Fill Out Your Rpz Test Results Form

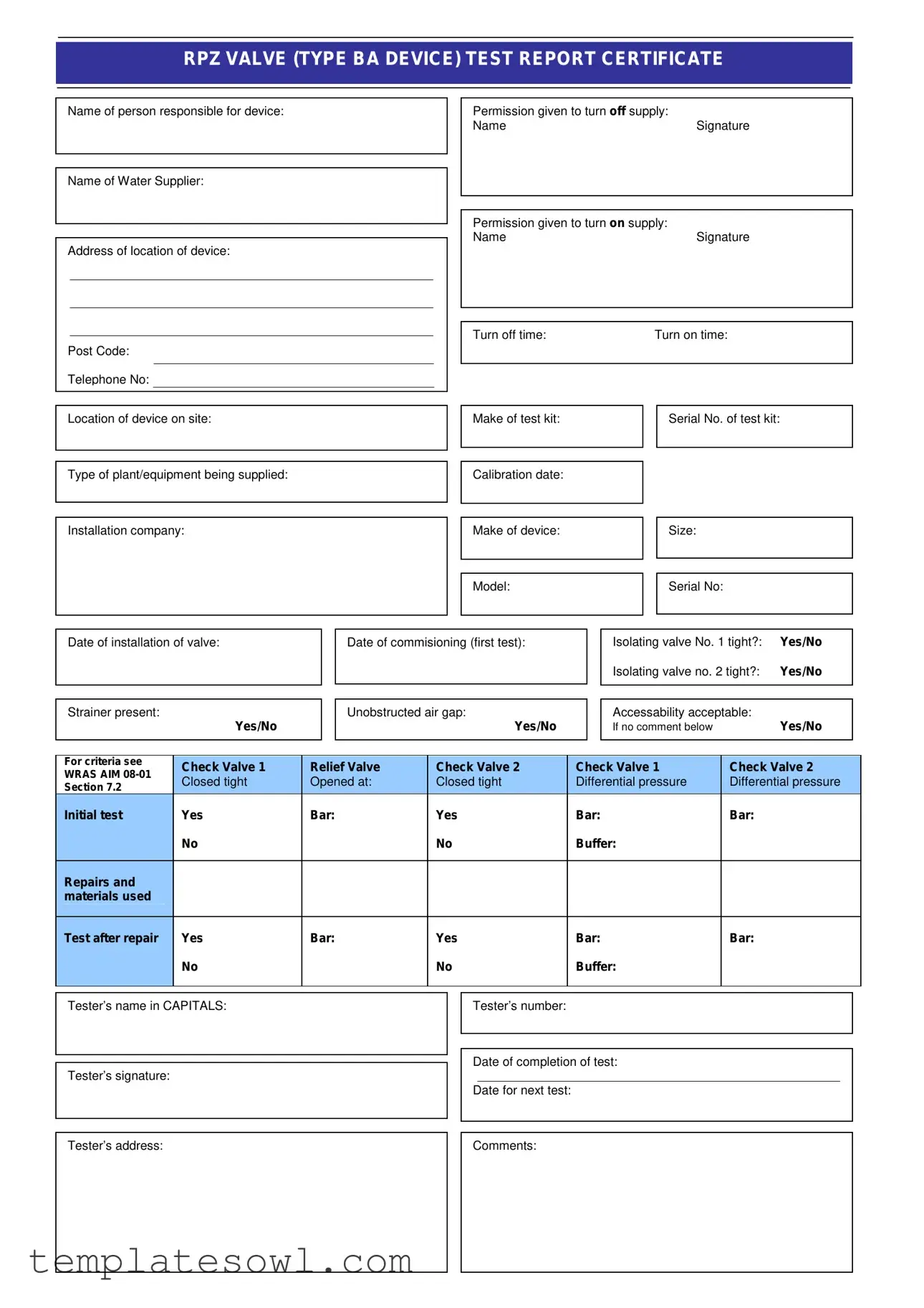

The RPZ Test Results form serves as a critical document in managing the safety and functionality of Reduced Pressure Zone (RPZ) valves, which are designed to prevent backflow into the drinking water supply. Key information captured in this form includes details about the person responsible for the device, the water supplier, and the installation specifics such as the date and location of the valve. The form also records essential testing parameters, including the calibration date of the test kit, the make and serial numbers of both the device and the test kit, and any relevant measurements like differential pressure. Throughout the testing process, users note whether specific components, such as isolating valves and air gaps, are functioning properly. If repairs were necessary, the form provides space to document materials used and the outcome of subsequent tests. Additionally, it includes a designated area for comments, ensuring that testers can add observations or instructions that may be vital for future assessments. This comprehensive approach not only ensures regulatory compliance but also enhances the overall safety of the water supply, making the RPZ Test Results form an indispensable tool for water quality management.

Rpz Test Results Example

RPZ VALVE (TYPE BA DEVICE) TEST REPORT CERTIFICATE

Name of person responsible for device:

Name of Water Supplier:

Address of location of device:

Post Code:

Telephone No:

Permission given to turn off supply: |

|

Name |

Signature |

Permission given to turn on supply: |

|

Name |

Signature |

Turn off time: |

Turn on time: |

|

|

Location of device on site:

Type of plant/equipment being supplied:

Installation company:

Make of test kit:

Calibration date:

Make of device:

Serial No. of test kit:

Size:

Model: |

|

Serial No: |

|

|

|

Date of installation of valve:

Strainer present:

Yes/No

Date of commisioning (first test):

Unobstructed air gap:

Yes/No

Isolating valve No. 1 tight?: |

Yes/No |

Isolating valve no. 2 tight?: |

Yes/No |

|

|

|

|

Accessability acceptable: |

Yes/No |

If no comment below |

|

|

|

|

For criteria see |

|

Check Valve 1 |

|

Relief Valve |

|

Check Valve 2 |

|

Check Valve 1 |

|

Check Valve 2 |

|

|

|

WRAS AIM |

|

|

|

|

|

|

||||||

|

|

Closed tight |

|

Opened at: |

|

Closed tight |

|

Differential pressure |

|

Differential pressure |

|

||

|

Section 7.2 |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Initial test |

|

|

Yes |

Bar: |

Yes |

Bar: |

Bar: |

|||||

No

No

Buffer:

Repairs and |

|

|

|

|

|

materials used |

|

|

|

|

|

|

|

|

|

|

|

Test after repair |

Yes |

Bar: |

Yes |

Bar: |

Bar: |

|

No |

|

No |

Buffer: |

|

|

|

|

|

|

|

Tester’s name in CAPITALS:

Tester’s number:

Tester’s signature:

Date of completion of test: Date for next test:

Tester’s address:

Comments:

Form Characteristics

| Fact Name | Details |

|---|---|

| Form Title | RPZ Valve (Type BA Device) Test Report Certificate |

| Responsible Person | Name of the person responsible for the device must be entered. |

| Water Supplier | Name of the water supplier needs to be included. |

| Location Information | The address and post code of the device's location are required. |

| Turn Off and On Permissions | Signatures for both turning off and turning on the water supply are needed. |

| Installation Details | Date of installation and the installation company must be documented. |

| Test Kit Information | Details including make, model, and calibration date of the test kit should be provided. |

| Testing Results | Sections on differential pressure and valve tightness must be accurately filled out. |

| Tester Information | Tester’s name, number, signature, and address should be clearly recorded. |

| Date for Next Test | The form must specify the date for the next scheduled test. |

Guidelines on Utilizing Rpz Test Results

After you have reviewed the Rpz Test Results form, proceed to fill it out with the required information. It is crucial to ensure accuracy, as this form might be used for compliance and reporting purposes. Follow the steps outlined below to complete the form correctly.

- Name of person responsible for device: Enter the full name of the individual responsible for the RPZ valve.

- Name of Water Supplier: Write the name of the water supply company.

- Address of location of device: Provide the complete address where the RPZ valve is located.

- Post Code: Fill in the corresponding postal code.

- Telephone No: Enter a contact number for follow-up inquiries.

- Permission given to turn off supply: Write the name of the person giving permission and provide their signature.

- Permission given to turn on supply: Again, write the name of the person and their signature who gives the permission.

- Turn off time: Specify the time when the water supply is turned off.

- Turn on time: Indicate the time when the supply is turned back on.

- Location of device on site: Describe where the device is situated within the property.

- Type of plant/equipment being supplied: State the type of plant or equipment connected to the RPZ valve.

- Installation company: Mention the name of the company that installed the RPZ valve.

- Make of test kit: Record the brand or manufacturer of the test kit used.

- Calibration date: Enter the date when the test kit was last calibrated.

- Make of device: Specify the manufacturer of the RPZ valve.

- Serial No. of test kit: Fill in the serial number associated with the test kit.

- Size: Indicate the size of the RPZ valve.

- Model: Write the model number of the RPZ valve.

- Serial No: Provide the serial number of the RPZ valve.

- Date of installation of valve: Input the installation date of the valve.

- Strainer present: Indicate "Yes" or "No" as applicable.

- Date of commissioning (first test): Enter the date of the first test conducted.

- Unobstructed air gap: Indicate "Yes" or "No" if an unobstructed air gap is present.

- Isolating valve No. 1 tight?: Answer "Yes" or "No".

- Isolating valve no. 2 tight?: Again, answer "Yes" or "No".

- Accessibility acceptable: Indicate "Yes" or "No".

- If no comment below: Provide any comments if accessibility was deemed unacceptable.

- For criteria see: Note any relevant compliance criteria as necessary.

- Check Valve 1: Indicate the status of Check Valve 1.

- Check Valve 2: Indicate the status of Check Valve 2.

- Closed tight: Confirm if it is closed tightly. Answer "Yes" or "No" as appropriate.

- Opened at: Specify the time if opened.

- Differential pressure: Enter the differential pressure readings.

- Section 7.2 Initial test: Provide results for the initial test including pressures.

- Buffer: Indicate as required.

- Repairs and materials used: Document any repairs made and the materials used.

- Test after repair: Fill out the results after any repairs.

- Tester’s name in CAPITALS: Provide the name of the tester in capital letters.

- Tester’s number: Enter the tester's contact number.

- Tester’s signature: The tester should sign the form.

- Date of completion of test: Record the date when the test was completed.

- Date for next test: Indicate when the next test is scheduled to occur.

- Tester’s address: Write the complete address of the tester.

- Comments: Provide any additional comments as necessary.

What You Should Know About This Form

What is the purpose of the RPZ Test Results form?

The RPZ Test Results form serves to document the test results of Reduced Pressure Zone (RPZ) valves. These valves are essential for ensuring safe and reliable water supply systems by preventing backflow and contamination. The form captures crucial details about the testing process, results, and responsible parties.

Who is responsible for filling out the RPZ Test Results form?

The form should be completed by a qualified tester who is certified to inspect and test RPZ devices. It requires input from both the testing individual and the water supplier, ensuring that all relevant information is accurately recorded.

What information is included in the form?

The RPZ Test Results form includes various details such as the responsible person's name, water supplier information, device location, installation details, test kit specifics, dates of installation and commissioning, and the outcomes of critical tests related to the RPZ valve's functionality.

How do I indicate permission for turning off the water supply?

Two sections in the form allow for this indication—one for permission to turn off and another for permission to turn on the supply. Each section requires the name and signature of the person granting permission, ensuring accountability.

What do the terms "closed tight" and "opened at" refer to in the test results?

"Closed tight" indicates that the valve properly seals to prevent any backflow. "Opened at" records the pressure at which the valve begins to release water safely. These readings are critical for evaluating the valve's performance during the test.

What should I do if an isolating valve is not tight?

If an isolating valve is not tight, this could indicate a potential issue that may compromise the safety of the water supply. The tester should note this in the comments section and take appropriate measures, which may include repairs or further assessments.

What is the significance of the unobstructed air gap?

An unobstructed air gap is crucial for the proper functioning of the RPZ valve. It prevents backflow by allowing air to enter the plumbing system, which prevents contaminants from being drawn into the clean water supply. The form records whether this air gap is appropriate.

How often should the RPZ valve be tested?

The next test date should be recorded on the form. Typically, RPZ valves require testing annually or based on the regulations of the local water authority. This ensures ongoing compliance and safety in the water supply system.

What details should be included in the comments section?

The comments section allows for any observations or additional notes related to the testing process or valve performance. This might include issues noted during the test, recommendations for repairs, or general observations about the equipment.

Who should keep a copy of the RPZ Test Results form?

Both the water supplier and the person responsible for the device should maintain copies of the RPZ Test Results form. This ensures that all parties have access to critical information regarding the valve's performance and compliance with safety regulations.

Common mistakes

Filling out the RPZ Test Results form is a crucial task that requires attention to detail. Many individuals make mistakes that can hinder the reliability of the submitted data. One common error occurs when the person filling out the form forgets to include the name of the person responsible for the device. This information is essential because it identifies who is accountable for the operation and maintenance of the RPZ valve.

Another frequent mistake is neglecting to provide accurate contact information for the water supplier. The form asks for the supplier's name, address, and telephone number. Omitting or incorrectly entering this information can lead to misunderstandings or delays in addressing any issues related to the water supply.

Some people also fail to record the turn off and turn on times appropriately. These timestamps are vital for tracking the testing process and ensuring compliance with regulatory requirements. Without accurate timing, the validity of the test results may be questioned.

The location of the device on site is another area frequently overlooked. This information helps inspectors and maintenance personnel locate the RPZ valve easily in case further action is necessary. When this information is left blank or incomplete, it can cause confusion during future inspections.

One must not forget to indicate whether the strainer is present. Selecting "Yes" or "No" is important, as it can affect the valve's performance and the overall safety of the water system. Failing to clarify this detail might lead to expensive repairs or unsafe water conditions.

Participants often make the mistake of leaving the differential pressure readings blank or incorrectly filled. These readings indicate the functionality of the safety mechanisms in place. Inaccurate information can compromise the assessment of the valve's performance.

It is crucial to ensure that the tester’s name, number, and signature are provided in a clear manner. Some individuals tend to use cursive or illegible handwriting, making it challenging for others to verify who conducted the test. Clear documentation helps maintain accountability and transparency throughout the testing process.

Providing an installation date for the valve is also essential. Omitting this detail can prevent a clear understanding of the valve's lifecycle and its need for maintenance or replacement. Date tracking is as critical for compliance as it is for operational integrity.

In the comments section, users frequently leave vague or unhelpful statements. Clear, concise remarks can provide necessary context for the results. Comments should describe any challenges encountered during testing or unusual findings that may require further attention.

Lastly, neglecting to indicate the date for the next test can lead to lapses in compliance. Regular testing is essential for safety, and an unclear schedule can cause significant issues in adhering to regulatory standards. Consistent testing helps safeguard the water supply and ensures that all safety protocols are met.

Documents used along the form

The RPZ Test Results form is used to document the testing of Reduced Pressure Zone (RPZ) devices. Along with this form, several other documents may be necessary for compliance and record-keeping. Below are some commonly used forms associated with the RPZ Test Results form.

- Maintenance Log: This document keeps track of all maintenance activities performed on the RPZ device. It includes dates of service, types of maintenance, and names of individuals who conducted the work.

- Installation Certificate: This certificate verifies that the RPZ device has been properly installed according to applicable codes and standards. It usually includes installation dates, the installer’s information, and confirmation of compliance.

- Calibration Certificate: This document is proof that the testing equipment used for the RPZ test has been calibrated. It details calibration dates, equipment specifications, and the professional who performed the calibration.

- Water Quality Report: A report documenting the quality of the water supply is often required. It typically includes information on water testing results, contaminants present, and any actions taken to address water quality issues.

Maintaining accurate records through these documents helps ensure compliance with regulations and promotes water safety. Having a complete set of documentation can facilitate inspections and audits when necessary.

Similar forms

Backflow Prevention Device Test Report: This document provides a detailed report on testing a device designed to prevent backflow in plumbing systems. Similar to the Rpz Test Results form, it includes information about the device's location, installation details, and test results.

Test and Maintenance Report for Fire Protection Systems: Like the Rpz Test Results form, this report documents inspections and tests conducted on fire suppression systems. It includes authorization signatures, dates of tests, and compliance information.

Water Quality Testing Report: This document outlines the results of testing water quality at a specific location. It includes the name of the responsible individual, testing methods used, and dates of sample collection, similar to the detailed structure of the Rpz Test Results form.

Equipment Maintenance Log: Emphasizing routine maintenance, this log records service history, inspections, and repairs made to various equipment. It shares a similar format in that both documents include responsible personnel and dates of service.

Pump Performance Test Report: This report details performance metrics for installed pumps. It includes information such as the pump's make, model, location, and testing results, paralleling the structure found in the Rpz Test Results form.

Heating System Inspection Report: This document assesses the condition and performance of heating systems. Information about the system's components and performance metrics are documented, akin to those in the Rpz Test Results form.

Compliance Inspection Report: This report outlines findings from a regulatory compliance inspection. Like the Rpz Test Results form, it includes details about the entity inspected, the inspector's conclusions, and any necessary approvals.

Installation Acceptance Certificate: This certificate confirms the successful installation of a device or system. It requires signatures from responsible parties and includes technical details, similar to the format of the Rpz Test Results form.

Service Call Report: This document captures information related to service calls for maintenance or repairs. It includes identification details, time frames, and findings, similar to the structured approach of the Rpz Test Results form.

Safety Inspection Checklist: Focusing on safety protocols, this checklist documents inspections conducted on facilities or equipment. It summarizes findings and includes signatures, reflecting the comprehensive nature of the Rpz Test Results form.

Dos and Don'ts

When filling out the RPZ Test Results form, attention to detail is crucial. Here are six essential guidelines to follow, along with some pitfalls to avoid.

- Always provide accurate contact information. Include your name, position, and the contact details of the water supplier to ensure easy communication.

- Clearly indicate the installation and calibration dates. This information is vital for maintaining the integrity of the equipment and scheduling future tests.

- Confirm the tightness of isolating valves. Ensure that both valves are checked and report accurately whether they are tight.

- Document any issues or comments. If any accessibility problems arise, note them clearly to prevent future complications.

- Sign and date the tester's section. Your signature indicates responsibility for the accuracy of the information provided.

- Double-check for completeness. Ensure that every required field is filled out before submission to avoid delays.

However, there are also certain mistakes to steer clear of:

- Do not leave any mandatory fields blank. Incomplete forms can lead to processing delays.

- Avoid assumptions about information. Always verify details like valve tightness rather than making guesses.

- Refrain from using abbreviations that may not be universally understood. Clarity is paramount.

- Don’t forget to keep a copy of the completed form for your records.

- Never rush through the form. Taking your time reduces the risk of errors.

- Do not skip the comments section if there are relevant observations. Providing context can be crucial.

Adhering to these do's and don'ts can facilitate a smooth testing process while ensuring compliance and safety in water supply management.

Misconceptions

Understanding the RPZ Test Results form can prevent confusion and ensure compliance within water safety regulations. However, there are several myths surrounding this important document. Here are six common misconceptions clarified.

- The form is only for specialists to understand. While the form contains technical information, it is designed to be comprehensible to any individual responsible for the RPZ valve. Familiarity with the form assists in maintaining water safety.

- A signature on the form guarantees a successful test. Signing the RPZ Test Results form indicates that the testing was conducted, not that the valve passed. It’s crucial to review the detailed results to ensure the device operates correctly.

- All fields on the form must be completed for it to be valid. Not every field needs to be filled. Some entries may not apply to your situation. It's important to provide accurate information in the relevant sections.

- The date of installation and date of commissioning are the same. These two dates often differ. The installation date refers to when the device was put in place, while commissioning is when the device was first tested and approved for use.

- A 'Yes' or 'No' answer is sufficient for all questions. While binary answers are common, providing additional comments where necessary can clarify issues. This additional information often aids in future inspections.

- The tester does not need to be certified. It is essential that the person filling out the RPZ Test Results form is properly trained and certified. This ensures the integrity and reliability of the testing process.

Addressing these misconceptions can lead to a more efficient process when dealing with RPZ Test Results. Each entry on the form plays a crucial role in maintaining safe water supply standards.

Key takeaways

When filling out the RPZ Test Results form, several important considerations ensure compliance and accuracy.

- Ensure Accuracy: Carefully enter all details, particularly names, addresses, and device specifics. Mistakes can lead to compliance issues.

- Obtain Permissions: Have the necessary permissions documented before turning off or on the water supply to avoid disruptions.

- Document Dates: Clearly record dates of installation, commissioning, and the last test. This helps maintain a proper maintenance schedule.

- Test Results: Provide precise readings for pressures and confirm the status of valves. Any repairs should be noted in detail.

- Comment Section: Utilize the comments area to clarify any unique situations or findings during testing, especially if accessibility is an issue.

- Signature Requirement: Make sure the tester signs and dates the form. This verification step assures authenticity.

- Next Test Date: Set and document the date for the next test to ensure ongoing compliance with safety regulations.

Following these key takeaways helps streamline the process of completing the RPZ Test Results form and ensures adherence to necessary protocols.

Browse Other Templates

Broome County Sheriff's Office - Four character references from Broome County residents are required.

H1003 Form - The relationship description is important for HHSC to understand the context of representation.