Fill Out Your Nfpa Fire Pump Inspection Form

The NFPA Fire Pump Inspection form plays a crucial role in ensuring that fire pump systems remain functional and safe throughout their operational lifespan. This comprehensive form encompasses a series of checks that must be performed weekly over a three-month period. Each inspection is methodically documented, requiring the inspector to assess a variety of components such as the heat levels in the pump room, the status of valves, and the overall integrity of the system. Key areas of focus include evaluating pressure in suction and system lines, verifying the fill level of the suction reservoir, and ensuring that all pilot lights illuminate correctly, indicating normal operation of the pumps and associated electrical systems. The inspector must also confirm that no leaks exist in any attached piping or hoses, while also checking critical elements like battery condition and oil levels in various components. Additionally, this form allows for the documentation of any unsatisfactory findings, which must be explained in the comments section. By adhering to the guidelines set forth by the NFPA, facilities can maintain their fire pump systems effectively and uphold the safety standards essential for fire protection operations.

Nfpa Fire Pump Inspection Example

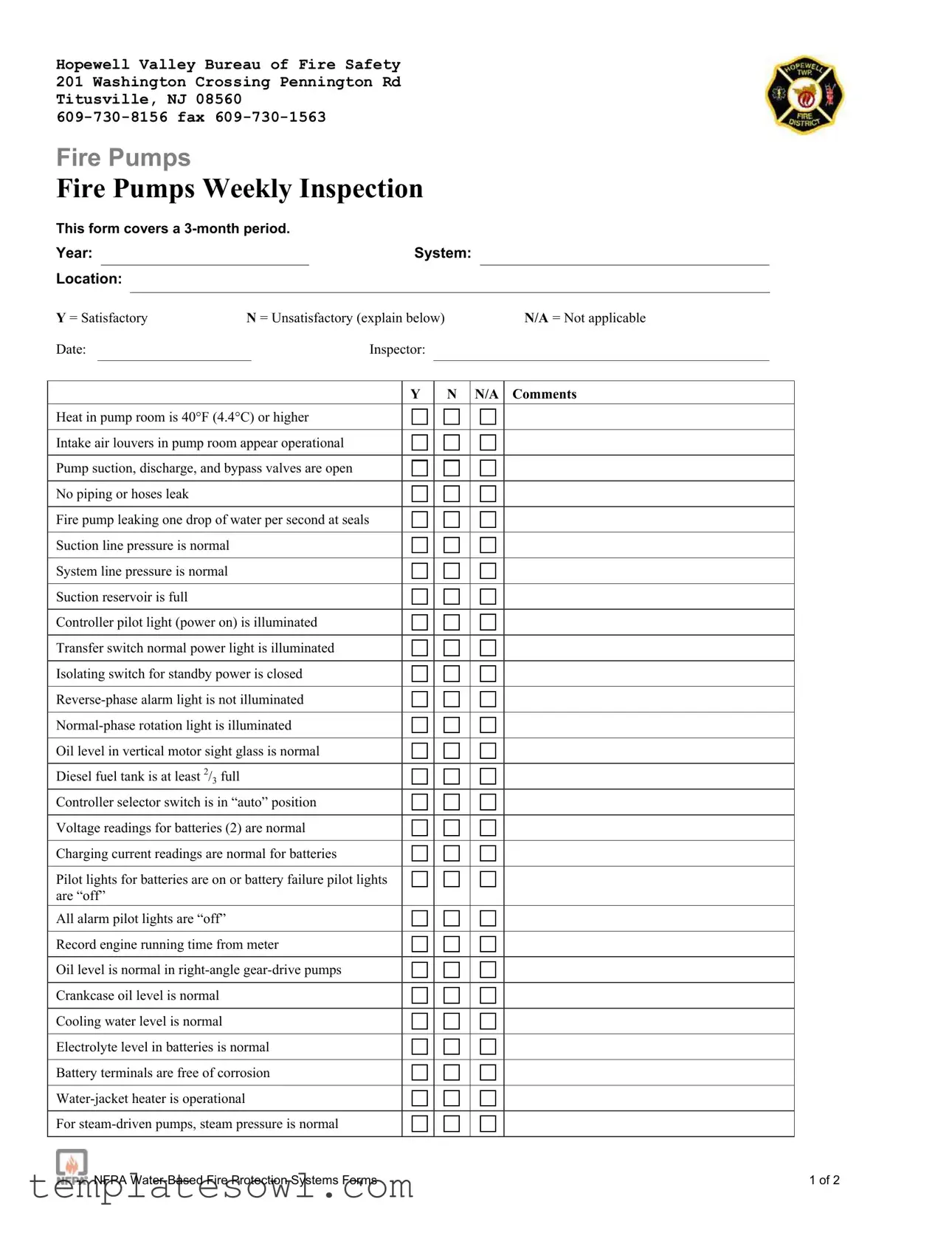

Hopewell Valley Bureau of Fire Safety 201 Washington Crossing Pennington Rd Titusville, NJ 08560

Fire Pumps

Fire Pumps Weekly Inspection

This form covers a

Year:System:

Location:

Y = Satisfactory |

N = Unsatisfactory (explain below) |

N/A = Not applicable |

Date:Inspector:

YN N/A Comments

Heat in pump room is 40°F (4.4°C) or higher

Intake air louvers in pump room appear operational

Pump suction, discharge, and bypass valves are open

No piping or hoses leak

Fire pump leaking one drop of water per second at seals

Suction line pressure is normal

System line pressure is normal

Suction reservoir is full

Controller pilot light (power on) is illuminated

Transfer switch normal power light is illuminated

Isolating switch for standby power is closed

Oil level in vertical motor sight glass is normal

Diesel fuel tank is at least 2/3 full

Controller selector switch is in “auto” position

Voltage readings for batteries (2) are normal

Charging current readings are normal for batteries

Pilot lights for batteries are on or battery failure pilot lights are “off”

All alarm pilot lights are “off”

Record engine running time from meter

Oil level is normal in

Crankcase oil level is normal

Cooling water level is normal

Electrolyte level in batteries is normal

Battery terminals are free of corrosion

For

NFPA |

1 of 2 |

Hopewell Valley Bureau of Fire Safety 201 Washington Crossing Pennington Rd Titusville, NJ 08560

YN N/A Comments

Examine exhaust system for leaks

Check lube oil heater for operation (diesel pumps)

Drain condensate trap of cooling system

Check for water in diesel fuel tank

Business Representative __________________________________ Phone_____________________

Signature ________________________________________________ Date ______________________

NFPA |

2 of 2 |

Form Characteristics

| Fact Name | Description |

|---|---|

| Inspection Frequency | This form is designed for weekly inspections that cover a three-month period to ensure fire pump functionality. |

| Location of Use | The inspection form is applicable to the Hopewell Valley Bureau of Fire Safety in Titusville, NJ. |

| Compliance Standards | The inspection must adhere to the National Fire Protection Association (NFPA) standards to ensure safety and effectiveness. |

| Contact Information | For queries or concerns, individuals can reach the bureau at 609-730-8156 or fax at 609-730-1563. |

Guidelines on Utilizing Nfpa Fire Pump Inspection

Completing the NFPA Fire Pump Inspection form accurately ensures that each aspect of the inspection is documented properly. Following the steps outlined below will help facilitate the process.

- At the top of the form, fill in the Year, System, and Location fields.

- Indicate the Date of inspection and the name of the Inspector.

- For each inspection item, mark the appropriate response with a Y for Satisfactory, N for Unsatisfactory, or N/A to designate Not Applicable.

- Provide comments for any items marked N to explain the unsatisfactory condition.

- Review the condition of the following items and ensure to record your findings:

- Temperature in the pump room

- Intake air louvers operation

- Valves’ functioning status (suction, discharge, bypass)

- Check for leaks in piping or hoses

- Leakage from the fire pump seals

- Pressure readings for suction and system line

- Condition of the suction reservoir

- Illumination of controller pilot light

- Normal operation of transfer switch power light

- Condition of isolating switch for standby power

- Status of reverse-phase alarm light

- Indication of normal-phase rotation light

- Check oil level in vertical motor

- Diesel fuel tank level

- Controller selector switch position

- Voltage and charging current readings for batteries

- Status of battery pilot lights

- Engine running time

- Oil levels in right-angle gear-drive pumps

- Crankcase oil level

- Cooling water level

- Electrolyte level in batteries

- Corrosion status on battery terminals

- Functionality of water-jacket heater

- Steam pressure for steam-driven pumps

- Examine the exhaust system and check for any signs of leakage.

- Inspect the lube oil heater operation (for diesel pumps).

- Drain the condensate trap of the cooling system.

- Check the diesel fuel tank for water contamination.

- Fill in the Business Representative field along with the corresponding Phone number.

- Have the designated representative sign the form with their Signature and record the Date.

What You Should Know About This Form

What is the purpose of the NFPA Fire Pump Inspection form?

The NFPA Fire Pump Inspection form is designed to help fire safety inspectors evaluate the operational status of fire pumps over a three-month period. It ensures that all necessary checks are performed to confirm that the fire pump system is functioning correctly and complies with safety regulations. This form covers various aspects of the fire pump, including mechanical functionality, electrical status, and fluid levels to ensure readiness in case of a fire emergency.

Who is responsible for filling out the inspection form?

The assigned fire safety inspector is responsible for completing the NFPA Fire Pump Inspection form. This individual is typically trained in fire safety protocols and procedures. The inspector must follow the checklist and document the condition of each item, noting any issues or concerns, in order to provide a comprehensive overview of the fire pump's performance.

How often should the inspection form be completed?

The inspection form should be completed on a weekly basis. Regular inspections are essential for ensuring the fire pump is in optimal condition and capable of operating effectively during an emergency. Documenting the findings weekly allows for timely identification of possible issues, which contributes to maintaining the system's overall reliability.

What should be done if an inspection item is marked as "Unsatisfactory"?

If any item on the inspection form is marked as "Unsatisfactory," it is crucial to provide a detailed explanation in the comments section. The responsible party should address the identified issues promptly to restore the fire pump's functionality. This may involve repairs, further inspections, or notifying appropriate personnel to take corrective action. Addressing unsatisfactory conditions ensures that fire safety protocols are maintained and the system remains operational at all times.

What are some key components that the form assesses during the inspection?

The form evaluates several critical components of the fire pump system. Key areas include the temperature in the pump room, the operational status of intake air louvers, valve conditions, pump leak checks, and the overall pressure of suction and system lines. Additionally, it assesses indicators such as the controller pilot light, battery readings, and the oil levels in various parts of the pump. Each component's functionality is vital for ensuring the fire pump works effectively when needed.

Is there a specific format for recording comments on the inspection form?

While the inspection form includes space for comments, there is no strict format required for recording them. Inspectors should provide clear and concise explanations regarding any items marked "Unsatisfactory" or any other observations that may impact the fire pump's performance. Specific details are encouraged to facilitate the understanding of issues and the necessary actions for resolution. Clarity in comments ensures effective communication within the team responsible for fire safety management.

Common mistakes

Filling out the NFPA Fire Pump Inspection form is crucial for ensuring fire safety. However, many individuals make mistakes that could lead to serious consequences. One common error is not providing accurate dates. The date of inspection should reflect when the inspection actually took place. If this information is incorrect, it can create confusion during any follow-up inspections or evaluations.

Another mistake is not including complete comments for unsatisfactory conditions. If an aspect of the inspection receives an "N" for unsatisfactory, it's essential to explain why. Failing to provide this detail means that issues may not be addressed properly, putting safety at risk.

Some also check "N/A" without justification for items that are applicable. It's important to ensure that all relevant questions are answered appropriately. Marking something as "not applicable" without grounds may suggest a lack of diligence during the inspection process.

Inconsistent use of the Y, N, N/A format can lead to confusion. Using this system correctly is imperative for clarity. One should make sure that each line is filled out with its corresponding symbol as a way to maintain order and understanding in the report.

A frequent oversight involves neglecting to inspect all components thoroughly. For instance, verifying the oil level in the right-angle gear-drive pumps is crucial. If only some aspects are checked, it could overlook potential problems that may arise later.

Lastly, failing to get a proper signature and contact information from the business representative can create liability issues. This section is necessary as it holds parties accountable. Complete signatures and clear contact details ensure that there is a point of contact for any questions or follow-up actions.

Documents used along the form

When dealing with fire safety systems, particularly fire pump inspections, there are several key documents commonly used alongside the NFPA Fire Pump Inspection form. Understanding these additional forms can enhance compliance with safety regulations and ensure that fire safety equipment is in optimal working condition.

- NFPA 25 Inspection Report: This report tracks the inspection, testing, and maintenance of water-based fire protection systems. Regular entries help monitor system reliability and compliance with standards set by the National Fire Protection Association.

- Maintenance Log: A detailed record of all maintenance activities performed on fire pumps, including dates and descriptions of work done. This log assists in maintaining a clear history for audits and inspections.

- Test and Inspection Certificate: Issued upon completion of an inspection, this certificate verifies that the fire pump and related systems have been tested and meet the required standards, providing peace of mind to building owners and occupants.

- Operating Manual: This document provides essential information about the operation of a fire pump, including emergency procedures and troubleshooting guides. Familiarity with the manual can enhance quick responses during emergencies.

- Repair Request Form: When repairs are needed, this form documents issues and specific actions required. It ensures that necessary repairs are tracked and addressed in a timely manner to maintain system integrity.

- Emergency Contact List: An important document that contains contact information for all relevant personnel, including emergency responders and responsible parties. Having this list readily available can expedite communication during a fire event.

- System Design Plans: Architectural and engineering plans detailing the layout of the fire protection system. These plans serve as a reference for inspections and any potential system modifications.

- Risk Assessment Document: An evaluation that identifies potential fire hazards within a facility. This document supports the development of a comprehensive fire safety strategy, including the role of fire pumps.

- Fire Safety Training Records: Documentation of training sessions for staff on fire safety protocols, including the operation of fire pumps. Well-trained staff can significantly reduce response times during emergencies.

Integrating these forms with the NFPA Fire Pump Inspection form ensures a complete approach to fire safety management. Together, they facilitate regular maintenance checks, compliance with standards, and a thorough understanding of the systems in place, ultimately enhancing safety for everyone involved.

Similar forms

The NFPA Fire Pump Inspection form is important for ensuring the safe and reliable operation of fire pumps. Several other documents serve similar purposes in fire safety and equipment inspection contexts. Here are five similar documents:

- Fire Alarm System Inspection Report: This document assesses the functionality and compliance of fire alarm systems. It checks components like detection devices, alarms, and control panels, similar to how the Fire Pump Inspection form evaluates the operational status of fire pumps.

- Emergency Lighting Inspection Form: Just like the Fire Pump Inspection, this form verifies that emergency lighting systems work properly. It involves checking battery life, light intensity, and overall functionality to ensure safety during power outages.

- Sprinkler System Inspection Report: This report details the inspections of sprinkler systems. It covers aspects such as water flow, valve operations, and pressure readings, paralleling the checks performed on fire pumps.

- Generator Inspection Checklist: Similar to the Fire Pump Inspection form, this checklist ensures that backup generators are operational. It includes inspections of fuel levels, battery conditions, and operational test runs, ensuring readiness in emergencies.

- Fire Extinguisher Inspection Form: This form documents inspections of portable fire extinguishers. It involves checking pressure gauges, accessibility, and condition, aligning with how fire pumps are evaluated for immediate availability and effectiveness.

These documents collectively contribute to a comprehensive fire safety program, ensuring that all critical systems are functioning as intended to protect life and property.

Dos and Don'ts

When filling out the NFPA Fire Pump Inspection form, it's essential to follow best practices to ensure accuracy and compliance. Here are seven recommendations that cover both what to do and what to avoid:

- Do: Ensure that the pump room temperature is recorded accurately. Heat should be 40°F (4.4°C) or higher.

- Do: Confirm that all intake air louvers in the pump room are operational. This is crucial for proper ventilation.

- Do: Thoroughly check that all valves, including suction, discharge, and bypass, are open to ensure water can flow properly.

- Do: Document any leaks, especially from the fire pump seals. Even a single drop per second can indicate a problem.

- Don’t: Skip commenting on any items marked as “N” for unsatisfactory. Always provide clear explanations.

- Don’t: Leave information blank. Every field should either be filled out or marked as “N/A” if it doesn’t apply.

- Don’t: Forget to check the normal-phase and reverse-phase alarm lights. Proper illumination is key to identifying potential issues.

Misconceptions

There are several misconceptions about the NFPA Fire Pump Inspection form. Here are some of the most common ones:

- The form is only for fire departments. Many people assume this form is solely for use by firefighters. In reality, it’s also meant for business owners and property managers to ensure their safety equipment is functional.

- Weekly inspections are unnecessary. Some believe that inspections can be done less frequently. Regular weekly inspections are crucial for identifying issues before they become serious problems.

- Only trained professionals can fill it out. While it's helpful to have technical knowledge, anyone involved in the property’s safety can complete the form after being properly instructed.

- All items must be satisfactory. People often think that every part of the inspection must be marked satisfactory. The form accommodates for unsatisfactory and not applicable ratings, encouraging transparency about equipment conditions.

- The form is the same everywhere. Many assume that this form is standardized nationwide. Different locations may have specific needs which could affect how the form is filled out.

- Using the form is optional. Some property owners may mistakenly believe they can choose not to use the form. In many cases, however, proper documentation is required for safety compliance.

- It only focuses on the fire pump. This form also considers the entire fire protection system, including alarms and valves, ensuring comprehensive safety checks.

- Once completed, the form is not needed again. Many think the completed form can be discarded afterward. In fact, it should be kept for records and future inspections.

- Comments section is not important. Some people overlook the comments section. This space is essential for noting concerns or issues that need addressing.

- Inspection results do not impact safety ratings. Many believe that passing the inspection alone ensures safety. Continuous monitoring and maintenance are key to keeping fire systems effective and compliant.

Understanding these misconceptions can help ensure that the NFPA Fire Pump Inspection form is utilized effectively to protect lives and property.

Key takeaways

When it comes to ensuring the reliability of fire pumps, using the NFPA Fire Pump Inspection Form is essential. Here are some key takeaways to help you:

- Know the Purpose: This form is designed for weekly inspections over a three-month period, ensuring that all components of the fire pump are functioning correctly.

- Fill Out Basic Information: Be sure to provide the year, system, and location at the top of the form for clear identification.

- Understand Inspection Criteria: Each item must be marked as Satisfactory (Y), Unsatisfactory (N), or Not Applicable (N/A). Take time to explain any unsatisfactory marks in the comments section.

- Comment on Findings: Comments are crucial. If you mark any item as unsatisfactory, include a brief explanation to document what the issue is.

- Monitor Required Levels: Ensure that oil levels, coolant levels, and diesel fuel levels are checked. This information is critical for pump operation.

- Test Electrical Components: Thermally inspect pilot lights, battery health, and electrical connections. A well-maintained electrical system keeps everything running smoothly.

- Follow Up on Issues: If any inspections reveal problems, schedule maintenance immediately. This proactive approach helps prevent equipment failure during an emergency.

By following these takeaways, you'll not only fill out the NFPA Fire Pump Inspection Form with confidence but also contribute to the overall safety and functionality of your fire protection system.

Browse Other Templates

Prudential Life Insurance Surrender Form - A statement of declaration must be signed by the applicant for confirmation of information accuracy.

Florida Notice of Commencement Form - Successfully submitting this form can ease the path to construction completion.