Fill Out Your Mechanical Pump Inspection Form

Ensuring the reliability and efficiency of fire safety systems is paramount, particularly in environments where fire risks are prevalent. The Mechanical Pump Inspection form plays a crucial role in assessing the operational integrity of fire pumps. This comprehensive document details a weekly checklist designed to capture essential performance metrics over the span of one week. Key elements include parameters such as the operational status, suction and discharge pressures, as well as the pump's performance under various conditions. Each inspection is recorded by designated personnel who meticulously evaluate factors such as noise levels, vibrations, and even overheating components. The form ensures thorough diligence by allowing for the documentation of observations, such as packing gland tightness and oil pressure readings, which are critical in determining the health of the pump. With this systematic approach, potential issues can be identified and addressed promptly, allowing fire safety equipment to function seamlessly when needed most. By adhering to these inspection protocols as outlined by the Hopewell Valley Bureau of Fire Safety, facilities can maintain compliance with industry standards and, more importantly, safeguard lives.

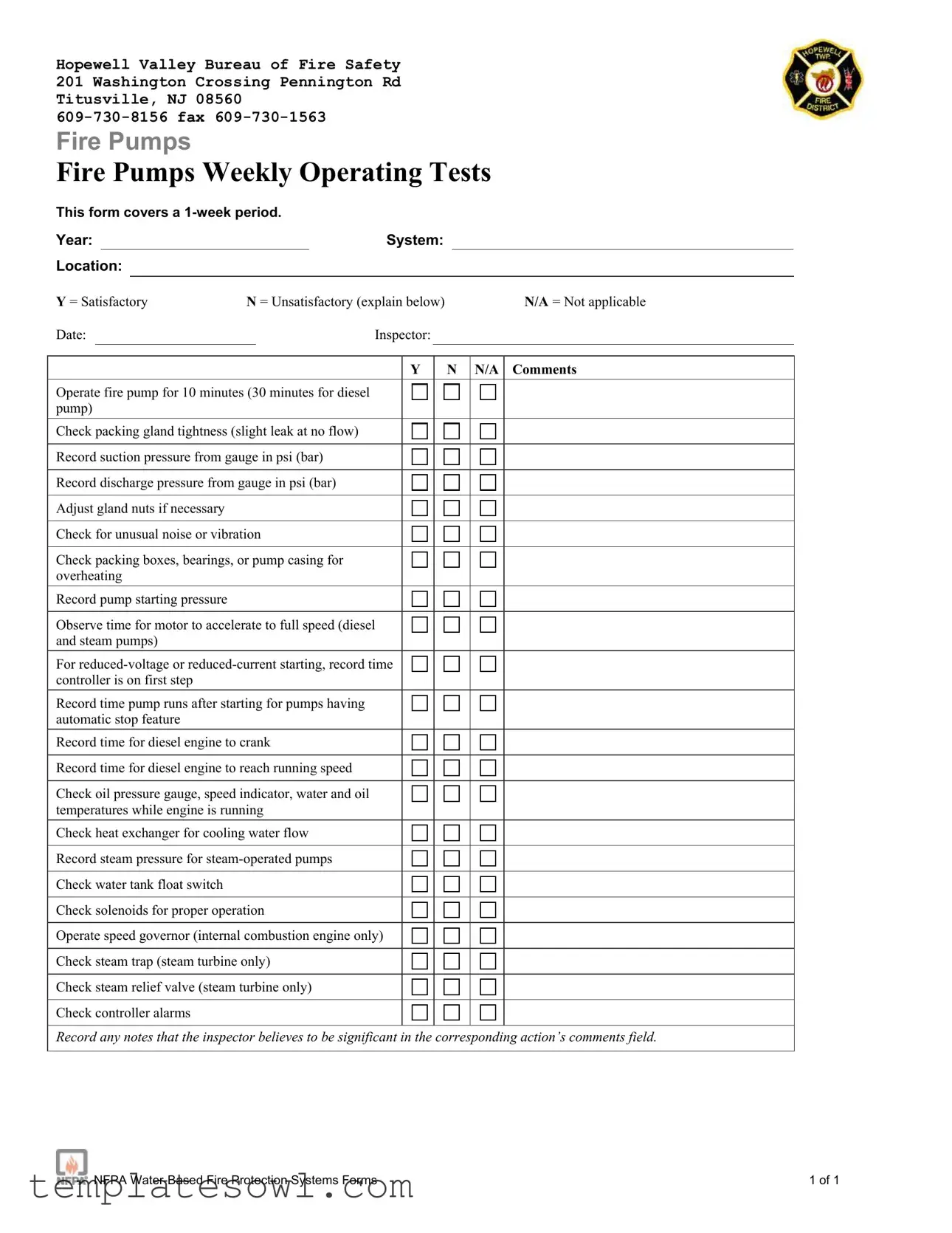

Mechanical Pump Inspection Example

Hopewell Valley Bureau of Fire Safety 201 Washington Crossing Pennington Rd Titusville, NJ 08560

Fire Pumps

Fire Pumps Weekly Operating Tests

This form covers a

Year:System:

Location:

Y = Satisfactory |

N = Unsatisfactory (explain below) |

N/A = Not applicable |

Date:Inspector:

YN N/A Comments

Operate fire pump for 10 minutes (30 minutes for diesel pump)

Check packing gland tightness (slight leak at no flow)

Record suction pressure from gauge in psi (bar)

Record discharge pressure from gauge in psi (bar)

Adjust gland nuts if necessary

Check for unusual noise or vibration

Check packing boxes, bearings, or pump casing for overheating

Record pump starting pressure

Observe time for motor to accelerate to full speed (diesel and steam pumps)

For

Record time pump runs after starting for pumps having automatic stop feature

Record time for diesel engine to crank

Record time for diesel engine to reach running speed

Check oil pressure gauge, speed indicator, water and oil temperatures while engine is running

Check heat exchanger for cooling water flow

Record steam pressure for

Check water tank float switch

Check solenoids for proper operation

Operate speed governor (internal combustion engine only)

Check steam trap (steam turbine only)

Check steam relief valve (steam turbine only)

Check controller alarms

Record any notes that the inspector believes to be significant in the corresponding action’s comments field.

NFPA |

1 of 1 |

Form Characteristics

| Fact Name | Description |

|---|---|

| Governing Body | This form is part of the regulations set by the Hopewell Valley Bureau of Fire Safety in New Jersey. |

| Contact Information | The contact number for the bureau is 609-730-8156, and fax number is 609-730-1563. |

| Inspection Frequency | Inspections using this form are conducted weekly, covering a 1-week period. |

| Operating Tests | The tests involve operating the fire pump for 10-30 minutes, depending on the pump type. |

| Pump Start Information | The inspector must record how long it takes for the pump to start and reach full running speed. |

| Performance Indicators | Pressure readings for both suction and discharge are recorded in psi or bar. |

| Visual Checks | Inspectors must check for unusual noise, vibrations, and overheating in various pump components. |

| Oil and Temperature Monitoring | Oil pressure, speed, and temperature checks must be noted while the engine is running. |

| Documentation of Issues | Any unsatisfactory conditions must be explained in the comments section of the form. |

Guidelines on Utilizing Mechanical Pump Inspection

Completing the Mechanical Pump Inspection form is essential for ensuring compliance and safety. Follow these steps carefully to provide accurate information. After you fill out the form, you will need to submit it to the designated department for review.

- Fill in the year, system, and location at the top of the form.

- Record the date and the name of the inspector.

- For each inspection item, mark Y for satisfactory, N for unsatisfactory, or N/A if not applicable.

- For any unsatisfactory marks, provide a brief explanation in the comments section.

- Operate the fire pump for the required duration: 10 minutes or 30 minutes for a diesel pump.

- Check the packing gland tightness and note if there is a slight leak.

- Record the suction pressure and discharge pressure from the gauges in psi or bar.

- If needed, adjust the gland nuts.

- Inspect for any unusual noise or vibration.

- Check the packing boxes, bearings, or pump casing for signs of overheating.

- Document the pump starting pressure.

- Observe how long it takes for the motor to reach full speed.

- If applicable, record the time for any reduced-voltage or reduced-current starting.

- For pumps with an automatic stop feature, document how long they run after starting.

- Record the time it takes for the diesel engine to crank and to reach running speed.

- Check the oil pressure gauge, speed indicator, and monitor water and oil temperatures while the engine is running.

- Inspect the heat exchanger for proper cooling water flow.

- For steam-operated pumps, record the steam pressure.

- Ensure the water tank float switch is functioning.

- Check solenoids for proper operation.

- Operate the speed governor if the engine is an internal combustion type.

- For steam turbines, check the steam trap and steam relief valve.

- Verify that controller alarms are operational.

- Make any additional notes in the comments field related to significant observations made during the inspection.

What You Should Know About This Form

What is the purpose of the Mechanical Pump Inspection form?

The Mechanical Pump Inspection form is designed to ensure that fire pumps operate effectively and safely. It allows inspectors to document the performance of the fire pump over a one-week period, noting any issues that may arise during testing.

How often should the form be completed?

The form should be completed weekly. Regular inspections help identify any potential problems before they become serious issues, keeping the fire pump in optimal working condition.

What information is required on the form?

Key information includes the year, system, location of the pump, inspection date, and the inspector's name. The form also requires performance details such as pressures, operation time, and any unusual findings or comments.

What does the "Y = Satisfactory, N = Unsatisfactory" section mean?

This section allows inspectors to evaluate the effectiveness of the fire pump. A “Y” indicates satisfactory performance, while an “N” requires an explanation of what went wrong. This helps in tracking issues and ensuring they are addressed promptly.

What should be checked during the inspection?

Inspectors need to check various aspects, including the operating time of the pump, pressure readings, gland tightness, unusual noises, and overall functionality of components like solenoids and heat exchangers. Each of these elements is crucial to the pump's operation.

What should be noted in the comments section of the form?

Any significant observations or irregularities should be recorded in the comments section. This could include unusual noises, readings that deviate from normal, or concerns about specific components. Thorough notes can help in troubleshooting issues later.

Where can I find additional resources or assistance regarding the form?

For further information, you can contact the Hopewell Valley Bureau of Fire Safety directly at 609-730-8156. They can provide guidance on completing the form or answer any questions related to fire pump inspections.

Common mistakes

Completing the Mechanical Pump Inspection form accurately is essential for ensuring fire safety compliance. However, individuals often make common mistakes that can lead to misunderstandings or miscommunications regarding the equipment's condition. One major mistake is failing to provide specific details in the comments section. This area is crucial for conveying issues or observations that may not be directly addressed by the checklist. When inspectors skip this step, they can create uncertainties about the pump's performance, which could have serious implications in an emergency.

Another frequent error involves misunderstanding the significance of the N/A option. Some individuals mark N/A for components they have not checked, rather than for those that genuinely don't apply to the system in question. This misstep can lead to an incomplete picture of the pump's operational status. It's important to remember that each entry in the form should reflect actual evaluations; if something was overlooked, it needs to be explained to avoid confusion.

Additionally, discrepancies in the pressure readings are common. Inspectors may forget to record the suction and discharge pressure or accidentally write down incorrect values. Such errors undermine the reliability of the inspection. Ownership of the responsibility for accurate readings ensures that subsequent users can trust the data provided. The pressure gauges should always be checked thoroughly, and the recorded values must reflect what was observed at the time of inspection.

Another area where mistakes can occur is in recording the operational times for various functions, such as the time for the motor to reach full speed or the time for the diesel engine to crank. Often, inspectors either neglect to note these times or record them inaccurately. To prevent complications, it is advised to have a stopwatch handy. This ensures that the information collected is precise, which is especially important when analyzing system performance over time.

Finally, many overlook the importance of checking for unusual noises or vibrations while the pump operates. These observations are often dismissed as inconsequential. However, they can indicate underlying problems that might not be immediately apparent in other tests. Therefore, it’s critical to take the time to listen and observe during each inspection. Recognizing these signs early can lead to timely repairs, enhancing overall safety.

Documents used along the form

The Mechanical Pump Inspection form is an essential document that helps ensure the proper function of fire pumps in various settings. Alongside this form, several other documents contribute to a comprehensive understanding of fire safety management and equipment status. Below is a list of forms and documents often used together with the Mechanical Pump Inspection form.

- Fire Pump Maintenance Log: This document records all maintenance activities performed on fire pumps. It includes details such as service dates, the nature of work done, and parts replaced. Keeping this log helps track the pump's service history and ensures compliance with maintenance schedules.

- Inspection Checklist: This checklist outlines various criteria for evaluating fire pump performance. Inspectors use it to ensure that all necessary tests are conducted, providing a uniform approach to inspections and making it easier to identify any issues that may need attention.

- Testing Results Record: This records the outcomes of tests conducted on fire pump systems. It includes critical measurements like pressure readings and flow rates, enabling quick reference to assess whether the pump meets required standards and specifications.

- Operational Procedures Manual: This manual provides guidelines on how to operate fire pumps safely and effectively. It includes instructions for starting, stopping, and troubleshooting common issues, becoming an essential resource for staff responsible for pump operation.

- NFPA Reporting Templates: These are standardized forms used to report incidents and inspections per National Fire Protection Association (NFPA) guidelines. The templates help ensure that all necessary data is captured for compliance, improving safety and accountability.

- Maintenance Agreement: This document outlines the terms of service between the maintenance provider and the facility owner. It specifies expectations regarding inspections, repairs, and overall service, fostering clear communication and accountability between parties involved.

By utilizing these documents in conjunction with the Mechanical Pump Inspection form, individuals and organizations can better ensure the reliability and safety of their fire pump systems. Regular and thorough documentation plays a critical role in fire safety management and regulatory compliance.

Similar forms

- Fire Pump Maintenance Log: Like the Mechanical Pump Inspection form, this document tracks the performance and maintenance of fire pumps over a specified time. It includes similar checklists to monitor operational efficiency, ensuring compliance and safety standards are met.

- Daily Equipment Inspection Checklist: This form is utilized to document the daily checks for all types of mechanical equipment. The focus is on operational readiness, much like the weekly pump tests, where any issues must be noted and addressed promptly.

- Hydraulic System Inspection Report: This document shares objectives with the Mechanical Pump Inspection form, assessing the performance and integrity of hydraulic systems. Items covered include pressure readings and operational tests, ensuring system effectiveness.

- Emergency Equipment Check Form: Similar in purpose, this checklist ensures that emergency response equipment functions correctly. It records crucial tests and observations, paralleling the systematic checks found in pump inspections.

- Preventive Maintenance Schedule: This document outlines regular maintenance tasks for equipment, including pumps. It aligns with the inspection form by detailing inspection intervals and expected outcomes to keep machinery in peak condition.

- NFPA Inspection and Testing Report: Following NFPA guidelines, this report closely resembles the Mechanical Pump Inspection form. It documents the inspection results and includes criteria such as performance metrics and safety compliance, ensuring a standard approach to assessments.

Dos and Don'ts

When filling out the Mechanical Pump Inspection form, it is crucial to ensure accuracy and thoroughness. The following are essential dos and don'ts that should be kept in mind:

- Do fill in the year, system, and location clearly at the beginning of the form.

- Do make sure to operate the pump for the required time before recording results.

- Do check and secure the packing gland tightness to prevent leaks.

- Do observe and record any unusual noises or vibrations during pump operation.

- Don't skip recording the suction and discharge pressure; these readings are crucial.

- Don't leave the comments section blank; provide explanations for unsatisfactory results.

- Don't neglect to check oil pressure and temperature gauges while the engine is running.

- Don't forget to verify that all safety alarms and solenoids function properly.

Misconceptions

There are several misconceptions about the Mechanical Pump Inspection form that can lead to confusion or errors during the inspection process. Understanding these misconceptions can ensure more accurate and effective inspections.

- The form is only for fire pumps. Many people believe that the form applies solely to fire pumps; however, it can also be used for diesel and steam pumps across different systems. This versatility is important for ensuring that all types of pumps are adequately inspected.

- Inspection results are only satisfactory or unsatisfactory. While the form utilizes the options of "Y" for satisfactory and "N" for unsatisfactory, inspectors can also denote items as "N/A" if they do not apply to the specific context of the pump being inspected. This option allows for more precise reporting.

- All inspections take the same amount of time. Some individuals think that every inspection can be completed in a consistent timeframe. The truth is that the duration depends on the type of pump and its condition. Diesel pumps, for instance, may require a longer time to operate compared to others.

- Not all notes are important. There is a belief that only major issues need to be recorded in the comments section. However, the form provides a space for inspectors to document any significant observations, regardless of how small they may seem. This can be helpful for future reference and safety.

- The inspection is a one-time process. Many think that once an inspection is done, it is no longer necessary. In reality, the Mechanical Pump Inspection should be performed regularly as part of a comprehensive maintenance program to ensure ongoing reliability and safety.

- The form cannot be adjusted for special circumstances. Some users assume that the Mechanical Pump Inspection form is rigid and cannot be modified. In fact, inspectors may adapt their notes and comments based on the specific conditions or requirements present during the inspection.

Clarifying these misconceptions can lead to better understanding and adherence to safety protocols, ultimately enhancing the effectiveness of fire safety measures.

Key takeaways

The Mechanical Pump Inspection form is a critical tool in ensuring the proper functioning of fire pumps. Here are key takeaways to consider when filling out and utilizing this form:

- Review the Form Carefully: Familiarize yourself with all sections of the form before starting the inspection.

- Identify the Time Period: The form is designed for a one-week period. Clearly indicate the dates and specific information for that week.

- Complete All Sections: Ensure that each section is filled out. Use "Y" for satisfactory, "N" for unsatisfactory, and "N/A" where applicable.

- Document Everything: Comments are essential. Explain any unsatisfactory results thoroughly to provide context.

- Operational Tests: Conduct various tests like operating the pump and checking packing gland tightness as listed on the form.

- Record Key Measurements: Pay close attention to suction and discharge pressures, and properly note them in psi or bar.

- Monitor Engine Performance: For diesel and steam pumps, note the times it takes for the engine to crank and reach running speed.

- Check Fluid Levels: Assess oil pressure, water temperatures, and other indicators during operation to ensure everything is working correctly.

- Be Observant: Look for any unusual noises, vibrations, or overheating that could indicate malfunctioning components.

- Ensure Safety Features Are Functional: Check alarms and solenoids to confirm they operate as intended to guarantee safety during operation.

Using this form correctly can enhance pump reliability and ensure that safety systems are functioning effectively.

Browse Other Templates

Cr 180 Form - Notice of the petition hearing must be given at least 30 days in advance to relevant parties.

Sample Letter for Leave of Absence From Work - This form plays a crucial role in the administrative process for employee leave.

Charitable Registration Document,Nonprofit Registration Form,Illinois Charity Registration,Charitable Organization Registration,Charitable Trust Registration Statement,Solicitation for Charity Form,Fundraising Registration Statement,Illinois Charitab - Contact information for the chief executive officer must be provided.