Fill Out Your Material Safety Sheet Form

Understanding the Material Safety Data Sheet (MSDS) is crucial for anyone dealing with hazardous materials in the workplace. This essential document is typically structured into sixteen sections, each designed to provide specific information about a chemical product. At the outset, the MSDS identifies the chemical product and its manufacturer, including contact details and emergency information. The subsequent sections delve into the composition of the product, highlighting any hazardous ingredients, their percentages, and relevant identification numbers. Moreover, the sheet elucidates potential health risks associated with exposure, ranging from skin contact to inhalation or ingestion, ensuring users are forewarned. First-aid measures are outlined to offer immediate guidance in case of an incident, while details on fire-fighting measures specify flammability and combustion risks. Sections dedicated to accidental release measures and safe handling practices ensure incidents are minimized through proper storage and use protocols. Personal protective equipment recommendations and exposure limits are also crucial, reinforcing the importance of safety in varied environments. The physical and chemical properties section provides insights into the substance's characteristics, with stability and reactivity information further informing safety precautions. Toxicological data, including effects of exposure and potential environmental impact, highlight the broader implications of handling such materials. Finally, the MSDS serves to remind users of regulatory compliance, detailing legal obligations in relation to transportation, disposal, and classification. The comprehensive nature of the MSDS makes it not just a safety tool, but a legal and ethical imperative that underscores the responsibility individuals and organizations have in ensuring safety not only for themselves but also for the environment and the community at large.

Material Safety Sheet Example

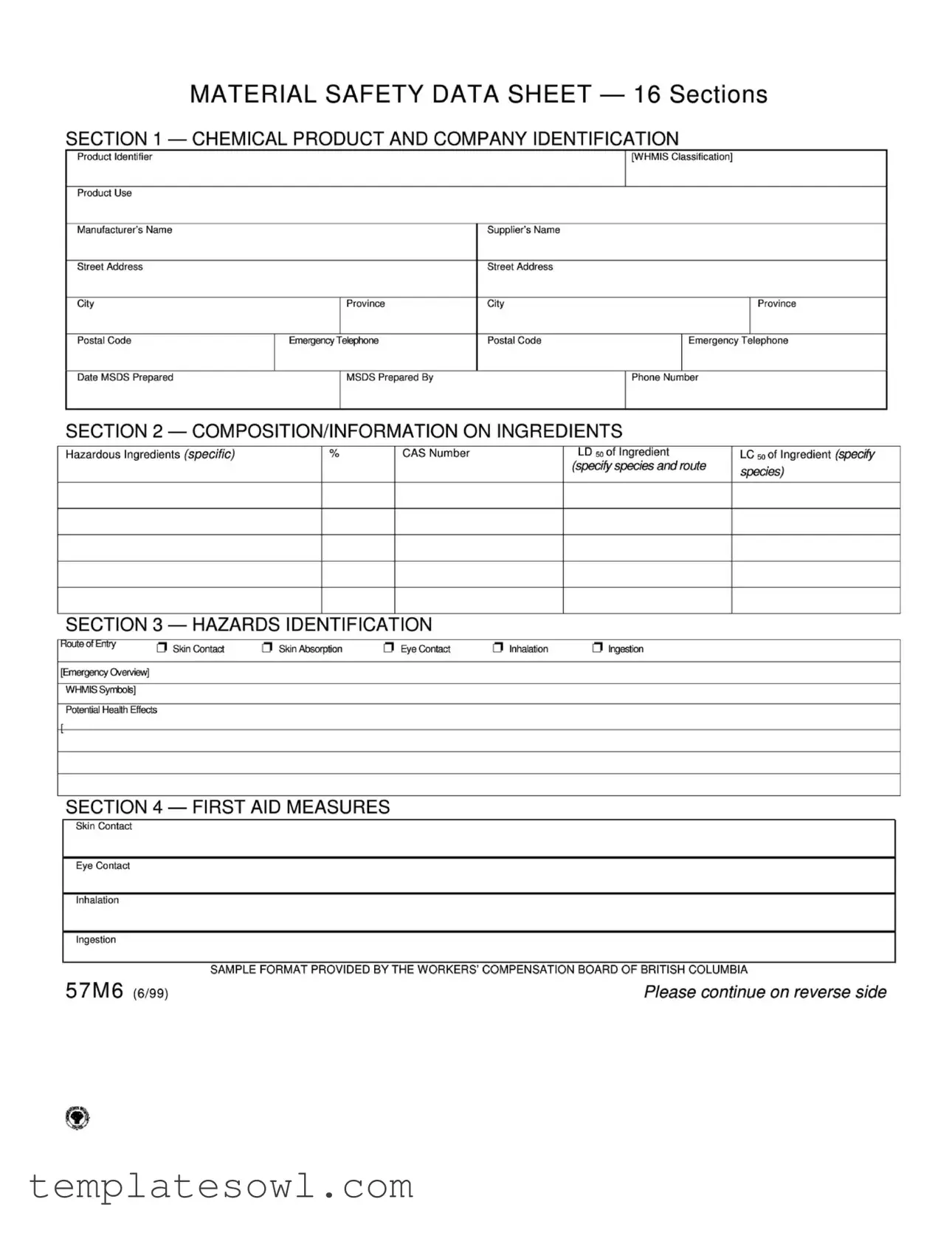

MATERIAL SAFETY DATA SHEET — 16 Sections |

||||

SECTION 1 — CHEMICAL PRODUCT AND COMPANY IDENTIFICATION |

|

|||

Product Identifier |

|

|

[WHMIS Classification] |

|

Product Use |

|

|

|

|

Manufacturer's Name |

|

Supplier’s Name |

|

|

Street Address |

|

Street Address |

|

|

City |

Province |

City |

|

Province |

Postal Code |

Emergency Telephone |

Postal Code |

Emergency Telephone |

|

Date MSDS Prepared |

MSDS Prepared By |

Phone Number |

|

|

SECTION 2 — COMPOSITION/INFORMATION ON INGREDIENTS |

|

|||

Hazardous Ingredients (specific) |

% |

CAS Number |

LD so of Ingredient |

LC so of Ingredient (specify |

|

|

|

(specify species and route |

species) |

|

|

|

|

|

SECTION 3 — HAZARDS IDENTIFICA1RON

О Skin Contact |

П Skin Absorption |

П Eye Contact |

П Inhalation |

П Ingestion |

[Emergency Overview]

WHMIS Symbols]

Potential Health Effects

SECTION 4 — FIRST AID MEASURES

5 7 M 6 (6/99) |

Please continue on reverse side |

Product

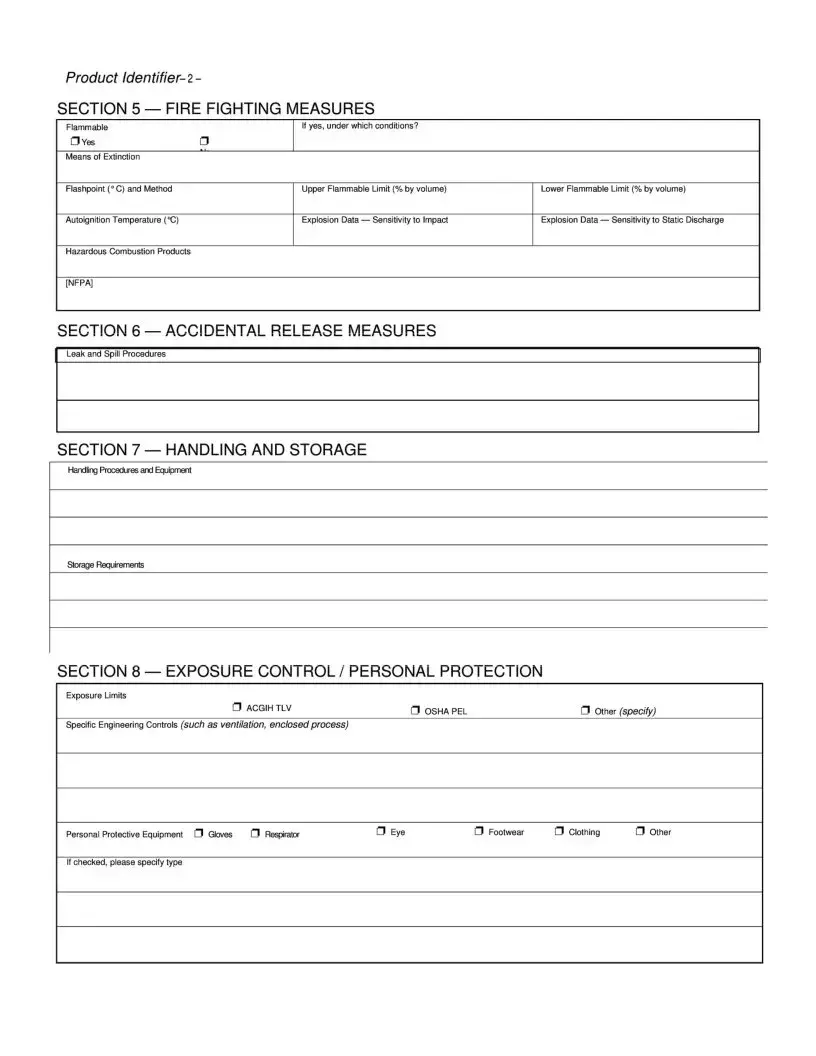

SECTION 5 — FIRE FIGHTING MEASURES

Flammable |

If yes, under which conditions? |

|

Yes |

|

|

Means of Extinction |

|

|

Flashpoint (°C) and Method |

Upper Flammable Limit (% by volume) |

Lower Flammable Limit (% by volume) |

Autoignition Temperature (°C) |

Explosion Data — Sensitivity to Impact |

Explosion Data — Sensitivity to Static Discharge |

Hazardous Combustion Products |

|

|

[NFPA] |

|

|

SECTION 6 — ACCIDENTAL RELEASE MEASURES

Leak and Spill Procedures

SECTION 7 — HANDLING AND STORAGE

SECTION 8 — EXPOSURE CONTROL / PERSONAL PROTECTION

Exposure Limits

ACGIH TLV |

0SHA pEL |

Д Other (Specify) |

Specific Engineering Controls (such as ventilation, enclosed process)

Personal Protective Equipment |

Gloves |

Respirator |

Eye |

Footwear |

Clothing |

Other |

If checked, please specify type

Product Identifiers -

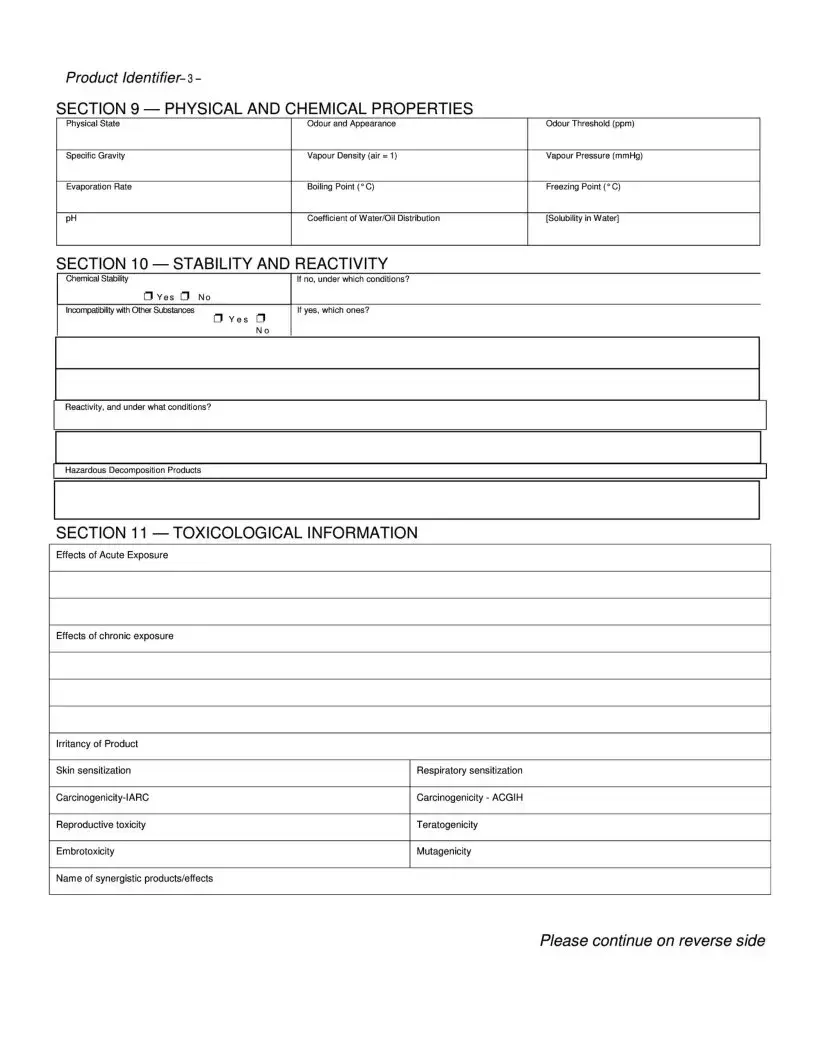

SECTION 9 — PHYSICAL AND CHEMICAL PROPERTIES

Physical State |

Odour and Appearance |

Odour Threshold (ppm) |

Specific Gravity |

Vapour Density (air = 1) |

Vapour Pressure (mmHg) |

Evaporation Rate |

Boiling Point (°C) |

Freezing Point (°C) |

pH |

Coefficient of Water/Oil Distribution |

[Solubility in Water] |

SECTION 10 — STABILITY AND REACTIVITY

Chemical Stability |

If no, under which conditions? |

О Yes П No

Incompatibility with Other Substances |

If yes, which ones? |

|

Yes |

|

N о |

Reactivity, and under what conditions?

Hazardous Decomposition Products |

| |

SECTION 11 — TOXICOLOGICAL INFORMATION

Effects of Acute Exposure

Effects of chronic exposure

Irritancy of Product |

|

Skin sensitization |

Respiratory sensitization |

Carcinogenicity - ACGIH |

|

Reproductive toxicity |

Teratogenicity |

Embrotoxicity |

Mutagenicity |

Name of synergistic products/effects |

|

Please continue on reverse side

Product Identifier- 4-

SECTION 12 — ECOLOGICAL INFORMATION

[Aquatic Toxicity]

SECTION 13 — DISPOSAL CONSIDERATIONS

Waste Disposal

SECTION 14

Special Shipping Information

TOG

[IMO]

PIN

[DOT]

[CAO]

SECTION 15 — REGULATORY INFORMATION

[WHMIS Classification] |

[OSHA] |

[SERA] |

[TSCA] |

This product has been classified in accordance with the hazard criteria of the

Controlled Products Regulations (CPR) and the MSDS contains all of the information required by CPR.

SECTION 16

Form Characteristics

| Fact Name | Description |

|---|---|

| Purpose | The Material Safety Data Sheet (MSDS) provides essential information about the properties of a chemical substance and the necessary precautions for handling it safely. |

| Structure | An MSDS is organized into 16 sections, each detailing various aspects, such as product identification, hazards, and first aid measures, ensuring a comprehensive understanding of the chemical. |

| Regulatory Compliance | In the United States, the Occupational Safety and Health Administration (OSHA) mandates the creation and dissemination of MSDSs to promote workplace safety. |

| Consumer Safety | MSDSs play a critical role in safeguarding both workers and the general public by informing them of potential hazards associated with chemical exposure. |

| Accessibility | Employers are required to make MSDSs readily available to employees, ensuring they have access to vital safety information regarding the chemicals they may encounter. |

| State-Specific Laws | In addition to federal guidelines, various states may have specific laws governing MSDS requirements, such as California's Proposition 65, which mandates clear disclosure of certain hazardous chemicals. |

Guidelines on Utilizing Material Safety Sheet

Filling out the Material Safety Data Sheet (MSDS) is an essential step in ensuring safety around hazardous substances. All relevant information must be accurately provided to comply with regulations and to protect users effectively. With the right approach, completing this form becomes straightforward.

- SECTION 1 — CHEMICAL PRODUCT AND COMPANY IDENTIFICATION: Start by entering the product name, its intended use, and details about the manufacturer, including their name, address, province, and emergency contact number. Provide your name as the person preparing the sheet, along with your phone number.

- SECTION 2 — COMPOSITION/INFORMATION ON INGREDIENTS: List any hazardous ingredients along with their respective percentages, CAS numbers, and LD50/LC50 data for the specified species.

- SECTION 3 — HAZARDS IDENTIFICATION: Mark all applicable routes of exposure such as skin contact, eye contact, inhalation, and ingestion. Include WHMIS symbols if relevant and describe potential health effects.

- SECTION 4 — FIRST AID MEASURES: Outline the first aid procedures corresponding to the hazards identified in the previous section.

- SECTION 5 — FIRE FIGHTING MEASURES: Note whether the material is flammable and provide the means of extinction, flashpoint, and other important thermal properties related to combustion.

- SECTION 6 — ACCIDENTAL RELEASE MEASURES: Provide clear procedures for leak and spill management to prevent environmental contamination.

- SECTION 7 — HANDLING AND STORAGE: Describe safe handling practices and storage requirements to maintain safety.

- SECTION 8 — EXPOSURE CONTROL / PERSONAL PROTECTION: List applicable exposure limits and recommend personal protective equipment, such as gloves and respirators.

- SECTION 9 — PHYSICAL AND CHEMICAL PROPERTIES: Fill in the physical state, specific gravity, pH, boiling point, and other relevant characteristics of the substance.

- SECTION 10 — STABILITY AND REACTIVITY: Provide information regarding the stability of the chemical and any potential hazardous reactions.

- SECTION 11 — TOXICOLOGICAL INFORMATION: Detail the effects of acute and chronic exposure, including irritancy and any carcinogenic effects.

- SECTION 12 — ECOLOGICAL INFORMATION: Discuss the ecological impact, particularly any aquatic toxicity.

- SECTION 13 — DISPOSAL CONSIDERATIONS: Give instructions on the proper disposal of the product and its container.

- SECTION 14 — TRANSPORT INFORMATION: Include details about shipping information, such as appropriate transport regulations and identifiers.

- SECTION 15 — REGULATORY INFORMATION: State the relevant safety regulations that apply to the product, ensuring compliance.

- SECTION 16 — OTHER INFORMATION: Provide any additional data or sources that might be helpful for safe handling and compliance.

What You Should Know About This Form

What is a Material Safety Data Sheet (MSDS)?

A Material Safety Data Sheet, commonly known as an MSDS, is a document that provides detailed information about a chemical product. It includes essential details such as potential hazards, safety precautions, and handling instructions. The main purpose of an MSDS is to ensure the safety of individuals who work with hazardous materials.

What information is included in an MSDS?

An MSDS typically contains 16 sections, including information on the chemical product, hazardous ingredients, potential health effects, first aid measures, fire-fighting measures, accidental release procedures, handling and storage guidelines, exposure control, and waste disposal considerations. Each section contains specific details relevant to the chemical's safety and handling.

How should I use an MSDS?

Who prepares the MSDS?

The manufacturer or supplier of the chemical product is responsible for preparing the MSDS. They ensure that the information is accurate, up-to-date, and compliant with regulatory standards. Anyone using hazardous chemicals should always refer to the most current version of the MSDS。

What should I do in case of an emergency related to a chemical?

In case of a chemical emergency, consult the MSDS for first aid measures and emergency contact information. The sheet will provide specific instructions on what to do in specific situations, such as skin or eye contact, inhalation, or ingestion. Contact emergency services if needed and provide them with the relevant MSDS information.

Where can I find the MSDS for a product?

You can usually obtain an MSDS from the manufacturer’s website, or by contacting the supplier directly. Many companies make their MSDS available online for easy access. Additionally, workplaces that use hazardous materials should maintain an updated file of MSDSs for all chemicals in use.

What is meant by hazardous ingredients in the MSDS?

Hazardous ingredients are substances that can pose significant risks to health or safety. The MSDS will list any hazardous components contained in the chemical product, along with their concentration percentages. This information is crucial for understanding the potential risks associated with the product.

What are the fire-fighting measures listed in the MSDS?

Fire-fighting measures in the MSDS describe how to handle a fire involving the chemical product. This includes information on whether the substance is flammable, what means of extinction are recommended, and details such as flashpoint and hazardous combustion products. Following these measures can help ensure safety during a fire emergency.

What does the "exposure control/personal protection" section include?

This section outlines recommended practices for minimizing exposure to hazardous materials. It includes information on allowable exposure limits, personal protective equipment (PPE) needed, and engineering controls such as ventilation. Adhering to this guidance is essential for maintaining a safe working environment.

What regulatory information is found in an MSDS?

The regulatory information section includes details about compliance with various safety regulations, such as WHMIS, OSHA, and TSCA. This section ensures that the product meets official safety criteria and provides users with important information related to legal and safe handling of the chemical.

Common mistakes

When filling out a Material Safety Data Sheet (MSDS), individuals often encounter several pitfalls. One major mistake is the omission of accurate chemical product identification. This section is vital as it outlines the product identifier, its uses, and manufacturer's details. Failing to provide complete information can lead to miscommunication and potentially hazardous situations.

Another common error involves improper classification of hazardous ingredients. It is essential to include specific percentages and Chemical Abstracts Service (CAS) numbers for each hazardous component. Neglecting these details risks underestimating the dangers associated with the product, which can affect safety protocols in workplaces.

Individuals also frequently overlook the importance of detailing potential health effects in the hazard identification section. Simply stating that a product is hazardous without explaining the specific risks—such as skin or eye contact, inhalation, or ingestion—creates gaps in understanding. Those handling the materials may not recognize the precautions necessary to ensure their safety.

The section dedicated to first aid measures is often inadequately filled out. If an incident were to occur, clear first aid information could be life-saving. Generalities should be avoided; instead, specific instructions outlining the steps to take in various emergency scenarios should be provided. This detail is crucial for swift and effective responses in a crisis.

A misunderstanding of fire-fighting measures is yet another mistake. Providing vague information regarding flammability, means of extinguishing flames, and hazardous combustion products can leave workers unprepared in an emergency. Clear quantitative data, such as flashpoints and limits, should be included to enhance safety during potential fire situations.

In the handling and storage section, individuals may neglect to specify necessary precautions. Guidelines about the temperature, humidity, and other conditions required during storage effectively prevent accidents. This oversight could lead to dangerous reactions or degradations of the materials involved.

Finally, personnel filling out the MSDS may fail to adequately describe personal protective equipment (PPE) requirements. This information is vital to ensure that employees understand what protective gear is needed while handling the chemical. If instructions about gloves, respirators, or eye protection are unclear or incomplete, it increases the risk of exposure.

Documents used along the form

Alongside the Material Safety Data Sheet (MSDS), there are several other important forms and documents that help ensure safety and compliance in handling hazardous materials. Below is a list of these documents, each serving a specific purpose in the safety and regulatory landscape.

- Safety Data Sheet (SDS): This document provides detailed information about a chemical product, including its properties, hazards, handling instructions, and emergency procedures. It covers information similar to an MSDS but follows the Globally Harmonized System (GHS) format, making it globally recognized.

- Labeling Information: Labels on hazardous materials contain essential details such as the product name, hazard symbols, and safety precautions. They are critical for on-site identification and help ensure safety during handling and transportation.

- Incident Report Form: This document is used to report accidents, spills, or exposure incidents involving hazardous materials. It records vital information about the event, facilitating prompt response and preventive measures for future incidents.

- Hazard Communication Program: A comprehensive plan that outlines how a workplace will communicate hazards associated with chemicals. It details training requirements, labeling, and access to safety data sheets.

- Emergency Response Plan: A document outlining procedures to follow in case of a hazardous materials emergency. It includes evacuation plans, contact information for local emergency services, and specific actions to mitigate risks.

- Training Records: Documentation of employee training sessions regarding hazardous materials. It ensures workers are informed about safety protocols, hazard recognition, and the proper use of personal protective equipment (PPE).

Understanding these documents is crucial for maintaining a safe workplace and complying with regulatory requirements. Each form complements the MSDS in ensuring the safe handling, storage, and disposal of hazardous substances.

Similar forms

The Material Safety Data Sheet (MSDS) is one of several key documents used to communicate information about hazardous materials. Here is a list of four other important documents that share similarities with the MSDS:

- Safety Data Sheet (SDS): The SDS serves the same purpose as the MSDS but is structured according to globally harmonized classifications. Both documents provide essential information regarding the safe handling, storage, and potential hazards of chemicals.

- Labeling Requirements: Labels on hazardous materials and chemicals often summarize critical information found in the MSDS. They include hazard symbols, precautionary statements, and storage instructions to ensure quick understanding and awareness during handling.

- Exposure Control Plans: These plans outline procedures for minimizing employee exposure to hazardous materials. Like the MSDS, they detail specific measures to ensure workplace safety and the use of personal protective equipment.

- Workplace Hazard Assessment: This assessment identifies and evaluates potential hazards in the workplace. Similar to the MSDS, it aims to protect employees by documenting risks and ensuring that safety measures are implemented.

Dos and Don'ts

When filling out the Material Safety Data Sheet (MSDS), it’s important to take care to ensure accuracy and compliance. Here’s a list of what you should and shouldn’t do:

- Do: Read each section carefully before filling it out.

- Do: Provide detailed and specific information for all hazardous ingredients.

- Do: Include emergency contact numbers for immediate assistance.

- Do: List any potential health hazards associated with the material.

- Do: Ensure that the data reflects the most current information available.

- Don’t: Leave any sections blank without a valid reason.

- Don't: Use vague terms; be as precise as possible.

- Don't: Forget to update the sheet if any new information arises.

- Don't: Use out-of-date or irrelevant safety data in the form.

Misconceptions

Misconceptions about Material Safety Data Sheets (MSDS) can lead to misunderstanding their importance. Here are some common myths along with the facts that clarify them.

- Myth 1: MSDSs are optional and not necessary for all chemicals.

- Myth 2: All MSDSs are the same.

- Myth 3: MSDSs only cover health hazards.

- Myth 4: Once you have an MSDS, you don’t need to update it.

- Myth 5: You can read the MSDS only if you have a scientific background.

- Myth 6: The information on an MSDS does not need to be communicated to employees.

- Myth 7: MSDSs are only for emergency responders.

- Myth 8: Digital MSDSs are not as reliable as paper ones.

- Myth 9: You don’t need to keep MSDSs once the chemical is used up.

This is not true. MSDSs are required for hazardous chemicals. They provide essential information about handling, storage, and emergency measures.

Every MSDS is tailored to a specific chemical. The information varies based on the properties and hazards of that particular substance.

While health hazards are a significant part, MSDSs also include information on fire hazards, environmental risks, and safe handling techniques.

MSDSs must be updated whenever new information becomes available or if regulations change. Regular reviews are important.

MSDSs are designed to be user-friendly. Anyone, regardless of their background, can understand the basic safety information provided.

It's crucial to share MSDS information with employees. They need to be aware of the hazards and safety measures involved in their work.

While emergency responders use them, MSDSs are essential for anyone who handles chemicals, ensuring everyone's safety.

As long as the digital MSDS is from a credible source, it is just as reliable as a paper document. Accessibility is often better in digital format.

It’s good practice to retain MSDSs for a specified period after a chemical is depleted. This helps in any future inquiries or incidents.

Understanding these misconceptions ensures better safety practices and compliance in the workplace. Always refer to the specific MSDS for details related to the chemicals you are handling.

Key takeaways

Filling out a Material Safety Data Sheet (MSDS) is essential for ensuring safe handling and awareness of hazardous materials. Here are some key takeaways to consider:

- Know the Components: The MSDS consists of 16 sections that provide crucial information about a chemical product. Familiarize yourself with each section for comprehensive understanding.

- Identify the Product: Section 1 demands accurate product identification. Include the manufacturer’s details, including emergency contact numbers.

- Understand Composition: Section 2 outlines the hazardous ingredients. List each ingredient along with its percentage and CAS number.

- Recognize Hazards: Section 3 evaluates potential health effects. Properly indicate risks related to skin contact, inhalation, and other exposure routes.

- First Aid Measures: Quickly refer to Section 4 for first aid steps. This section is vital during emergencies.

- Fire Safety: Firefighting details in Section 5 are crucial. Know the flammability, flashpoint, and means of extinction.

- Handling Guidelines: Section 7 provides important handling and storage instructions. Adhering to these reduces risk.

- Personal Protection: Consult Section 8 for recommended personal protective equipment. Proper gear is essential for safety.

- Physical Properties: Section 9 includes critical physical and chemical properties. Understanding these helps in assessing risks.

- Disposal Considerations: Follow Section 13 for proper waste disposal methods. Improper disposal can harm the environment.

By being thorough when completing and using the MSDS, everyone involved contributes to a safer workplace and better environmental protection.

Browse Other Templates

Cdph 612 - This form helps ensure that facilities meet the community's healthcare needs effectively.

When a Veteran Dies Who Gets the Flag - The application helps keep the memory of the veteran alive through the flag.

Anne Arundel County Rental License - It's important for tenants to understand their responsibilities for utilities incurred during the lease term.