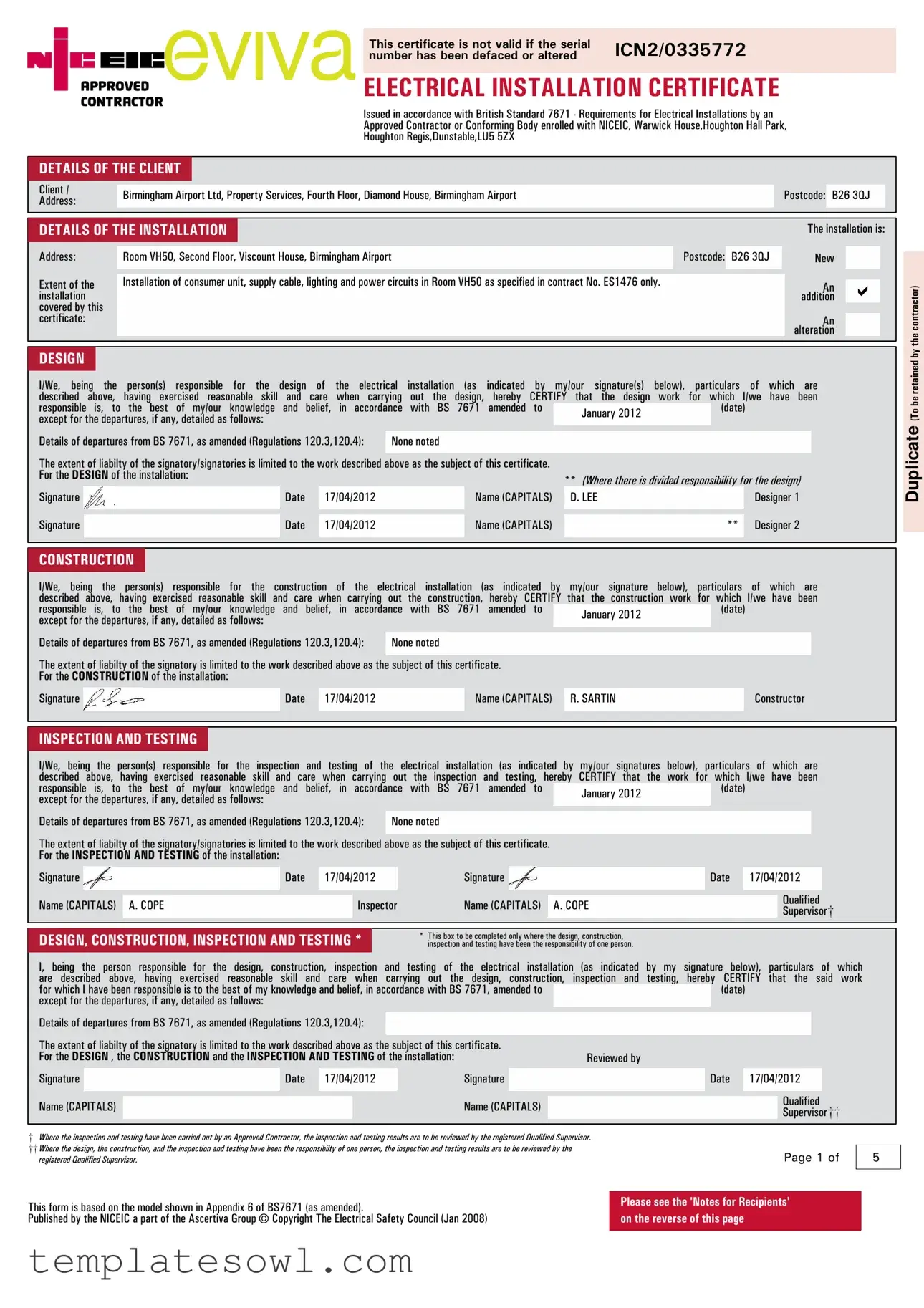

Fill Out Your Niceic Electrical Certificate Form

The NICEIC Electrical Certificate is a crucial document in the safety and compliance of electrical installations across the UK. Designed in accordance with British Standard 7671, this form acts as a testament to the work performed by an Approved Contractor or Conforming Body registered with the National Inspection Council for Electrical Installation Contracting (NICEIC). The certificate encompasses various aspects of the installation, including detailed information about the client, the specific installation site, and a comprehensive description of the work completed, such as the installation of consumer units, power circuits, and lighting systems. Essential signatures from the design, construction, and inspection parties affirm their commitment to industry standards and regulations, ensuring that the installation adheres to safety requirements. Additionally, the document includes areas for recording the characteristics of the supply system, earthing arrangements, and any recommendations for future inspections. Ultimately, the NICEIC Electrical Certificate serves as both a declaration of compliance and a vital reference for electrical safety in properties such as Birmingham Airport, where precision and adherence to standards are paramount.

Niceic Electrical Certificate Example

This certificate is not valid if the serial |

ICN2/0335772 |

|

number has been defaced or altered |

||

|

||

|

|

ELECTRICAL INSTALLATION CERTIFICATE

Issued in accordance with British Standard 7671 - Requirements for Electrical Installations by an

Approved Contractor or Conforming Body enrolled with NICEIC, Warwick House,Houghton Hall Park,

Houghton Regis,Dunstable,LU5 5ZX

DETAILS OF THE CLIENT

Client / |

Birmingham Airport Ltd, Property Services, Fourth Floor, Diamond House, Birmingham Airport |

Postcode: |

B26 3QJ |

|

Address: |

||||

|

|

|

DETAILS OF THE INSTALLATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The installation is: |

||||||||||||

Address: |

|

|

Room VH50, Second Floor, Viscount House, Birmingham Airport |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Postcode: |

B26 3QJ |

|

|

New |

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

Extent of the |

|

|

Installation of consumer unit, supply cable, lighting and power circuits in Room VH50 as specified in contract No. ES1476 only. |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

An |

á |

|

||||||||||||||||||||||||||||||||||||||

installation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

addition |

|

|||||

covered by this |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

certificate: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

An |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

alteration |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DESIGN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I/We, being the person(s) responsible |

for the design of the electrical |

installation |

|

(as |

indicated |

by |

|

my/our signature(s) |

|

below), |

particulars |

of |

which |

are |

|

|

||||||||||||||||||||||||||||||||||||

described above, having exercised reasonable skill and care when carrying |

out the design, hereby CERTIFY |

that |

the |

design |

work |

for which I/we have been |

|

|

||||||||||||||||||||||||||||||||||||||||||||

responsible is, |

to |

the best of my/our |

knowledge and |

belief, in |

accordance |

with BS |

7671 |

amended |

to |

|

|

|

|

January 2012 |

|

|

|

|

|

|

|

(date) |

|

|

|

|

|

|

|

|

||||||||||||||||||||||

except for the departures, if any, detailed as follows: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Details of departures from BS 7671, as amended (Regulations 120.3,120.4): |

|

None noted |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

The extent of liabilty of the signatory/signatories is limited to the work described above as the subject of this certificate. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

For the DESIGN of the installation: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

** (Where there is divided responsibility for the design) |

|

|

|||||||||||||||||||||||||||

Signature |

|

|

|

|

|

|

|

|

|

|

Date |

|

17/04/2012 |

|

|

|

|

|

|

|

Name (CAPITALS) |

|

D. LEE |

|

|

|

|

|

|

|

|

|

|

|

Designer 1 |

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

Signature |

|

|

|

|

|

|

|

|

|

|

Date |

|

17/04/2012 |

|

|

|

|

|

|

|

Name (CAPITALS) |

|

|

|

|

|

|

|

|

|

|

** |

Designer 2 |

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

CONSTRUCTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

I/We, being the person(s) responsible |

for the construction of the electrical |

installation |

(as |

indicated |

by |

my/our |

signature |

below), |

particulars |

of |

which |

are |

|

|

||||||||||||||||||||||||||||||||||||||

described above, having exercised reasonable skill and care when carrying out the construction, hereby CERTIFY that the construction work for which I/we have been |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

responsible is, |

to |

the best of my/our |

knowledge and |

belief, in |

accordance |

with BS |

7671 |

amended |

to |

|

|

|

|

January 2012 |

|

|

|

|

|

|

|

(date) |

|

|

|

|

|

|

|

|

||||||||||||||||||||||

except for the departures, if any, detailed as follows: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

Details of departures from BS 7671, as amended (Regulations 120.3,120.4): |

|

None noted |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

The extent of liabilty of the signatory is limited to the work described above as the subject of this certificate. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

For the CONSTRUCTION of the installation: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

Signature |

|

|

|

|

|

|

|

|

|

|

Date |

|

17/04/2012 |

|

|

|

|

|

|

|

Name (CAPITALS) |

|

R. SARTIN |

|

|

|

|

|

|

|

|

|

|

Constructor |

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

INSPECTION AND TESTING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

I/We, being the person(s) responsible for the inspection and testing of the electrical |

installation (as indicated by my/our |

signatures below), particulars of |

which |

are |

|

|

||||||||||||||||||||||||||||||||||||||||||||||

described above, having exercised reasonable skill and care when carrying out |

the inspection and testing, hereby CERTIFY that the work |

for which |

I/we |

have |

been |

|

|

|||||||||||||||||||||||||||||||||||||||||||||

responsible is, |

to |

the best of my/our |

knowledge and |

belief, in |

accordance |

with BS |

7671 |

amended |

to |

|

|

|

|

January 2012 |

|

|

|

|

|

|

|

(date) |

|

|

|

|

|

|

|

|

||||||||||||||||||||||

except for the departures, if any, detailed as follows: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

Details of departures from BS 7671, as amended (Regulations 120.3,120.4): |

|

None noted |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

The extent of liabilty of the signatory/signatories is limited to the work described above as the subject of this certificate. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

For the INSPECTION AND TESTING of the installation: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

Signature |

|

|

|

|

|

|

|

|

|

|

Date |

|

17/04/2012 |

|

|

|

|

|

|

|

Signature |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Date |

17/04/2012 |

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Qualified |

|

|

|||

Name (CAPITALS) |

A. COPE |

|

|

|

|

|

|

Inspector |

|

|

|

|

Name (CAPITALS) |

|

A. COPE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SupervisorÚ |

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

DESIGN, CONSTRUCTION, INSPECTION AND TESTING * |

|

|

|

|

* |

This box to be completed only where the design, construction, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|

|

inspection and testing have been the responsibility of one person. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||

I, being the person |

responsible for the |

design, construction, |

inspection |

and |

testing |

of |

the |

electrical |

installation (as |

indicated |

by my |

signature below), particulars of which |

||||||||||||||||||||||||||||||||||||||||

are described |

above, |

having exercised |

reasonable skill |

and |

care |

when |

carrying |

out |

the design, |

|

construction, |

inspection |

and |

testing, |

hereby CERTIFY that the said work |

|||||||||||||||||||||||||||||||||||||

for which I have been responsible is to the best of my knowledge and belief, in accordance with BS 7671, amended to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(date) |

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

except for the departures, if any, detailed as follows: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

Details of departures from BS 7671, as amended (Regulations 120.3,120.4): |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

The extent of liabilty of the signatory is limited to the work described above as the subject of this certificate. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

For the DESIGN , the CONSTRUCTION and the INSPECTION AND TESTING of the installation: |

|

|

|

|

|

|

|

|

|

|

Reviewed by |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

Signature |

|

|

|

|

|

|

|

|

|

|

Date |

|

17/04/2012 |

|

|

|

|

|

|

|

Signature |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Date |

17/04/2012 |

|

|

|

|

||||||||||

Name (CAPITALS) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Name (CAPITALS) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Qualified |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SupervisorÚÚ |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ÚWhere the inspection and testing have been carried out by an Approved Contractor, the inspection and testing results are to be reviewed by the registered Qualified Supervisor. ÚÚ Where the design, the construction, and the inspection and testing have been the responsibilty of one person, the inspection and testing results are to be reviewed by the

registered Qualified Supervisor. |

Page 1 of |

5 |

Duplicate (To be retained by the contractor)

This form is based on the model shown in Appendix 6 of BS7671 (as amended).

Published by the NICEIC a part of the Ascertiva Group © Copyright The Electrical Safety Council (Jan 2008)

Please see the 'Notes for Recipients' on the reverse of this page

This certificate is not valid if the serial |

ICN2/0335772 |

|

number has been defaced or altered |

||

|

||

|

|

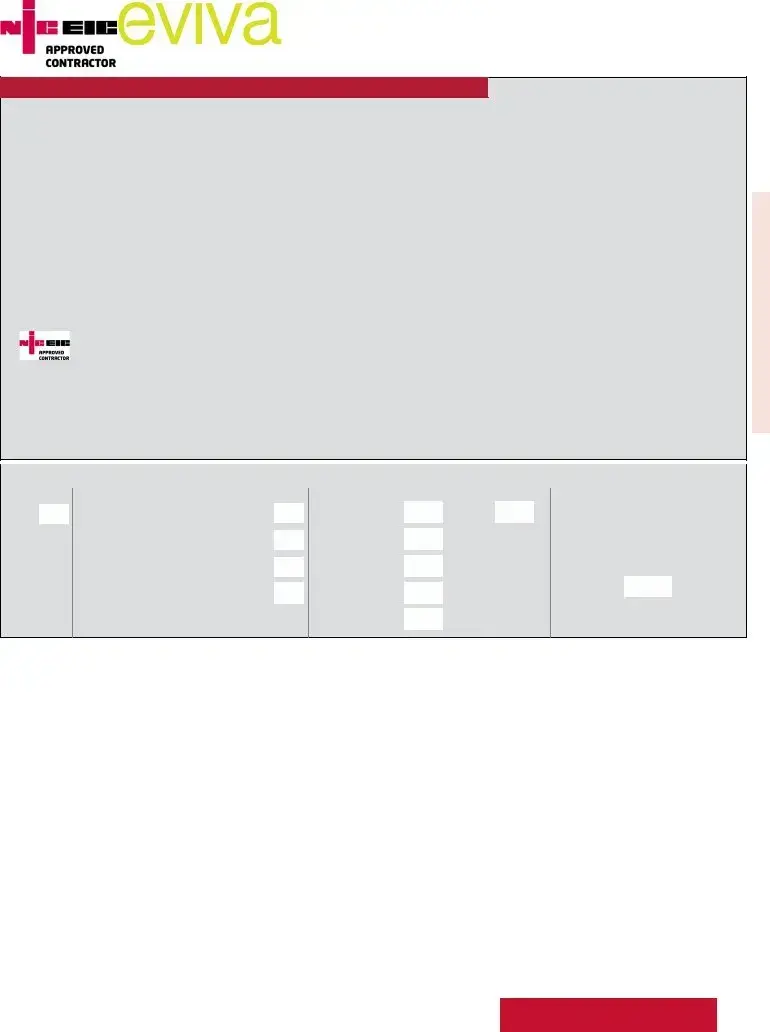

PARTICULARS OF THE ORGANISATION(S) RESPONSIBLE FOR THE ELECTRICAL INSTALLATION

DESIGN (1) |

Organisation |

Ú Eviva Services Ltd |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rapide Building |

|

NICEIC Enrolment No |

502741000 |

|

|

Address: |

|

|

|||||

|

|

Ramp Road |

|

|

(where appropriate) |

|

|

|

|

|

|

|

|

||

|

|

Birmingham Airport |

|

Branch number: |

|

|

|

|

|

Birmingham |

|

|

|

|

|

|

|

|

Postcode: B26 3QJ |

(if applicable) |

|

|

|

|

|

West Midlands |

|

|

|||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

DESIGN (2) |

Organisation |

Ú |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NICEIC Enrolment No |

|

|

Address: |

|

|

|

|

|

||

|

|

|

(where appropriate) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Branch number: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Postcode: |

(if applicable) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ú |

Organisation |

Eviva Services Ltd |

|

|

|

|

|

CONSTRUCTION |

|

|

|

|

|

|

|

|

|

Rapide Building |

|

NICEIC Enrolment No |

502741000 |

|

|

Address: |

|

|

|||||

|

|

Ramp Road |

|

|

(Essential Infomation) |

|

|

|

|

|

|

|

|

||

|

|

Birmingham Airport |

|

Branch number: |

|

|

|

|

|

Birmingham |

|

|

|

|

|

|

|

|

Postcode: B26 3QJ |

(if applicable) |

|

|

|

|

|

West Midlands |

|

|

|||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

INSPECTION |

Organisation |

Ú Eviva Services Ltd |

|

|

|

|

|

AND TESTING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rapide Building |

|

NICEIC Enrolment No |

502741000 |

|

|

Address: |

|

|

|||||

|

|

Ramp Road |

|

|

(where appropriate) |

|

|

|

|

|

|

|

|

||

|

|

Birmingham Airport |

|

Branch number: |

|

|

|

|

|

Birmingham |

|

|

|

|

|

|

|

|

Postcode: B26 3QJ |

(if applicable) |

|

|

|

|

|

West Midlands |

|

|

|||

|

|

|

|

|

|||

SUPPLY CHARACTERISTICS AND EARTHING ARRANGEMENTS |

Tick boxes and enter details, as appropriate |

|

|

Duplicate (To be retained by the contractor)

Ý System Type(s) |

Ý Number and Type of Live Conductors

Nature of Supply Parameters

Ý Characteristics of Primary Supply |

N/A |

|

|

|

N/A |

|

|

|

TT |

N/A |

|

|

IT |

N/A |

|

|

Other

a.c. |

á |

|

|

d.c. |

|

|

|

2 pole |

|||

N/A |

N/A |

||||

(3 wire) |

|||||

|

|

|

|

|

|

N/A |

|

|

|

3 pole |

|

|

|

|

|

|

|

N/A |

á |

other |

|||

(4 wire) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

N/A

N/A

N/A

Nominal Uþ Voltage(s):

Nominal frequency, fþ

Prospective fault current, IÙÄÅ

External earth fault loop impendance, Ñ ÄÅ

Number of supplies

400

50

>20

0.01

1

V

Hz

kA

É

UÒþ 230 V

Notes:

(1)by enquiry

(2)by enquiry or by measurement

(3)where more than one supply, record the higher or highest values

(4)by measurement

Overcurrent Protective Device(s) |

BS(EN) |

BS EN |

|

||

|

|

|

|

|

|

|

|

|

|

Type |

MCCB |

|

|

|

|

|

|

|

|

|

|

|

|

|

Rated current630 |

|

A |

||

|

|

|

||

|

|

|

||

50 |

|

kA |

||

capacity |

|

|||

|

|

|

|

|

PARTICULARS OF INSTALLATION AT THE ORIGIN |

|

Tick boxes and enter details, as appropriate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

Ý Means of Earthing |

|

|

|

|

|

Type: |

|

Details of Installation Earth Electrode (where applicable) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

Distributor's |

|

á |

|

|

|

|

N/A |

|

|

|

Location: |

N/A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

(eg rod(s),tape etc) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

facility: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

Installation |

|

N/A |

|

|

|

Electrode |

N/A |

(É) |

|

Method of |

N/A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

resistance, RÕ: |

|

measurement: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

earth electrode: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Ý Main Switch or |

|

|

|

|

|

Maximum |

|

|

|

|

|

Amps |

|

|

|

|

|

|

|

Protection measure |

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

630 |

|

|

|

|

|

|

|

|

|

ADS |

|

|

|

|

|

|

|

|

||||||||||||||

* (applicable only where an RCD is suitable and is used as a main |

|

Demand (Load) |

|

|

|

|

|

|

|

|

|

against electric shock: |

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

Type: |

BS EN |

|

Voltage |

415 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

V |

|

|

|

|

|

|

|

|

Protective Bonding Conductors |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

BS(EN) |

|

rating |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

Rated |

|

|

|

Earthing conductor |

|

|

Main protective bonding conductors |

|

|

Bonding of |

|

|

|

|

|

||||||||||||||

No of |

3 |

|

|

|

|

|

|

630 |

A |

Conductor |

Copper |

|

|

Conductor |

Copper |

|

|

|

|

|

Water |

á |

Gas |

á |

|

|

|

|

|

|

|||||||

Poles |

|

|

|

|

current,IÐ |

|

material |

|

|

material |

|

|

|

|

|

service |

Service |

|

|

|

|

|

|

||||||||||||||

Supply |

|

|

|

|

|

RCD operating |

|

|

Conductor |

|

|

|

|

|

Conductor |

|

|

|

|

|

|

|

Oil |

|

Structural |

á |

|

|

|

|

|

|

|||||

conductors |

Copper |

|

|

N/A |

mA |

120 |

|

|

mmâ |

|

70 |

|

|

mmâ |

|

N/A |

|

|

|

|

|

|

|||||||||||||||

|

|

current, IÜ * |

|

|

|

|

|

|

|

|

|

|

service |

steel |

|

|

|

|

|

|

|||||||||||||||||

material |

|

|

|

|

|

|

|

|

|

|

|

csa |

|

|

|

|

|

|

csa |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Supply |

|

|

|

|

mmâ |

RCD operating |

|

|

Continuity |

á |

|

(á) |

|

|

Continuity] |

á |

|

(á) |

|

|

|

Lightning |

á |

Other incoming |

|

N/A |

|

|

|

|

|

|

|||||

conductors |

240 |

|

|

time (atIÜ )* |

N/A |

ms |

|

|

|

|

|

|

|

protection |

service(s) |

|

|

|

|

|

|

|

|||||||||||||||

csa |

|

|

|

|

check |

|

|

|

|

|

check |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

COMMENTS ON EXISTING INSTALLATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: Enter 'NONE' or, where appropriate, the page number(s) |

|

|

|

|

|

|||||||||

|

|

|

|

|

In the case of an alteration or additions see Section 633 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of addional page(s) of comments on the existing installation. |

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

NEXT INSPECTION |

|

ò Enter interval in terms of years, months or weeks, as appropriate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ò |

Five Years |

|

|

|

|

|

|

|

|

|

|

|||||

I/We the designer(s), RECOMMEND that this installation is further inspected and tested after an interval of not more than |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ú Where the Approved Contractor responsible for the construction of the electrical installation has also been responsible for the designand the inspection and testing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

of that installation, the 'Particulars of the Organisation responsible for the Electrical Installation' may be recorded only in the section entitled 'CONSTRUCTION' |

|

|

|

|

|

|

|

Page 2 of |

|

5 |

|

|

|

||||||||||||||||||||||||

Ý Where a number of sources are available to supply the installation, and where the data given for the primary source may differ from other sources, |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||

a separate sheet must be provided which identifies the relevant information relating to each additional source. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

This form is based on the model shown in Appendix 6 of BS7671 (as amended).

Published by the NICEIC a part of the Ascertiva Group © Copyright The Electrical Safety Council (Jan 2008)

Please see the 'Notes for Recipients' on the reverse of this page

This certificate is not valid if the serial |

ICN2/0335772 |

|

number has been defaced or altered |

||

|

||

|

|

|

SCHEDULE OF ITEMS INSPECTED |

|

|

Ú See note below |

||||||

|

PROTECTIVE MEASURES AGAINST ELECTRIC SHOCK |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Basic and fault protection |

|

|

|

|

|

|

||

|

Extra low voltage |

|

|

|

|

|

||||

|

N/A |

SELV |

N/A |

|

PELV |

|||||

|

Double or reinforced insulation |

|

|

|

|

|||||

|

|

|

Double or Reinforced Insulation |

|

||||||

|

N/A |

|

||||||||

|

|

|

|

|

|

|

|

|

||

|

|

Basic Protection |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|||

|

á |

Insulation of live parts |

á |

|

|

Barriers or enclosures |

||||

|

|

|

|

|

||||||

|

N/A |

Obstacles ** |

N/A |

|

Placing out of reach ** |

|||||

|

|

|

|

|

|

|

|

|

|

|

Fault protection

Automatic disconnection of supply

áPresence of earthing conductor

áPresence of circuit protective conductors

áPresence of main protective bonding conductors

|

Presence of earthing arrangements for combined |

|

N/A |

||

protective and functional purposes |

||

|

||

|

Presence of adequate arrangements for alternative |

|

N/A |

||

source(s), where applicable |

||

|

N/A |

FELV |

|

|

áChoice and setting of protective and monitoring devices (for fault protection and/or overcurrent protection)

N/A |

Absence of protective conductors |

|||

|

|

Presence of |

||

N/A |

||||

Electrical separation |

||||

|

|

For one item of current using equipment |

||

N/A |

||||

|

|

For more than one item of current using equipment** |

||

N/A |

||||

|

|

|

|

|

|

Additional protection |

|

|

|

|

|

|

|

|

|

Presence of residual current device(s) |

|||

N/A |

||||

|

|

|

|

|

áPresence of supplementry bonding conductors

**for use in controlled supervised/conditions only

Prevention of mutual detrimental influence

áProximity of

áSegregation of Band I and Band II circuits or Band II insulation used

áSegregation of safety Circuits

Identification

áPresence of diagrams, instructions, circuit charts and similar information

áPresence of danger notices and other warning notices

áLabelling of protective devices, switches and terminals

áidentification of conductors

Cables and Conductors

áSelection of conductors for current carrying capacity and voltage drop

áErection methods

áRouting of cables in prescribed zones

áCables incorporating earthed armour or sheath or run in an earthed wiring system, or otherwise protected against nails, screws and the like

Additional protection by 30mA RCD for cables concealed in walls

N/A (where required,in premises not under the supervision of skilled or instructed persons)

áConnection of conductors

áPresence of fire barriers, suitable seals and protection against thermal effects

General

áPresence and correct location of appropriate devices for isolation and switching

áAdequacy of access to switchgear and other equipment

N/A |

Particular protective measures for special installations and locations |

|

|

áConnection of

áCorrect connection of accessories and equipment

N/A |

Presence of undervoltage protective devices |

|

|

áSelection of equipment and protective measures appropriate to external influences

áSelection of appropriate functional switching devices

Duplicate (To be retained by the contractor)

SCHEDULE OF ITEMS TESTED |

Ú See note below |

|

|

áExternal earth fault loop impendance,Ñ

N/A |

Installation earth electrode resistance, RÕ |

|

|

áContinuity of protective conductors

áContinuity of ring final circuit conductors

áInsulation resistance between live conductors

áInsulation resistance between live conductors and Earth

N/A |

Protection by seperation of circuits |

|

|

N/A

N/A

á

á

á

N/A

á

á

Basic protection by barrier or enclosure provided during erection

Insulation of

Polarity

Earth fault loop impendance,Ö

Verification of phase sequence

Operation of resudual current devices

Functional testing of assemblies

Verification of voltage drop

SCHEDULE OF ADDITIONAL RECORDS* (See attached schedule) |

Page No(s) |

|

Note: Additional page(s) must be identified by the Electrical Installation Certificate serial number and page number(s).

ÚAll boxes must be completed. 'á' indicates that an inspection or a test was carried out and that the result was satisfactory. 'N/A' indicates that an

inspection or a test was not applicable to the particular installation |

Page 3 of |

5 |

*Where the electrical works to which this certificate relates includes the installation of a fire alarm system and/or an emergency lighting system (or a part of such system), this electrical safety certificate should be accompanied by the particular certificate(s) for the system(s).

This form is based on the model shown in Appendix 6 of BS7671 (as amended).

Published by the NICEIC a part of the Ascertiva Group © Copyright The Electrical Safety Council (Jan 2008)

This certificate is not valid if the serial |

ICN2/0335772 |

|

number has been defaced or altered |

||

|

||

|

|

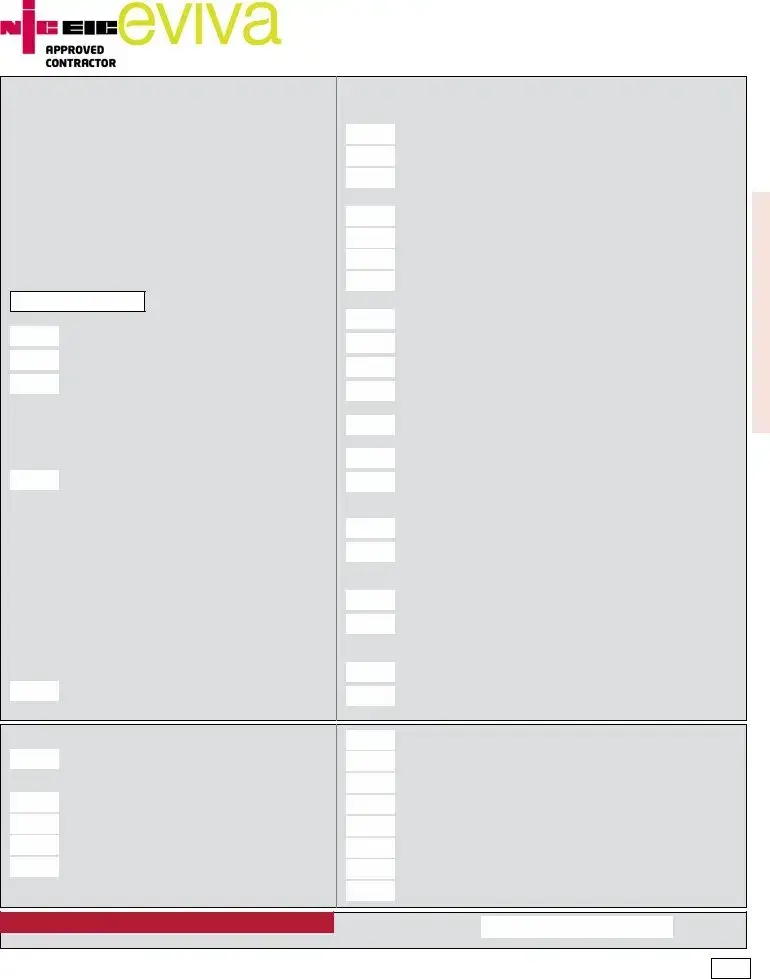

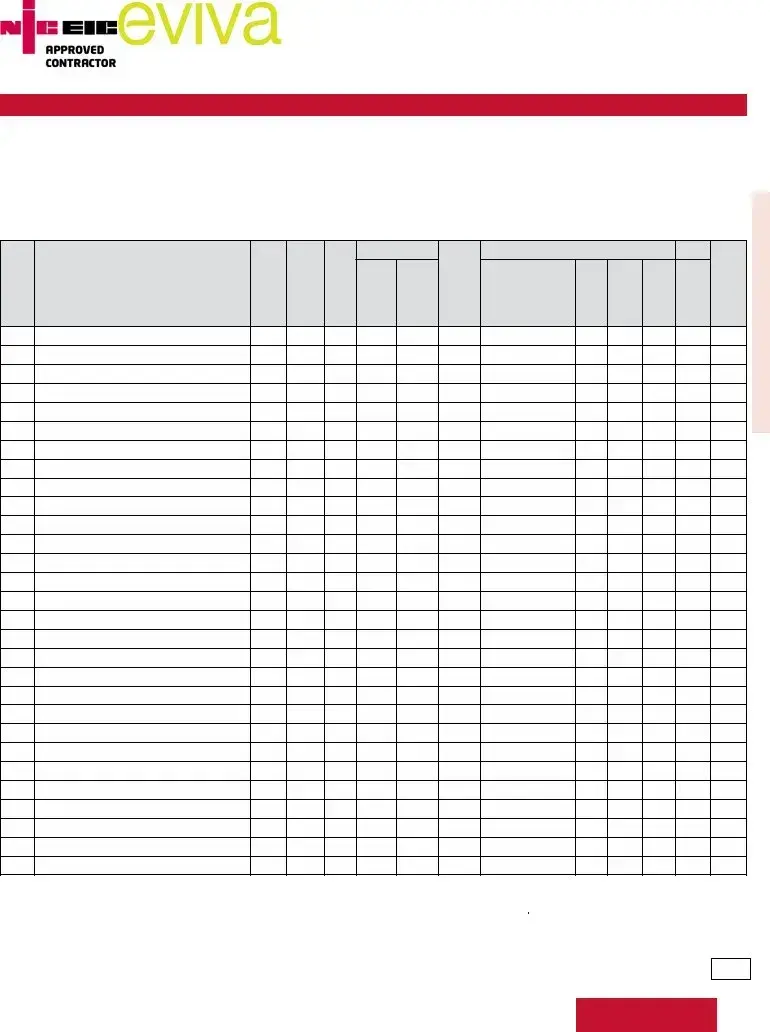

SCHEDULE OF CIRCUIT DETAILS

FOR THE INSTALLATION

CIRCUIT DETAILS

TO BE COMPLETED IN EVERY CASE |

|

TO BE COMPLETED ONLY IF THE DISTRIBUTION BOARD IS NOT CONNECTED DIRECTLY TO THE ORIGIN OF THE INSTALLATION* |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Location of |

|

|

|

|

|

|

|

|

|

|

|

|

|

VH50, Second Floor, Viscount |

|

Supply to distribution |

|

|

|

|

No of |

|

Nominal |

|

|

||

|

Landlords Distribution Panel T2 circuit 5L3 |

|

1 |

230 |

V |

||||||||

distribution board: |

House |

|

|

||||||||||

|

board is from: |

|

phases: |

voltage: |

|||||||||

|

|

|

|

|

|

|

|

|

Associated |

N/A |

|

|

|

|

|

|

Overcurrent protective device for the distribution circuit: |

|

|

RCD (if any): BS(EN) |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|||||

Distribution |

DB T2/5L3 |

|

Type: |

BS 3871 MCB Type 2 |

Rating: |

45 |

A |

RCD No |

N/A |

IÜ |

N/A |

mA |

|

board designation: |

|

BS(EN) |

of poles: |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Circuit designation |

|

|

|

|

|

Circuit |

Max. disconnection time permitted |

|

Overcurrent protective devices |

|

RCD |

7671 |

||

|

|

|

|

|

conductors: csa |

|

|

||||||||

Circuit number and phase |

|

Type of wiring |

(see code) |

|

Number of points served |

Live |

cpc |

|

BS (EN) |

|

|

|

|

BS |

|

|

|

|

|

by BS 7671 |

|

|

Operating current, IÜ |

Maximum Ö permitted by |

|||||||

|

Reference method |

|

|

|

Type No |

Rating |

|||||||||

|

|

|

|

|

|

(mmâ) |

(mmâ) |

(s) |

|

|

|

(A) |

(kA) |

(mA) |

(É) |

1 /L1 |

Ring Main |

B/E |

|

B |

10 |

4.0 |

2.5 |

0.2 |

|

60898 MCB |

C |

32 |

10 |

N/A |

0.72 |

|

|

|

|||||||||||||

2 /L1 |

Lighting |

B |

|

B |

6 |

2.5 |

2.5 |

0.2 |

|

60898 MCB |

C |

16 |

10 |

N/A |

1.44 |

|

|

|

|||||||||||||

3 /L1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 /L1

Duplicate (To be retained by the contractor)

Þ See Table 4A2 of Appendix 4 of BS 7671

|

|

|

|

|

CODES |

FOR TYPE OF |

WIRING |

|

A |

B |

C |

D |

E |

F |

G |

H |

O (Other - please state) |

|

|

|

|

|

|

|

|

|

PVC/PVC |

PVC cable |

PVC cables |

PVC cables |

PVC cables |

PVC/SWA |

XLPE/SWA |

Mineral- |

|

cables |

in metallic |

in |

in metallic |

in |

cables |

cables |

insulated |

|

|

conduit |

conduit |

trunking |

trunking |

|

|

cables |

|

|

|

|

|

|

|

|

|

|

* In such cases, details of the distribution

Page 4 of

5

This form is based on the model shown in Appendix 6 of BS7671 (as amended).

Published by the NICEIC a part of the Ascertiva Group © Copyright The Electrical Safety Council (Jan 2008)

See next page for Schedule of Test Results

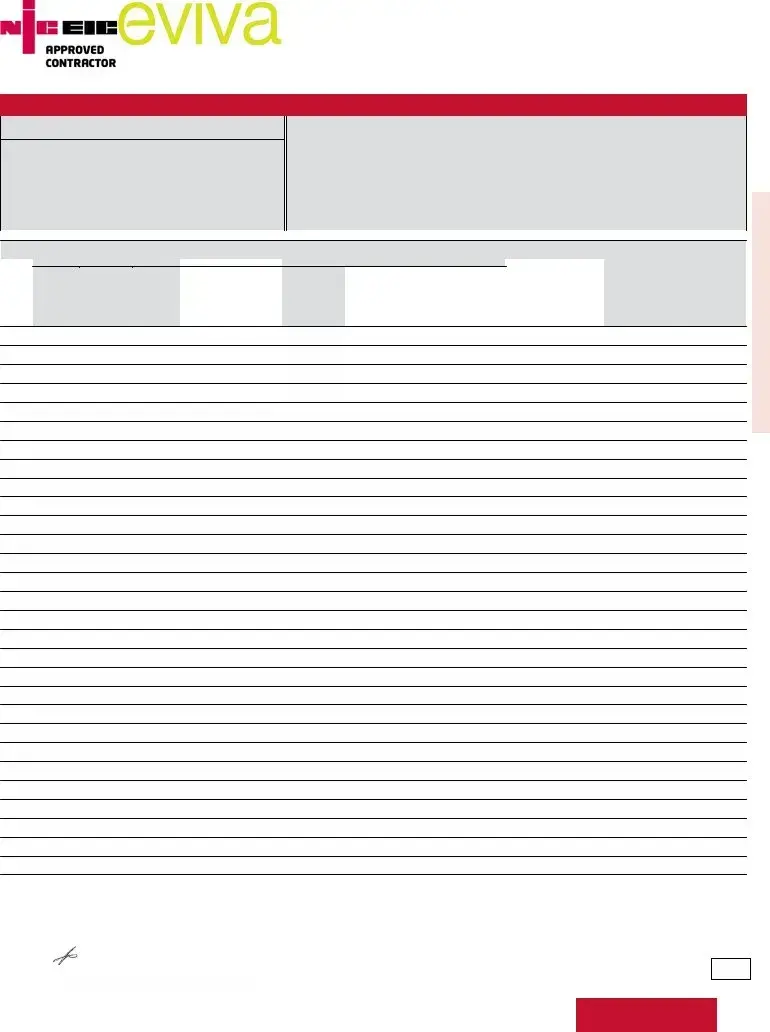

TO BE COMPLETED ONLY IF THE DISTRIBUTION BOARD IS NOT CONNECTED

DIRECTLY TO THE ORIGIN OF THE INSTALLATION

Characteristics at this distribution board

|

|

Yes |

|

|

|

|

|

Confirmation of supply polarity |

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* See note below |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

Ö |

*0.32 |

|

|

|

|

É |

|

|

|

Operating times |

At IÜ |

|

N/A |

|

|

ms |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of associated |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

IÙ |

*0.66 |

|

|

|

|

|

kA |

|

|

|

|

RCD (if any) |

At 5IÜ |

|

N/A |

|

|

ms |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Circuit impedances |

|

|

|

|

|

|

|

|

|

|||

|

numberCircuit |

phaseand |

|

|

|

|

|

|

|

|

|

|

|

|

|

(É) |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Ring final circuits only |

|

|

|

All |

circuits |

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

(measured end to end) |

|

|

(At least |

one column |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

to be |

completed) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

rã |

|

|

|

|

|

rÐ |

|

|

rå |

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

(Line) |

|

|

|

(Neutral) |

|

|

(cpc) |

|

Rã + Rå |

|

Rå |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 /L1 |

|

|

0.15 |

|

|

|

|

015 |

|

|

|

0.25 |

|

|

|

0.10 |

|

|

|

N/A |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

2 /L1 |

|

|

N/A |

|

|

|

|

N/A |

|

|

|

N/A |

|

|

|

0.21 |

|

|

|

N/A |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

3 /L1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

4 /L1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This certificate is not valid if the serial |

ICN2/0335772 |

|

number has been defaced or altered |

|

|

|

|

|

|

|

|

SCHEDULE OF TEST RESULTS |

|

|

FOR THE INSTALLATION |

|

|

TEST RESULTS |

|

|

|

|

|

Test instruments (serial numbers) used: |

|

Earth fault loop |

|

7014230 |

|

|

|

|

|

|

|

RCD |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

impedance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Insulation |

|

|

|

|

|

|

|

|

|

|

|

Other |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

6027902 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

resistance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Continuity |

|

|

|

|

|

|

|

|

|

|

Other |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

6027902 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Insulation |

resistance |

|

|

|

Polarity |

|

|

Maximum |

|

|

|

RCD |

operating |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

measured earth |

|

|

|

times |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

fault loop |

at IÜ |

|

|

at 5IÜ |

||||||

Line/Line Ú |

Line/Neutral Ú |

Line/Earth Ú |

Neutral/Earth Ú |

|

|

|

|

impedance, Ö |

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* See note below |

|

|

|

|

|

(if applicable) |

||||

(MÉ) |

|

(MÉ) |

(MÉ) |

(MÉ) |

(á) |

|

(É) |

|

|

(ms) |

|

|

|

(ms) |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N/A |

|

|

200 |

|

|

200 |

|

|

200 |

|

|

á |

|

|

|

0.42 |

|

|

N/A |

|

|

|

|

N/A |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N/A |

|

|

200 |

|

|

200 |

|

|

200 |

|

|

á |

|

|

|

0.53 |

|

|

N/A |

|

|

|

|

N/A |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Duplicate (To be retained by the contractor)

*Note: Where the installation can be supplied by more than one source, such as primary source (eg public supply) and a secondary source (eg standby generator), the higher or highest values must be recorded.

TESTED BY

Signature: |

|

Position: |

Technical Engineer |

|

|

|

|||

|

|

Date of |

|

|

|

|

|

|

|

Name: |

A. COPE |

16/04/2012 |

|

|

(CAPITALS) |

testing: |

|

||

|

|

|

||

|

|

|

|

|

This form is based on the model shown in Appendix 6 of BS7671 (as amended).

Published by the NICEIC a part of the Ascertiva Group © Copyright The Electrical Safety Council (Jan 2008)

Page 5 of

See previous page for Schedule of Circuit Details

5

Form Characteristics

| Fact Name | Description |

|---|---|

| Issuing Body | This electrical certificate is issued by NICEIC, a recognized authority in the UK for electrical safety. |

| Valid Serial Number | The certificate must display an intact serial number, ICN2/0335772. Any alteration renders it invalid. |

| Regulatory Compliance | The form is compliant with British Standard 7671, which outlines the safety requirements for electrical installations. |

| Details of the Installation | Information about the client's installation, including the address, will appear on the certificate. In this case, it is for Birmingham Airport’s Room VH50. |

| Signatories' Liability | The liability of the signatories is confined to the work described in the certificate. This emphasizes the importance of the specified tasks being carried out diligently. |

| Inspection Timeliness | It is recommended that the installation be inspected and tested again within five years to ensure ongoing compliance and safety. |

Guidelines on Utilizing Niceic Electrical Certificate

Filling out the Niceic Electrical Certificate form is an important task that ensures compliance with electrical installation standards. Careful attention should be paid to each section to guarantee accuracy and completeness. Here are the steps to guide you through the process.

- Start with the Certificate Number: Enter the certificate number in the designated field, ensuring the serial number remains unaltered.

- Client Details: Fill out the client’s name, address, and postcode. For example, use: Birmingham Airport Ltd, Diamond House, Birmingham Airport, B26 3QJ.

- Installation Details: Provide a precise address of the installation along with particulars like the extent of the project and the specific location within the premises—Room VH50, Second Floor, Viscount House, Birmingham Airport, B26 3QJ.

- Design Section: Identify the individual(s) responsible for the design. Include their signatures and dates. If there are multiple designers, list them all.

- Construction Section: Similar to the design section, indicate those accountable for construction. Again, provide their signatures and dates.

- Inspection and Testing Section: Record the names, signatures, and dates of those who performed the inspection and testing of the installation.

- Schedule of Items Inspected: Tick the relevant boxes that apply based on the inspection outcomes and provide additional comments if needed.

- Schedule of Test Results: Document test results. It is crucial to include serial numbers of the test instruments used and ensure all fields are filled accurately.

- Circuit Details: Complete the schedule of circuit details for the installation, mention associated distribution boards, and reference relevant codes.

- Final Review: Ensure all sections are completely filled and signatures are present in the necessary areas. Check compliance with the standards mentioned for validity.

After completing the form, keep in mind that any errors could invalidate the certificate. Take your time to review it thoroughly to ensure that everything is filled out correctly before submission. This careful preparation helps to maintain safety and compliance in electrical installations.

What You Should Know About This Form

What is the NICEIC Electrical Certificate form?

The NICEIC Electrical Certificate form is an important document issued for electrical installations. It confirms that the work carried out meets the necessary safety standards, particularly the British Standard 7671. Only approved contractors or organizations enrolled with NICEIC can issue this certificate, indicating that the work has been completed in compliance with the regulations.

Who issues the NICEIC Electrical Certificate?

The NICEIC Electrical Certificate is issued by approved contractors or organizations that are part of the National Inspection Council for Electrical Installation Contracting (NICEIC). These entities are qualified to ensure that electrical installations comply with safety and performance standards.

What information is included in the certificate?

The certificate includes crucial details such as the client’s information, the installation site, description of the work completed, and the signatures of the responsible parties (designers, constructors, inspectors). It verifies that the installation meets the current regulations and mentions any departures from those regulations if applicable.

Is the NICEIC Electrical Certificate valid forever?

No, the NICEIC Electrical Certificate is not valid indefinitely. It typically outlines a recommended inspection interval, often suggesting that the installation undergo further inspection and testing within five years. Regular checks help ensure ongoing safety and compliance with current standards.

What should I do if the serial number is defaced or altered?

If the certificate's serial number is defaced or altered, the document is considered invalid. It is crucial to keep the certificate in a safe condition. In case of damage, contact the issuing contractor for guidance on obtaining a replacement certificate.