceived risk level.

- Completing a JSA is just paperwork. Some believe that signing off on a JSA is just a formality. However, it serves a crucial role in identifying hazards and implementing controls to protect workers.

- All employees can ignore the JSA once it’s completed. Once a JSA is completed, it doesn’t mean it should be forgotten. Continual awareness of potential hazards is essential. Employees should regularly review the JSA and the associated safety procedures.

- The JSA is a one-time process. Many assume that a JSA only needs to be completed once for a job. On the contrary, it should be updated and reviewed frequently, especially when changes occur in the work process or environment.

- Personal protective equipment (PPE) is the only control measure. While PPE is important, relying solely on it is not the best practice. The JSA emphasizes a hierarchy of controls where eliminating or substituting hazards should be prioritized over PPE use.

- All hazards are covered in every JSA. Some people think that a JSA will always identify every potential hazard. However, it is crucial for employees to actively communicate and report any new hazards observed during the work process, as conditions can change.

Understanding the true purpose and proper use of the JSA form can lead to a safer work environment for everyone involved.

Key takeaways

The Job Safety Analysis (JSA) form is an essential tool for evaluating risks associated with a specific work activity. Understanding how to effectively fill out and utilize this form can promote a safer working environment.

- The form captures important business details, including the business name, contact information, and the nature of the work activity.

- A clear list of who is involved in the job activity must be provided along with their positions and contact information.

- It is crucial to specify the tools, materials, and personal protective equipment used during the work activity.

- Before you begin filling out the risk assessment section, familiarize yourself with the risk rating table. It assists in evaluating the likelihood and consequence of potential hazards.

- Completing the risk controls section requires a systematic approach. The hierarchy of controls should be utilized, starting with the most effective measures like elimination and substitution.

- Individuals responsible for each job step need to be identified clearly, ensuring accountability for workplace safety.

- Regularly reviewing the JSA is essential to adapting to any changes in work processes or equipment that may introduce new risks.

- Make sure to document the date and signature of the person who authorized the job safety analysis. This serves as a formal acknowledgment of the risks assessed and the planned control measures.

Browse Other Templates

Bls Certification - It is an important step for anyone looking to enhance their medical knowledge.

What Is a Vehicle Lien - This contract replaced the previous award number 01187 under the same classification.

When Do You Need Probate - Consent from other individuals with equal or higher priority to serve must be documented within the form if applicable.