Fill Out Your Liftap Form

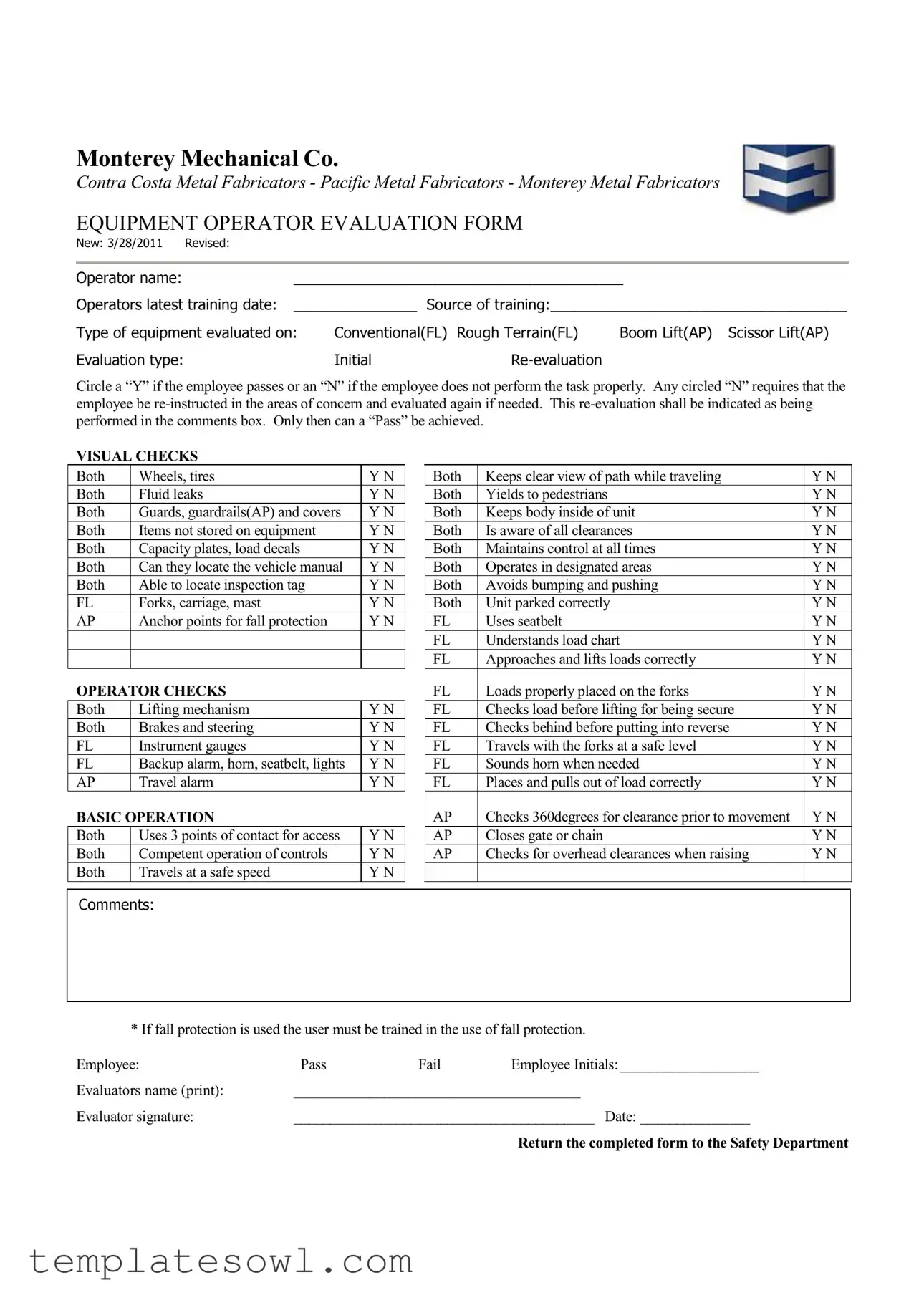

The Liftap form is an essential tool designed for the evaluation of equipment operators within various construction and mechanical industries. First introduced in March 2011, this form plays a pivotal role in ensuring the safety and competence of personnel operating specialized machinery such as rough terrain forklifts, boom lifts, and scissor lifts. With its structured approach, the form requires evaluators to assess an operator's performance through a series of visual checks and operational tasks, fostering a safe work environment. Each section introduces crucial elements for consideration, such as vehicle control, adherence to safety protocols, and awareness of surroundings. For every task, evaluators circle a “Y” for passing or an “N” for failing, with clear protocols established for addressing any deficiencies. If an operator does not perform a task correctly, they must undergo re-instruction and be re-evaluated, ensuring that all employees are held to high safety standards. The comprehensive nature of the Liftap form not only verifies skills but also emphasizes the importance of training and ongoing assessment, as reflected in the requirement to document training dates and sources. This form is not just a checklist; it is a commitment to operational excellence and safety in the workplace.

Liftap Example

Monterey Mechanical Co.

Contra Costa Metal Fabricators - Pacific Metal Fabricators - Monterey Metal Fabricators

EQUIPMENT OPERATOR EVALUATION FORM

New: 3/28/2011 Revised:

Operator name: |

________________________________________ |

|||

Operators latest training date: |

_______________ |

Source of training:____________________________________ |

||

Type of equipment evaluated on: |

Conventional(FL) Rough Terrain(FL) |

Boom Lift(AP) Scissor Lift(AP) |

||

Evaluation type: |

|

Initial |

|

|

Circle a “Y” if the employee passes or an “N” if the employee does not perform the task properly. Any circled “N” requires that the employee be

VISUAL CHECKS |

|

|

|

|

|

|

Both |

Wheels, tires |

Y N |

|

Both |

Keeps clear view of path while traveling |

Y N |

Both |

Fluid leaks |

Y N |

|

Both |

Yields to pedestrians |

Y N |

Both |

Guards, guardrails(AP) and covers |

Y N |

|

Both |

Keeps body inside of unit |

Y N |

Both |

Items not stored on equipment |

Y N |

|

Both |

Is aware of all clearances |

Y N |

Both |

Capacity plates, load decals |

Y N |

|

Both |

Maintains control at all times |

Y N |

Both |

Can they locate the vehicle manual |

Y N |

|

Both |

Operates in designated areas |

Y N |

Both |

Able to locate inspection tag |

Y N |

|

Both |

Avoids bumping and pushing |

Y N |

FL |

Forks, carriage, mast |

Y N |

|

Both |

Unit parked correctly |

Y N |

AP |

Anchor points for fall protection |

Y N |

|

FL |

Uses seatbelt |

Y N |

|

|

|

|

FL |

Understands load chart |

Y N |

|

|

|

|

FL |

Approaches and lifts loads correctly |

Y N |

OPERATOR CHECKS |

|

|

FL |

Loads properly placed on the forks |

Y N |

|

Both |

Lifting mechanism |

Y N |

|

FL |

Checks load before lifting for being secure |

Y N |

Both |

Brakes and steering |

Y N |

|

FL |

Checks behind before putting into reverse |

Y N |

FL |

Instrument gauges |

Y N |

|

FL |

Travels with the forks at a safe level |

Y N |

FL |

Backup alarm, horn, seatbelt, lights |

Y N |

|

FL |

Sounds horn when needed |

Y N |

AP |

Travel alarm |

Y N |

|

FL |

Places and pulls out of load correctly |

Y N |

BASIC OPERATION |

|

|

AP |

Checks 360degrees for clearance prior to movement |

Y N |

|

Both |

Uses 3 points of contact for access |

Y N |

|

AP |

Closes gate or chain |

Y N |

Both |

Competent operation of controls |

Y N |

|

AP |

Checks for overhead clearances when raising |

Y N |

Both |

Travels at a safe speed |

Y N |

|

|

|

|

Comments:

* If fall protection is used the user must be trained in the use of fall protection.

Employee: |

Pass |

Fail |

Employee Initials:___________________ |

Evaluators name (print): |

______________________________________ |

||

Evaluator signature: |

_________________________________________ Date: _______________ |

||

Return the completed form to the Safety Department

Form Characteristics

| Fact Name | Detail |

|---|---|

| Form Name | Liftap Equipment Operator Evaluation Form |

| Governing Law | This form is relevant under OSHA regulations regarding equipment operator safety. |

| Initial Release Date | The form was first issued on March 28, 2011. |

| Re-evaluation Requirement | If any task is circled as "N," the employee must be re-instructed and re-evaluated. |

| Training Confirmation | Operators must disclose their latest training date and source of training on the form. |

| Safety Department Submission | Completed forms must be returned to the Safety Department for review and record-keeping. |

Guidelines on Utilizing Liftap

After gathering the necessary information, you are ready to fill out the Liftap form. This form helps document the evaluation process of equipment operators to ensure safety standards are met. Be methodical as you complete each section, and remember to provide accurate details to avoid any discrepancies.

- Start by entering the operator's name in the designated space.

- Fill in the operator's latest training date.

- Provide the source of training for the operator.

- Select the type of equipment evaluated by marking the appropriate choice (Conventional, Rough Terrain, Boom Lift, Scissor Lift).

- Indicate the evaluation type by circling either "Initial" or "Re-evaluation."

- For each visual check and operator check, circle “Y” for pass or “N” for fail as applicable. Be sure to review each item carefully.

- If any “N” is marked, list the areas of concern in the comments box and indicate that re-evaluation is needed.

- To complete the form, fill in the employee initials and the evaluator’s name, print clearly.

- Finally, have the evaluator sign the form and date it.

- Return the completed form to the Safety Department for processing.

What You Should Know About This Form

What is the purpose of the Liftap form?

The Liftap form serves as an equipment operator evaluation tool designed to assess the competence and safety practices of individuals operating various types of lifting equipment. It outlines specific criteria that operators must meet. By using this form, employers ensure their employees are properly trained and capable of operating machinery like forklifts or boom lifts safely.

How should I fill out the evaluation portion of the Liftap form?

When filling out the evaluation portion, you will need to circle a “Y” for Yes if the operator performs the task correctly and circle an “N” for No if they do not. If you circle an “N,” it’s essential to provide a clear explanation in the comments box. This is important because any “N” indicates the operator requires further instruction before being re-evaluated.

What types of equipment does the Liftap form cover?

The Liftap form evaluates operators on various equipment types, including Conventional Forklifts (FL), Rough Terrain Forklifts (FL), Boom Lifts (AP), and Scissor Lifts (AP). Each type has specific criteria to measure operator competence, ensuring a wide range of machinery is considered in safety evaluations.

What steps should be taken if the operator does not pass an evaluation?

If an operator does not pass the evaluation, immediate action must be taken. This involves re-instructing the employee in the areas where they struggled. After training, the operator should be evaluated again. Unless they demonstrate the necessary skills and knowledge to pass, they are not cleared for operation.

Who is responsible for completing and signing the Liftap form?

Every evaluation must be filled out by a qualified evaluator who has the necessary understanding of the equipment and safety standards. The evaluator is required to print their name and provide a signature, confirming they conducted the evaluation accurately. This ensures accountability and a record of the assessment.

Where should the completed Liftap form be submitted?

Upon completing the Liftap form, it must be submitted to the Safety Department of your organization. This department will review the evaluations to ensure compliance with safety protocols and track operator training progress. Proper submission is crucial for maintaining workplace safety standards.

Common mistakes

When filling out the Liftap form, several common mistakes often occur that can lead to complications down the line. Being aware of these pitfalls can help ensure the form is completed accurately and effectively.

One frequent error is the failure to properly document the operator's latest training date. This crucial piece of information confirms that the operator has received recent training, which is essential for safe equipment operation. If left blank or incorrectly filled out, it can raise questions about compliance with safety standards and could lead to issues with certification.

Another mistake often seen is neglecting to circle the appropriate "Y" or "N" for each evaluation question. This oversight can create ambiguity regarding the operator's performance, as it makes it unclear whether they passed or failed specific tasks. Each "N" indicates a need for further instruction, so without proper marking, essential corrective actions may be overlooked.

Additionally, many evaluators forget to include comments in the designated area, especially when there are any "N" responses. Comments are not just a formality; they provide context for the evaluation, detailing what areas require re-instruction or additional training. Missing this detail can hinder follow-up actions necessary for improving the operator's skills.

Finally, a common oversight occurs in the signatures and initials sections. It's important that both the employee and evaluator sign and date the form. Without these signatures, the document may not hold any validity, which can cause issues in record-keeping and compliance verification. Ensuring completeness in this step solidifies the evaluation process.

Documents used along the form

The Liftap form is an important document used in evaluating equipment operators. However, there are several other forms and documents that often accompany it to ensure thorough evaluation and compliance. Here are some of the key documents to consider:

- Training Certification: This document confirms that the operator has received the necessary training to operate specific types of equipment. It usually includes the trainer's name, training date, and the subjects covered.

- Incident Report Form: In case of an accident or near miss, this form records essential details like what happened, how it occurred, and any contributing factors. It helps in addressing safety concerns and preventing future incidents.

- Equipment Maintenance Log: This log tracks the maintenance and repairs of equipment to ensure it is in safe working condition. Regular updates help identify patterns and the need for major repairs before they become critical.

- Operator’s Manual: This manual provides specific instructions for the equipment being operated. It typically includes operational guidelines, maintenance schedules, and safety precautions, ensuring operators follow best practices.

- Pre-Operation Checklist: This checklist allows operators to conduct a quick safety inspection of the equipment before use. It usually covers critical safety features and operational conditions to ensure safe operation.

- Safety Meeting Minutes: These minutes summarize the discussions and decisions made during safety meetings. They can highlight changes or emphasis on safety protocols that all operators should be aware of.

Using these additional documents alongside the Liftap form creates a comprehensive approach to operator safety and equipment management. It ensures that all aspects of training, evaluation, and maintenance are covered, leading to a safer working environment.

Similar forms

- Training Record: Like the Liftap form, a training record documents an employee's training history, including dates and sources of training. It helps verify that the operator possesses the necessary skills and knowledge.

- Incident Report: Similar to the Liftap form, an incident report records specific events related to equipment operation, detailing who was involved and what happened. This document is crucial for identifying trends and preventing future incidents.

- Job Safety Analysis (JSA): Like the Liftap form, a JSA identifies potential hazards associated with a job before it begins. It ensures safety protocols are followed and operational procedures are in place.

- Safety Inspection Checklist: A safety inspection checklist functions similarly to the Liftap form by assessing equipment condition and operator compliance with safety regulations. Regular checks help maintain a safe working environment.

- Operator License: Much like the Liftap form, an operator license verifies that a person is qualified to operate specific machinery. It represents an essential step in ensuring safety and compliance with regulations.

- Equipment Maintenance Log: The Liftap form and maintenance log both serve as records of equipment status and performance. Each document emphasizes the importance of ongoing care to prevent malfunctions and ensure safety.

- Accident Investigation Report: An accident investigation report shares similarities with the Liftap form in that it reviews incidents to determine causes and prevent future occurrences, focusing on the actions of the operator and equipment performance.

- Performance Review: Like the Liftap form, a performance review evaluates an employee's capabilities and adherence to safety standards. It can help identify areas where additional training might be needed.

- Compliance Audit Checklist: The compliance audit checklist works similarly to the Liftap form by assessing adherence to regulatory standards. It ensures that all safety policies are followed in the workplace.

Dos and Don'ts

Things to Do When Filling Out the Liftap Form:

- Write the operator's full name clearly in the designated space.

- Provide the latest training date accurately.

- Circle 'Y' or 'N' for each evaluation check to indicate performance.

- Document any areas of concern in the comments box for transparency.

- Ensure all required signatures are included at the end of the form.

Things Not to Do When Filling Out the Liftap Form:

- Do not leave any fields blank, including the operator's name and training source.

- Avoid circling only 'Y' without proper evaluation of all required checks.

- Do not omit comments if the employee fails the evaluation on any task.

- Refrain from using abbreviations or unclear handwriting that may cause confusion.

Misconceptions

Here are five misconceptions about the Liftap form that may lead to misunderstandings regarding its purposes and requirements:

- The Liftap form is only for new operators. Many believe it is exclusively for evaluating new operators. In reality, the form is also intended for the re-evaluation of existing operators to ensure ongoing compliance and safety.

- An operator can pass with any "N" marks. Some think that any circled “N” will not affect the outcome. However, even a single “N” requires re-instruction. A pass can only be achieved after all concerns are addressed.

- Only equipment operators need to fill out the form. While the operator does complete the form, the safety evaluator must also sign it. Their input is crucial for a thorough evaluation process.

- The form's purpose is solely for record-keeping. Some view the Liftap form as just a formality. In truth, it plays an essential role in ensuring safety standards and operator competency, fostering a safer work environment.

- Once completed, the form is discarded. Many might think the form is unimportant after submission. In fact, it must be returned to the Safety Department for proper record-keeping and compliance verification.

Key takeaways

Filling out and using the Liftap form involves careful attention to detail and adherence to specific guidelines. The following key takeaways outline essential aspects to consider.

- The operator's name and latest training date must be clearly filled out to ensure accurate recordkeeping.

- Any evaluation marked with an “N” for failing to perform a task requires immediate re-instruction in the noted areas.

- All visual checks, operator checks, and basic operation items should be marked thoroughly before submitting the form.

- Comments should be utilized to provide clarity on any areas that necessitate further training or re-evaluation.

- It is crucial to return the completed form to the Safety Department promptly for compliance and safety tracking purposes.

Browse Other Templates

Bank Application Form - Enter your Social Security number as a required identification.

Ssa Form 821 - Your completed form will become part of your Social Security records permanently.

Wisconsin Estimated Tax Form - Using the personalized 1-ES voucher ensures timely posting of payments to the correct account.