Fill Out Your Hot Work Permit Form

Before engaging in any hot work activities, understanding the Hot Work Permit form is crucial for maintaining safety and compliance in the workspace. Designed to mitigate risks associated with operations that involve open flames, heat, or sparks, this form encompasses essential procedures that every worker must adhere to. Activities such as welding, cutting, soldering, brazing, and even roof work using torches are classified under hot work and require prior approval. Key details like the date of the operation and job location must be filled in, ensuring everyone involved is on the same page. A thorough checklist of precautions confirms that necessary safety measures, such as availability of fire extinguishers and removal of flammable materials, are properly implemented. Additionally, monitoring of the area, including fire watch responsibilities, plays a crucial role in safeguarding against potential hazards. The completion of this form not only emphasizes the importance of preparation but also serves as a record of safety checks performed before, during, and after hot work operations, allowing for a proactive approach to workplace safety.

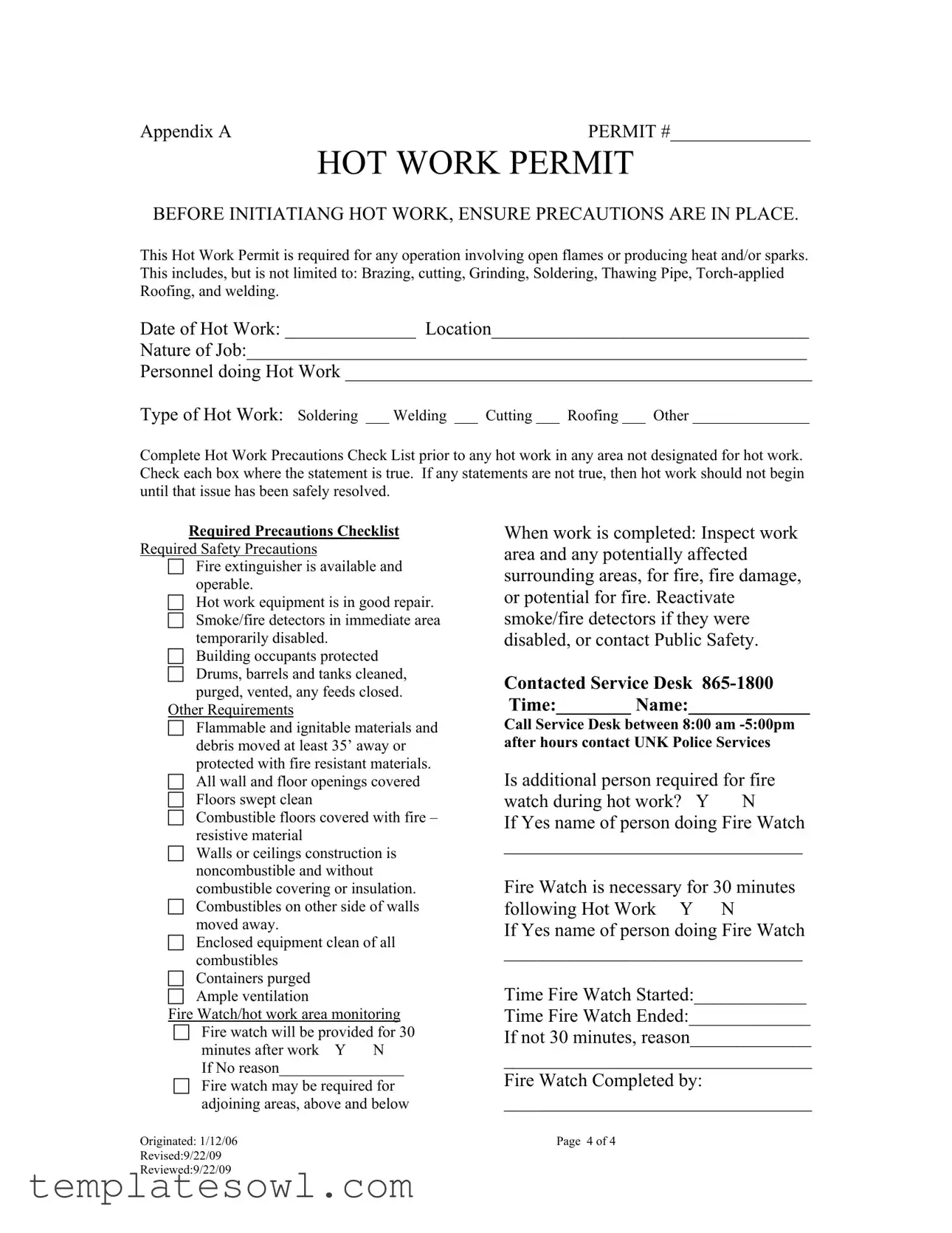

Hot Work Permit Example

Appendix A |

PERMIT #_______________ |

|

HOT WORK PERMIT |

BEFORE INITIATIANG HOT WORK, ENSURE PRECAUTIONS ARE IN PLACE.

This Hot Work Permit is required for any operation involving open flames or producing heat and/or sparks. This includes, but is not limited to: Brazing, cutting, Grinding, Soldering, Thawing Pipe,

Date of Hot Work: ______________ Location__________________________________

Nature of Job:____________________________________________________________

Personnel doing Hot Work __________________________________________________

Type of Hot Work: Soldering ___ Welding ___ Cutting ___ Roofing ___ Other _______________

Complete Hot Work Precautions Check List prior to any hot work in any area not designated for hot work. Check each box where the statement is true. If any statements are not true, then hot work should not begin until that issue has been safely resolved.

Required Precautions Checklist

Required Safety Precautions

Fire extinguisher is available and operable.

Hot work equipment is in good repair.

Smoke/fire detectors in immediate area temporarily disabled.

Building occupants protected

Drums, barrels and tanks cleaned,

purged, vented, any feeds closed. Other Requirements

Flammable and ignitable materials and debris moved at least 35’ away or protected with fire resistant materials.

All wall and floor openings covered

Floors swept clean

Combustible floors covered with fire – resistive material

Walls or ceilings construction is noncombustible and without combustible covering or insulation.

Combustibles on other side of walls moved away.

Enclosed equipment clean of all combustibles

Containers purged

Ample ventilation

Fire Watch/hot work area monitoring

Fire watch will be provided for 30

minutes after work Y N If No reason________________

Fire watch may be required for adjoining areas, above and below

Originated: 1/12/06

Revised:9/22/09

Reviewed:9/22/09

When work is completed: Inspect work area and any potentially affected surrounding areas, for fire, fire damage, or potential for fire. Reactivate smoke/fire detectors if they were disabled, or contact Public Safety.

Contacted Service Desk

Call Service Desk between 8:00 am

Is additional person required for fire watch during hot work? Y N

If Yes name of person doing Fire Watch

________________________________

Fire Watch is necessary for 30 minutes following Hot Work Y N

If Yes name of person doing Fire Watch

________________________________

Time Fire Watch Started:____________

Time Fire Watch Ended:_____________

If not 30 minutes, reason_____________

_________________________________

Fire Watch Completed by:

_________________________________

Page 4 of 4

Form Characteristics

| Fact Name | Fact Details |

|---|---|

| Purpose | The Hot Work Permit ensures that safety measures are in place before commencing tasks that involve open flames or produce heat and/or sparks. |

| Types of Work Covered | This permit is necessary for various activities, including welding, cutting, brazing, soldering, and torch-applied roofing, among others. |

| Required Precautions | Before starting, personnel must complete a Hot Work Precautions Check List, ensuring all safety measures are adhered to. |

| Fire Watch Requirement | A fire watch is mandatory for 30 minutes after completing hot work. This individual monitors the area for potential fire hazards. |

| State-Specific Regulations | In many states, hot work regulations are governed by OSHA standards and state fire codes, which may vary from one jurisdiction to another. |

| Emergency Contact | In case of emergencies, the designated Service Desk should be contacted, and the local police or fire services are available for after-hours issues. |

Guidelines on Utilizing Hot Work Permit

A Hot Work Permit form is essential for ensuring safety before beginning any task that involves flames or produces heat and sparks. Adhering to the guidelines and completing the form accurately will help mitigate risks in the work area.

- Enter the permit number at the top of the form.

- Fill in the date of the hot work.

- Specify the location where the hot work will take place.

- Describe the nature of the job in detail.

- List the names of personnel who will be performing the hot work.

- Select the type of hot work being done by marking the appropriate box. Options include Soldering, Welding, Cutting, Roofing, or Other.

- Complete the Hot Work Precautions Checklist by checking each box next to the required statements that are true. Ensure that there are no unchecked boxes for items that must be completed prior to starting work.

- Provide the necessary details regarding fire watch and monitoring. Indicate if a fire watch will be provided for 30 minutes after work and, if no, provide a reason.

- If additional fire watch personnel are needed, enter the name and provide start and end times for the fire watch.

- Upon completing the hot work, inspect the work area and surrounding areas for any potential fire hazards. Reactivate smoke/fire detectors if previously disabled and contact Public Safety.

- Finally, complete the section for the fire watch, noting who performed it and confirming whether it lasted for the required 30 minutes.

Once the form is fully filled out, it's crucial to ensure that all precautions are observed to maintain safety during and after the hot work process. Immediate compliance can prevent potential incidents and protect everyone involved.

What You Should Know About This Form

What is a Hot Work Permit?

A Hot Work Permit is a formal document required before starting any activity that involves open flames or creates heat and sparks. This includes processes like welding, cutting, and more. It serves to ensure that necessary safety precautions are taken to prevent fires and related hazards.

When do I need to obtain a Hot Work Permit?

A Hot Work Permit is necessary any time you're engaging in activities that produce heat or sparks in areas not designated for hot work. Whether it’s performing maintenance or construction tasks that involve brazing, soldering, or grinding, obtaining the permit is essential for safety compliance.

What types of hot work require a permit?

Various activities necessitate a Hot Work Permit. These include but are not limited to: welding, cutting, grinding, soldering, thawing pipes, and torch-applied roofing. Whenever your work involves the risk of creating sparks or open flames, you should secure a permit.

What precautions must be checked before starting hot work?

Before commencing any hot work, you must complete the Required Precautions Checklist. This checklist includes verifying that a fire extinguisher is available and functional, ensuring hot work equipment is in good condition, and confirming that flammable materials are moved a safe distance away. If any precaution is not met, the work cannot begin until the issue is resolved.

Is a fire watch required during hot work?

Yes, a fire watch is typically required during hot work and for 30 minutes after the work is completed. The individual assigned to the fire watch is responsible for monitoring the area for any signs of fire and ensuring that safety protocols are followed. Make sure to document the time the fire watch starts and ends.

What should I do if I discover a fire or potential fire hazard?

If a fire or potential fire hazard is discovered after completing your work, it is crucial to inspect both the work area and any surrounding areas for fire risks. Reactivate fire safety systems like smoke detectors if they were turned off during the job. If there's immediate danger, contacting Public Safety is vital.

Can I disable smoke detectors during hot work?

While it may be necessary to temporarily disable smoke or fire detectors in the immediate area to prevent false alarms, this should be done with caution. It is essential to reactivate these systems immediately after the work is finished or notify Public Safety to ensure overall safety.

What should I include in the Hot Work Permit application?

Your Hot Work Permit application should detail the date of the hot work, the specific location where the work is taking place, the nature of the job, and the name of personnel conducting the work. Also include the type of hot work being performed and ensure that all safety precautions are checked off.

How can I contact support if I have questions about the Hot Work Permit?

If you have questions regarding the Hot Work Permit, you can contact the Service Desk at 865-1800 between 8:00 am and 5:00 pm. For any concerns after hours, reaching out to UNK Police Services is recommended for immediate assistance.

Common mistakes

Filling out the Hot Work Permit form accurately is essential to ensure safety during operations involving open flames or sparks. One common mistake occurs when individuals fail to specify the location accurately. Not providing a clear and specific location can lead to confusion and increase the risk of accidents, as different areas may have different safety considerations.

Another frequent error involves not checking the required precautions checklist thoroughly. Skipping this step can overlook critical safety measures, such as ensuring that fire extinguishers are available and operable. Without proper checks, not all safety hazards may be addressed, potentially endangering personnel and property.

People also sometimes neglect to indicate the type of hot work being performed. Failing to select the relevant category—such as welding, cutting, or soldering—can create ambiguity about the specific risks involved. This oversight can complicate the implementation of appropriate safety precautions tailored to the nature of the work.

Moreover, there is often confusion surrounding the duties of the fire watch. Individuals may not indicate whether a fire watch is required or fail to provide the name of the person assigned to this critical role. A clear designation of responsibility helps ensure that someone is monitoring the work area for potential fire hazards, which is vital for overall safety.

Another mistake involves the timing of initiating the fire watch. Individuals might either start the fire watch too late or not complete it for the required 30 minutes after the hot work is finished. Documenting the start and end times accurately is essential for compliance with safety regulations and to ensure the area remains monitored.

Lastly, there is a possibility of not reactivating smoke or fire detectors after the hot work is completed. Failing to reactivate these systems can leave a facility vulnerable to undetected fires. Proper follow-up is crucial, as it restores safety measures that protect both personnel and property.

Documents used along the form

When engaging in hot work activities, it is essential to ensure safety measures are not only planned but meticulously documented. Various forms and documents complement the Hot Work Permit form to promote the highest safety standards. Below are some common documents used alongside the Hot Work Permit:

- Job Safety Analysis (JSA): This document outlines potential hazards associated with specific tasks. It encourages workers to identify risks before beginning a job and determine the appropriate safety measures to mitigate those risks.

- Safety Data Sheet (SDS): Whenever hazardous materials are involved, an SDS must accompany them. This form provides detailed information about the properties of a substance, its hazards, and precautions needed for safe handling.

- Fire Watch Log: A record of observations by designated personnel during and after hot work. It documents the fire watch's activities and any unusual occurrences, ensuring accountability and awareness during potentially dangerous tasks.

- Pre-Work Safety Checklist: This is a quick reference for workers to confirm all safety measures have been put in place before commencing any job. It ensures that the necessary equipment, fire protection measures, and personal protective equipment (PPE) are ready.

- Incident Report Form: Should an incident occur during hot work, this form captures critical details about the event. It becomes a vital tool for follow-up investigations and developing strategies to prevent similar occurrences in the future.

Familiarity with these documents can significantly enhance safety practices when conducting hot work. Ensuring that all precautions are documented and followed can minimize risks and protect both personnel and property.

Similar forms

Understanding the importance of safety in environments where hot work is conducted is crucial. The Hot Work Permit is one important document, but it shares similarities with several other forms that aim to ensure a safe work environment. Here are six documents that are similar to the Hot Work Permit, along with explanations of their connections.

- Lockout/Tagout (LOTO) Permit: Just like the Hot Work Permit, the LOTO permit ensures that machines and equipment are properly shut off and not able to be started up again prior to the completion of maintenance or servicing. Both permits prioritize safety by preventing accidental activation during hazardous work.

- Confined Space Entry Permit: This document is essential before entering a confined space, ensuring that all safety measures are in place to protect workers. Similar to the Hot Work Permit, it requires a thorough checklist of precautions to mitigate risks associated with limited space and potential hazards.

- Excavation Permit: Before digging into the ground, an excavation permit is required to assess the potential dangers, such as underground utilities or unstable soil. This is akin to the Hot Work Permit in that it identifies hazards and requires safety checks to prevent accidents.

- Worksite Hazard Assessment: Conducting a hazard assessment before starting any job is vital. This document identifies risks in the work environment, similar to how the Hot Work Permit requires a checklist of safety precautions specific to hot work activities.

- Electrical Safety Permit: Before working on electrical systems, this permit ensures that safety protocols are established to prevent electrical hazards. Like the Hot Work Permit, it involves verifying that safe conditions are met to protect workers from dangers associated with their tasks.

- Fire Safety Plan: This comprehensive plan outlines measures and responses to potential fire hazards in a workplace. Just as the Hot Work Permit requires fire safety precautions before initiating hot work, a fire safety plan sets the groundwork for preventing and responding to fire-related incidents.

These documents underscore the significance of maintaining safe practices across various hazardous activities. Each serves a critical role in promoting safety and ensuring that everyone goes home safe at the end of the day.

Dos and Don'ts

When filling out the Hot Work Permit form, it is vital to ensure accuracy and adherence to safety measures. Follow these guidelines to make the process smooth and effective.

- Do carefully read the entire form before beginning to fill it out.

- Do provide clear and specific information regarding the nature of the job.

- Do check each item on the required precautions checklist rigorously.

- Do ensure the personnel performing the hot work are properly trained and equipped.

- Do include an adequate description of the work area and any special conditions.

- Don't ignore any unaddressed safety concerns highlighted in the checklist.

- Don't attempt to proceed with hot work unless all precautions are confirmed as true.

- Don't leave the work area unattended until the fire watch duties are completed.

- Don't forget to reactivate smoke/fire detectors after the work is finished.

By adhering to these do's and don'ts, you can help ensure a safer working environment for everyone involved.

Misconceptions

There are several common misconceptions about the Hot Work Permit form that can lead to confusion and potential safety hazards. Understanding these misconceptions is crucial to ensuring a safe working environment. Here is a breakdown of five prevalent misunderstandings:

-

A Hot Work Permit is only needed for welding.

This is not true. While welding does require a permit, the Hot Work Permit is necessary for any operation that involves open flames or creates heat and sparks. This includes activities such as brazing, cutting, grinding, soldering, thawing pipes, and torch-applied roofing, among others.

-

The provided checklist is optional.

The checklist included in the Hot Work Permit is essential. Before any hot work begins, every item must be checked off to confirm safety precautions are in place. If any precautions cannot be met, hot work must not commence until those issues are addressed.

-

All hot work can be performed anywhere.

This misconception can be dangerous. Hot work may only occur in designated areas or with appropriate protective measures in place. Areas where hot work is performed must be cleared of flammable materials or adequately protected using fire-resistant materials.

-

Once the hot work is finished, there’s no need for monitoring.

Some may believe that after completing hot work, it’s safe to walk away. However, a fire watch must be maintained for at least 30 minutes after the work is completed to monitor for any smoldering embers or potential flare-ups in the area.

-

The responsibility for safety lies solely with the supervisor.

This is a misconception that can lead to lapses in safety. While supervisors play a crucial role, every personnel involved in hot work must take responsibility for following safety protocols. It requires teamwork to ensure compliance with the Hot Work Permit stipulations.

By dispelling these misconceptions, companies can foster a safer working environment and comply with necessary safety regulations. Always prioritize communication and thorough understanding when it comes to safety procedures.

Key takeaways

Here are some key takeaways on how to fill out and use the Hot Work Permit form effectively:

- Understand the Necessity: The Hot Work Permit is essential for any tasks involving flames or heat-producing activities. This includes welding, cutting, grinding, and more. Be clear on the nature of the job you are undertaking.

- Complete Precautions Checklist: Before starting any hot work, ensure that all precautions have been checked off. This includes verifying that fire extinguishers are operable and that the area is cleared of flammable materials.

- Assign a Fire Watch: A fire watch is required during and for at least 30 minutes after hot work is completed. Determine if an additional person is needed and document their information clearly on the permit.

- Post-Work Inspection: After finishing the hot work, inspect the area thoroughly for signs of fire or damage. Reactivate any disabled fire detectors and report your findings to ensure safety protocols are upheld.

Browse Other Templates

Pds Form 2023 Editable - Adjustment or modifications for any errors discovered.

Coca Cola Fundraiser - Help fuel your team's performance through this fundraiser.

Perio Charts - Charts help visualize conditions to enhance understanding and discussion.