Fill Out Your Hvac Inspection Checklist Form

When it comes to maintaining a healthy and comfortable indoor environment, regular HVAC inspections play a crucial role. An effective HVAC Inspection Checklist is a valuable tool that assists technicians in evaluating different components of the heating, ventilation, and air conditioning system. This comprehensive form covers various aspects, such as the condition of major mechanical equipment, air handling units, and distribution systems. It emphasizes the importance of preventive maintenance, ensuring that elements like boilers, chillers, and cooling towers operate efficiently. The checklist also takes into account the overall cleanliness of the mechanical room and the presence of potentially harmful odors or contaminants. Furthermore, it addresses indoor air quality by assessing ventilation systems and their proper functioning, including filters and humidistats. By documenting essential information like equipment conditions, maintenance schedules, and potential problem areas, this checklist helps create a systematic approach to HVAC management, ensuring a safe and efficient system while promoting optimal indoor air quality.

Hvac Inspection Checklist Example

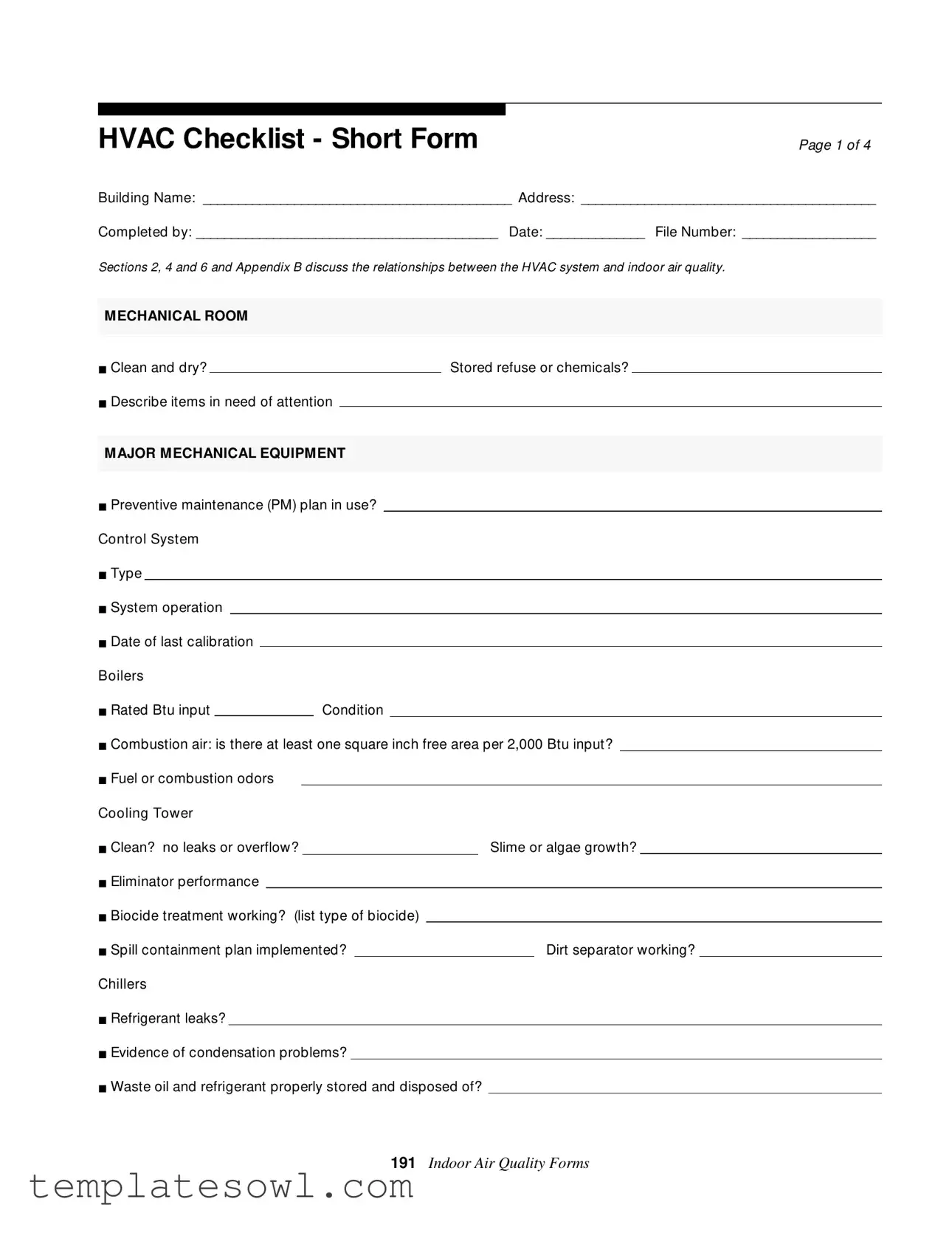

HVAC CHECKLIST - SHORT FORM

Page 1 of 4

Building Name: ____________________________________________ Address: __________________________________________

Completed by: ___________________________________________ Date: ______________ File Number: ___________________

Sections 2, 4 and 6 and Appendix B discuss the relationships between the HVAC system and indoor air quality.

MECHANICAL ROOM

■ Clean and dry? |

|

Stored refuse or chemicals? |

■Describe items in need of attention

MAJOR MECHANICAL EQUIPMENT

■Preventive maintenance (PM) plan in use? Control System

■Type

■System operation

■Date of last calibration

Boilers

■ Rated Btu input |

|

Condition |

■Combustion air: is there at least one square inch free area per 2,000 Btu input?

■Fuel or combustion odors

Cooling Tower

■ Clean? no leaks or overflow? |

|

Slime or algae growth? |

■Eliminator performance

■Biocide treatment working? (list type of biocide)

■ Spill containment plan implemented? |

|

Dirt separator working? |

Chillers

■Refrigerant leaks?

■Evidence of condensation problems?

■Waste oil and refrigerant properly stored and disposed of?

191Indoor Air Quality Forms

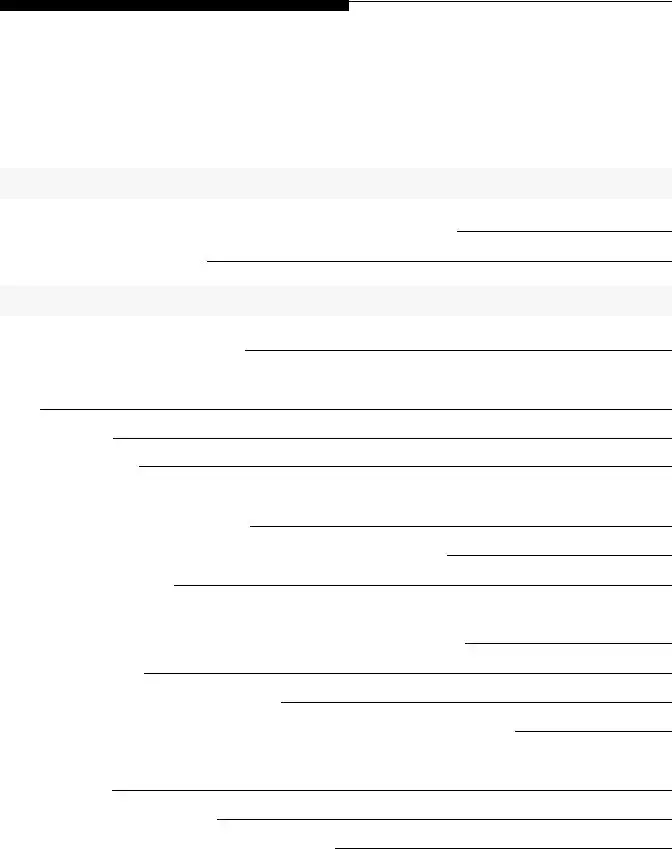

HVAC CHECKLIST - SHORT FORM

Page 2 of 4

Building Name: ____________________________________________ Address: __________________________________________

Completed by: ___________________________________________ Date: ______________ File Number: ___________________

AIR HANDLING UNIT

■ Unit identification |

|

Area served |

Outdoor Air Intake, Mixing Plenum, and Damper

■Outdoor air intake location

■Nearby contaminant sources? (describe)

■Bird screen in place and unobstructed?

■ Design total cfm |

|

outdoor air (O.A.) cfm |

|

date last tested and balanced |

|

|

|

|||

■ Minimum % O.A. (damper setting) |

|

Minimum cfm O.A. |

(total cfm x minimum % O.A.) |

|

= |

|

||||

|

|

|

|

|||||||

|

|

|

|

|

|

|

100 |

|

|

|

■Current O.A. damper setting (date, time, and HVAC operating mode)

■Damper control sequence (describe)

■Condition of dampers and controls (note date)

Fans

■ Control sequence

■ Condition (note date)

■ Indicated temperatures |

supply air |

|

mixed air |

|

return air |

|

outdoor air |

|

|

|||||||||||

■ Actual temperatures |

supply air |

mixed air |

return air |

|

outdoor air |

|

|

|||||||||||||

Coils |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

■ Heating fluid discharge temperature |

|

|

|

|

ΔT |

|

cooling fluid discharge temperature |

ΔT |

||||||||||||

■ Controls (describe) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

■ Condition (note date) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Humidifier |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

■ Type |

|

|

|

if biocide is used, note type |

|

|

|

|

|

|

|

|

||||||||

■Condition (no overflow, drains trapped, all nozzles working?)

■No slime, visible growth, or mineral deposits?

Indoor Air Quality Forms 192

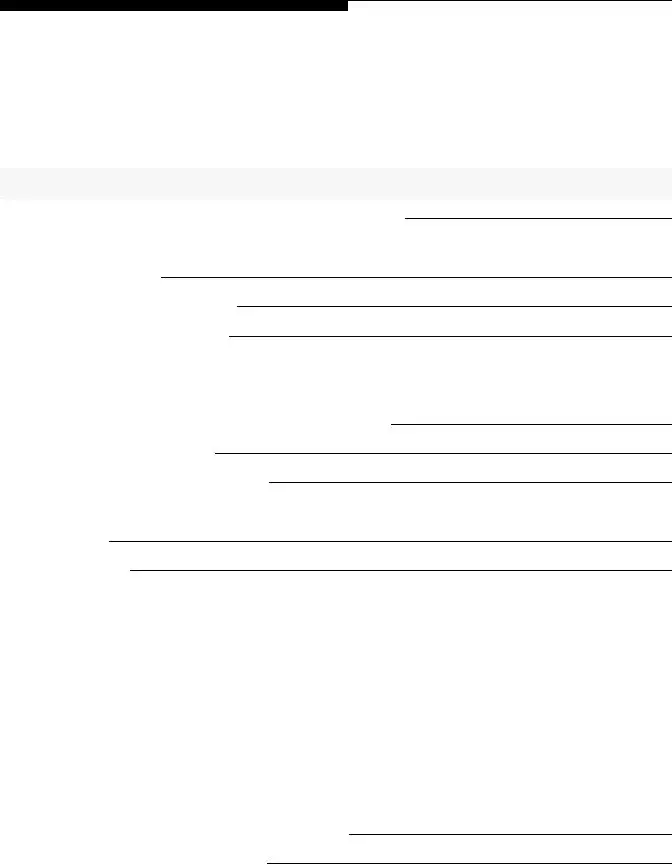

HVAC CHECKLIST - SHORT FORM

Page 3 of 4

Building Name: ____________________________________________ Address: __________________________________________

Completed by: ___________________________________________ Date: ______________ File Number: ___________________

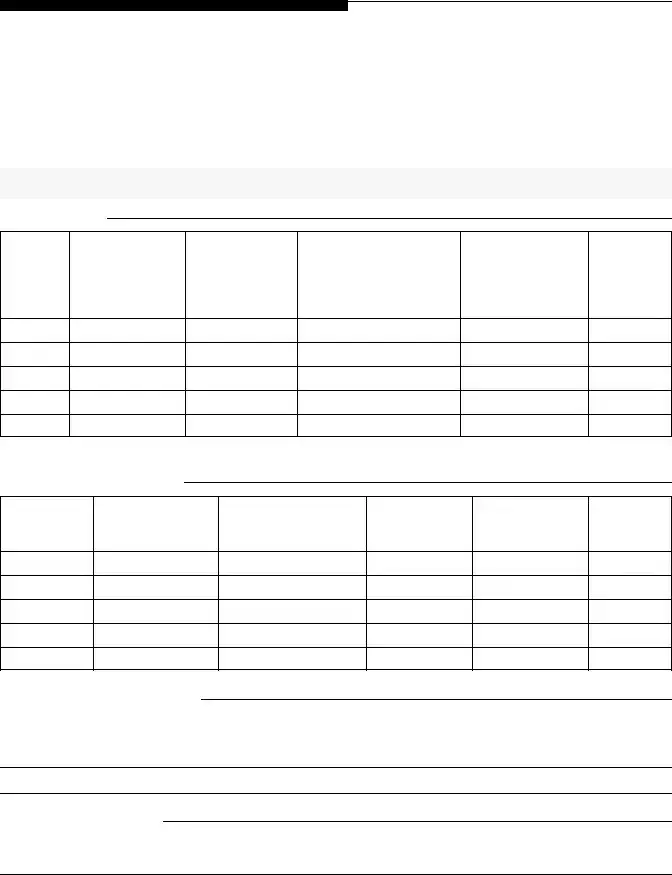

DISTRIBUTION SYSTEM

Zone/ Room

System

Type

Supply Air |

Return Air |

|

Power Exhaust |

|

|||

|

|

|

|

|

|

|

|

ducted/ |

cfm* |

ducted/ |

cfm* |

cfm* |

|

control |

serves |

unducted |

|

unducted |

|

|

|

|

(e.g. toilet) |

|

|

|

|

|

|

|

|

Condition of distribution system and terminal equipment (note locations of problems)

■Adequate access for maintenance?

■Ducts and coils clean and obstructed?

■ Air paths unobstructed? |

supply |

|

return |

|

transfer |

|

exhaust |

|

|

|

|

|

|

■Note locations of blocked air paths, diffusers, or grilles

■Any unintentional openings into plenums?

■Controls operating properly?

■Air volume correct?

■Drain pans clean? Any visible growth or odors?

FILTERS

Location

Type/Rating

Size

Date Last Changed

Condition (give date)

193Indoor Air Quality Forms

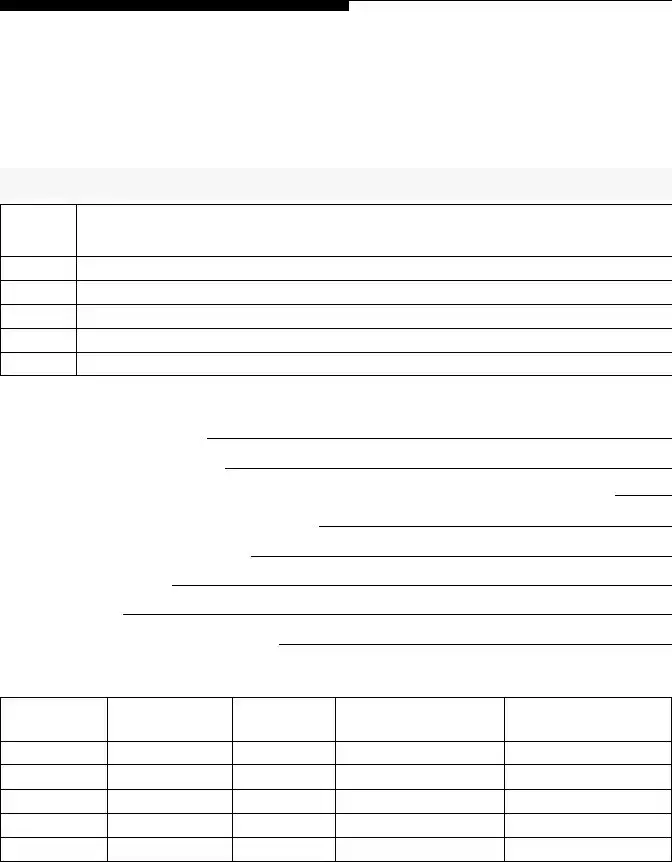

HVAC CHECKLIST - SHORT FORM

Page 4 of 4

Building Name: ____________________________________________ Address: __________________________________________

Completed by: ___________________________________________ Date: ______________ File Number: ___________________

OCCUPIED SPACE

Thermostat types

Zone/ Room

Thermostat Location

What Does Thermostat Control? (e.g., radiator, AHU- 3)

Setpoints

Summer |

Winter |

|

|

Measured Temperature

Day/ Time

Humidistats/Dehumidistats type

Zone/ Room

Humidistat/

Dehumidistat

Location

What Does It

Control?

Setpoints

(% RH)

Measured Temperature

Day/ Time

■Potential problems (note location)

■Thermal comfort or air circulation (drafts, obstructed airflow, stagnant air, overcrowding, poor thermostat location)

■Malfunctioning equipment

■Major sources of odors or contaminants (e.g., poor sanitation, incompatible uses of space)

Indoor Air Quality Forms 194

Form Characteristics

| Fact Name | Description |

|---|---|

| Purpose of Checklist | The HVAC Inspection Checklist is used to assess the condition and effectiveness of heating, ventilation, and air conditioning systems to ensure they meet safety and performance standards. |

| Governing Law | In many states, HVAC inspections must comply with local building codes and regulations that dictate indoor air quality standards. |

| Mechanical Room Criteria | Inspection includes assessing if the mechanical room is clean, dry, and free of stored refuse or chemicals, promoting safety and functionality. |

| Preventive Maintenance | A preventive maintenance plan should be in place for major mechanical equipment to ensure longevity and performance. |

| Cooling Tower Assessment | The checklist requires inspection for cleanliness, leaks, and proper functioning of biocide treatments to manage algae and slime growth. |

| Indoor Air Quality Relationship | Sections 2, 4, and 6, along with Appendix B, discuss how HVAC system performance directly affects indoor air quality, underscoring its importance. |

| Thermostat and Humidity Controls | The checklist evaluates thermostat types and humidity controls, ensuring they function properly and are set to appropriate levels for occupant comfort. |

Guidelines on Utilizing Hvac Inspection Checklist

Completing the HVAC Inspection Checklist requires attention to detail and a clear understanding of the various components of the system. Follow these steps to ensure all necessary information is accurately recorded.

- Begin by entering the Building Name, Address, and the name of the person Completed by. Fill in the Date and File Number at the top of the form.

- For the Mechanical Room section, check if the area is clean and dry. Note any stored refuse or chemicals and describe any items that need attention.

- In the Major Mechanical Equipment section, indicate if a preventive maintenance plan is in use. Specify the type of control system and its operation. Include the date of the last calibration.

- Fill out the details for Boilers, including the rated BTU input and conditions concerning combustion air and any fuel or combustion odors.

- Review the Cooling Tower details, checking for cleanliness, leaks, slime or algae growth. Confirm the performance of eliminators and the effectiveness of biocide treatment.

- Check Chillers for refrigerant leaks, condensation problems, and the proper storage of waste oil and refrigerant.

- In the Air Handling Unit section, provide the unit identification and area served. Note the location of outdoor air intake and any nearby contaminant sources, ensuring that the bird screen is unobstructed.

- Record the design total CFM for outdoor air, minimum settings, and current damper settings, noting any sequences for operation.

- Evaluate the condition of fans and their control sequences, indicating temperatures for supply, mixed, return, and outdoor air.

- Document the condition of coils, including temperature discharge, and details about humidification systems present, ensuring there are no overflow issues or visible growths in the humidifier.

- Under the Distribution System, specify the zone or room, the system type, and airflow amounts. Assess the condition of the distribution system and note any maintenance access or cleanliness issues.

- Update the Filters section with the location, type, size, date last changed, and the condition of filters.

- In the Occupied Space section, identify thermostat types and their locations. Document setpoints for summer and winter and record measured temperatures.

- Finally, note any potential problems regarding thermal comfort or major sources of odors or contaminants.

What You Should Know About This Form

What is the purpose of the HVAC Inspection Checklist?

The HVAC Inspection Checklist serves as a comprehensive tool to assess the overall condition and performance of heating, ventilation, and air conditioning systems. It identifies essential components that contribute to indoor air quality and the efficiency of the HVAC system. By following this checklist, inspectors can ensure that maintenance procedures are followed, identify potential issues early, and ensure compliance with safety and health standards.

What key components are included in the inspection?

The checklist examines several critical areas within the HVAC system. It covers the mechanical room, major mechanical equipment such as boilers and chillers, air handling units, the distribution system, and filters. Specific attention is given to cleanliness, operational conditions, and potential hazards. Inspectors must analyze airflow paths, control systems, and the presence of any contaminants, ensuring all elements work harmoniously to promote a safe indoor environment.

How often should the HVAC Inspection Checklist be completed?

Who is responsible for completing the HVAC Inspection Checklist?

The HVAC Inspection Checklist should be completed by qualified personnel with a robust understanding of HVAC systems and indoor air quality principles. This may include HVAC technicians, building engineers, or trained maintenance staff. Their expertise ensures a thorough examination and allows for proper documentation of findings, which can be critical for referencing and regulatory compliance.

What should be done if issues are identified during the inspection?

If any issues arise during the inspection, they must be documented clearly. It is crucial to prioritize these findings based on severity, and immediate corrective actions should be taken, especially in areas affecting health and safety. Depending on the nature of the problem, repairs may require consultation with specialized HVAC professionals. Follow-up inspections should be planned to verify the successful resolution of identified issues and to reassess system performance.

Common mistakes

When filling out the HVAC Inspection Checklist form, several common mistakes can lead to incomplete or inaccurate information. These oversights can ultimately affect the quality of the inspection and the performance of the HVAC system.

One frequent error is failing to specify locations clearly. For instance, when asking for the building name and address, some may simply write “office” instead of providing the complete details. Without this information, it becomes challenging to track inspections or follow up on issues.

Another mistake involves overlooking specific measurements, such as the total cubic feet per minute (cfm) for outdoor air intake. The checklist requests these specifics to ensure the system is effectively circulating air. Missing or improperly recorded values can lead to unsafe air quality or inefficient operation.

Sometimes, individuals complete the checklist without adequately addressing the condition of equipment. When noting issues, simply stating, “it’s fine” can be misleading. Instead, it’s important to describe both the current condition and any maintenance actions that are needed. Detailed notes ensure that maintenance staff have a clear understanding of what needs attention.

Additionally, respondents may neglect to indicate dates for the last calibration or maintenance checks. Keeping track of these dates is crucial for compliance with safety standards and ensuring that equipment operates efficiently. Without this information, it can be difficult to track maintenance schedules and verify that the HVAC system is working optimally.

Lastly, a common pitfall is not reviewing the entire form for completeness before submission. Skipping sections that may seem less important or assuming that others will fill in the gaps can lead to significant delays or complications later on. Always double-checking the form ensures that every necessary detail has been captured, allowing for a comprehensive inspection.

Documents used along the form

The HVAC Inspection Checklist form serves as a critical guide for ensuring that HVAC systems function efficiently and maintain good indoor air quality. In addition to this checklist, several other documents may be used to support the inspection process. These documents help in tracking maintenance schedules, noting issues, and ensuring compliance with regulations. Here’s a list of commonly used forms and documents that often accompany the HVAC Inspection Checklist.

- Maintenance Log: This document records all maintenance activities performed on the HVAC system, including dates, services completed, and any observations made during the servicing.

- Service Agreement: This is a contract between the building management and a service provider outlining the terms and conditions for routine inspections and repairs of the HVAC system.

- Indoor Air Quality Assessment: This form documents the evaluation of air quality within the building, measuring factors such as pollutants, temperature, and humidity levels.

- Energy Efficiency Report: This report analyzes the energy consumption of the HVAC system and suggests improvements to enhance efficiency and reduce costs.

- Equipment Warranty Documentation: This document details the warranties for HVAC equipment, specifying coverage periods and conditions for repairs or replacements.

- Filter Change Schedule: This schedule outlines when air filters should be replaced, helping to maintain optimal air quality and system performance.

- Compliance Checklists: These checklists ensure that HVAC systems adhere to local, state, and federal regulations regarding safety and environmental impact.

- System Specifications Manual: This manual contains detailed specifications for the HVAC system, including manufacturer details, installation procedures, and maintenance guidelines.

- Incident Report Form: This document is used to report any significant issues detected during inspections, such as system failures or safety hazards.

Utilizing these documents alongside the HVAC Inspection Checklist can lead to better management of HVAC systems, ensuring they operate efficiently and safely. Together, they form a comprehensive framework that supports proactive maintenance and regulatory compliance in any facility.

Similar forms

The HVAC Inspection Checklist form shares similarities with several other key documents used in the field of building management and maintenance. Below is a list highlighting these related documents and how they align with the HVAC checklist:

- Building Maintenance Checklist: Like the HVAC checklist, a building maintenance checklist surveys specific areas and systems, ensuring the facility remains in good repair and complies with safety standards.

- Indoor Air Quality Assessment Form: This form focuses on evaluating air quality factors that the HVAC checklist also addresses, such as contaminants and humidity levels to ensure a healthy environment.

- Service and Repair Log: Similar to the HVAC form, this log documents maintenance actions taken. It helps ensure that any issues identified in the inspection are properly addressed over time.

- Energy Audit Report: While the HVAC checklist inspects system components, an energy audit evaluates system efficiency, revealing potential energy-saving upgrades that can improve performance.

- Safety Inspection Checklist: This document, like the HVAC checklist, details safety concerns and procedural checks, ensuring that all systems are not just functioning but also safe for occupancy.

- Preventive Maintenance Plan: Both the preventive maintenance plan and the HVAC form focus on routine checks and best practices. They help in scheduling regular reviews to keep systems operating efficiently.

Dos and Don'ts

When filling out the HVAC Inspection Checklist form, take care to follow these guidelines for a thorough and accurate submission. Here’s what you should and shouldn’t do:

- Do: Ensure all sections are fully completed before submission.

- Do: Report any observed issues clearly and in detail.

- Do: Use the correct terminology when describing equipment and issues.

- Do: Double-check all measurements and settings for accuracy.

- Do: Maintain a clean and organized working environment while conducting the inspection.

- Don't: Skip any questions, even if you feel there are no issues.

- Don't: Use vague language; precision matters.

- Don't: Ignore prior maintenance records; they can provide valuable insights.

- Don't: Overlook the safety considerations while inspecting equipment.

By adhering to these practices, you will contribute significantly to the efficiency and safety of the HVAC system.

Misconceptions

There are several misconceptions surrounding the HVAC Inspection Checklist form that can lead to confusion and improper utilization. Below are some common misconceptions, along with clarifications to help users understand the checklist's purpose better.

- This form is only for commercial buildings. Many people believe that HVAC checklists apply only to commercial spaces. In reality, residential properties can benefit from inspections as well.

- Completion of the checklist is optional. Some think that using this form is a suggestion rather than a necessity. In truth, thorough inspections help maintain system efficiency and safety.

- All HVAC systems are the same. While many HVAC systems serve the same purpose, each system has unique components. The checklist accounts for these differences to ensure nothing is overlooked.

- Once an inspection is done, the checklist is no longer useful. It’s a common myth that the checklist only serves for the moment of inspection. In fact, it can be a valuable resource for future inspections and maintenance planning.

- The checklist can be completed by anyone. Some may assume that the form can be filled out by anyone with minimal knowledge. However, trained professionals should conduct HVAC inspections to ensure accuracy and safety.

- Environmental factors don't matter for HVAC systems. Many people overlook the impact of external factors such as humidity and pollution. The checklist emphasizes the importance of accounting for these conditions in maintaining indoor air quality.

- The checklist guarantees the HVAC system will work perfectly. It’s a misconception that completing the checklist alone ensures full system functionality. The form identifies areas of concern but does not assure a failure-free system.

- Indoor air quality is not a priority. Some users believe the checklist focuses solely on the mechanical aspects of HVAC systems. In fact, several sections address indoor air quality, making it a critical component of the inspection.

- Regular maintenance isn't necessary. Many assume once the system is inspected, they can forgo regular maintenance. Consistent checks and upkeep are crucial for an efficient HVAC system and longevity.

- The form is too complicated to understand. Although the checklist contains technical details, it is designed to be user-friendly. Simplified descriptions and clear sections help users follow along easily.

Understanding these misconceptions about the HVAC Inspection Checklist can significantly enhance the effectiveness of building maintenance and improve indoor air quality for occupants.

Key takeaways

The HVAC Inspection Checklist form is an important tool for ensuring that heating, ventilation, and air conditioning systems are operating correctly. Here are some key takeaways about filling out and using this form:

- Use the checklist to document every part of the HVAC system, from the mechanical room to the air handling units.

- Always include the building name, address, and the name of the person completing the checklist to maintain accurate records.

- Check the condition of major mechanical equipment and ensure a preventive maintenance plan is in place.

- Pay special attention to indoor air quality; Sections 2, 4, and 6 provide important insights into this aspect.

- Note any signs of leaks or unusual odors, as these can indicate potential issues with the system.

- Document the condition of filters and specify when they were last changed to ensure good air quality.

- Inspect outside air intakes for contamination sources and verify that dampers are functioning properly.

- Regularly evaluate the thermal comfort levels within occupied spaces, documenting any temperature inconsistencies.

- Be thorough when describing items that need attention; accurate descriptions will help in addressing issues effectively.

Browse Other Templates

How Long Do Credits Last for College - Transcripts sent via fax are considered unofficial.

Verification of Employment - For second mortgages, the applicant may hand-carry the verification forms to their employers.