Fill Out Your Haccp Form

HACCP, or Hazard Analysis and Critical Control Points, plays a crucial role in ensuring food safety within food establishments. The HACCP form is a structured document that aids food business operators in identifying potential hazards that could compromise the safety of their products during various processes. Key components of the HACCP form include a Hazard Analysis Table, which outlines steps in the food preparation process and identifies potential chemical, physical, and biological hazards. This table helps determine whether certain hazards are significant, along with justifications for those decisions and the preventive measures to be implemented. Additionally, a ROP HACCP Plan Summary highlights critical control points (CCPs), detailing the hazards associated with each point, critical limits for control measures, and monitoring procedures to ensure compliance. Monitoring includes who is responsible, how often checks should be performed, and what corrective actions to take if deviations occur. Record-keeping is vital, with logs for refrigeration and freezers capturing essential temperature data, corrective actions, and worker verification. Finally, the thermometer calibration log ensures that the instruments used for monitoring temperatures remain accurate. All these components work together to create a comprehensive food safety system, fostering consumer trust and promoting public health.

Haccp Example

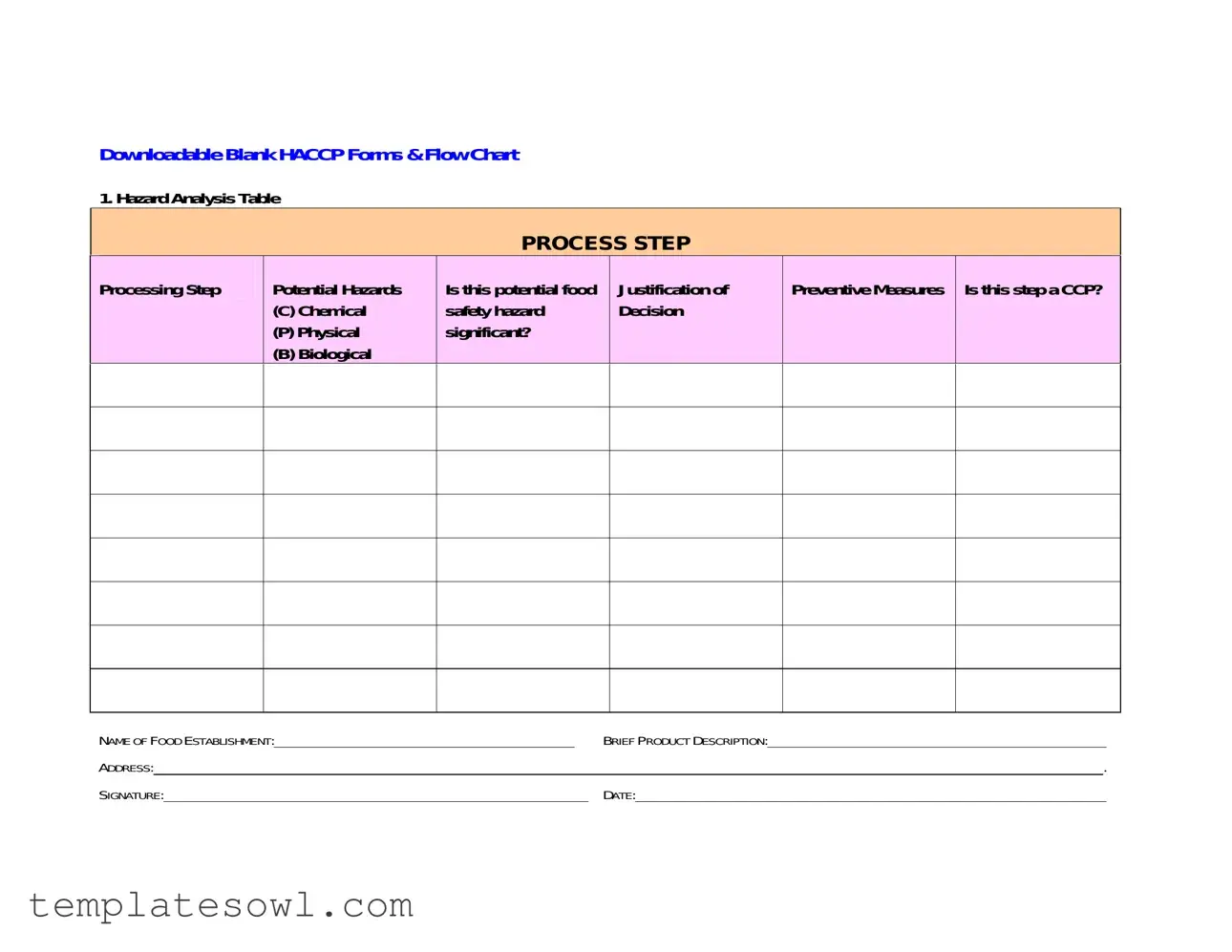

Downloadable Blank HACCP Forms & Flow Chart

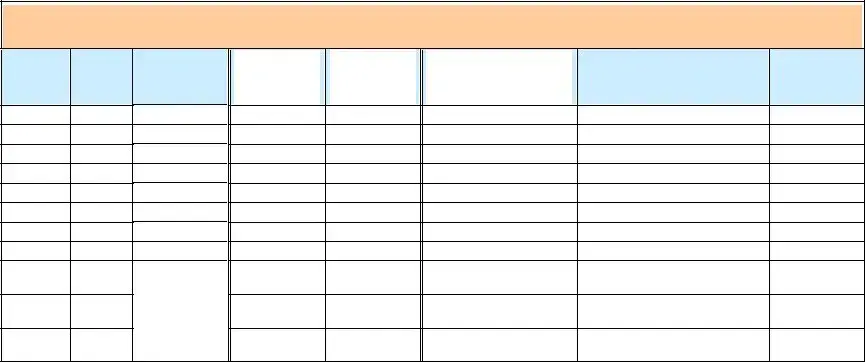

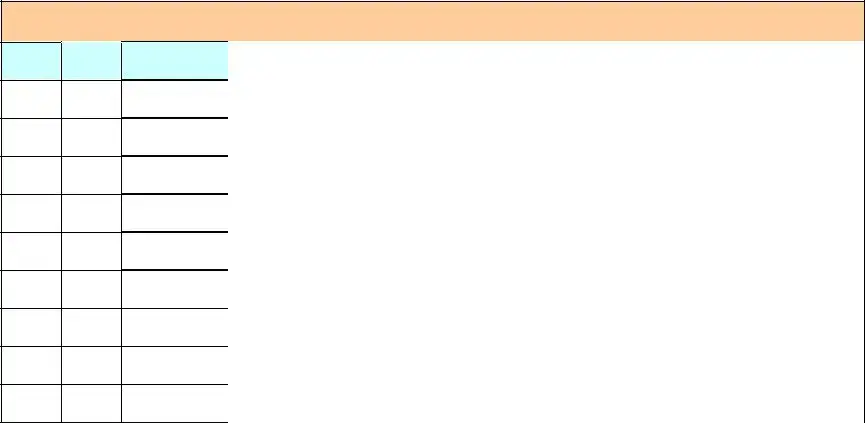

1. Hazard Analysis Table

PROCESS STEP

Processing Step

Potential Hazards

(C)Chemical

(P)Physical

(B)Biological

Is this potential food safety hazard significant?

Justification of Decision

Preventive Measures Is this step a CCP?

NAME OF FOOD ESTABLISHMENT: |

|

BRIEF PRODUCT DESCRIPTION: |

||||||

ADDRESS: |

|

|

|

|

. |

|||

SIGNATURE: |

|

|

DATE: |

|||||

|

|

|

|

|

|

|

|

|

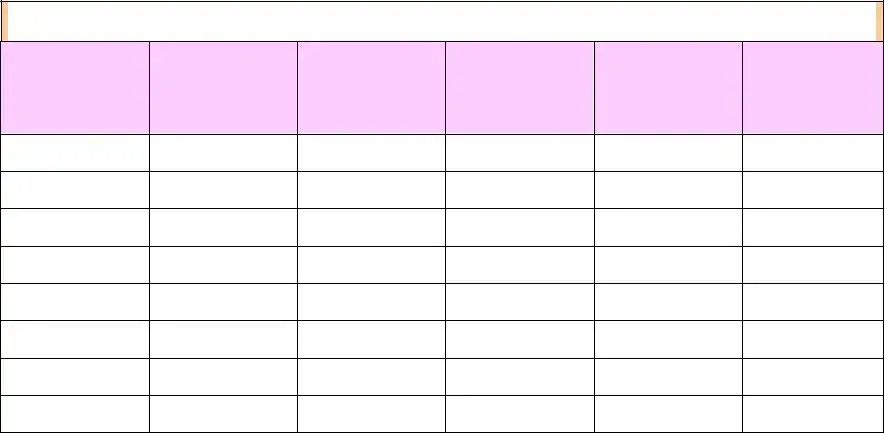

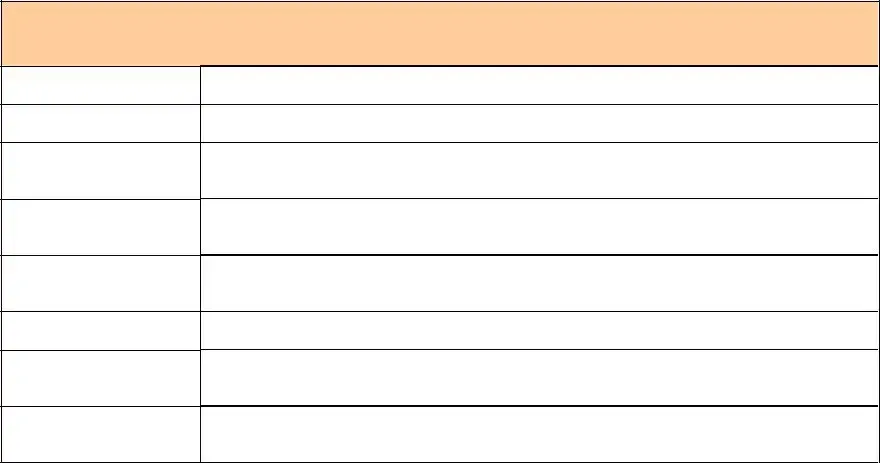

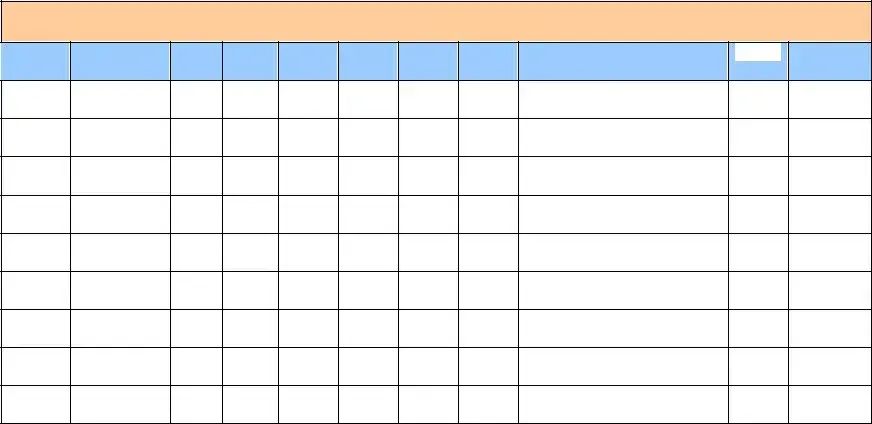

2.ROP HACCP Plan Summary

CCP

Critical Control Point (CCP)

Hazard

Description

Critical Limits

for each Control

Measure

Monitoring

What |

How |

Frequency |

Who |

|

|

|

|

|

|

|

|

Corrective Verification

Action Activities

Record- keeping Procedures

NAME OF FOOD ESTABLISHMENT: |

|

BRIEF PRODUCT DESCRIPTION: |

||||||

ADDRESS: |

|

|

|

|

. |

|||

SIGNATURE: |

|

|

DATE: |

|||||

|

|

|

|

|

|

|

|

|

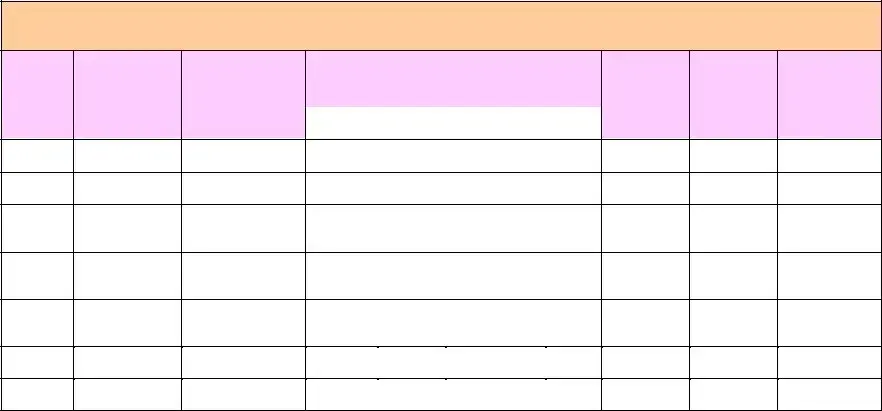

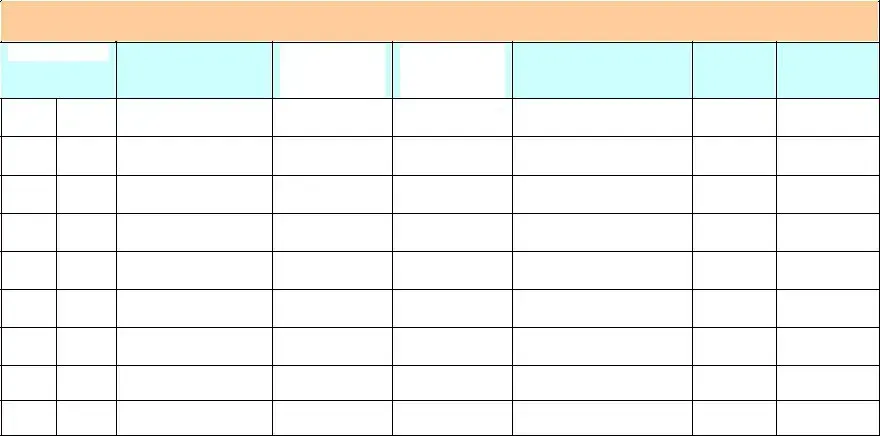

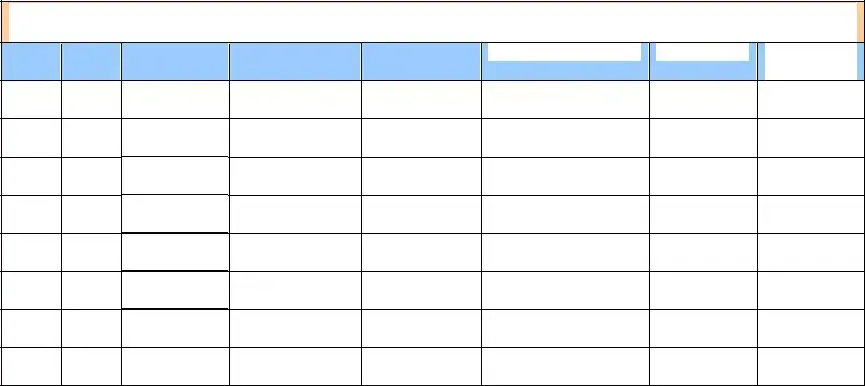

3. Refrigeration / Freezer Log

Refrigeration / Freezer Log

Location/

Unit Description

Date

Time

Temperature

Corrective Action

Food Worker

Initials

Manager

Initials / Date

Instructions: A designated foodservice employee will record the location or description of holding unit, date, time, air temperature, corrective action, and initials on this Log. The supervisor of the food operation will verify that foodservice workers have taken the required temperatures by visually monitoring food workers during the shift and reviewing, initialing, and dating this log daily. This log should be maintained for a minimum of 90 days after the food has been consumed.

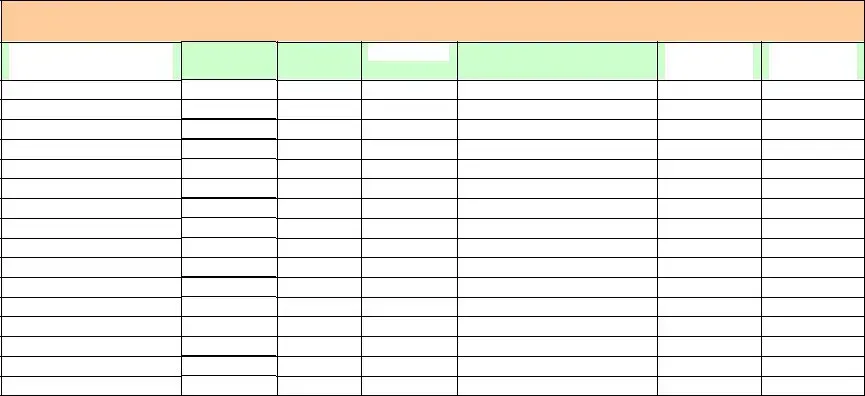

4. Thermometer Calibration Log

Thermometer Calibration Log

Date Time

Test Reference

Thermometer Thermometer

ID# Reading

Test

Thermometer

Reading

Adjustments Required

(Yes / No)

Corrective Action

Initials

Verification (Records Review) by and Date: ________________________________

Instructions: Foodservice workers will record the calibration temperature and corrective action taken each time thermometer is calibrated. The supervisor of the food operation will verify that foodservice employees are using and calibrating thermometers properly by making visual observations of employee activities during all hours of operation. The supervisor of the operation will review and initial the log daily. This log should be maintained for a minimum of 90 days after the food has been consumed.

Thermometers intended for measuring hot temperature items, such as cooked product, will be calibrated in hot water, while those used for taking lower temperatures will be calibrated in ice water. All thermometers will be calibrated within + or – 2 degrees F.

5. Corrective Action Log

Product:

Date / Time:

Deviation:

Cause of Deviation:

Cause of Deviation Eliminated By:

CCP Under Control After Corrective Actions Taken:

Preventative Measures:

Corrective Action Log

Lot ID:

Designated Food Worker:

Product Disposition:

Verification (Records Review) by and Date: |

________________________________ |

6. Cooking & Reheating Temperature Log

Cooking and Reheating Temperature Log

Date and Time

Food Item

Internal

Temperature /

Time

Internal

Temperature /

Time

Corrective Action Taken

Initials |

Verified By / Date

Instructions: Record product name, time, the two temperatures/times, and any corrective action taken on this form. The supervisor of the food operation will verify that food workers have taken the required cooking temperatures by visually monitoring food workers and preparation procedures during the shift and reviewing, initialing, and dating this log daily. This log should be maintained for a minimum of 90 days after the food has been consumed.

7. Holding Times & Temperatures

Holding Times and Temperatures

Date |

Food Item |

1st Measurement |

2nd Measurement |

Corrective Action |

||||

(e.g. enter holding) |

(e.g. exit holding) |

|||||||

|

|

Time |

Temp |

Initials |

Time |

Temp |

Initials |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Supervisory Employee’s Initials and Date: ______________________

Instructions: Take and record the temperature of the food when placed in holding units and when removed from holding units. If pans are moved directly from ovens to holding units, simply record the end cooking temperature on this form.

8. Receiving Log

Date |

Time |

Vendor |

|

|

or Supplier |

Receiving Log (Transporting)

Product Name |

Temperature (oF) |

Corrective Action Taken |

Initials/Date |

Manager |

|

|

|

|

Initials/Date |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Instructions: Use this Log for deliveries or receiving foods from suppliers. Record any temperatures and corrective action taken on the Receiving Log. The supervisor of the food operation will verify that foodservice workers are receiving products using the proper procedure by visually monitoring foodservice workers during the shift and reviewing the log daily. The Receiving log should be maintained for a minimum of 90 days after the food has been consumed.

9. Cooling Temperature Log

Cooling Temperature Log

Date

Food Item

Time / Temp

Time / |

Temp |

Time / Temp

Time / Temp

Time / Temp

Time / Temp

Corrective Actions Taken

Initials

Verified

By / Date

Instructions: Record temperatures every hour during the cooling cycle. Record corrective actions, if applicable. If no foods are cooled on any working day, indicate “No Foods Cooled” in the Food Item column. The supervisor of the food operation will verify that the designated food worker is cooling food properly by visually monitoring the food worker during the shift and reviewing, initialing, and dating the log daily. The Cooling Log should be kept for a minimum of 1 year.

10. Damaged or Discarded Product Log

Damaged or Discarded Product Log

Date |

Time |

Vendor |

|

|

or Supplier |

Product Name

Temperature

Corrective Action Taken

Initials/Date

Manager

Initials/Date

Instructions: Designated food worker will record product name, quantity, action taken, reason, initials, and date each time a food or food product is damaged and/or will be discarded. The supervisor the food operation will verify that food workers are discarding damaged food properly by visually monitoring foodservice workers during the shift and reviewing, initialing, and dating this log daily. The Damaged or Discarded Product Log should be. maintained for a minimum of 90 days after the food has been consumed.

Form Characteristics

| Fact Name | Fact Description |

|---|---|

| Purpose | The HACCP form is used to identify, evaluate, and control food safety hazards within food establishment processes. |

| Components | The form includes sections for hazard analysis, critical control points, refrigeration logs, and thermometer calibration logs. |

| Food Establishment Details | Each HACCP form requires basic information such as the name of the food establishment, a brief product description, and location. |

| Signatures and Dates | The form must include signatures and dates from designated food service employees to validate records and logs. |

| Monitoring Frequencies | Specific frequencies for monitoring critical control points must be indicated to ensure consistent safety practices. |

| Record Retention | Logs must be maintained for a minimum of 90 days after food has been consumed to ensure accountability and traceability. |

| Corrective Actions | Each section of the form includes a designated space for documenting corrective actions taken in response to any noted deviations. |

| State-Specific Regulations | Compliance with state-specific HACCP regulations may apply, and they vary by state. For instance, some states require adherence to the Food Code established by the FDA. |

| Temperature Monitoring | Temperature control is a key element of the HACCP form, especially noted in refrigeration/freezer logs and thermometer calibration logs. |

Guidelines on Utilizing Haccp

Filling out the HACCP form involves several steps to ensure comprehensive food safety planning. After gathering the necessary information, follow these clear steps to complete the form accurately.

- Download the HACCP Form: Access the blank HACCP form and save it on your device.

- Fill in Basic Information: Enter the name of your food establishment, a brief product description, and the address at the top of the form.

- Complete the Hazard Analysis Table: For each processing step:

- Identify potential hazards (chemical, physical, biological).

- Determine if the hazard is significant.

- Provide justification for your decision.

- List preventive measures.

- Indicate if this step is a Critical Control Point (CCP).

- Prepare the ROP HACCP Plan Summary: Document the CCP, hazard description, critical limits for control measures, monitoring procedures, correct actions, and verification activities.

- Set Up Refrigeration / Freezer Log: Record details about location, date, time, and temperature. Include corrective actions and initials of the food workers and manager.

- Fill Out Thermometer Calibration Log: Write down the date, time, test readings, and any required adjustments for each thermometer you calibrate.

- Document Corrective Action Log: Note down product details, date/time, cause of any deviations, and actions taken to resolve them.

After completing the form, review it for accuracy and ensure you have signed and dated it. It’s important to maintain these records for effective food safety management.

What You Should Know About This Form

What is the purpose of the HACCP form?

The HACCP form is designed to help food establishments identify and manage potential hazards that could affect food safety. It provides a structured approach to food safety management by documenting processes and preventive measures. Through completing the form, establishments can ensure that they systematically analyze each step of their food preparation process to maintain safety standards and comply with regulations.

What information is included in the hazard analysis table?

The hazard analysis table includes several key components. First, it lists the processing steps involved in food preparation. For each step, potential hazards such as chemical, physical, and biological threats are identified. The table prompts establishments to assess whether each potential hazard is significant. Justifications for decisions made regarding the hazards must also be included, along with preventive measures to address them. Finally, establishments mark whether each processing step is a critical control point (CCP).

How should a refrigeration/freezer log be maintained?

The refrigeration/freezer log must be maintained by a designated foodservice employee. This log records the location or description of the holding unit, the date, the time, and the air temperature at specified intervals. Corrective actions taken in response to temperature deviations should also be noted, along with the initials of the food worker. A supervisor must verify that workers are accurately taking temperatures by monitoring their activities, reviewing, initialing, and dating the log daily. Logs should be kept for at least 90 days after food consumption.

What is the procedure for maintaining a thermometer calibration log?

Foodservice workers are responsible for maintaining the thermometer calibration log. In this log, workers record the calibration temperature along with corrective actions taken each time a thermometer is calibrated. Supervisors must verify proper usage and calibration by observing employee activities continuously during operations. The supervisor will review and initial the log daily as well. Like other logs, this calibration log should be retained for a minimum of 90 days after food has been consumed, ensuring that the thermometers remain accurate for food safety.

What does the corrective action log document?

The corrective action log captures important information pertaining to issues found during food handling and safety practices. Each entry includes the product involved, the date and time of the deviation, the cause of the deviation, and how the issue was addressed. Additionally, the log requires documentation about whether the critical control point (CCP) was brought back under control following the corrective actions. Preventative measures and product disposition are also recorded, ensuring a thorough account of any actions taken to maintain food safety standards.

Common mistakes

Filling out the HACCP form is crucial for ensuring food safety, yet many individuals make avoidable mistakes. One common error is failing to identify potential hazards accurately. Hazards can be chemical, physical, or biological. If these are not clearly identified at each processing step, the entire risk assessment is compromised. It’s essential to take time to understand the specific risks associated with each step in your process.

Another frequent mistake is inadequate justification of the significance of hazards. Each identified hazard should be assessed to determine if it poses a significant risk to food safety. Many skip this step or provide insufficient reasoning, leading to gaps in the risk management strategy. Providing a thorough justification based on established food safety guidelines strengthens the overall plan.

A third mistake occurs during the selection of preventive measures. Often, individuals list preventive measures without considering their effectiveness or feasibility. It’s important to choose measures that are practical and can be implemented consistently. Engaging your entire team in this process can help ensure that everyone understands and can execute the measures outlined.

Identifying Critical Control Points (CCPs) can be another area where mistakes occur. Some users mistakenly label non-critical points as CCPs while overlooking actual critical points. This misstep can lead to significant food safety risks. Clarifying the criteria that make a point critical in your process is vital for accurately identifying each CCP.

Documentation errors are also common. Users may fail to maintain a record of monitoring activities and corrective actions. This oversight can hinder the traceability of food safety practices. Keeping thorough and accurate records is essential for compliance and for demonstrating that monitoring and corrective actions have been effectively implemented.

Overlooking the requirement for verification activities is another mistake made by many when completing the HACCP form. Verification helps ensure that the food safety plan operates as intended. Lacking proper verification can lead to false security regarding food safety protocols and potential hazards.

A seventh mistake involves the incomplete calibration of thermometers. Not documenting the calibration process accurately can lead to temperature discrepancies that can affect food safety. Following the proper calibration procedures and maintaining records is vital for ensuring that instruments provide accurate readings.

Lastly, some individuals do not review and update the HACCP plan regularly. It is essential to revisit the plan frequently to ensure it reflects current practices and identifies new hazards. Regular updates based on changing processes, ingredients, or equipment help ensure that food safety measures remain effective and compliant.

Documents used along the form

The HACCP (Hazard Analysis Critical Control Point) form is an essential tool for food safety management. It helps in identifying and mitigating potential hazards during food production. Along with the HACCP form, various other documents can play a crucial role in ensuring food safety practices are met consistently. Here’s a list of additional forms and documents that are often used in conjunction with the HACCP form:

- Hazard Analysis Table: This table outlines the various steps in the food processing operation. It identifies potential hazards—chemical, physical, or biological—and determines if they are significant. It also details preventive measures and identifies critical control points (CCPs).

- ROP HACCP Plan Summary: This document summarizes the critical control points in the ROP (Reduced Oxygen Packaging) process. It includes details on hazards, critical limits for control measures, monitoring methods, and corrective actions that might be required.

- Refrigeration / Freezer Log: This log tracks the temperature of refrigeration or freezer units. It includes fields for date, time, temperature readings, corrective actions taken, and initializations by food workers and managers to ensure compliance and safe food storage.

- Thermometer Calibration Log: This log records the calibration details of thermometers used in food service. It includes temperature readings and any necessary adjustments, ensuring thermometers accurately measure food temperatures.

- Corrective Action Log: Used to document deviations from the established food safety protocols, this log includes information on the cause of deviation, corrective actions taken, and verification steps to confirm that the food safety hazards are under control.

- Sanitation Standard Operating Procedures (SSOP): These procedures detail the cleaning and sanitizing processes necessary for food safety. The SSOP includes instructions for cleaning schedules, cleaning agents, and methods of verification.

- Food Safety Training Records: This document serves as a log of training sessions for food workers. It includes names of participants, dates of training, and topics covered, ensuring that staff are informed about food safety practices.

- Supplier Assurance Program: A system that ensures suppliers adhere to food safety standards. This document includes details on supplier certifications, audits, and any other compliance measures taken to verify food safety.

- Audit and Inspection Reports: These reports summarize findings from periodic inspections or audits of the food operation. The documents detail compliance with food safety practices and any areas needing improvement.

Using these documents alongside the HACCP form creates a comprehensive food safety management system. Together, they help mitigate risks, ensure compliance, and promote safe food handling practices across all operations.

Similar forms

- Food Safety Plan: Similar to the HACCP form, a Food Safety Plan outlines procedures to ensure food safety, addressing risks associated with food preparation and handling. It requires identifying potential hazards and establishing control measures.

- Sanitation Standard Operating Procedures (SSOP): SSOPs detail cleaning and sanitizing methods in food facilities. Like the HACCP form, they focus on maintaining a safe food environment and preventing contamination.

- Food Recall Plan: This plan spells out the steps to be taken in case of a food safety issue requiring a recall. Both documents emphasize the importance of risk management and quick response to protect the public.

- Temperature Log: A temperature log tracks the storage temperatures of food. This document, like the HACCP form's Refrigeration/Freezer Log, ensures food is kept at safe temperatures to prevent spoilage and contamination.

- Training Records: These records document employee training on food safety practices. Similar to the HACCP form, they emphasize accountability and the role of staff in maintaining safe food handling processes.

- Incident Report Form: This form documents any food safety incidents, like contamination or illness. Similar to the Corrective Action Log, it records deviations and corrective measures taken to prevent future occurrences.

- Supplier Compliance Records: These records verify that suppliers meet safety standards for food products. Like the HACCP form, they are part of the overall risk management strategy to ensure food safety from source to table.

- Allergen Control Plan: This document identifies and manages allergens in food products. Similar to the HACCP form, it aims to prevent cross-contamination, ensuring safe consumption for allergic individuals.

- Internal Audit Checklist: This checklist helps verify compliance with food safety standards. Similar to the monitoring procedures in HACCP, it ensures that all required practices are being followed.

- Quality Control Log: This log records observations and actions related to product quality. Similar to the Critical Control Points in the HACCP form, it focuses on maintaining high standards throughout the food production process.

Dos and Don'ts

When filling out the HACCP form, attention to detail is crucial. Here is a list of things to consider:

- Use clear and legible handwriting to ensure all information is readable.

- Double-check all entries for accuracy before submitting the form.

- Keep copies of completed forms for your records.

Misconceptions

Here are some common misconceptions about HACCP forms, along with clarifications for each.

-

HACCP forms are only necessary for large food establishments.

This is not true. All food businesses, regardless of size, benefit from a HACCP plan. Having one helps ensure food safety practices are followed consistently.

-

Completing the forms is a one-time task.

Many believe that once the forms are completed, there’s no need to revisit them. In reality, these forms require regular updates and monitoring to remain effective.

-

HACCP forms are overly complicated and unnecessary.

While they may seem complex at first glance, HACCP forms are designed to streamline food safety processes. Properly used, they enhance safety, not hinder it.

-

The forms are only for tracking temperatures.

This is a common misunderstanding. HACCP forms cover a wide range of food safety protocols, including hazard analysis and preventive measures.

-

Only supervisors need to fill out the HACCP forms.

In fact, all staff involved in food handling should know how to fill out these forms. Teamwork is crucial in maintaining food safety standards.

-

Once filled out, the forms don’t need verification.

Verification is essential! Regular reviews of completed forms help ensure that safety practices are being followed and that corrective actions taken are effective.

-

If there are no issues, the logs don’t need to be maintained.

It's a common belief that logs can be discarded if no problems occur. However, maintaining records for a minimum of 90 days provides a valuable safety history and can be crucial if questions arise later.

Key takeaways

Understanding how to properly fill out and use the HACCP form is essential for ensuring food safety in any establishment. Here are some key takeaways:

- Accurate Hazard Identification: Clearly identify potential hazards—chemical, physical, and biological—at each processing step. This step is crucial for determining if a hazard is significant.

- Critical Control Points: Determine which steps in the process are critical control points (CCPs) where hazards must be controlled to ensure food safety.

- Document Everything: Keep detailed records in the HACCP log for monitoring temperatures, corrective actions, and verification activities. Each entry should include pertinent information like date and time.

- Regular Calibration: Thermometers must be calibrated regularly to ensure accuracy. Record the calibration readings and any adjustments needed, as this step is vital for reliable temperature control.

- Corrective Actions: Outline corrective actions taken when deviations occur. Document the cause of the deviation and steps taken to regain control of the CCP.

- Retention of Records: Maintain all logs for a minimum of 90 days after the food has been consumed. This retention period supports compliance and helps track any potential issues.

By paying careful attention to these key points, food establishments can enhance their food safety practices and comply with HACCP requirements effectively.

Browse Other Templates

Template:l4jbryv0qsq= Autopsy Report - Indicates if family was present at the time of death.

Superior Authorization Form - Indicate the expected length of therapy for the requested medication.

Blind Person Eye - Ensures that all pertinent information is documented for review.