Fill Out Your Megger Test Form

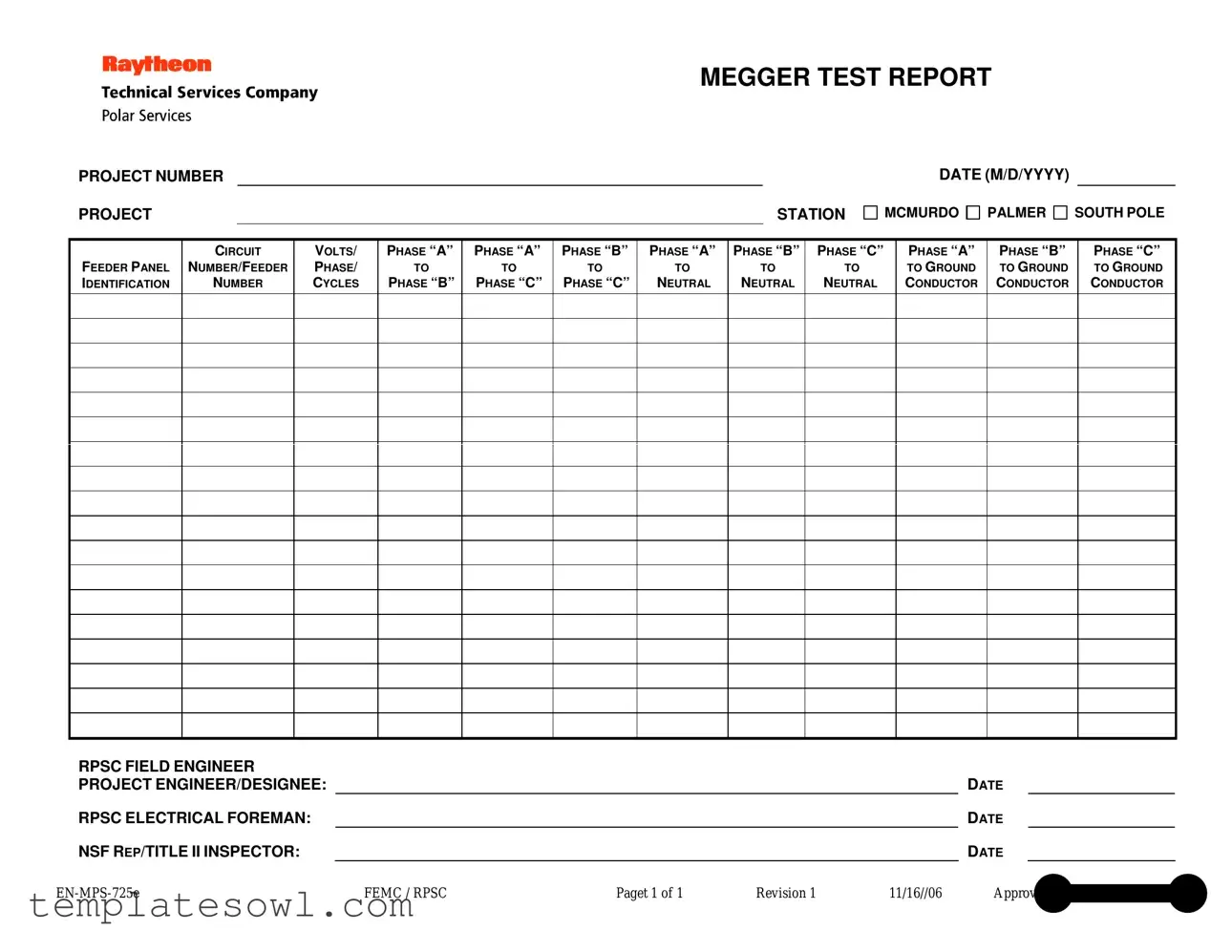

The Megger Test form is an essential tool for conducting electrical insulation resistance tests on various projects, such as those found in remote locations like McMurdo, Palmer, and the South Pole. This document is structured to gather important information, including the project’s identification details, station, and testing date. It captures readings across three phases—A, B, and C—alongside their voltage levels, which helps electricians and engineers assess the integrity of insulation and connectivity. The form requires data points, such as phase-to-phase voltage, phase-to-neutral measurements, and phase-to-ground resistance values. It also identifies key personnel involved in the testing process, notably the RPSC field engineer and the project engineer, ensuring accountability and clarity in communication. This detailed documentation not only supports compliance with safety standards but also aids in identifying potential issues in electrical systems before they escalate. With careful completion, the Megger Test form becomes a reliable record of testing outcomes, contributing to enhanced electrical safety and operational efficiency.

Megger Test Example

MEGGER TEST REPORT

PROJECT NUMBER

PROJECT |

|

STATION |

DATE (M/D/YYYY)

MCMURDO

PALMER

PALMER

SOUTH POLE

SOUTH POLE

FEEDER PANEL IDENTIFICATION

CIRCUIT

NUMBER/FEEDER

NUMBER

VOLTS/

PHASE/

CYCLES

PHASE “A”

TO

PHASE “B”

PHASE “A”

TO

PHASE “C”

PHASE “B”

TO

PHASE “C”

PHASE “A”

TO

NEUTRAL

PHASE “B”

TO

NEUTRAL

PHASE “C”

TO

NEUTRAL

PHASE “A”

TO GROUND CONDUCTOR

PHASE “B”

TO GROUND CONDUCTOR

PHASE “C”

TO GROUND CONDUCTOR

RPSC FIELD ENGINEER |

|

|

|

|

|

|

PROJECT ENGINEER/DESIGNEE: |

|

|

|

|

DATE |

|

RPSC ELECTRICAL FOREMAN: |

|

|

|

|

DATE |

|

NSF REP/TITLE II INSPECTOR: |

|

|

|

|

DATE |

|

FEMC / RPSC |

Paget 1 of 1 |

Revision 1 |

11/16//06 |

Approved by Wayne L. Cornell |

||

Form Characteristics

| Fact Name | Description |

|---|---|

| Project Number | The Megger Test Report requires a unique project number to identify the specific project associated with the electrical testing. |

| Station Location | Test results are tied to specific stations, including notable locations like McMurdo, Palmer, and South Pole. |

| Date Format | The date must be entered in the format M/D/YYYY, ensuring consistency and clarity in recording the test date. |

| Circuit Identification | Circuit and feeder numbers must be indicated for accurate identification of the specific electrical circuits being tested. |

| Signatures Required | The report mandates signatures from the RPSC Electrical Foreman, Field Engineer, and NSF Representative for verification and accountability. |

Guidelines on Utilizing Megger Test

Filling out the Megger Test form requires accuracy and attention to detail to ensure that all necessary information is captured. This form helps document various electrical measurements and observations. To properly complete the form, follow these step-by-step instructions.

- Project Number: Write the specific project number at the top of the form.

- Project Station: Indicate the project station, choosing from the provided options: McMurdo, Palmer, or South Pole.

- Date: Fill in the date using the format (M/D/YYYY).

- Feeder Panel Identification: Specify the identification for the feeder panel used during the test.

- Circuit Number/Feeder Number: Enter the circuit or feeder number that corresponds to the test being conducted.

- Volts/Phase/Cycles: Record the voltage, phase, and cycles relevant to your measurements.

- Phase Measurements: For each phase pairing, fill in the measurements:

- Phase “A” to Phase “B”

- Phase “A” to Phase “C”

- Phase “B” to Phase “C”

- Phase “A” to Neutral

- Phase “B” to Neutral

- Phase “C” to Neutral

- Phase “A” to Ground

- Phase “B” to Ground

- Phase “C” to Ground

- RPSC Field Engineer: Sign and date the section for the field engineer who conducted the test.

- Project Engineer/Designee: Have the project engineer or designee sign and date the corresponding area.

- RPSC Electrical Foreman: Include the signature and date from the electrical foreman.

- NSF Rep/Title II Inspector: The inspector should sign and provide the date for record-keeping purposes.

After completing this form, review all entries for clarity and correctness. This ensures that critical data is preserved for later reference, contributing to the overall safety and reliability of the electrical project.

What You Should Know About This Form

What is a Megger Test and why is it important?

A Megger Test, also known as insulation resistance testing, is a method used to assess the integrity of electrical insulation. It helps ensure that insulation is functioning properly and can prevent electrical failures or hazards. A good insulation resistance reading indicates that the electrical components are safe to operate, reducing the risk of short circuits and potential electrical fires.

What information is included in the Megger Test form?

The Megger Test form captures several essential details. It includes the project number, project station, and date of the test. You'll also find information about the feeder panel identification and the circuit number. Additionally, the form records voltage readings between various phases and to neutral, as well as readings to ground. This comprehensive documentation helps track the performance of electrical systems over time.

How do I fill out the Megger Test form?

To fill out the Megger Test form, start by entering the project number and the project station. Next, record the test date in the specified format (M/D/YYYY). Identify the feeder panel and circuit numbers. Measure and document voltage readings between each phase and to neutral and ground. Lastly, ensure that the signatures of relevant personnel, such as the RPSC Field Engineer and Electrical Foreman, are included on the form for validation.

What should I do if I get a low insulation resistance reading?

If you obtain a low insulation resistance reading during the test, it may indicate a problem with the insulating material. Take action by first rechecking the measurement to confirm accuracy. If the reading remains low, it’s important to investigate further for potential issues like damaged wiring or moisture. Depending on the findings, repairs or replacements of affected components may be necessary to ensure safety.

Who is responsible for completing the Megger Test?

The responsibility of completing the Megger Test typically falls on qualified electrical technicians or engineers. They should have the proper training to conduct these tests accurately. Documentation can be signed by the RPSC Field Engineer, Project Engineer, or a designated representative who oversees the testing process to ensure accountability and compliance.

How often should Megger Testing be conducted?

The frequency of Megger Testing varies depending on industry standards, the type of equipment, and usage. In general, it’s advisable to perform these tests annually or whenever there is significant electrical work done. Regular testing helps identify problems before they lead to major failures, ensuring ongoing safety and performance of electrical systems.

Common mistakes

Filling out the Megger Test form accurately is essential for maintaining electrical safety and ensuring proper documentation. However, many people make common mistakes that can lead to significant issues down the line. Here are seven frequent errors to avoid when completing the form.

First and foremost, incorrect project identification can lead to confusion later. Ensure that the project number and station are filled in correctly. Double-check each entry before submission to confirm that it aligns with the associated paperwork and actual on-site work.

Another prevalent mistake is failing to verify the date format. The form specifies a date format of M/D/YYYY, yet some individuals might mistakenly use D/M/YYYY or other variations. This oversight can create discrepancies and impact record-keeping.

When it comes to panel identification, using vague or incomplete labels can hinder future reference. Clearly identify the feeder panel, ensuring that the identification aligns with existing records. Specificity is crucial, especially for maintenance and troubleshooting efforts.

In the section concerning voltage readings, omitting or misplacing values is often seen. Each phase must be documented accurately. Be vigilant in recording the volts for phase combinations like “A” to “B” and “A” to neutral. Errors can lead to faulty assumptions about system performance.

Another critical piece of information is the ground conductor readings. Some forms are filled out without these vital entries. Always ensure that phase readings to ground are included, as they provide important safety data that cannot be overlooked.

Additionally, neglecting to have signatures can render the report incomplete. Each responsible individual, including the field engineer, project engineer or designee, and electrical foreman, must sign and date the form. These signatures confirm that the readings are accurate and the report has been reviewed.

Lastly, submitting the form without a final review is a mistake made all too often. Before turning in the Megger Test report, a thorough check for any potential errors or omissions is invaluable. This final step can save time, resources, and ensure the integrity of your documentation.

Documents used along the form

In the realm of electrical testing and documentation, there are several essential forms that accompany the Megger Test form. These documents help ensure comprehensive testing and adherence to safety standards. Below are some of the other key forms commonly used alongside the Megger Test.

- Electrical Inspection Report: This document outlines the results from a professional examination of electrical systems and components. It details any identified issues and provides recommendations, ensuring the safety and functionality of the systems in question.

- Grounding System Test Report: This report focuses on the evaluation of the grounding system integrity. It records measurements taken from various grounding points, helping to ensure that the system effectively protects against electrical faults and disturbances.

- Voltage Test Report: A crucial document that records results from voltage testing conducted on electrical circuits. It documents the voltage levels measured and highlights any irregularities that may affect system performance and safety.

- Preventive Maintenance Checklist: This checklist serves as a proactive tool that outlines routine maintenance tasks for electrical equipment. By keeping track of these tasks, it helps in identifying potential issues before they escalate, ensuring the reliability of electrical systems.

Each of these documents plays a vital role in maintaining a safe and effective electrical environment. By utilizing them alongside the Megger Test form, it's possible to achieve thorough oversight and enhancement of electrical safety protocols.

Similar forms

The Megger Test form plays an essential role in documenting electrical testing processes. Here are eight documents that fit a similar category and share key features with the Megger Test form:

- Electrical Inspection Report: This report outlines the findings of electrical inspections, detailing the condition of systems, equipment, and any safety issues noted during the assessment.

- Test Result Certificate: Similar to the Megger Test form, this certificate verifies the results of testing performed on electrical installations and offers a summary of the performance metrics observed.

- Commissioning Report: This document summarizes the results of system tests prior to going live. It ensures that all electrical components are functioning as intended, much like the Megger Test form assesses insulation resistance.

- Preventive Maintenance Log: A log that tracks maintenance activities performed on electrical systems and devices. It often includes tests performed and their outcomes, paralleling the documentation style of the Megger Test form.

- Incident Report: This report captures details of any electrical incidents or failures. It includes the conditions leading up to the incident and actions taken, similar to how the Megger Test form records testing conditions and results.

- Compliance Audit Report: This report is used to document adherence to electrical standards and regulations. It shares similarities with the Megger Test form in its focus on verifying systems against specified benchmarks.

- Risk Assessment Document: This document evaluates potential risks associated with electrical systems and includes findings from tests like those documented in the Megger Test form, emphasizing safety and functionality.

- Load Test Report: This report details the results from stress tests performed on electrical systems. It similarly formats results and observations, ensuring systems operate under realistic load conditions.

Each of these documents plays a vital role in maintaining and ensuring the safe operation of electrical systems, just as the Megger Test form does.

Dos and Don'ts

Filling out the Megger Test form correctly is essential for ensuring that your electrical testing is documented properly. Here are some key dos and don’ts to keep in mind:

- Do carefully check the project number before starting to make sure it aligns with your current Gig test.

- Do write the date in the correct format (M/D/YYYY) to avoid confusion later on.

- Do fill in the identification for the feeder panel clearly to ensure accurate records.

- Do enter all voltage and cycle information completely for each phase.

- Do verify all readings before signing off to ensure they are accurate.

- Don’t leave any section blank; incomplete information can lead to complications down the line.

- Don’t use acronyms or abbreviations that could confuse someone reviewing the form.

- Don’t forget to neatly print all entries to ensure clarity and readability.

- Don’t rush through the form; taking your time helps prevent mistakes.

- Don’t forget to have the project engineer or designee sign and date the form to authorize it.

Misconceptions

Many people have misunderstandings about the Megger Test, a critical tool for ensuring the safety and reliability of electrical systems. Below are nine common misconceptions, accompanied by clarifying explanations.

- The Megger Test is only for new installations. Many believe this test is reserved for newly constructed electrical systems. However, it is vital for both new and existing installations. Regular testing helps identify potential issues before they become serious problems.

- A high resistance reading means everything is fine. Some assume that a high resistance reading always indicates a secure installation. While it’s a good sign, it doesn’t guarantee that other issues, like weak connections, aren't present.

- Megger Testing can be done on any type of electrical system. Not all systems are suitable for the Megger Test. For instance, sensitive electronic equipment may be damaged by the high voltage used in testing. Always verify compatibility before proceeding.

- The Megger is the only test needed for electrical safety. Relying solely on the Megger Test can be misleading. It should be part of a comprehensive inspection process that includes other testing methods for a complete picture of electrical safety.

- The Megger is only for contractors. This tool is often associated with contractors, but it’s valuable for anyone responsible for electrical safety. Facility managers and safety inspectors can also benefit from using Megger testing.

- Once a test is passed, it never has to be done again. This misconception leads to dangerous practices. Electrical systems can degrade over time, so regular testing is essential to maintain safety and functionality.

- All Megger Tests are conducted the same way. There are various types of Megger Tests tailored for specific applications. Understanding these differences is crucial for selecting the appropriate test for each situation.

- Results from a Megger Test are universally standardized. Test results can vary based on factors like temperature and humidity. Context is key in interpreting these readings accurately.

- The Megger Test is unnecessary if visual inspections are conducted. Visual inspections are important, but they can't replace the detailed insights gained through testing. The Megger Test uncovers hidden issues that might be missed during a visual check.

By addressing these misconceptions, individuals can better appreciate the significance of the Megger Test in maintaining electrical safety and performance.

Key takeaways

The Megger Test form is a vital tool in assessing the insulation quality of electrical systems. Properly filling out this form ensures accuracy and reliability in electrical testing. Below are key takeaways for effectively using the Megger Test form.

- Project Identification: Clearly note the project number and station at the top of the form. This associates the test results with the specific electrical project.

- Accurate Dates: Include the date of testing in the correct format (M/D/YYYY) to maintain an organized record.

- Phase Measurements: Record all phase-to-phase and phase-to-neutral measurements. This data is critical for evaluating system balance and insulation integrity.

- Grounding Information: Take care to fill in grounding measurements accurately. These indicate the effectiveness of grounding systems, which is essential for safety.

- Conductor Identification: Clearly identify each circuit and feeder by its corresponding number. This helps prevent confusion in the analysis of results.

- Signature Requirements: Ensure that the RPSC Field Engineer, Project Engineer/Designee, and NSF Rep/Title II Inspector sign the form. Their approvals are often necessary for compliance purposes.

- Review Before Submission: Double-check all entries for accuracy. Errors in the report can lead to misdiagnoses of electrical issues.

- Keep Records: Retain a copy of the completed Megger Test form for future reference. This can be useful for tracking insulation performance over time.

By following these guidelines, users can maintain the integrity of the Megger Test process and contribute to the overall safety and functionality of electrical installations.

Browse Other Templates

Jdf 1000 Colorado - The form emphasizes the importance of detailed disclosures in family law.

Dr Precipitation - List any other allergies that should be considered.

Renew Registration Pa - The total income reported must not exceed $19,200 to qualify for the fee reduction.