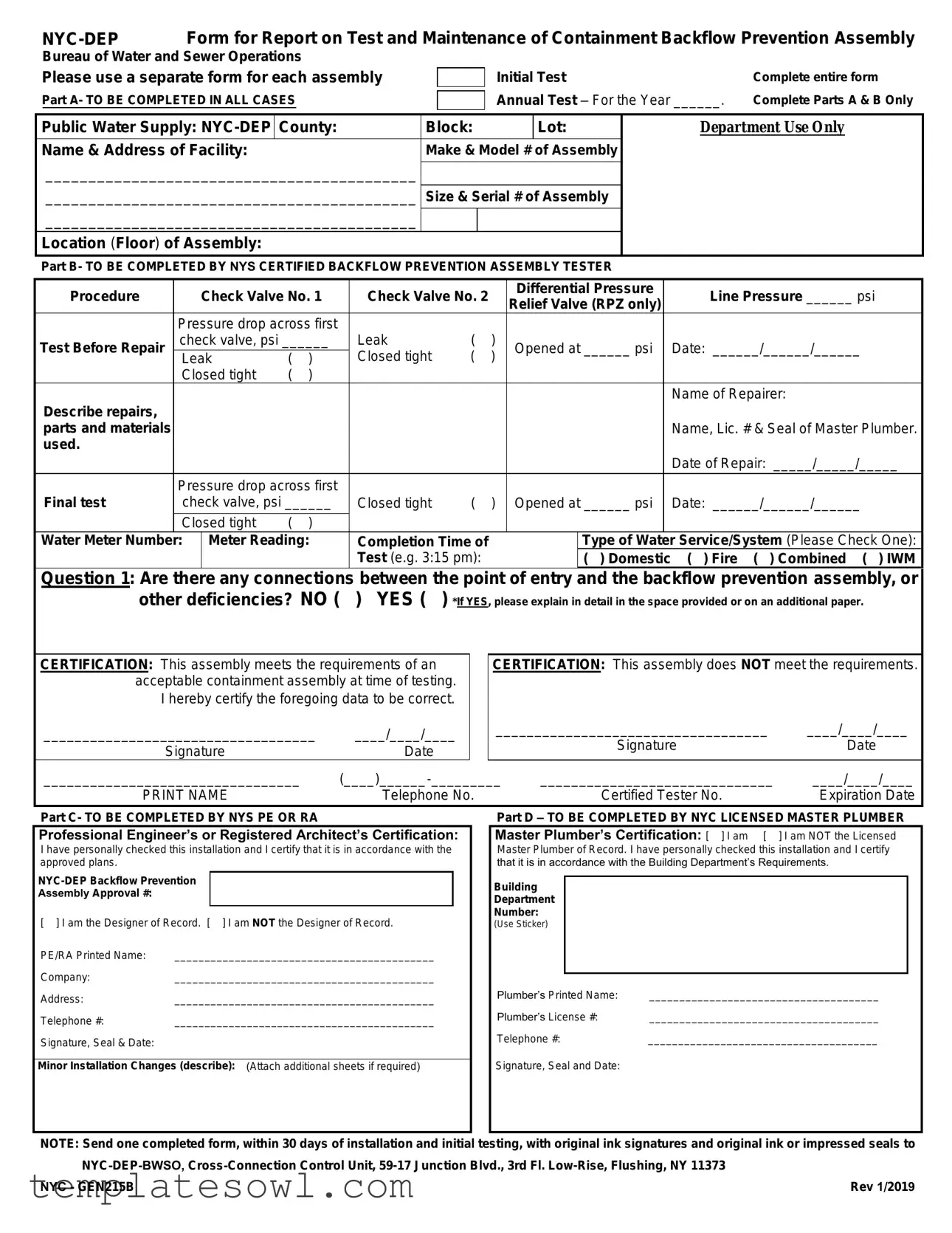

Fill Out Your Gen215B Form

The Gen215B form is a crucial document used for the reporting and maintenance of containment backflow prevention assemblies in New York City. This form serves multiple purposes, including the documentation of initial and annual tests of these assemblies. The reporting process requires detailed information about the specific assembly being tested, including its make, model, size, and location within the facility. For accurate assessments, it mandates input from various certified professionals, such as a New York State certified backflow prevention assembly tester, a licensed master plumber, and possibly a professional engineer or registered architect. These professionals must provide their certifications, signatures, and any necessary repairs or changes made during the testing process. In addition to the technical specifications, the form addresses key operational aspects, such as checking for any connections that might pose compliance issues and verifying the assembly's effectiveness at the time of testing. Timeliness is essential, as the completed form must be submitted to the New York City Department of Environmental Protection within 30 days of the initial installation and testing, ensuring compliance with city regulations.

Gen215B Example

Form for Report on Test and Maintenance of Containment Backflow Prevention Assembly |

Bureau of Water and Sewer Operations

Please use a separate form for each assembly

Part A- TO BE COMPLETED IN ALL CASES

Initial Test |

Complete entire form |

Annual Test – For the Year ______. |

Complete Parts A & B Only |

Public Water Supply: |

County: |

|

Block: |

|

|

Lot: |

|

|

Department Use Only |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Name & Address of Facility: |

|

|

|

Make & Model # of Assembly |

|

|

|

||||||||

___________________________________________ |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||||

___________________________________________ |

|

|

|

|

|

|

|

||||||||

Size & Serial # of Assembly |

|

|

|

||||||||||||

___________________________________________ |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Location (Floor) of Assembly: |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||||||

Part B- TO BE COMPLETED BY NYS CERTIFIED BACKFLOW PREVENTION ASSEMBLY TESTER |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Procedure |

|

Check Valve No. 1 |

Check Valve No. 2 |

|

Differential Pressure |

|

Line Pressure ______ psi |

||||||||

|

|

Relief Valve (RPZ only) |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Pressure drop across first |

|

|

|

|

|

|

|

|

|

|

|

|||

Test Before Repair |

check valve, psi ______ |

Leak |

( |

|

) |

Opened at ______ psi |

|

Date: ______/______/______ |

|||||||

|

|

|

|

Closed tight |

( |

|

) |

|

|||||||

Leak |

( |

) |

|

||||||||||||

|

|

|

|

|

|

|

|

||||||||

|

Closed tight |

( |

) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Name of Repairer: |

Describe repairs, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

parts and materials |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Name, Lic. # & Seal of Master Plumber. |

used. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Date of Repair: _____/_____/_____ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pressure drop across first |

|

|

|

|

|

|

|

|

|

|

|

|||

Final test |

check valve, psi ______ |

Closed tight |

( |

|

) |

Opened at ______ psi |

|

Date: ______/______/______ |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Closed tight |

( |

) |

|

|

|

|

|

|

|

|

|

|

|

|

Water Meter Number: |

Meter Reading: |

Completion Time of |

|

|

|

Type of Water Service/System (Please Check One): |

|||||||||

|

|

|

|

|

Test (e.g. 3:15 pm): |

|

|

|

( ) Domestic |

( ) Fire ( ) Combined ( ) IWM |

|||||

Question 1: Are there any connections between the point of entry and the backflow prevention assembly, or other deficiencies? NO ( ) YES ( )

CERTIFICATION: This assembly meets the requirements of an |

|

CERTIFICATION: This assembly does NOT meet the requirements. |

|||

acceptable containment assembly at time of testing. |

|

|

|

|

|

I hereby certify the foregoing data to be correct. |

|

|

|

|

|

___________________________________ |

____/____/____ |

|

___________________________________ |

____/____/____ |

|

|

|

Signature |

Date |

||

Signature |

Date |

|

|

||

|

|

|

|

||

_________________________________ |

______________________________ |

____/____/____ |

|||

PRINT NAME |

Telephone No. |

|

Certified Tester No. |

Expiration Date |

|

Part C- TO BE COMPLETED BY NYS PE OR RA

Professional Engineer’s or Registered Architect’s Certification:

I have personally checked this installation and I certify that it is in accordance with the approved plans.

Assembly Approval #:

[ ] I am the Designer of Record. [ ] I am NOT the Designer of Record.

PE/RA Printed Name: |

___________________________________________ |

Company: |

___________________________________________ |

Address: |

___________________________________________ |

Telephone #: |

___________________________________________ |

Signature, Seal & Date: |

|

Minor Installation Changes (describe): (Attach additional sheets if required)

Part D – TO BE COMPLETED BY NYC LICENSED MASTER PLUMBER

Master Plumber’s Certification: [ ] I am [ ] I am NOT the Licensed

Master Plumber of Record. I have personally checked this installation and I certify that it is in accordance with the Building Department’s Requirements.

Building

Department

Number:

(Use Sticker)

Plumber’s Printed Name: |

______________________________________ |

Plumber’s License #: |

______________________________________ |

Telephone #: |

______________________________________ |

Signature, Seal and Date: |

|

NOTE: Send one completed form, within 30 days of installation and initial testing, with original ink signatures and original ink or impressed seals to

NYC - GEN215B |

Rev 1/2019 |

INSTRUCTION FOR COMPLETION OF

“Report on Test and Maintenance of Containment Backflow Prevention Assembly”

(FORM GEN215B)

Use a separate form for each particular assembly

Indicate Initial Test or Annual Test by checking the appropriate choice.

Initial Test and Certification: Complete all 4 parts.

Annual

Please follow these tips to have the form completed:

Part A: To be completed in ALL cases for the current address, block and lot #s, the tested BFP assembly (make, model # in full, size and serial #) and actual location of the tested assembly (floor/level, vault, hot box) along with a specific location (meter/boiler/pump room, store, garage, etc.), if any.

Part B: NYS Certified Backflow Prevention Assembly Tester shall fill out this portion in ALL cases:

Include the line pressure (taken at number 1 test cock with shutoff valve number 1 closed).

Include the pressure drop across the first check valve (the pressure differential between the second and the third test cocks).

Include the condition of check valves # 1 and 2.

Describe repairs, parts and materials used, replacement of assembly and details of procedures. If any, complete final test.

Indicate the water meter # (8 digits) and reading.

Completion time of test refers to the time of day (e.g. 8:00 am) and test date.

Check actual type of the water service/system (Internal Water Main “IWM”).

Be sure to answer (check) Question 1. If the answer is “YES”, explain in the space provided. A connection for a properly installed and certified parallel assembly should not be construed as a connection. Hose cocks and spigots shall be considered as connections. Tees/ells shall be removed completely and hard pipe.

Then, clearlyprint, type or rubber stamp: Date, Name, Phone #, Certified Tester # and Certified Tester Expiration Date.

Part C: Complete for Initial Test Report only!

The NYS Licensed Professional Engineer or Registered Architect (PE/RA) shall complete Part C. Be sure to fill in the following:

The

Indicate whether being the designer of record or not.

Indicate minor changes, if any. Use back or additional pages as required. Indicate “See Back” or “See Additional Pages” as appropriate. If an equivalent make and model # of assembly is used, the PE or RA shall certify that the submission is acceptable and will not cause any adverse hydraulic effects on the water system. Also satisfy the submersion calculations (for RPZ/RPD assemblies only, if installed below grade level).

If the installation changes meet DEP requirements while deviating from the approved plans, the job shall be resubmitted for

When the installation deviates from the approved plans and minimum requirements are not satisfied, the job should NOT be certified.

Part D: NYC Licensed Master Plumber shall complete Part D. Be sure to fill in the following:

Indicate whether being the Licensed Master Plumber of record or not

The Department of Buildings Number (ARA #, ALT #, NB #, LAA #, etc.). Use of sticker is preferred.

Licensed Master Plumber’s Name.

Licensed Master Plumber’s License #.

Licensed Master Plumber’s Telephone Number.

Original Ink Signature, raised impression Seal of Licensed Master Plumber & Date.

Notes: The PE/ RA, Licensed Master Plumber & Certified Tester shall sign the same form for each particular assembly. For each completed form, USE ORIGINAL INK SIGNATURES & ORIGINAL INK OR RAISED IMPRESSION SEALS. Mail one completed form to: NYC-

Refer to “NEW YORK CITY

NYC - GEN215B |

Rev. 1/2019 | DCN: |

Form Characteristics

| Fact Name | Details |

|---|---|

| Purpose | The Gen215B form is used to report on the test and maintenance of containment backflow prevention assemblies for the NYC Department of Environmental Protection (NYC-DEP). |

| Completion Requirement | All sections of the form must be completed for the initial test, while only Parts A and B are required for annual tests. |

| Deadline for Submission | The completed form must be submitted to NYC-DEP within 30 days of installation and initial testing. It must include original signatures and seals. |

| Governing Law | This form is governed by the New York State laws regarding plumbing and water supply systems. |

Guidelines on Utilizing Gen215B

Completing the Gen215B form can seem daunting, but breaking it down into manageable steps can simplify the process. This form is essential for documenting the testing and maintenance of a backflow prevention assembly, ensuring the safety and integrity of water systems. Follow these steps closely to fill it out correctly.

- Start by indicating whether this is an Initial Test or an Annual Test by checking the appropriate box at the top of the form.

- Fill out Part A with the following information:

- Current address

- County, block, and lot numbers

- Name and address of the facility

- Make and model number of the assembly

- Size and serial number of the assembly

- Location (floor) of the assembly

- In Part B, the New York State Certified Backflow Prevention Assembly Tester should provide:

- Line pressure (taken with shutoff valve closed)

- Pressure drop across the first check valve

- Condition of check valves #1 and #2

- Details of any repairs made, including parts and materials used

- Date of the test

- Water meter number and reading

- Completion time of the test

- Type of water service system

- Address Question 1 in Part B. Indicate YES or NO for connections between the point of entry and backflow prevention assembly.

- In Part C, if applicable:

- Provide the NYC-DEP Backflow Prevention Assembly Approval number

- Indicate if you are the Designer of Record

- List any minor installation changes that were made

- In Part D, the Licensed Master Plumber should fill out:

- Indicate if they are the Licensed Master Plumber of Record

- Department of Buildings Number

- Name, license number, and telephone number of the Licensed Master Plumber

- Signature, raised impression seal, and date

- Verify that all required parties have signed and sealed the form using original ink.

- Make sure to send the completed form to the indicated address within 30 days of installation:

- NYC-DEP-BWSO

- Cross-Connection Control Unit

- 59-17 Junction Blvd., 3rd Fl. Low-Rise

- Flushing, NY 11373

Following these steps will help in successfully completing the Gen215B form. Pay attention to each section and ensure that all necessary information is accurately provided to facilitate the review process by the relevant authorities.

What You Should Know About This Form

What is the purpose of the Gen215B form?

The Gen215B form is a mandatory document for reporting the test and maintenance of containment backflow prevention assemblies. It ensures that backflow protection devices are properly tested and certified, thereby safeguarding the public water supply from contamination.

Who needs to fill out the Gen215B form?

The form must be completed by various professionals including the NYS Certified Backflow Prevention Assembly Tester, a Professional Engineer (PE) or Registered Architect (RA), and a NYC Licensed Master Plumber. Each role has specific sections of the form they are responsible for completing.

How do I know whether to complete an Initial Test or an Annual Test?

Select the appropriate option based on the situation. If this is the first time the backflow prevention assembly is being tested or installed, mark it as an Initial Test. After that, for subsequent years, use the Annual Test option. Remember to fill out all required parts accordingly.

What details should I include in Part A of the form?

In Part A, you should provide the NYS Department of Environmental Protection (DEP) information, including the public water supply, county, block, and lot numbers. Additionally, include the facility name and address, assembly make and model number, size, serial number, and location where the assembly is installed.

What specific information is needed from the Certified Tester?

The Certified Tester must report line pressure, pressure drop across check valves, and the condition of the valves. They should also detail any repairs made, parts replaced, and the water meter number with its reading. Accurate completion is crucial for the integrity of the test results.

Can I attach additional sheets to clarify my answers?

Yes, if there is not enough space on the form to provide complete information, you can attach additional sheets. Make sure to reference this in the main body of the form by stating "See Additional Pages" where necessary.

What happens if the assembly does not meet the required standards?

If the backflow prevention assembly does not meet the required standards, it must be clearly noted on the form. Subsequent remedial actions should be taken to ensure compliance, and a retest may be required to certify that the issues have been addressed.

Is there a deadline for submitting the completed form?

Yes, the completed Gen215B form must be submitted within 30 days of the installation and initial testing. Ensure that all signatures are in original ink to comply with submission standards.

Where do I send the completed Gen215B form?

The completed form should be mailed to the NYC-DEP's Bureau of Water and Sewer Operations. The address is Cross-Connection Control Unit, 59-17 Junction Boulevard, 3rd Fl. Low-Rise, Flushing, NY 11373-5108.

Common mistakes

Filling out the Gen215B form can seem straightforward, but many individuals make common mistakes that can lead to delays or rejections. One of the most frequent errors involves incomplete information. It's crucial to provide all requested details such as the make, model, size, and serial number of the assembly. Missing even one of these pieces of information can result in the form being returned for corrections, causing unnecessary frustration.

Another common mistake occurs when people fail to properly distinguish between an initial test and an annual test. The form requires specific sections to be filled out depending on the type of test being conducted. Confusion about which sections to complete can lead to confusion for both the submitter and the reviewing agency. Ensure to carefully review the instructions to determine which parts of the form apply to your situation.

Additionally, individuals frequently overlook the importance of including accurate pressure readings, particularly in Part B. Entries for values such as line pressure and pressure drop are critical. Inaccurate numbers can impede the assessment of the backflow prevention assembly's functionality. Take the time to double-check these figures before submitting the form.

Certification signatures present another area where mistakes can occur. It's vital that each section requiring certification is signed by the appropriate licensed professional. This includes the Professional Engineer, Registered Architect, and the NYC Licensed Master Plumber. Each must provide original ink signatures and seals. Missing signatures can halt the processing of the form.

Lastly, people often neglect to send in the form promptly. The submission must occur within 30 days of the initial testing and installation. Delays could result in penalties or other enforcement actions. Being proactive about submitting all parts of the form within the required timeline is essential to prevent complications down the line.

Documents used along the form

The Gen215B form is crucial for reporting on the testing and maintenance of containment backflow prevention assemblies. Several other documents often accompany this form to ensure comprehensive compliance and proper record-keeping. Below is a list of commonly used forms and documents that may be needed alongside the Gen215B form, along with brief descriptions of each.

- Installation Approval Application: Required to obtain permission before any backflow prevention assembly is installed, ensuring the planned installation meets local regulations.

- Inspection Report: This document details the findings from an inspection of the backflow prevention system, highlighting any issues that need attention.

- Maintenance Log: A record of all maintenance performed on the backflow prevention assembly, including dates, actions taken, and personnel involved.

- Testing Certification: This form is submitted by the licensed tester confirming that the backflow prevention assembly has passed all necessary tests.

- Repair Documentation: A record that outlines any repairs made to the backflow prevention assembly, including parts replaced and the repair technician's details.

- Compliance Confirmation Letter: A letter issued by regulatory bodies confirming that the backflow prevention assembly complies with all relevant standards and codes.

- Public Water Supply Letter: This document provides notification from local water authorities regarding the connection of the backflow prevention assembly to public water systems.

- Cross-Connection Survey: A survey that assesses potential cross-connections within a facility and ensures that backflow prevention measures are being properly implemented.

- Notification of System Changes: A form that reports any changes made to the water service or the backflow prevention assembly that could affect its operation.

- Annual Review Checklist: A checklist used during the annual review of the backflow prevention systems to ensure all requirements are met and documented.

Completing the required forms and submitting them in a timely manner is essential for compliance and safety. Each of these documents plays a role in maintaining the integrity of the water supply and protecting public health. Taking the necessary steps to gather and submit these forms will provide peace of mind and assurance that all regulations are being followed appropriately.

Similar forms

The Gen215B form is a critical document associated with the testing and maintenance of containment backflow prevention assemblies. Several forms present similarities in structure and purpose. Below, you will find a list of documents that share attributes with the Gen215B form, detailing how they are alike:

- Form 33-1234: Hazardous Waste Manifest - Like the Gen215B form, this document is designed to track the testing and inspection of systems. Both require detailed information about the system being evaluated, including identification numbers, specific locations, and signatures from certified professionals. Each form serves to ensure compliance with safety regulations.

- Form 12-3456: Water Quality Testing Report - This report also requires thorough documentation of tests conducted on water quality. Both forms demand certification from an authorized tester and provide space for recording readings, results, and any necessary repairs or comments on conditions that may affect safety.

- Form 45-6789: Backflow Prevention Assembly Approval - Similar to the Gen215B, this form is employed to obtain and document official approval for backflow assemblies. Both documents necessitate details about the assembly's specifications and certification by qualified engineers or plumbers.

- Form 78-9012: Plumbing Inspection Report - Both forms serve as official records of inspections related to plumbing safety. They require detailed descriptions of the assembly and outcomes of the inspections, ensuring compliance with municipal codes and safety measures.

- Form 56-7890: Fire Safety Inspection Certification - Much like the Gen215B form, this certification must be completed by a licensed professional. Both forms include similar sections for detailed technical information and for documenting any deficiencies observed during the inspection.

- Form 90-1234: HVAC System Inspection Report - This report shares the requirement of being filled out in detail by a certified inspector. Each document necessitates a finalization process that includes signatures and timestamps to verify that inspections have been duly completed.

- Form 01-2345: Facility Condition Assessment Report - Both forms assess the condition and compliance of installed systems. Each requires specific data collection and has sections dedicated to narrated findings and recommended follow-up actions or repairs, thereby ensuring the efficient management of safety standards.

These forms and the Gen215B form all aim to establish safety and compliance through rigorous assessment and documentation procedures. Their similarities reflect a shared commitment to maintaining high standards in public health and safety systems.

Dos and Don'ts

When filling out the Gen215B form, careful attention to detail is essential. Here are five important dos and don'ts to keep in mind.

- Do check off whether it is an Initial Test or an Annual Test at the start of the form.

- Do provide complete details about the Backflow Prevention Assembly, including make, model, size, and serial number.

- Do ensure that all signatures are in original ink. Use original ink or raised impression seals as required.

- Do indicate the specific location of the assembly thoroughly, mentioning floor and room type.

- Do answer question 1 accurately; if the answer is "YES," be prepared to explain any deficiencies.

- Don't forget to complete all relevant parts of the form for an Initial Test; include all required sections.

- Don't leave any sections blank; all parts of the form must be filled out to ensure acceptance.

- Don't substitute printed or stamped names for original signatures.

- Don't assume minor changes do not need to be reported; document any changes accurately.

- Don't delay in mailing the form; send it within 30 days of installation and initial testing to avoid penalties.

Misconceptions

- Misconception 1: Only one form is needed for multiple assemblies.

- Misconception 2: The form can be submitted without original signatures.

- Misconception 3: The Annual Test is the same as the Initial Test.

- Misconception 4: Minor installation changes do not need to be reported.

Each containment backflow prevention assembly requires its own Gen215B form. This means that if you have multiple assemblies, you will need to fill out a separate form for each one. This ensures that every assembly is properly documented and tested individually.

The Gen215B form must have original ink signatures and seals. This applies to the Licensed Master Plumber, the Certified Tester, and any involved Professional Engineers or Registered Architects. Electronic signatures or photocopies are not accepted.

While both tests are important, they require different completion processes. The Initial Test mandates filling out all four parts of the form, while the Annual Test only requires Parts A and B. Be sure to indicate which type of test you are submitting.

Even small changes to the installation must be documented on the form. If there are any alterations from the original approved plans, it is essential to describe these changes and complete any necessary certifications. Failing to do so could lead to compliance issues.

Key takeaways

Filling out and using the Gen215B form requires attention to detail and a clear understanding of the process. Here are some key takeaways to help ensure successful completion:

- Use Separate Forms: It is essential to complete a separate Gen215B form for each backflow prevention assembly. This organization helps maintain clarity and accuracy.

- Identify the Test Type: Clearly indicate whether the form is for an initial test or an annual test. Initial tests require completion of all four parts (A, B, C, and D), while annual tests only need Parts A and B.

- Accurate Information: Provide precise details about the facility, assembly make and model, size, serial number, and location. Inaccuracies can delay processing or lead to compliance issues.

- Signature Requirements: Ensure that all required signatures are original ink signatures. Include the certified tester, NYS licensed professional engineer or registered architect, and the licensed master plumber's signatures along with their respective seals.

Browse Other Templates

Credit Application Template for Business - Each vendor's phone number is essential for follow-up inquiries.

When Can I Loan in Sss - The loan application form must be printed in capital letters using black ink.