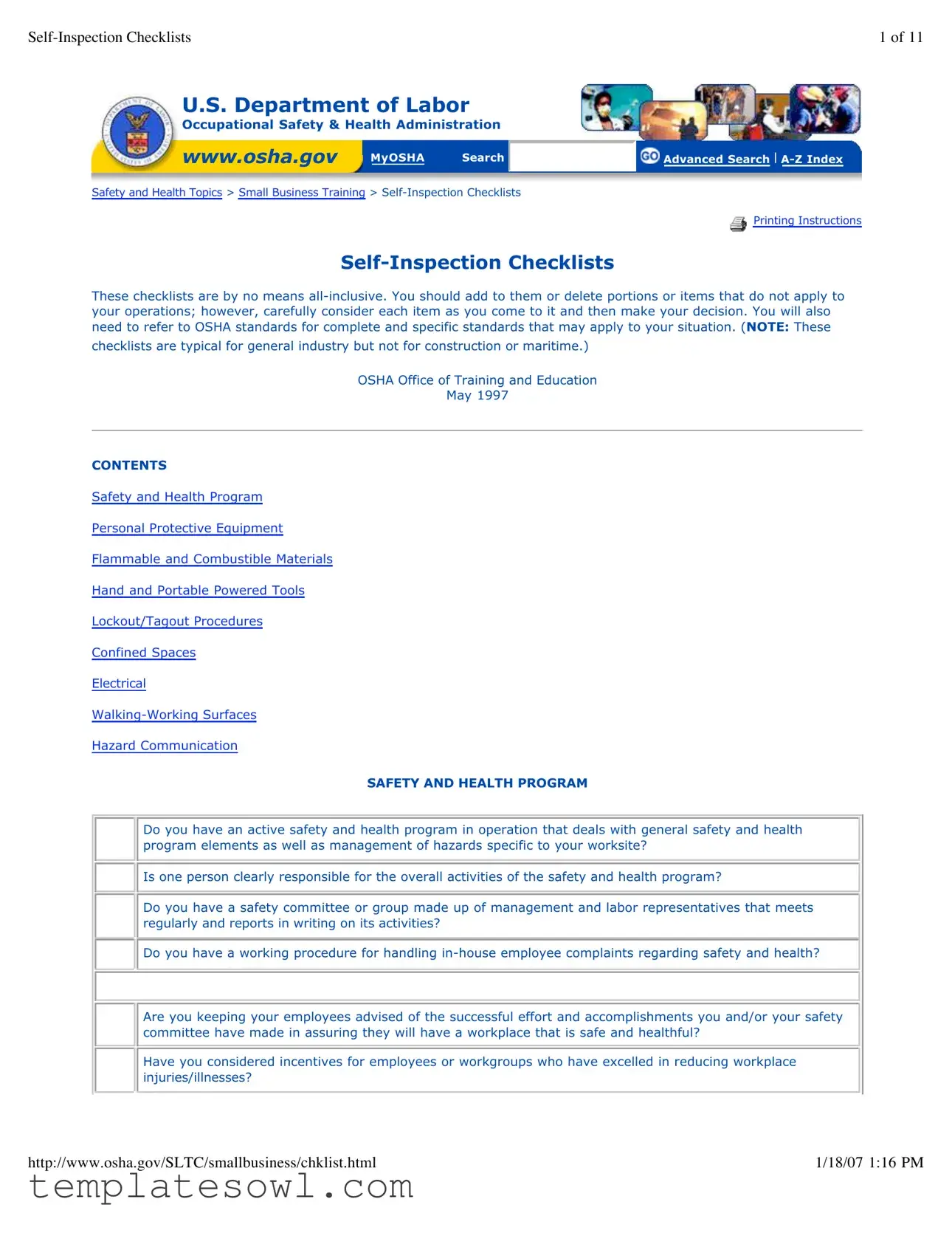

Fill Out Your Osha Workplace Inspection Checklist Form

When it comes to workplace safety, the OSHA Workplace Inspection Checklist form serves as an essential tool for employers to identify potential hazards and ensure the protection of their employees. This comprehensive checklist encompasses major elements of workplace safety, including safety and health programs, personal protective equipment (PPE), and the proper handling of flammable and combustible materials. Each section is designed to guide employers through a systematic evaluation of their work environment. For instance, the safety and health program component prompts users to assess if there is a clearly defined responsibility for safety oversight and whether communication channels are established for employees to voice safety concerns. Additionally, the PPE section highlights the importance of assessing hazards that necessitate protective gear and mandates employee training on its proper use. The checklist also contains important guidance on the safe storage of hazardous materials and the maintenance of tools and equipment, ensuring that fire risks and injuries are minimized. While this checklist is tailored for general industry settings, its insights are invaluable for promoting a culture of safety and compliance in any organization. Employers are encouraged to adapt the checklist to fit their unique workplace conditions, allowing for a proactive approach to health and safety management.

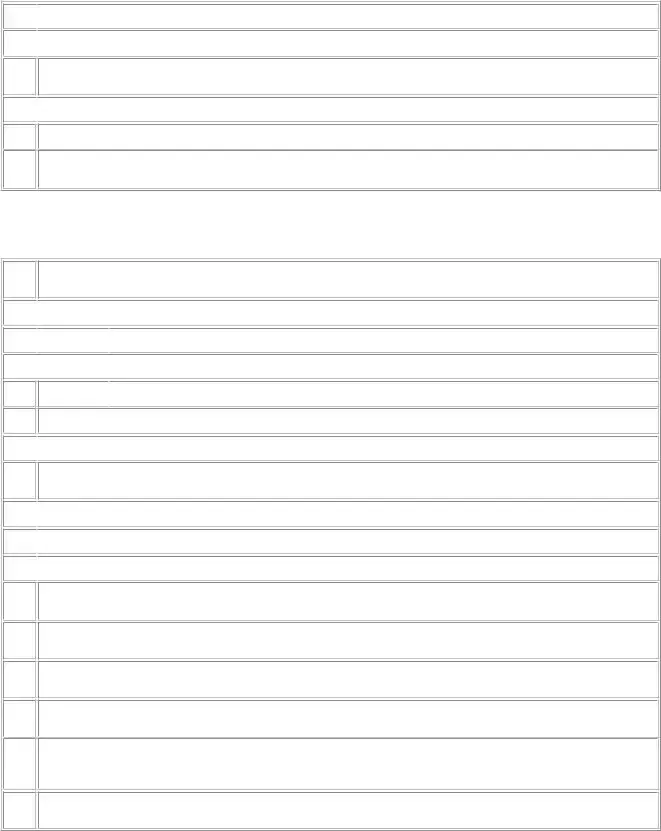

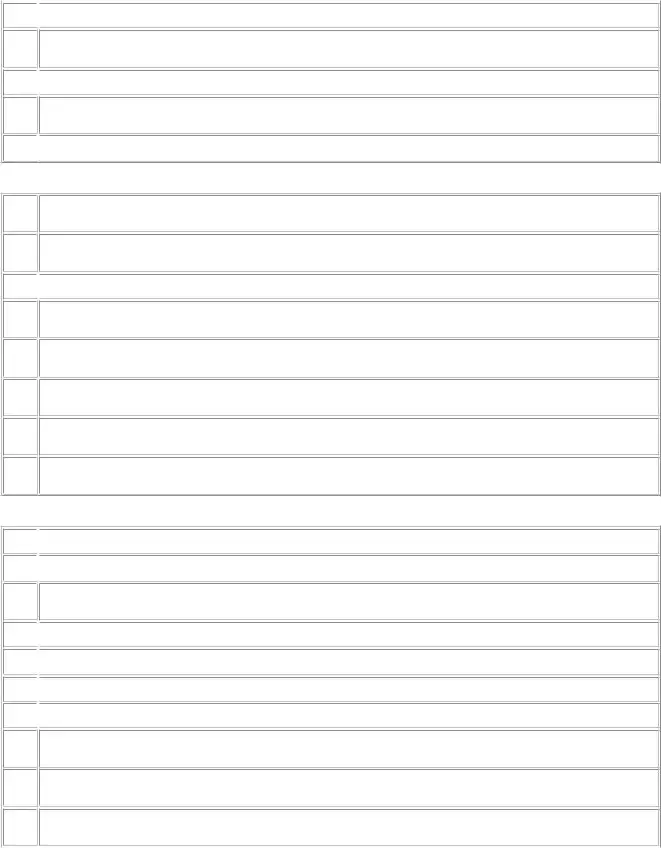

Osha Workplace Inspection Checklist Example

1 of 11 |

U.S. Department of Labor

Occupational Safety & Health Administration

www.osha.gov  MyOSHA [skip navigational links] Search

MyOSHA [skip navigational links] Search

Advanced Search |

Advanced Search |

Safety and Health Topics > Small Business Training >

Printing Instructions

Printing Instructions

These checklists are by no means

checklists are typical for general industry but not for construction or maritime.)

OSHA Office of Training and Education

May 1997

CONTENTS

Safety and Health Program

Personal Protective Equipment

Flammable and Combustible Materials

Hand and Portable Powered Tools

Lockout/Tagout Procedures

Confined Spaces

Electrical

Hazard Communication

SAFETY AND HEALTH PROGRAM

Do you have an active safety and health program in operation that deals with general safety and health program elements as well as management of hazards specific to your worksite?

Is one person clearly responsible for the overall activities of the safety and health program?

Is one person clearly responsible for the overall activities of the safety and health program?

Do you have a safety committee or group made up of management and labor representatives that meets regularly and reports in writing on its activities?

Do you have a working procedure for handling

Are you keeping your employees advised of the successful effort and accomplishments you and/or your safety committee have made in assuring they will have a workplace that is safe and healthful?

Have you considered incentives for employees or workgroups who have excelled in reducing workplace injuries/illnesses?

http://www.osha.gov/SLTC/smallbusiness/chklist.html |

1/18/07 1:16 PM |

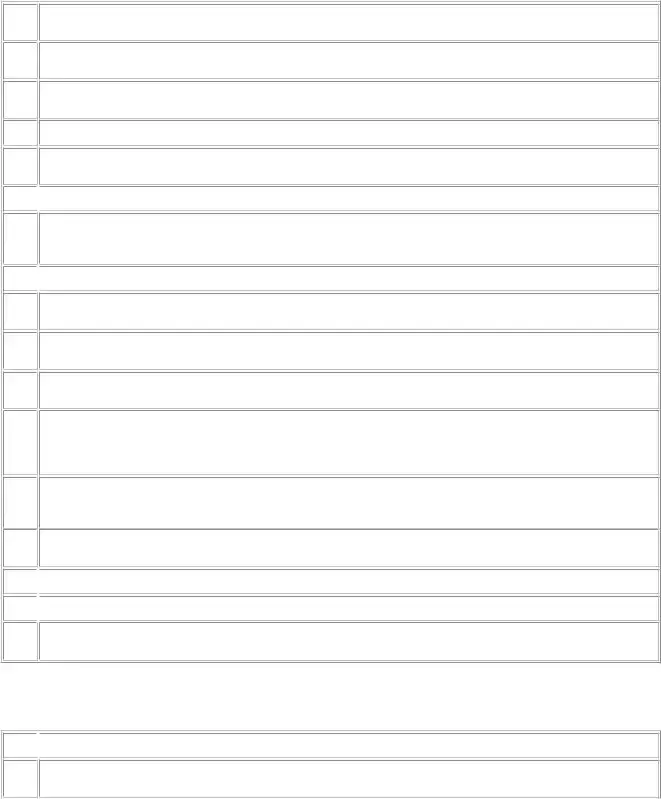

2 of 11 |

PERSONAL PROTECTIVE EQUIPMENT

Are employers assessing the workplace to determine if hazards that require the use of personal protective equipment (for example, head, eye, face, hand, or foot protection) are present or are likely to be present?

If hazards or the likelihood of hazards are found, are employers selecting and having affected employees use properly fitted personal protective equipment suitable for protection from these hazards?

Has the employee been trained on ppe procedures, that is, what ppe is necessary for a job task, when they need it, and how to properly adjust it?

Are protective goggles or face shields provided and worn where there is any danger of flying particles or corrosive materials?

Are approved safety glasses required to be worn at all times in areas where there is a risk of eye injuries such as punctures, abrasions, contusions or burns?

Are employees who need corrective lenses (glasses or contacts) in working environments having harmful exposures, required to wear only approved safety glasses, protective goggles, or use other medically approved precautionary procedures?

Are protective gloves, aprons, shields, or other means provided and required where employees could be cut or where there is reasonably anticipated exposure to corrosive liquids, chemicals, blood, or other potentially infectious materials? See 29 CFR 1910.1030(b) for the definition of "other potentially infectious materials."

Are hard hats provided and worn where danger of falling objects exists?

Are hard hats provided and worn where danger of falling objects exists?

Are hard hats inspected periodically for damage to the shell and suspension system?

Are hard hats inspected periodically for damage to the shell and suspension system?

Is appropriate foot protection required where there is the risk of foot injuries from hot, corrosive, or poisonous substances, falling objects, crushing or penetrating actions?

Are approved respirators provided for regular or emergency use where needed?

Are approved respirators provided for regular or emergency use where needed?

Is all protective equipment maintained in a sanitary condition and ready for use?

Is all protective equipment maintained in a sanitary condition and ready for use?

Do you have eye wash facilities and a quick drench shower within the work area where employees are exposed to injurious corrosive materials? Where special equipment is needed for electrical workers, is it available?

Where food or beverages are consumed on the premises, are they consumed in areas where there is no exposure to toxic material, blood, or other potentially infectious materials?

Is protection against the effects of occupational noise exposure provided when sound levels exceed those of the OSHA noise standard?

Are adequate work procedures, protective clothing and equipment provided and used when cleaning up spilled toxic or otherwise hazardous materials or liquids?

Are there appropriate procedures in place for disposing of or decontaminating personal protective equipment contaminated with, or reasonably anticipated to be contaminated with, blood or other potentially infectious materials?

FLAMMABLE AND COMBUSTIBLE MATERIALS

Are combustible scrap, debris, and waste materials (oily rags, etc.) stored in covered metal receptacles and removed from the worksite promptly?

Is proper storage practiced to minimize the risk of fire including spontaneous combustion?

Is proper storage practiced to minimize the risk of fire including spontaneous combustion?

http://www.osha.gov/SLTC/smallbusiness/chklist.html |

1/18/07 1:16 PM |

3 of 11 |

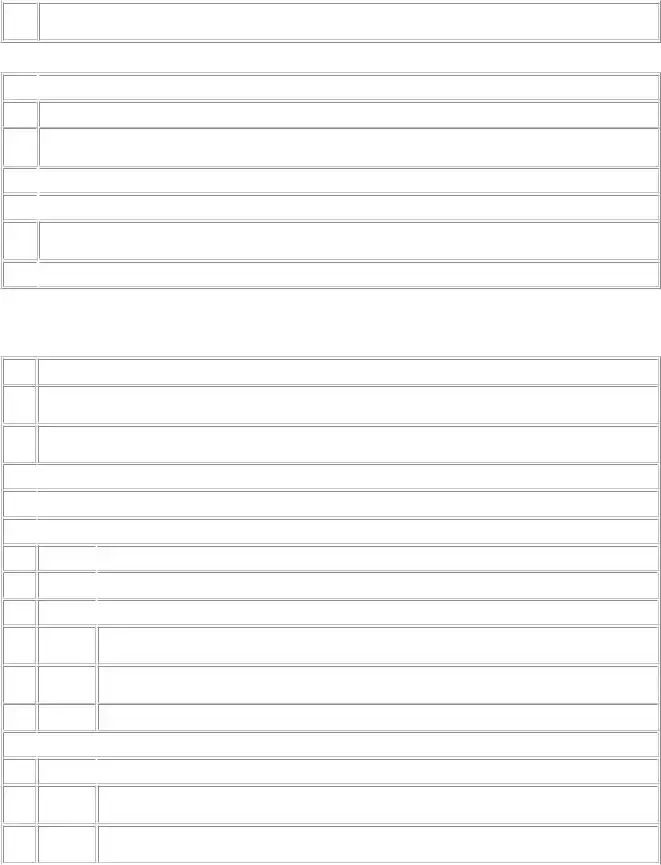

Are approved containers and tanks used for the storage and handling of flammable and combustible liquids?

Are approved containers and tanks used for the storage and handling of flammable and combustible liquids?

Are all connections on drums and combustible liquid piping, vapor and liquid tight?

Are all connections on drums and combustible liquid piping, vapor and liquid tight?

Are all flammable liquids kept in closed containers when not in use (for example, parts cleaning tanks, pans, etc.)?

Are bulk drums of flammable liquids grounded and bonded to containers during dispensing? Do storage rooms for flammable and combustible liquids have

Are bulk drums of flammable liquids grounded and bonded to containers during dispensing? Do storage rooms for flammable and combustible liquids have

Do storage rooms for flammable and combustible liquids have mechanical or gravity ventilation?

Is liquefied petroleum gas stored, handled, and used in accordance with safe practices and standards?

Is liquefied petroleum gas stored, handled, and used in accordance with safe practices and standards?

Are "NO SMOKING" signs posted on liquefied petroleum gas tanks?

Are "NO SMOKING" signs posted on liquefied petroleum gas tanks?

Are liquefied petroleum storage tanks guarded to prevent damage from vehicles?

Are liquefied petroleum storage tanks guarded to prevent damage from vehicles?

Are all solvent wastes and flammable liquids kept in

Is vacuuming used whenever possible rather than blowing or sweeping combustible dust? Are firm separators placed between containers of combustibles or flammables, when stacked one upon another, to assure their support and stability?

Are fuel gas cylinders and oxygen cylinders separated by distance, and

Are fuel gas cylinders and oxygen cylinders separated by distance, and

Are fire extinguishers selected and provided for the types of materials in areas where they are to be used?

Are fire extinguishers selected and provided for the types of materials in areas where they are to be used?

Class A Ordinary combustible material fires.

Class A Ordinary combustible material fires.

Class B Flammable liquid, gas or grease fires.

Class B Flammable liquid, gas or grease fires.

Class C

Class C

Are appropriate fire extinguishers mounted within 75 feet of outside areas containing flammable liquids, and within 10 feet of any inside storage area for such materials?

Are extinguishers free from obstructions or blockage?

Are extinguishers free from obstructions or blockage?

Are all extinguishers serviced, maintained and tagged at intervals not to exceed 1 year?

Are all extinguishers serviced, maintained and tagged at intervals not to exceed 1 year?

Are all extinguishers fully charged and in their designated places?

Are all extinguishers fully charged and in their designated places?

Where sprinkler systems are permanently installed, are the nozzle heads so directed or arranged that water will not be sprayed into operating electrical switch boards and equipment?

Are "NO SMOKING" signs posted where appropriate in areas where flammable or combustible materials are used or stored?

Are safety cans used for dispensing flammable or combustible liquids at a point of use?

Are all spills of flammable or combustible liquids cleaned up promptly?

Are all spills of flammable or combustible liquids cleaned up promptly?

Are storage tanks adequately vented to prevent the development of excessive vacuum or pressure as a result of filling, emptying, or atmosphere temperature changes?

http://www.osha.gov/SLTC/smallbusiness/chklist.html |

1/18/07 1:16 PM |

4 of 11 |

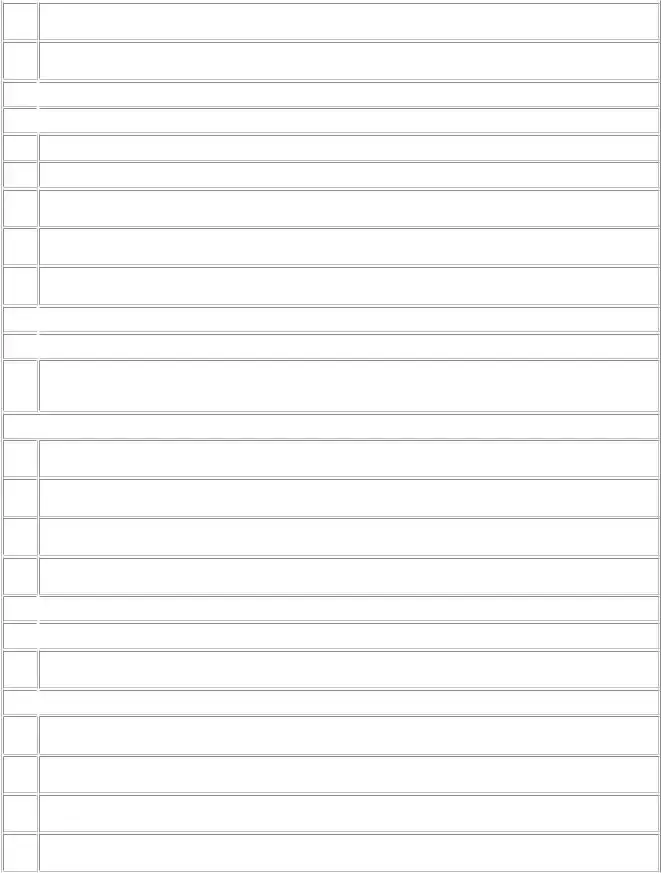

Are storage tanks equipped with emergency venting that will relieve excessive internal pressure caused by fire exposure?

Are "NO SMOKING" rules enforced in areas involving storage and use of hazardous materials?

Are "NO SMOKING" rules enforced in areas involving storage and use of hazardous materials?

HAND AND PORTABLE POWERED TOOLS

Hand Tools and Equipment

Are all tools and equipment (both company and employee owned) used by employees at their workplace in good condition?

Are hand tools such as chisels and punches, which develop mushroomed heads during use, reconditioned or replaced as necessary?

Are broken or fractured handles on hammers, axes and similar equipment replaced promptly?

Are broken or fractured handles on hammers, axes and similar equipment replaced promptly?

Are worn or bent wrenches replaced regularly?

Are worn or bent wrenches replaced regularly?

Are appropriate handles used on files and similar tools?

Are appropriate handles used on files and similar tools?

Are employees made aware of the hazards caused by faulty or improperly used hand tools?

Are employees made aware of the hazards caused by faulty or improperly used hand tools?

Are appropriate safety glasses, face shields, etc. used while using hand tools or equipment which might produce flying materials or be subject to breakage?

Are jacks checked periodically to ensure they are in good operating condition?

Are jacks checked periodically to ensure they are in good operating condition?

Are tool handles wedged tightly in the head of all tools?

Are tool cutting edges kept sharp so the tool will move smoothly without binding or skipping?

Are tools stored in dry, secure locations where they won't be tampered with?

Are tools stored in dry, secure locations where they won't be tampered with?

Is eye and face protection used when driving hardened or tempered spuds or nails?

Is eye and face protection used when driving hardened or tempered spuds or nails?

Portable (Power Operated) Tools and Equipment

Are grinders, saws and similar equipment provided with appropriate safety guards?

Are grinders, saws and similar equipment provided with appropriate safety guards?

Are power tools used with the correct shield, guard, or attachment, recommended by the manufacturer?

Are power tools used with the correct shield, guard, or attachment, recommended by the manufacturer?

Are portable circular saws equipped with guards above and below the base shoe? Are circular saw guards checked to assure they are not wedged up, thus leaving the lower portion of the blade unguarded?

Are rotating or moving parts of equipment guarded to prevent physical contact?

Are rotating or moving parts of equipment guarded to prevent physical contact?

Are all

Are effective guards in place over belts, pulleys, chains, sprockets, on equipment such as concrete mixers, and air compressors?

Are portable fans provided with full guards or screens having openings ½ inch or less?

Are portable fans provided with full guards or screens having openings ½ inch or less?

Is hoisting equipment available and used for lifting heavy objects, and are hoist ratings and characteristics appropriate for the task?

Are

Are pneumatic and hydraulic hoses on power operated tools checked regularly for deterioration or damage?

Are pneumatic and hydraulic hoses on power operated tools checked regularly for deterioration or damage?

http://www.osha.gov/SLTC/smallbusiness/chklist.html |

1/18/07 1:16 PM |

5 of 11 |

Are employees who operate

Are employees who operate

Is each

Is each

Is a sign at least 7 inches by 10 inches with bold face type reading

Are

Are

Are

Do

LOCKOUT/TAGOUT PROCEDURES

Is all machinery or equipment capable of movement, required to be

Where the power disconnecting means for equipment does not also disconnect the electrical control circuit:

Where the power disconnecting means for equipment does not also disconnect the electrical control circuit:

Are the appropriate electrical enclosures identified?

Are the appropriate electrical enclosures identified?

Is means provided to assure the control circuit can also be disconnected and

Is means provided to assure the control circuit can also be disconnected and

Is the

Are all equipment control valve handles provided with a means for

Are all equipment control valve handles provided with a means for

Does the

Are appropriate employees provided with individually keyed personal safety locks?

Are appropriate employees provided with individually keyed personal safety locks?

Are employees required to keep personal control of their key(s) while they have safety locks in use?

Are employees required to keep personal control of their key(s) while they have safety locks in use?

Is it required that only the employee exposed to the hazard, place or remove the safety lock?

Is it required that only the employee exposed to the hazard, place or remove the safety lock?

Is it required that employees check the safety of the

Are employees instructed to always push the control circuit stop button immediately after checking the safety of the

Is there a means provided to identify any or all employees who are working on

Are a sufficient number of accident preventive signs or tags and safety padlocks provided for any reasonably foreseeable repair emergency?

When machine operations, configuration or size requires the operator to leave his or her control station to install tools or perform other operations, and that part of the machine could move if accidentally activated, is such element required to be separately locked or blocked out?

In the event that equipment or lines cannot be shut down,

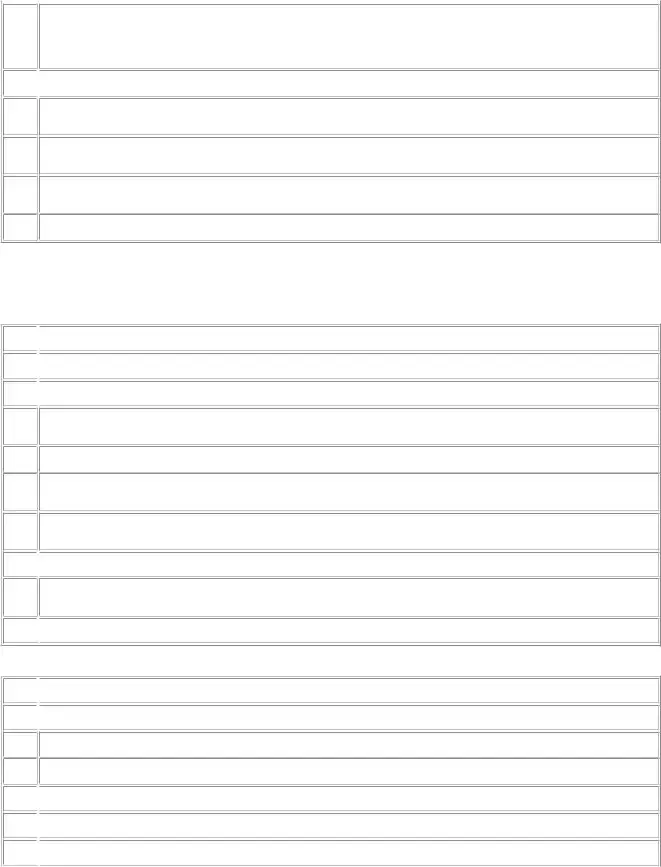

http://www.osha.gov/SLTC/smallbusiness/chklist.html |

1/18/07 1:16 PM |

6 of 11 |

CONFINED SPACES

Are confined spaces thoroughly emptied of any corrosive or hazardous substances, such as acids or caustics, before entry?

Are all lines to a confined space, containing inert, toxic, flammable, or corrosive materials valved off and blanked or disconnected and separated before entry?

Are all impellers, agitators, or other moving parts and equipment inside confined spaces

Is either natural or mechanical ventilation provided prior to confined space entry?

Are appropriate atmospheric tests performed to check for oxygen deficiency, toxic substances and explosive concentrations in the confined space before entry?

Is adequate illumination provided for the work to be performed in the confined space?

Is adequate illumination provided for the work to be performed in the confined space?

Is the atmosphere inside the confined space frequently tested or continuously monitored during conduct of work? Is there an assigned safety standby employee outside of the confined space. when required, whose sole responsibility is to watch the work in progress, sound an alarm if necessary, and render assistance?

Is the standby employee appropriately trained and equipped to handle an emergency?

Is the standby employee appropriately trained and equipped to handle an emergency?

Is the standby employee or other employees prohibited from entering the confined space without lifelines and respiratory equipment if there is any question as to the cause of an emergency?

Is approved respiratory equipment required if the atmosphere inside the confined space cannot be made acceptable

Is all portable electrical equipment used inside confined spaces either grounded and insulated, or equipped with ground fault protection?

Before gas welding or burning is started in a confined space, are hoses checked for leaks, compressed gas bottles forbidden inside of the confined space, torches lighted only outside of the confined area and the confined area tested for an explosive atmosphere each time before a lighted torch is to be taken into the confined space?

If employees will be using

Whenever

Is each confined space checked for decaying vegetation or animal matter which may produce methane?

Is each confined space checked for decaying vegetation or animal matter which may produce methane?

Is the confined space checked for possible industrial waste which could contain toxic properties?

Is the confined space checked for possible industrial waste which could contain toxic properties?

If the confined space is below the ground and near areas where motor vehicles will be operating, is it possible for vehicle exhaust or carbon monoxide to enter the space?

ELECTRICAL

Do you specify compliance with OSHA for all contract electrical work?

Do you specify compliance with OSHA for all contract electrical work?

Are all employees required to report as soon as practicable any obvious hazard to life or property observed in connection with electrical equipment or lines?

http://www.osha.gov/SLTC/smallbusiness/chklist.html |

1/18/07 1:16 PM |

7 of 11 |

Are employees instructed to make preliminary inspections and/or appropriate tests to determine what conditions exist before starting work on electrical equipment or lines?

When electrical equipment or lines are to be serviced, maintained or adjusted, are necessary switches opened,

Are portable electrical tools and equipment grounded or of the double insulated type?

Are portable electrical tools and equipment grounded or of the double insulated type?

Are electrical appliances such as vacuum cleaners, polishers, and vending machines grounded?

Are electrical appliances such as vacuum cleaners, polishers, and vending machines grounded?

Do extension cords being used have a grounding conductor?

Are multiple plug adaptors prohibited?

Are

Are all temporary circuits protected by suitable disconnecting switches or plug connectors at the junction with permanent wiring?

Do you have electrical installations in hazardous dust or vapor areas? If so, do they meet the National Electrical Code (NEC) for hazardous locations?

Is exposed wiring and cords with frayed or deteriorated insulation repaired or replaced promptly?

Is exposed wiring and cords with frayed or deteriorated insulation repaired or replaced promptly?

Are flexible cords and cables free of splices or taps?

Are flexible cords and cables free of splices or taps?

Are clamps or other securing means provided on flexible cords or cables at plugs, receptacles, tools, equipment, etc., and is the cord jacket securely held in place? Are all cord, cable and raceway connections intact and secure?

In wet or damp locations, are electrical tools and equipment appropriate for the use or location or otherwise protected?

Is the location of electrical power lines and cables (overhead, underground, underfloor, other side of walls) determined before digging, drilling or similar work is begun?

Are metal measuring tapes, ropes, handlines or similar devices with metallic thread woven into the fabric prohibited where they could come in contact with energized parts of equipment or circuit conductors?

Is the use of metal ladders prohibited in areas where the ladder or the person using the ladder could come in contact with energized parts of equipment, fixtures or circuit conductors?

Are all disconnecting switches and circuit breakers labeled to indicate their use or equipment served?

Are all disconnecting switches and circuit breakers labeled to indicate their use or equipment served?

Are disconnecting means always opened before fuses are replaced?

Are disconnecting means always opened before fuses are replaced?

Do all interior wiring systems include provisions for grounding metal parts of electrical raceways, equipment and enclosures?

Are all electrical raceways and enclosures securely fastened in place?

Are all electrical raceways and enclosures securely fastened in place?

Are all energized parts of electrical circuits and equipment guarded against accidental contact by approved cabinets or enclosures?

Is sufficient access and working space provided and maintained about all electrical equipment to permit ready and safe operations and maintenance?

Are all unused openings (including conduit knockouts) in electrical enclosures and fittings closed with appropriate covers, plugs or plates?

Are electrical enclosures such as switches, receptacles, and junction boxes, provided with tightfitting covers or plates?

http://www.osha.gov/SLTC/smallbusiness/chklist.html |

1/18/07 1:16 PM |

8 of 11 |

Are disconnecting switches for electrical motors in excess of two horsepower, capable of opening the circuit when the motor is in a stalled condition, without exploding? (Switches must be horsepower rated equal to or in excess of the motor hp rating.) Is low voltage protection provided in the control device of motors driving machines or equipment which could cause probable injury from inadvertent starting?

Is each motor disconnecting switch or circuit breaker located within sight of the motor control device?

Is each motor disconnecting switch or circuit breaker located within sight of the motor control device?

Is each motor located within sight of its controller or the controller disconnecting means capable of being locked in the open position or is a separate disconnecting means installed in the circuit within sight of the motor?

Is the controller for each motor in excess of two horsepower, rated in horsepower equal to or in excess of the rating of the motor it serves?

Are employees who regularly work on or around energized electrical equipment or lines instructed in the cardiopulmonary resuscitation (CPR) methods?

Are employees prohibited from working alone on energized lines or equipment over 600 volts?

General Work Environment

Is a documented, functioning housekeeping program in place?

Is a documented, functioning housekeeping program in place?

Are all worksites clean, sanitary, and orderly?

Are all worksites clean, sanitary, and orderly?

Are work surfaces kept dry or is appropriate means taken to assure the surfaces are

Are work surfaces kept dry or is appropriate means taken to assure the surfaces are

Are all spilled hazardous materials or liquids, including blood and other potentially infectious materials, cleaned up immediately and according to proper procedures?

Is combustible scrap, debris and waste stored safely and removed from the worksite properly?

Is all regulated waste, as defined in the OSHA bloodborne pathogens standard (1910.1030), discarded according to federal, state, and local regulations?

Are accumulations of combustible dust routinely removed from elevated surfaces including the overhead structure of buildings, etc.?

Is combustible dust cleaned up with a vacuum system to prevent the dust from going into suspension?

Is combustible dust cleaned up with a vacuum system to prevent the dust from going into suspension?

Is metallic or conductive dust prevented from entering or accumulating on or around electrical enclosures or equipment?

Are covered metal waste cans used for oily and

Are covered metal waste cans used for oily and

Walkways

Are aisles and passageways kept clear?

Are aisles and passageways kept clear?

Are aisles and walkways marked as appropriate?

Are aisles and walkways marked as appropriate?

Are wet surfaces covered with

Are holes in the floor, sidewalk or other walking surface repaired properly, covered or otherwise made safe?

Is there safe clearance for walking in aisles where motorized or mechanical handling equipment is operating?

Is there safe clearance for walking in aisles where motorized or mechanical handling equipment is operating?

Are materials or equipment stored in such a way that sharp projectives will not interfere with the walkway?

Are materials or equipment stored in such a way that sharp projectives will not interfere with the walkway?

Are spilled materials cleaned up immediately?

Are spilled materials cleaned up immediately?

http://www.osha.gov/SLTC/smallbusiness/chklist.html |

1/18/07 1:16 PM |

9 of 11 |

Are changes of direction or elevation readily identifiable?

Are changes of direction or elevation readily identifiable?

Are aisles or walkways that pass near moving or operating machinery, welding operations or similar operations arranged so employees will not be subjected to potential hazards?

Is adequate headroom provided for the entire length of any aisle or walkway?

Is adequate headroom provided for the entire length of any aisle or walkway?

Are standard guardrails provided wherever aisle or walkway surfaces are elevated more than 30 inches above any adjacent floor or the ground?

Are bridges provided over conveyors and similar hazards?

Are bridges provided over conveyors and similar hazards?

Floor and Wall Openings

Are floor openings guarded by a cover, a guardrail, or equivalent on all sides (except at entrance to stairways or ladders)?

Are toeboards installed around the edges of permanent floor openings (where persons may pass below the opening)?

Are skylight screens of such construction and mounting that they will withstand a load of at least 200 pounds?

Are skylight screens of such construction and mounting that they will withstand a load of at least 200 pounds?

Is the glass in the windows, doors, glass walls, etc., which are subject to human impact, of sufficient thickness and type for the condition of use?

Are grates or similar type covers over floor openings such as floor drains of such design that foot traffic or rolling equipment will not be affected by the grate spacing?

Are unused portions of service pits and pits not actually in use either covered or protected by guardrails or equivalent?

Are manhole covers, trench covers and similar covers, plus their supports designed to carry a truck rear axle load of at least 20,000 pounds when located in roadways and subject to vehicle traffic?

Are floor or wall openings in fire resistive construction provided with doors or covers compatible with the fire rating of the structure and provided with a

Stairs and Stairways

Are standard stair rails or handrails on all stairways having four or more risers?

Are standard stair rails or handrails on all stairways having four or more risers?

Are all stairways at least 22 inches wide?

Are all stairways at least 22 inches wide?

Do stairs have landing platforms not less than 30 inches in the direction of travel and extend 22 inches in width at every 12 feet or less of vertical rise?

Do stairs angle no more than 50 and no less than 30 degrees?

Do stairs angle no more than 50 and no less than 30 degrees?

Are step risers on stairs uniform from top to bottom?

Are step risers on stairs uniform from top to bottom?

Are steps on stairs and stairways designed or provided with a surface that renders them slip resistant?

Are steps on stairs and stairways designed or provided with a surface that renders them slip resistant?

Are stairway handrails located between 30 and 34 inches above the leading edge of stair treads?

Are stairway handrails located between 30 and 34 inches above the leading edge of stair treads?

Do stairway handrails have at least 3 inches of clearance between the handrails and the wall or surface they are mounted on?

Where doors or gates open directly on a stairway, is there a platform provided so the swing of the door does not reduce the width of the platform to less than 21 inches?

Where stairs or stairways exit directly into any area where vehicles may be operated, are adequate barriers and warnings provided to prevent employees stepping into the path of traffic?

http://www.osha.gov/SLTC/smallbusiness/chklist.html |

1/18/07 1:16 PM |

10 of 11 |

Do stairway landings have a dimension measured in the direction of travel, at least equal to the width of the stairway?

Elevated Surfaces

Are signs posted, when appropriate, showing the elevated surface load capacity?

Are signs posted, when appropriate, showing the elevated surface load capacity?

Are surfaces elevated more than 30 inches above the floor or ground provided with standard guardrails?

Are all elevated surfaces (beneath which people or machinery could be exposed to falling objects) provided with standard

Is a permanent means of access and egress provided to elevated storage and work surfaces?

Is a permanent means of access and egress provided to elevated storage and work surfaces?

Is required headroom provided where necessary?

Is required headroom provided where necessary?

Is material on elevated surfaces piled, stacked or racked in a manner to prevent it from tipping, falling, collapsing, rolling or spreading?

Are dock boards or bridge plates used when transferring materials between docks and trucks or rail cars?

Are dock boards or bridge plates used when transferring materials between docks and trucks or rail cars?

HAZARD COMMUNICATION

Is there a list of hazardous substances used in your workplace?

Is there a written hazard communication program dealing with Material Safety Data Sheets (MSDS), labeling, and employee training?

Is each container for a hazardous substance (i.e., vats, bottles, storage tanks, etc.) labeled with product identity and a hazard warning (communication of the specific health hazards and physical hazards)?

Is there a Material Safety Data Sheet readily available for each hazardous substance used?

Is there a Material Safety Data Sheet readily available for each hazardous substance used?

Is there an employee training program for hazardous substances?

Is there an employee training program for hazardous substances?

Does this program include:

Does this program include:

An explanation of what an MSDS is and how to use and obtain one?

An explanation of what an MSDS is and how to use and obtain one?

MSDS contents for each hazardous substance or class of substances?

MSDS contents for each hazardous substance or class of substances?

Explanation of "Right to Know?"

Explanation of "Right to Know?"

Identification of where an employee can see the employers written hazard communication program and where hazardous substances are present in their work areas?

The physical and health hazards of substances in the work area, and specific protective measures to be used?

Details of the hazard communication program, including how to use the labeling system and MSDS's?

Are employees trained in the following:

Are employees trained in the following:

How to recognize tasks that might result in occupational exposure?

How to recognize tasks that might result in occupational exposure?

How to use work practice and engineering controls and personal protective equipment and to know their limitations?

How to obtain information on the types selection, proper use, location, removal handling, decontamination, and disposal of personal protective equipment?

http://www.osha.gov/SLTC/smallbusiness/chklist.html |

1/18/07 1:16 PM |

Form Characteristics

| Fact Name | Details |

|---|---|

| Purpose | The OSHA Workplace Inspection Checklist helps employers evaluate their safety and health programs and policies. |

| Customizability | Users can modify the checklist by adding or removing items that apply to their specific operations. |

| Typical Use | This checklist is designed primarily for general industry and may not cover construction or maritime settings. |

| Standards Reference | Consult OSHA standards for specific guidelines that apply to different work environments. |

| Contents | Key areas covered include safety programs, personal protective equipment, and lockout/tagout procedures. |

| Compliance Role | The checklist helps ensure compliance with federal and state safety regulations. |

| Consultation Encouragement | Employers are advised to engage with safety committees for regular assessments and improvement suggestions. |

| Training Requirement | Employees should be trained on the proper use of personal protective equipment and safety tools outlined in the checklist. |

| Inspection Frequency | Regular inspections using the checklist should occur to maintain a safe workplace and address hazards promptly. |

| Documentation | Employers should document findings from inspections and take corrective actions when necessary to enhance safety. |

Guidelines on Utilizing Osha Workplace Inspection Checklist

Filling out the OSHA Workplace Inspection Checklist is an essential step in ensuring workplace safety and compliance. This form provides a structured way to assess various safety aspects of your work environment. By following these steps, you can effectively complete the checklist and address any potential hazards that may arise in your workplace.

- Obtain the OSHA Workplace Inspection Checklist form from the official OSHA website or your internal safety resources.

- Review the form to familiarize yourself with the different sections, such as Safety and Health Program, Personal Protective Equipment, and others.

- Begin with the first section. For each item listed, assess your workplace conditions and practices.

- Answer each question honestly, marking "Yes" or "No" based on your observations. Take note of any items that require immediate attention.

- Provide additional comments or details for items that may need improvement or explanation, ensuring clarity for future review.

- Continue through each section of the checklist, following the same process of evaluation and marking your responses.

- Once completed, review the checklist to ensure all areas have been addressed.

- Save an electronic copy or make a physical copy for your records before distributing it to relevant team members or management for review.

- Set a follow-up date to discuss findings with your team and implement necessary safety measures.

What You Should Know About This Form

What is the purpose of the OSHA Workplace Inspection Checklist Form?

The OSHA Workplace Inspection Checklist Form serves as a tool for employers to assess safety and health conditions in their workplace. By using this checklist, companies can systematically review their operations to identify potential hazards and ensure compliance with OSHA standards. It allows employers to recognize areas for improvement and take proactive measures to create a safer work environment for employees.

Who should use the OSHA Workplace Inspection Checklist Form?

This form is designed for use by employers in various industries, particularly in general industry settings. It is particularly beneficial for safety coordinators, managers, and team leaders who are responsible for maintaining workplace safety. While the checklist is comprehensive, users should feel free to modify it to fit their specific workplace needs and standards applicable to their operations.

What areas does the checklist cover?

The OSHA Workplace Inspection Checklist encompasses several critical areas important for workplace safety. Key topics include the safety and health program, personal protective equipment, flammable and combustible materials, hand and portable power tools, lockout/tagout procedures, confined spaces, electrical safety, walking-working surfaces, and hazard communication. Each section prompts users to evaluate specific aspects of their operations to ensure compliance and safety.

How often should the checklist be completed?

Regular completion of the checklist is advisable to maintain safety and health standards. Many businesses conduct self-inspections quarterly, but this frequency can vary based on specific workplace risks and changes in operations. After any incident or when new equipment or processes are introduced, it is prudent to complete the checklist to identify and resolve any newly arising safety issues.

Can the checklist be modified for specific workplace needs?

Yes, the OSHA Workplace Inspection Checklist is not intended to be all-inclusive. Users are encouraged to tailor the checklist to their unique operations by adding relevant items or omitting those that do not apply. This customization helps ensure that the checklist effectively addresses the specific hazards faced in a given workplace, improving the overall safety and compliance efforts.

Common mistakes

Filling out the OSHA Workplace Inspection Checklist can be a crucial task for ensuring safety in the workplace. However, many individuals make mistakes that can undermine the effectiveness of this process. One common error is failing to customize the checklist according to the specific operations of their workplace. The guidelines suggest that users consider adding or removing items based on their unique circumstances. Without this careful consideration, significant safety concerns relevant to the specific work environment may be overlooked.

Another mistake frequently seen is neglecting to ensure that all necessary personnel are involved in the inspection process. Having only one individual fill out the checklist may limit perspectives on potential hazards. Instead, it could be beneficial to involve a diverse team that includes representatives from various departments. This collaboration can lead to a more comprehensive understanding of the workplace hazards and appropriate safety measures.

Inaccurate or incomplete answers on the checklist can lead to oversight of important safety issues. Some individuals may rush through the form or skip questions altogether, thinking they do not require immediate attention. Each question on the checklist is designed to uncover specific hazards; skipping may result in undetected risks. Proper attention to each item is essential for identifying potential dangers.

Additionally, not keeping records of past inspections can create difficulties in tracking safety improvements and ongoing challenges. When individuals do not maintain a history of inspections, valuable data and trends may be lost. Regularly reviewing past checklist results can help identify persistent issues and evaluate the effectiveness of previous corrective actions.

Failing to train employees on the use of personal protective equipment (PPE) is another significant oversight. Even if the checklist indicates that PPE is available and in good condition, if employees do not know how to use it properly, safety measures cannot be effective. Regular training sessions are essential to ensure everyone understands the importance of PPE and how to utilize it correctly.

Moreover, some users misinterpret the checklist as a one-time activity rather than an ongoing process. To maintain a safe workplace, inspections should occur regularly, not solely when prompted by a checklist. By making safety audits a routine practice, potential hazards can be addressed proactively rather than reactively.

A lack of follow-up on identified issues also represents a common error. Simply noting problems on the checklist is insufficient if corrective actions are not implemented afterward. Assigning responsibility and establishing timelines for addressing safety concerns are necessary steps in promoting a culture of safety within the workplace.

Finally, overlooking the importance of employee feedback can hinder the effectiveness of the inspection process. Employees who work directly in specific environments often have valuable insights about potential hazards. Engaging them in discussions about safety concerns and incorporating their feedback into the checklist process can enhance the overall efficacy of workplace safety strategies.

Documents used along the form

The OSHA Workplace Inspection Checklist form is an essential tool for ensuring workplace safety. It can be utilized alongside several other important documents to enhance safety practices and compliance. Below are some commonly used forms and documents that complement the Osha checklist.

- Incident Report Form: This document is used to record details about workplace accidents or near misses. It helps in identifying root causes and implementing measures to prevent future incidents.

- Safety Data Sheets (SDS): SDS provide important safety information about hazardous materials being used in the workplace. They include details about chemical properties, hazards, handling procedures, and emergency measures.

- Personal Protective Equipment (PPE) Assessment: This document outlines the evaluation of potential hazards that may require the use of PPE, specifying what equipment is necessary for different tasks.

- Emergency Action Plan: This plan describes the procedures to follow in various emergency situations, such as fires or hazardous spills. It ensures that employees know how to respond effectively to protect themselves.

- Training Records: These documents record safety and health training sessions attended by employees. They serve as proof of training and help ensure compliance with regulatory requirements.

- Workplace Hazard Assessment: This assessment identifies and evaluates hazards present in the workplace. It guides employers in developing strategies to mitigate risks.

- Monthly Safety Inspection Report: Regular safety inspections are documented in this report, which tracks compliance and identifies areas that need improvement over time.

- Lockout/Tagout (LOTO) Procedure: This document details the procedures for de-energizing equipment before maintenance. It ensures that employees are protected from accidental machine start-up.

Utilizing these documents in conjunction with the OSHA Workplace Inspection Checklist fosters a safer work environment. Each document plays a crucial role in managing health and safety effectively, contributing to a culture of safety awareness.

Similar forms

The OSHA Workplace Inspection Checklist form is similar to other documents that focus on safety, inspection, and compliance within the workplace. Here’s a list of eight documents that share common elements with the checklist:

- Safety Audit Checklist: This document systematically evaluates workplace safety, similar to the OSHA checklist, ensuring compliance with safety standards and identifying potential hazards.

- Fire Safety Inspection Report: Like the OSHA checklist, this report focuses on fire prevention measures, assesses compliance with fire safety regulations, and identifies fire hazards.

- Equipment Safety Inspection Form: Both documents assess the condition of tools and machinery. Each aims to ensure equipment is safe to use and properly maintained, thus reducing the risk of accidents.

- Incident Report Form: This form documents workplace accidents or near misses. It is similar in that both aim to improve workplace safety by analyzing causes and implementing preventive measures.

- Hazardous Materials Inventory: This inventory lists substances that pose potential risks, paralleling the OSHA checklist in evaluating workplace hazards for safety compliance.

- Ergonomics Assessment Tool: Both the tool and the checklist evaluate workplace conditions that could lead to injuries. Ergonomics assessments focus on the human factors that contribute to safety, much like the OSHA form.

- Workplace Violence Prevention Plan: This document outlines strategies to reduce violence in the workplace. Similar to the OSHA checklist, it aims to identify risks and promote a safer work environment.

- Personal Protective Equipment Assessment: Both documents evaluate the need for personal protective gear in the workplace, ensuring that employees have the appropriate equipment to mitigate risks.

Dos and Don'ts

When filling out the OSHA Workplace Inspection Checklist form, it is important to follow specific guidelines to ensure accuracy and compliance. Here are ten things you should and shouldn't do:

- Do familiarize yourself with OSHA standards relevant to your industry before starting the checklist.

- Do ensure that all relevant staff are involved in the inspection process.

- Do customize the checklist by adding or removing items that do not apply to your operations.

- Do document findings clearly and provide detailed explanations for any issues identified.

- Do refer to past inspection reports for consistency and to track improvements or recurring issues.

- Don't rush through the form; take the time necessary to assess each item thoroughly.

- Don't ignore safety and health program elements that are important for your specific workplace.

- Don't use vague language in your findings; be specific about hazards and required actions.

- Don't forget to inform employees of the inspection results and proposed improvements.

- Don't neglect follow-up actions after the checklist is completed; act on any problems identified.

Misconceptions

- Myth: The OSHA Workplace Inspection Checklist is exhaustive. The checklist is not all-inclusive. Employers should modify it to suit their specific operations by adding or removing items as necessary.

- Myth: Using the checklist guarantees compliance with OSHA standards. While the checklist can help identify safety issues, it does not replace the need to understand and adhere to OSHA standards. Reference to specific standards is crucial for full compliance.

- Myth: The checklist is only relevant for large businesses. Small businesses also benefit from using the checklist. Its design accommodates a range of business sizes and types, making it applicable to various workplaces.

- Myth: Conducting inspections can be a one-time task. Inspections should be ongoing. Regular self-assessments help identify hazards continuously and promote a safer workplace rather than a single review.

- Myth: The checklist is only focused on physical safety. The checklist covers a wide array of safety concerns, including health programs and the use of personal protective equipment, addressing both physical and health-related hazards.

Key takeaways

- Customization is key. The checklist is a guide, not a complete solution. Feel free to modify it to fit your specific workplace needs.

- Prioritize hazards. Carefully evaluate each item and determine which hazards are most applicable to your operations.

- Compliance is crucial. Refer to OSHA standards to ensure that your workplace meets all necessary regulations.

- Assign responsibilities. Designate a person in charge of your workplace's safety and health program to maintain accountability.

- Encourage involvement. Establish a safety committee that includes both management and employees, and ensure it meets regularly.

- Provide proper training. Make sure employees are trained on personal protective equipment (PPE) and its appropriate use.

- Keep records. Document your inspections and any issues found, along with the steps taken to address them.

- Maintain equipment. Regularly check tools and safety equipment to ensure that they remain in good working condition.

- Promote safety awareness. Share information about safety accomplishments and encourage a culture of safety among all employees.

Browse Other Templates

Florida Health Care Surrogate Statute - Discussing the implications of this designation can deepen understanding and trust among family members.

Home Health Certification Form,Plan of Care for Home Health Services,Home Health Services Authorization,Patient Care and Treatment Plan,Intermittent Skilled Care Certification,Home Health Service Plan,CMS Home Care Certification Form,Home Health Prov - Patient consent is implied through the use and submission of this form.