Fill Out Your Job Hazard Analysis Form

The Job Hazard Analysis (JHA) form serves as a crucial tool in promoting workplace safety by systematically evaluating tasks to identify potential hazards. This form encompasses several key components essential for effective analysis. Initially, it requires a breakdown of the job into a sequence of basic steps, allowing for a clear understanding of each major task involved. Following this step, it emphasizes the identification of potential hazards associated with every task segment, urging users to consider all sources of energy and environmental factors that may contribute to risks. Lastly, the form prompts users to recommend procedures aimed at eliminating or minimizing these hazards, thereby safeguarding employees from accidents, injuries, or occupational illnesses. By thoroughly documenting these elements, the JHA form not only helps organizations comply with safety regulations but also cultivates a proactive approach to hazard prevention in the workplace.

Job Hazard Analysis Example

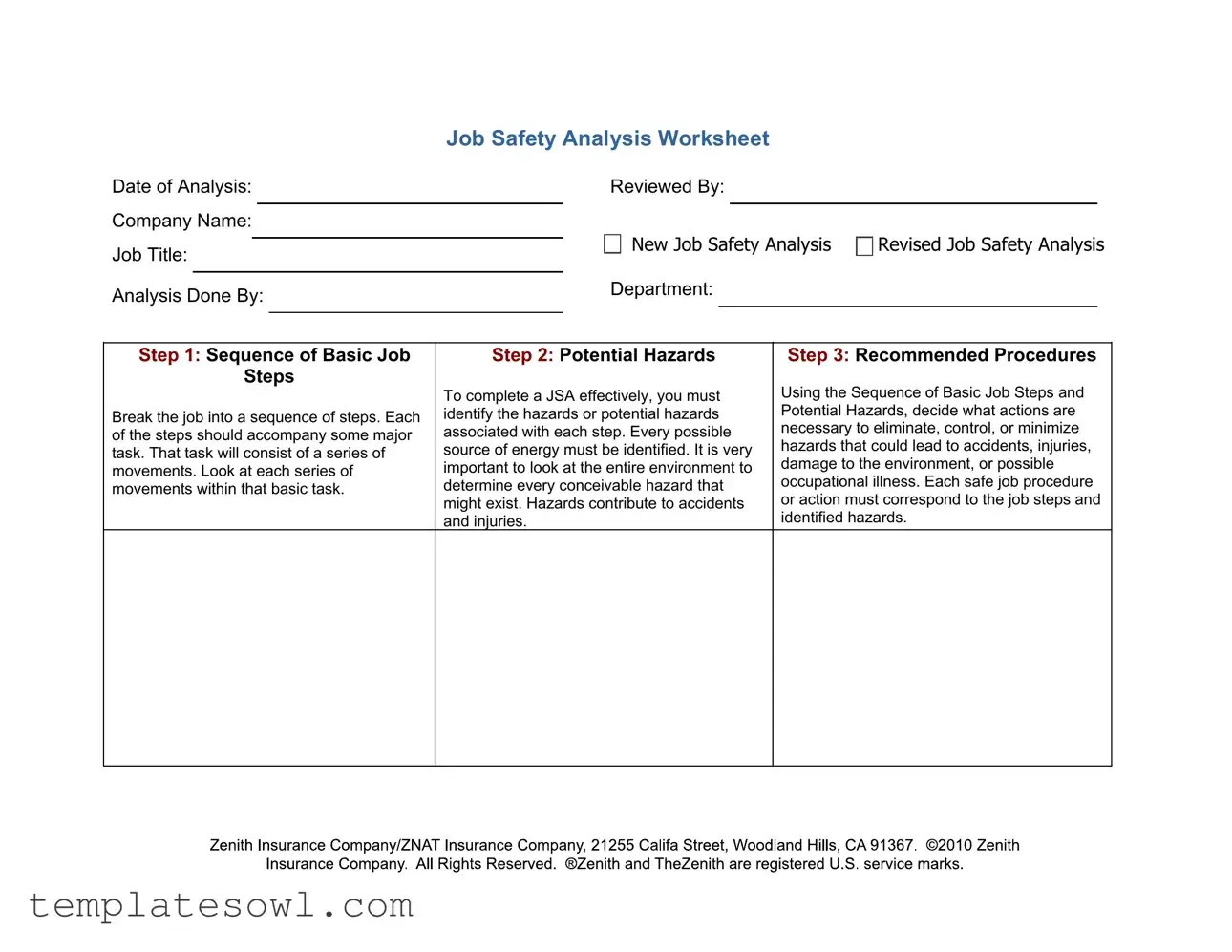

Job Safety Analysis Worksheet

Date of Analysis: |

|

Reviewed By: |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Company Name: |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

New Job Safety Analysis |

|

Revised Job Safety Analysis |

|||

|

|

|

|

|

|

|

|

|||||

Job Title: |

|

|

|

|||||||||

|

Department: |

|

|

|

||||||||

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

||||

Analysis Done By: |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Step 1: Sequence of Basic Job

Steps

Break the job into a sequence of steps. Each of the steps should accompany some major task. That task will consist of a series of movements. Look at each series of movements within that basic task.

Step 2: Potential Hazards

To complete a JSA effectively, you must identify the hazards or potential hazards associated with each step. Every possible source of energy must be identified. It is very important to look at the entire environment to determine every conceivable hazard that might exist. Hazards contribute to accidents and injuries.

Step 3: Recommended Procedures

Using the Sequence of Basic Job Steps and Potential Hazards, decide what actions are necessary to eliminate, control, or minimize hazards that could lead to accidents, injuries, damage to the environment, or possible occupational illness. Each safe job procedure or action must correspond to the job steps and identified hazards.

Job Safety Analysis Worksheet

Step 1: Sequence of Basic Job Steps |

Step 2: Potential Hazards |

Step 3: Recommended Procedures |

CONTINUED… |

CONTINUED… |

CONTINUED… |

|

|

|

Form Characteristics

| Fact Name | Details |

|---|---|

| Purpose | The Job Hazard Analysis (JHA) form is designed to assess potential hazards associated with job tasks to enhance workplace safety. |

| Process Steps | The JHA involves three main steps: identifying the sequence of job steps, recognizing potential hazards, and recommending procedures to mitigate those hazards. |

| Legal Requirement | In many states, such as California, employers are mandated by the Occupational Safety and Health Administration (OSHA) to conduct hazard assessments under specific workplace safety regulations. |

| Documentation | The JHA form includes sections for documentation such as the date of analysis, reviewed by, company name, job title, department, and the person conducting the analysis. |

Guidelines on Utilizing Job Hazard Analysis

Filling out the Job Hazard Analysis form is an important step in ensuring workplace safety. This structured approach will help in identifying potential hazards and recommending procedures to create a safer environment. Follow the steps carefully for each specific job being analyzed.

- Date of Analysis: Write the date when the analysis is conducted.

- Reviewed By: Indicate the name or position of the person reviewing the analysis.

- Company Name: Provide the name of the company conducting the analysis.

- Job Title: Specify the title of the job being analyzed.

- Department: Enter the department where the job is performed.

- Analysis Done By: Write the name or position of the person completing the analysis.

- Step 1: Sequence of Basic Job Steps: Break the job down into logical steps. List each major task that requires a series of movements.

- Step 2: Potential Hazards: For each step identified, identify potential hazards. Consider all possible energy sources and environmental factors that may pose risks.

- Step 3: Recommended Procedures: Based on the steps and identified hazards, outline actions that can eliminate or minimize risks. Recommend safe job procedures that correspond to each job step and the associated hazards.

What You Should Know About This Form

What is a Job Hazard Analysis (JHA) form?

A Job Hazard Analysis form is a tool used to identify potential hazards associated with specific job tasks. By breaking down a job into its basic steps, it helps in recognizing risks and implementing safe work procedures. This proactive approach can reduce accidents and enhance workplace safety.

How do I fill out a Job Hazard Analysis form?

Start by breaking the job into a sequence of basic steps. Each step should reflect a major task that involves several movements. Next, identify potential hazards associated with each step, considering all possible energy sources and environmental factors. Finally, recommend procedures to eliminate or control those hazards, ensuring they align with the job steps outlined.

Why is a Job Hazard Analysis important?

Conducting a Job Hazard Analysis is crucial for maintaining workplace safety. It helps identify risks before they lead to accidents or injuries. By understanding and addressing potential hazards, companies can protect employees and promote a safer work environment.

Who should conduct the Job Hazard Analysis?

Typically, the analysis should be done by someone knowledgeable about the job, such as a supervisor or safety officer. Involving employees who perform the tasks can also be beneficial, as they can provide valuable insights into potential hazards and suggest practical safety measures.

How often should a Job Hazard Analysis be updated?

A Job Hazard Analysis should be reviewed regularly, especially when changes occur in the job process, equipment, or workplace environment. Additionally, if an accident occurs or new hazards are identified, it's important to re-evaluate and update the analysis accordingly.

What are some common hazards to look for in a Job Hazard Analysis?

Common hazards include slips, trips, and falls; exposure to harmful substances; machinery operation; electrical hazards; and ergonomic risks. It's essential to assess the environment thoroughly to identify all potential sources of danger related to the job steps.

Can a Job Hazard Analysis help with compliance?

Yes, implementing a Job Hazard Analysis can aid in compliance with workplace safety regulations and standards. By identifying and addressing hazards, a company can demonstrate its commitment to employee safety and potentially avoid penalties or fines associated with unsafe practices.

Common mistakes

When filling out the Job Hazard Analysis (JHA) form, people often make several common mistakes that can compromise the safety and effectiveness of the analysis. Awareness of these pitfalls can significantly enhance the quality of the completed form.

One major mistake occurs in breaking down job steps. Some individuals may list steps too broadly or fail to capture all critical movements involved in a task. Each step should clearly represent a distinct action to ensure that no potential hazard is overlooked. If important steps are left out, associated risks might not be identified, leading to unsafe working conditions.

Another frequent error is inadequate identification of hazards. It is essential to thoroughly examine each job step for potential hazards. Some may only identify obvious dangers, like equipment malfunction, while ignoring subtler risks in the environment. Hazards can include anything from poor lighting to ergonomic issues. A comprehensive view is crucial for a complete hazard assessment.

A third mistake involves failing to document all potential hazards. Each conceivable source of energy must be identified, including mechanical, electrical, and chemical risks. Neglecting any of these elements can create gaps in the hazard analysis, exposing workers to unforeseen dangers.

Moreover, insufficient recommendations for safe procedures pose another challenge. After identifying potential hazards, it is crucial to propose effective controls or mitigations. Recommendations should be actionable and clearly linked to the hazards and job steps outlined in the analysis. Vague suggestions may leave room for misinterpretation and inadequate safety measures.

Lastly, some individuals fail to involve others in the process. Collaboration can bring diverse perspectives and insights, enhancing the overall analysis. Involving team members in discussions can help identify overlooked hazards and improve the recommended procedures, leading to a more robust and effective Job Hazard Analysis.

Documents used along the form

A Job Hazard Analysis (JHA) is a vital tool for ensuring workplace safety by identifying potential hazards and recommending what actions to take to mitigate those hazards. Several other forms and documents complement the JHA, helping organizations create comprehensive safety protocols. Each of these forms plays a specific role in enhancing workplace safety, streamlining processes, and documenting necessary information.

- Safety Data Sheet (SDS): This document provides information about the chemical properties, health hazards, safe handling, and emergency response measures related to a particular substance. It is essential for ensuring safe use of chemicals in the workplace.

- Incident Report Form: This form documents any workplace incidents or near misses. It includes details about the event, individuals involved, and outcomes, helping organizations analyze trends and improve safety measures.

- Personal Protective Equipment (PPE) Assessment: This assessment identifies the necessary personal protective equipment for specific tasks within the workplace. It ensures that employees are equipped to protect themselves from potential hazards present in their work environment.

- Training Records: These records track the safety training provided to employees. They include details about the type of training, dates, and participants, which helps organizations ensure compliance and monitor ongoing training needs.

- Job Safety Analysis Review Form: Following the initial JHA, this form is used to review and update the original analysis. It helps keep the safety procedures current and relevant to changing work conditions and jobs.

- Corrective Action Plan: This document outlines steps to correct identified deficiencies or incidents. It details who is responsible for each action and the timeline for implementation.

- Emergency Action Plan (EAP): This plan describes the procedures to follow in case of various emergencies, such as fires, chemical spills, or natural disasters. It ensures all employees know the needed steps to take to minimize harm during emergencies.

- Workplace Safety Policy: This document sets out the overall commitment of the organization to workplace safety. It outlines the responsibilities of management and employees in maintaining a safe work environment.

By effectively utilizing these forms and documents along with the Job Hazard Analysis, organizations can create a safer work environment for all employees. This holistic approach ensures that potential risks are considered proactively and mitigated through appropriate actions and procedures.

Similar forms

The Job Hazard Analysis (JHA) form closely resembles several other documents that serve similar purposes in workplace safety and risk management. Below is a list of ten documents related to the JHA, along with a brief explanation of how they are similar.

- Job Safety Analysis Worksheet: Like the JHA, this worksheet breaks down job tasks into steps and identifies hazards associated with each step, facilitating proactive safety measures.

- Risk Assessment Form: This form evaluates potential risks in workplace activities, similar to the JHA's focus on identifying hazards and mitigating them.

- Safe Work Method Statement (SWMS): An SWMS outlines how to carry out high-risk work safely, just as the JHA provides recommendations for controlling identified hazards.

- Incident Report Form: This document records details of workplace incidents. Both the JHA and incident reports aim to enhance safety protocols by analyzing hazards related to specific tasks.

- Safety Audit Checklist: A safety audit checklist reviews compliance with safety regulations. Similar to a JHA, it helps identify potential hazards in workplace practices.

- Equipment Safety Inspection Form: This form inspects the safety of tools and machinery. Like the JHA, it focuses on identifying hazards that could lead to accidents.

- Training Needs Analysis: This document evaluates employee training requirements based on job tasks and associated risks. It aligns with the JHA's goal of ensuring employees recognize and manage hazards.

- Environmental Hazard Assessment: Similar to the JHA, this assessment identifies potential environmental hazards related to job tasks and suggests control measures to mitigate risks.

- Emergency Action Plan: An emergency action plan outlines procedures for responding to emergencies. Both documents identify hazards and establish procedures for employee safety.

- Worksite Safety Plan: This overarching plan details safety policies and procedures at a worksite, similar in focus to the JHA’s identification and management of hazards related to specific tasks.

Dos and Don'ts

When filling out the Job Hazard Analysis form, it’s crucial to ensure accuracy and thoroughness. Here are six essential do's and don'ts to keep in mind:

- Do: Break down the job into clear, manageable steps to avoid confusion.

- Do: Identify all potential hazards by thoroughly assessing both the task and its environment.

- Do: Use specific language when describing hazards and recommended procedures to ensure clarity.

- Do: Involve team members in the analysis to provide diverse perspectives on potential hazards.

- Don't: Overlook minor hazards; even small risks can lead to accidents.

- Don't: Skip the review process; ensure the analysis is checked for accuracy and completeness.

By following these guidelines, you can promote workplace safety and effectively complete the Job Hazard Analysis form.

Misconceptions

Here are some common misconceptions about the Job Hazard Analysis (JHA) form:

- The JHA is only needed for high-risk jobs. Many believe that only jobs with obvious dangers require a JHA. In reality, all jobs can have hazards, and analyzing them helps improve safety for everyone.

- Once completed, the JHA never needs to be updated. Some people think a JHA is a one-time task. However, changes in processes, equipment, or personnel can introduce new hazards, necessitating regular review and updates.

- The JHA is a complicated and lengthy process. While it involves careful consideration, a JHA can be straightforward. A clear framework guides the analysis, making it manageable for any team to complete.

- Only managers need to be involved in the JHA. This misconception overlooks the value of frontline workers' insights. Those directly involved in the job often have the best understanding of potential hazards and effective controls.

- The JHA only focuses on physical hazards. Many fail to realize that a JHA also considers environmental and ergonomic hazards. Addressing all potential risks leads to a comprehensive safety plan.

- Once hazards are identified, the job is safe. Recognizing hazards is just one step. Effective control measures must be established to mitigate those hazards; identification alone does not ensure safety.

- The JHA is optional if safety training is provided. Some believe safety training suffices without a JHA. However, a JHA specifically outlines job-related hazards and control measures, making it an essential component of workplace safety.

- JHAs are only for compliance purposes. While regulatory compliance is important, the primary goal of a JHA is to promote a safer work environment. Employees benefit from proactive safety measures that arise from the analysis.

Key takeaways

Completing a Job Hazard Analysis (JHA) form is an essential part of ensuring workplace safety. Here are some key takeaways to remember:

- Break Down Tasks: Start by breaking the job into a series of basic steps. Each step represents a significant part of the task and should include specific movements involved in the work.

- Identify Hazards: Look closely for potential hazards associated with each step. Consider every possible source of energy and assess the entire work environment to identify any risks that could lead to accidents.

- Environmental Awareness: It’s crucial to be thorough. Hazards can come from unexpected places, so be vigilant about noting every conceivable risk that might exist in the workplace.

- Develop Safe Procedures: Based on the steps and identified hazards, establish safe operating procedures. These procedures should aim to eliminate, control, or minimize any identified risks.

- Match Procedures to Steps: Ensure that each recommended procedure corresponds directly to the job steps and the hazards identified. This correlation can help in effectively managing safety on the job.

Using the Job Hazard Analysis form systematically can significantly enhance safety and prevent workplace accidents. Approaching the analysis with diligence promotes a safer environment for everyone involved.

Browse Other Templates

What Is a Da Form 1059 Used for - Students can choose to provide additional comments or opt not to, based on preference.

The Appraisal Foundation - The addendum lays out specific assessment protocols to follow during appraisals.