Fill Out Your Pre Use Inspection Checklist Form

The Pre Use Inspection Checklist is an essential tool for operators of mobile cranes, designed to enhance safety and operational efficiency before any lifting activity begins. This checklist requires operators to perform a thorough examination of various components, ensuring everything is functioning correctly and safely. Key areas covered include the inspection of engine and hydraulic fluid levels, tire conditions, and the integrity of the telescoping boom. Additionally, operators check the condition of wire ropes, block mechanisms, and safety guards, along with the functionality of essential gauges and indicators. The form also emphasizes the importance of maintaining a visible load chart and hand signal chart for the benefit of the crew. Each aspect of the checklist addresses critical safety protocols, so if any item fails inspection, a service request must be made immediately. Keeping this form on the crane during operations serves as a reminder of the ongoing responsibility to ensure safe practices are followed at all times. This way, operators establish a standard for equipment readiness that ultimately protects everyone involved in the lifting process.

Pre Use Inspection Checklist Example

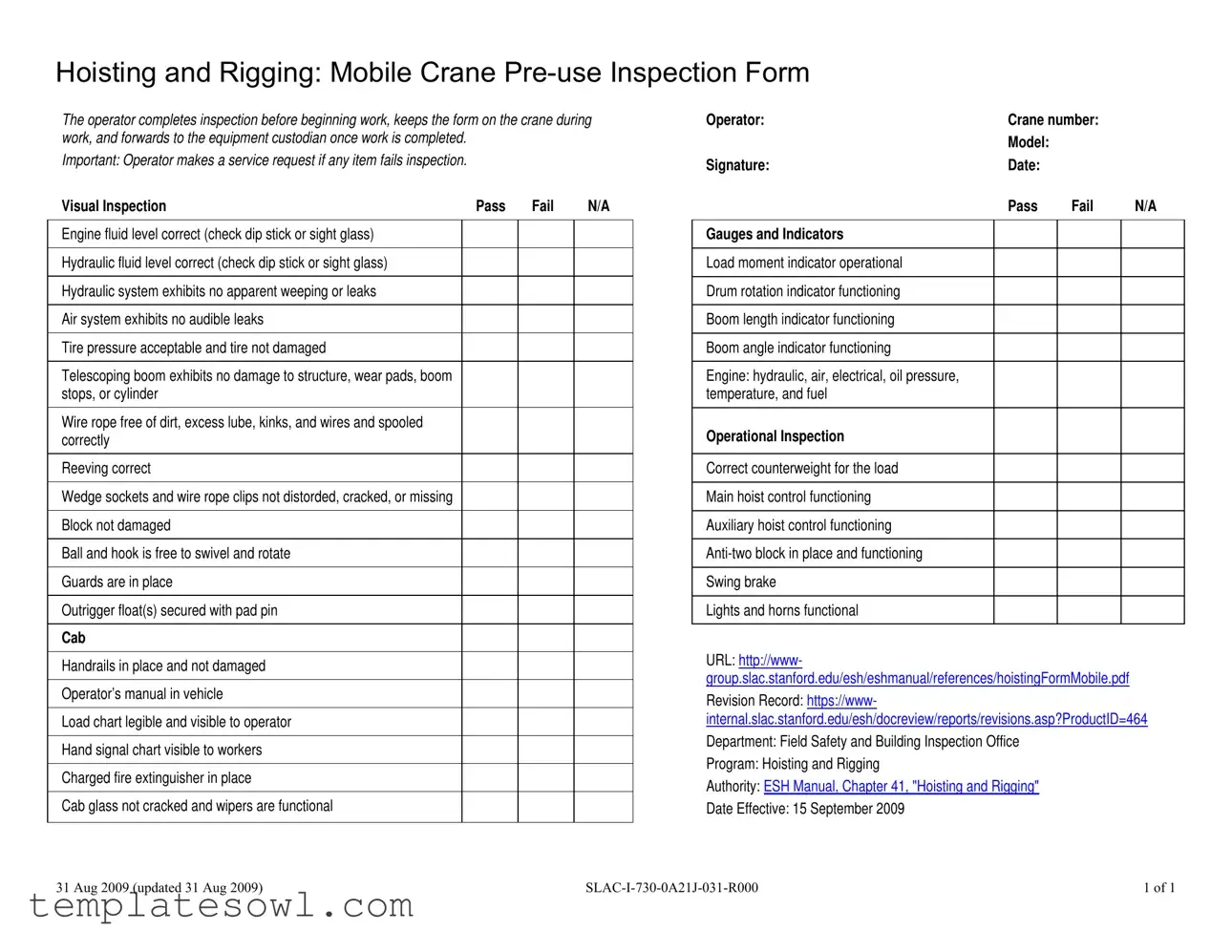

Hoisting and Rigging: Mobile Crane

The operator completes inspection before beginning work, keeps the form on the crane during work, and forwards to the equipment custodian once work is completed.

Important: Operator makes a service request if any item fails inspection.

Visual Inspection |

Pass |

Fail |

N/A |

Engine fluid level correct (check dip stick or sight glass)

Hydraulic fluid level correct (check dip stick or sight glass)

Hydraulic system exhibits no apparent weeping or leaks

Air system exhibits no audible leaks

Tire pressure acceptable and tire not damaged

Telescoping boom exhibits no damage to structure, wear pads, boom stops, or cylinder

Wire rope free of dirt, excess lube, kinks, and wires and spooled correctly

Reeving correct

Wedge sockets and wire rope clips not distorded, cracked, or missing

Block not damaged

Ball and hook is free to swivel and rotate

Guards are in place

Outrigger float(s) secured with pad pin

Cab

Handrails in place and not damaged

Operator’s manual in vehicle

Load chart legible and visible to operator

Hand signal chart visible to workers

Charged fire extinguisher in place

Cab glass not cracked and wipers are functional

Operator: |

Crane number: |

|

|

|

Model: |

|

|

Signature: |

Date: |

|

|

|

Pass |

Fail |

N/A |

|

|

|

|

Gauges and Indicators |

|

|

|

Load moment indicator operational

Drum rotation indicator functioning

Boom length indicator functioning

Boom angle indicator functioning

Engine: hydraulic, air, electrical, oil pressure, temperature, and fuel

Operational Inspection

Correct counterweight for the load

Main hoist control functioning

Auxiliary hoist control functioning

Swing brake

Lights and horns functional

URL: http://www- group.slac.stanford.edu/esh/eshmanual/references/hoistingFormMobile.pdf

Revision Record: https://www- internal.slac.stanford.edu/esh/docreview/reports/revisions.asp?ProductID=464

Department: Field Safety and Building Inspection Office

Program: Hoisting and Rigging

Authority: ESH Manual, Chapter 41, "Hoisting and Rigging"

Date Effective: 15 September 2009

31 Aug 2009 (updated 31 Aug 2009) |

1 of 1 |

Form Characteristics

| Fact Name | Details |

|---|---|

| Purpose | The Pre-Use Inspection Checklist is designed to ensure that mobile cranes are thoroughly inspected for safety before operations commence. |

| Operator Responsibility | The crane operator must complete the inspection form before starting work and keep it on the crane during operations. |

| Service Request | In the event of failed inspection items, the operator is required to make a service request to address the issues. |

| Documentation Retention | Once work is completed, the operator forwards the form to the equipment custodian, ensuring proper documentation of the inspection. |

| Governing Law | This inspection form is governed by the ESH Manual, Chapter 41, "Hoisting and Rigging," effective from 15 September 2009. |

Guidelines on Utilizing Pre Use Inspection Checklist

To ensure safety and compliance before using a mobile crane, completing the Pre-Use Inspection Checklist is essential. This checklist is a systematic way for operators to assess equipment functionality and safety. After completing the inspection form, the operator should keep it accessible on the crane during work and submit it to the equipment custodian once tasks are completed. If any inspection item fails, it is crucial to make a service request immediately.

- Begin by writing your name on the form as the operator.

- Note the crane number and model in the designated areas.

- Proceed to the visual inspection section. For each item listed, check the applicable box—Pass, Fail, or N/A. Make sure to assess the following:

- Engine fluid level

- Hydraulic fluid level

- Hydraulic system for leaks

- Air system for audible leaks

- Tire condition and pressure

- Telescoping boom structure

- Wire rope cleanliness and condition

- Wedge sockets and wire rope clips condition

- Block condition

- Ball and hook functionality

- Guard placement

- Outrigger float security

- Cab handrails condition

- Operator's manual accessibility

- Load chart visibility

- Hand signal chart visibility

- Fire extinguisher condition

- Cab glass condition and wiper functionality

- Next, complete the operational inspection section. Again, mark each item as Pass, Fail, or N/A. Assess:

- Counterweight correctness for the load

- Main hoist control functionality

- Auxiliary hoist control functionality

- Anti-two block functionality

- Swing brake functionality

- Lights and horns functionality

- Ensure that the gauges and indicators are operational. Mark each accordingly.

- Sign and date the form confirming completion of the inspection.

Once the form is filled out, keep it on the crane during operations for easy reference. Always follow up on any failed inspections by requesting service promptly.

What You Should Know About This Form

What is the purpose of the Pre Use Inspection Checklist Form?

The Pre Use Inspection Checklist Form is designed to ensure that all equipment, particularly mobile cranes, are thoroughly inspected for safety and operability before beginning work. By completing this checklist, operators can identify any potential issues early on, helping to prevent accidents and ensure a safe working environment.

Who is responsible for completing the checklist?

The operator of the mobile crane is responsible for completing the inspection checklist. They must carefully review each item, noting the condition of the crane and reporting any issues before beginning their work shift.

What should an operator do if they find a problem during the inspection?

If an operator identifies any item that fails inspection, they must make a service request for repairs. This immediate action is crucial to maintain safety and prevent further complications during operations.

What are some key items that are checked on the checklist?

The checklist includes various visual inspections such as checking fluid levels (engine and hydraulic), ensuring no leaks are present in the hydraulic and air systems, and verifying the condition of the tires and boom. Additionally, components like wire ropes, blocks, and safety guards are inspected for damage or wear.

Is it necessary to keep the checklist on the crane during work?

Yes, the completed checklist must remain on the crane throughout the workday. This practice ensures that any crew member can refer to it as needed for safety verification and compliance.

What happens to the checklist after the work is completed?

After the work is completed, the operator must forward the checklist to the equipment custodian. This step ensures that all inspections are documented and that any necessary follow-up actions can be taken regarding the equipment’s condition.

What items are included in the operational inspection portion of the checklist?

The operational inspection focuses on key functions such as checking whether the main and auxiliary hoist controls are functioning correctly. Additionally, it verifies that important indicators, like the load moment indicator and various gauge readings, are operational and in good working condition.

How can an operator effectively use the checklist?

An effective use of the checklist involves a systematic approach where each item is thoroughly checked and marked. Operators should take their time to ensure all items are evaluated accurately, ensuring a higher safety standard for all personnel involved.

Common mistakes

Filling out the Pre-Use Inspection Checklist form is essential for ensuring the safety and functionality of a mobile crane. However, there are common mistakes operators often make that can lead to unsafe conditions. Understanding these pitfalls is crucial for compliance and safety.

One frequent error is incomplete inspections. Operators may rush through the form, skipping checks or marking "N/A" too liberally. Every item on the checklist must be evaluated to ensure nothing goes unnoticed. Even minor issues can escalate if they are not addressed. Therefore, taking the time to conduct a thorough inspection is vital.

Another common mistake is improper documentation. Operators sometimes forget to sign and date the form or fail to include the crane number and model. This lack of detail can create confusion later on, especially if there are questions about the inspection's validity. Accurate record-keeping is essential for tracking safety compliance and for any potential audits.

Operators also often overlook reporting failures identified during the inspection. If an item fails the inspection, it is crucial to make a service request immediately. Neglecting to report issues can lead to serious accidents and jeopardizes both the operator’s safety and that of others on-site. Following proper protocols ensures that problems are addressed promptly.

Finally, failing to keep the checklist accessible during operations is a common oversight. The form should always be on the crane while it’s in use. This not only serves as a record of the pre-use inspection but also provides an easy reference in case of emergencies or incidents. Keeping it in sight ensures compliance and reinforces safety measures throughout the work period.

Documents used along the form

When preparing for safe operations with a mobile crane, a variety of documents accompany the Pre-Use Inspection Checklist. These forms not only support compliance with safety regulations but also ensure that operators can efficiently carry out their duties. Below are some common documents that typically accompany the Pre-Use Inspection Checklist.

- Hoisting and Rigging Safety Plan: This document outlines specific safety protocols, responsibilities, and procedures for safely conducting hoisting operations. It serves as a guideline for operators, ensuring that all safety measures are adhered to before work begins.

- Operator Qualification Records: These records verify that each crane operator has received the necessary training and certification to operate the machinery. They confirm that operators have the skills and knowledge to perform their tasks safely.

- Maintenance Log: This log records all maintenance activities performed on the crane including repairs, replacements, and routine inspections. It provides a historical account of the crane's upkeep, which can be vital for analyzing performance and reliability.

- Incident Report Forms: In the event of an accident or near miss, an incident report form documents the circumstances of the event. This helps in assessing risks and implementing improvements to prevent future occurrences.

- Load Charts: Load charts provide crucial specifications regarding the crane's lifting capacity under various conditions. Having this document accessible ensures that operators do not exceed safe load limits.

- Signal Person Certification: This certification form confirms that designated personnel are trained to give signals to the crane operator. It establishes clear communication standards necessary for safe operations.

- Pre-Task Safety Analysis (PTSA): Before beginning work, this form details potential hazards associated with the task and the measures in place to mitigate them. This proactive approach aids in identifying and addressing safety concerns before they arise.

- Daily Work Log: This log tracks daily operations, including crane usage, work performed, and any issues that arose during the shift. It ensures there is a record of daily activities that can be referenced later if needed.

- Emergency Response Plan: This document outlines the steps to be taken in the event of an emergency during crane operations. It delineates the roles of crew members and provides guidance on managing incidents effectively.

These documents collectively contribute to a safer workplace by ensuring that operators are equipped with the necessary information and protocols. Familiarity with each form promotes compliance with safety standards and enhances overall operational efficiency.

Similar forms

- Daily Safety Inspection Checklist: Similar to the Pre Use Inspection Checklist, this document is used to ensure that all safety protocols are followed daily, focusing on equipment and workplace conditions before work begins.

- Equipment Maintenance Log: This log records maintenance performed on equipment regularly. Like the Pre Use Inspection Checklist, it helps identify any issues that require attention.

- Incident Report Form: This form documents any incidents that occur during operations. Similar to the Pre Use Inspection Checklist, it emphasizes the importance of safety and thorough documentation in the workplace.

- First Aid Kit Inspection Checklist: This checklist ensures that first aid kits are stocked and ready for emergencies. It parallels the Pre Use Inspection Checklist in its focus on readiness and safety measures.

- Vehicle Inspection Report: This report is completed before using vehicles for work. Like the Pre Use Inspection Checklist, it addresses the functionality and safety of the vehicle components.

- Workplace Condition Survey: Conducted periodically to assess safety conditions, this survey aligns with the Pre Use Inspection Checklist's aim to ensure ongoing safety in the work environment.

- Fire Safety Inspection Checklist: This document outlines steps to verify that fire safety equipment is functional. It fulfills a similar purpose of maintaining safety and compliance as the Pre Use Inspection Checklist.

- Tool Inspection Form: Used to evaluate the condition of tools prior to use, this form shares a similar intent with the Pre Use Inspection Checklist in ensuring equipment is safe and effective.

- Hazardous Materials Inspection: This inspection ensures all hazardous materials are stored and handled properly. It shares the Pre Use Inspection Checklist’s focus on identifying potential risks to safety.

- Forklift Inspection Checklist: Conducted before using a forklift, this checklist serves a similar function to the Pre Use Inspection Checklist by ensuring that all operational components are safe for use.

Dos and Don'ts

When filling out the Pre Use Inspection Checklist form for a mobile crane, adhering to certain practices will ensure accuracy and compliance. Here’s a list of dos and don'ts.

- Do double-check all fluid levels, including engine and hydraulic fluids, before marking them on the form.

- Do ensure that all visual inspections are thoroughly completed, noting any issues that arise.

- Do keep the checklist accessible on the crane throughout the work day.

- Do provide clear, legible signatures and dates to confirm the inspection.

- Do promptly report any failed inspections to the appropriate authority.

- Don't rush through the inspection; take time to examine each component carefully.

- Don't ignore any visible damage or issues found during the inspection.

- Don't alter any entries on the checklist once confirmed; accuracy is critical.

- Don't forget to review the operator’s manual and load chart before beginning the inspection.

- Don't leave the form in the crane unattended, as it should be submitted after work completion.

Following these guidelines will help maintain safety and operational integrity while using the mobile crane.

Misconceptions

Understanding the Pre-Use Inspection Checklist is crucial for ensuring the safe operation of mobile cranes. However, there are some misconceptions that people often have regarding this form. Here are four common misunderstandings:

- It's Just a Formality: Some believe that the checklist is merely a bureaucratic requirement. In reality, completing the inspection form thoroughly helps identify potential safety hazards. This practice is vital for preventing accidents before they occur.

- The Operator Can Skip Steps if They Seem Fine: It's a common myth that operators can decide to skip certain checks if everything appears to be in working order. Every step of the checklist is important. Each item ensures the crane operates safely and efficiently, regardless of visual inspection.

- Only the Operator Needs to Complete It: Many think only the crane operator is responsible for the checklist. However, the entire crew benefits when they are familiar with the inspection process. Communication among team members promotes a safer working environment.

- Items Noted as 'Fail' Can Be Ignored: Some might think that if an item fails the inspection, it can be documented and then overlooked. This is not the case. Failing an inspection requires immediate action, such as making a service request. Prioritizing safety means addressing problems right away.

By addressing these misconceptions, everyone involved in the operation of mobile cranes can contribute to a safer workplace.

Key takeaways

Utilizing the Pre-Use Inspection Checklist is essential for ensuring the safe operation of mobile cranes. Here are key takeaways regarding its completion and use:

- The operator is responsible for completing the inspection form before starting any work.

- This form should remain on the crane throughout the operation for reference and documentation.

- Once the work is finished, the operator must submit the checklist to the equipment custodian.

- If any item fails the inspection, the operator is required to submit a service request immediately.

- A thorough visual inspection includes checking the engine fluid levels, hydraulic systems, and tires for damage.

- All safety features, such as guards and outriggers, must be verified to ensure they are in place and functioning correctly.

- Operational indicators and gauges need to be checked for functionality before beginning work.

- Maintaining an organized work environment includes having necessary operator manuals and load charts readily available.

Browse Other Templates

Da Form 2408-12 - Regularly updating the form helps ensure all aviation personnel have current information.

Boston Life Insurance - The mailing address for submission is P.O. Box 268956, Oklahoma City, OK 73126-8956.

Secondary Dependency - The form also inquires about the parent's marital status.