Fill Out Your Safety Construction Audit Form

Safety in construction is a critical concern for organizations committed to protecting workers and ensuring compliance with regulations. The Safety Construction Audit form is a vital tool that systematically evaluates various aspects of construction sites, enhancing accountability and promoting best practices. It encompasses key categories such as personal protective equipment (PPE), general work area conditions, electrical safety, lifting techniques, scaffolding, hazardous materials, ladder use, hot work operations, and worker training. By assessing each of these areas, the form helps identify potential risks and establishes a framework for maintaining a safer environment. The audit not only documents the presence or absence of safety measures like hard hats, safety glasses, and proper scaffolding, but it also enables supervisors to monitor compliance with safety practices. This proactive approach not only mitigates hazards but fosters a culture of safety awareness across construction teams. Through diligent completion of this form, safety officers can ensure that necessary precautions are taken, thereby protecting the health and welfare of all workers on site.

Safety Construction Audit Example

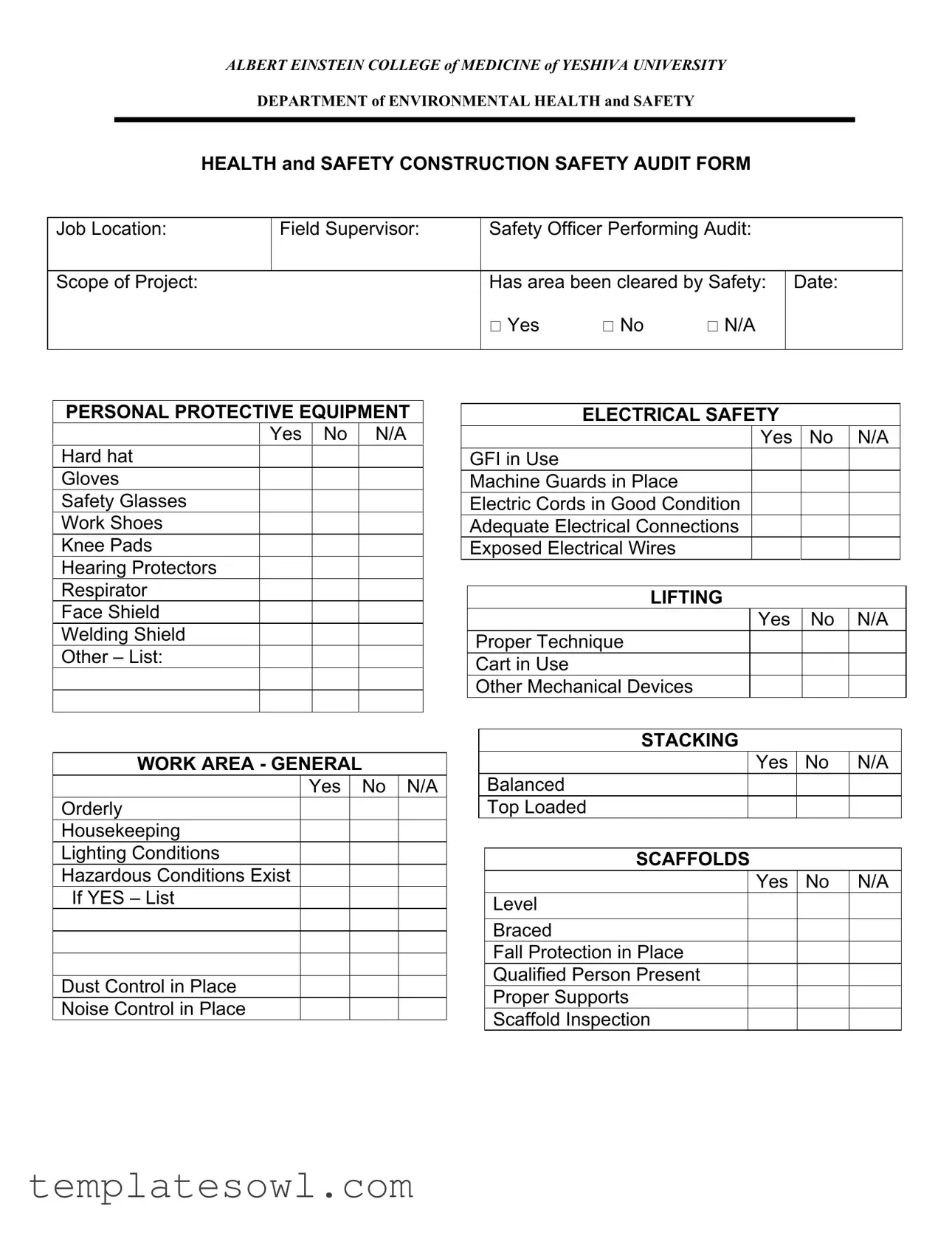

ALBERT EINSTEIN COLLEGE OF MEDICINE OF YESHIVA UNIVERSITY

DEPARTMENT OF ENVIRONMENTAL HEALTH AND SAFETY

HEALTH AND SAFETY CONSTRUCTION SAFETY AUDIT FORM

Job Location:

Field Supervisor:

Safety Officer Performing Audit:

Scope of Project:

Has area been cleared by Safety:

Date:

Yes No N/A

PERSONAL PROTECTIVE EQUIPMENT

Yes No N/A

Hard hat

Gloves

Safety Glasses

Work Shoes

Knee Pads

Hearing Protectors

Respirator

Face Shield

Welding Shield

Other – List:

WORK AREA - GENERAL

Yes No N/A

Orderly

Housekeeping

Lighting Conditions

Hazardous Conditions Exist

If YES – List

Dust Control in Place

Noise Control in Place

ELECTRICAL SAFETY

Yes No N/A

GFI in Use

Machine Guards in Place

Electric Cords in Good Condition

Adequate Electrical Connections

Exposed Electrical Wires

LIFTING

Yes No N/A

Proper Technique

Cart in Use

Other Mechanical Devices

STACKING

Yes No N/A

Balanced

Top Loaded

SCAFFOLDS

Yes No N/A

Level

Braced

Fall Protection in Place

Qualified Person Present

Proper Supports

Scaffold Inspection

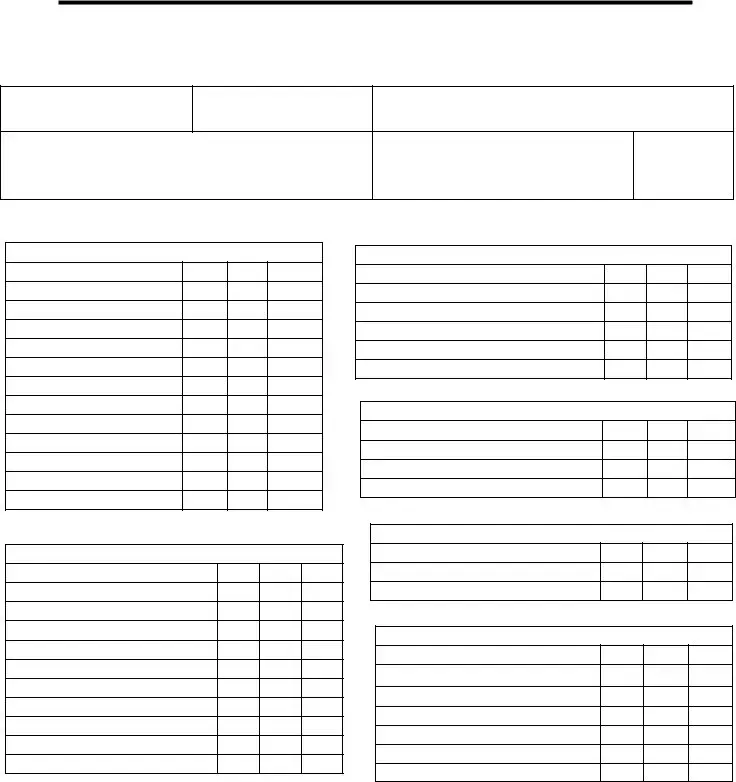

HEALTH AND SAFETY CONSTRUCTION SAFETY AUDIT FORM

HAZARDOUS MATERIALS USED

Chemicals:

Others – List:

Yes No N/A

Odor Present

MSDS Available

LADDERS

Yes No

In Use

Appropriate for Job

Used Correctly

Comments:

HOT WORK

Yes |

No |

N/A |

Burning, Torch, Welding Operations

Fire Extinguishers in Place

Fire Protection in Place

Proper PPE Worn

Fire Watch

|

|

|

|

WORKER TRAINING AND PERFORMANCE |

|

Yes |

No |

Workers Following Safety Practices |

|||

If No list problems: |

|

|

|

||

|

|

|

|||

Yes |

No |

Workers Need Retraining |

|||

List Names: |

|

|

|

|

|

Yes |

No |

Supervisor Informed |

|||

|

|

|

|

|

|

|

|

|

|

SUPERVISORS |

||

|

Yes |

No |

Supervisor was available and had reviewed project |

|||

If “No” Explain: |

|

|

|

|

||

|

|

|

|

|

||

|

Yes |

No |

Supervisor Informed of Audit Results |

|||

|

|

|

|

|

|

|

COMMENTS:

Safety Officer Signature |

Date |

cc:File

M. Nolty

Word\MyDocuments\Forms\CostructionH&SAuditForm |

May, 2003 |

|

r |

Form Characteristics

| Fact Name | Details |

|---|---|

| Form Title | The form is officially titled "Health and Safety Construction Safety Audit Form". |

| Institution | This audit form is used by Albert Einstein College of Medicine of Yeshiva University. |

| Purpose | Its main purpose is to evaluate safety practices on construction sites. |

| Job Details | Information is required regarding the job location, project scope, and supervisors involved. |

| Personal Protective Equipment (PPE) | The form includes a checklist to ensure a variety of PPE items are provided and used. |

| Electrical Safety Checks | There are specific questions regarding the use of electrical safety measures, including GFI outlets and cord conditions. |

| Hazardous Materials | It lists the need to identify hazardous chemicals and confirm that Material Safety Data Sheets (MSDS) are available. |

| Hot Work Precautions | Criteria on fire safety and the proper use of PPE during hot work activities like welding are specified. |

| Training and Supervision | The form assesses whether workers are following safety protocols and if supervisors are properly informed and available. |

| Compliance and Review | This form must be reviewed, and comments must be documented for continuous safety improvement. |

Guidelines on Utilizing Safety Construction Audit

Filling out the Safety Construction Audit form helps ensure that safety standards are being met at a construction site. This process entails careful observation and documentation of various safety measures. Follow these steps to complete the form accurately.

- Fill in the job location, field supervisor's name, safety officer performing the audit, scope of the project, safety area clearance, and the date at the top of the form.

- Assess personal protective equipment (PPE). Mark "Yes," "No," or "N/A" for each item listed, including hard hats, gloves, safety glasses, and more.

- Evaluate the work area. Answer the specific questions regarding housekeeping, lighting conditions, hazardous conditions, dust control, and noise control.

- Check electrical safety. Mark the appropriate boxes for GFI use, machine guards, electric cords condition, connections, and exposed wires.

- Review lifting procedures. Indicate if the proper techniques and equipment, such as carts and mechanical devices, are being used.

- Examine stacking practices. Ensure items are properly balanced and loaded on top.

- Inspect scaffolds. Confirm if they are level, braced, have fall protection in place, and if a qualified person is present.

- Identify hazardous materials in use. List any chemicals and note odor presence and if MSDS is available.

- Look at ladder usage. Note if they are in use, appropriate for the job, and used correctly.

- Assess hot work activities. Verify if any burning, welding, or torch operations are taking place, and check for proper fire protection and PPE usage.

- Evaluate worker training and performance. Indicate if workers are following safety practices. If not, list specific problems and names of workers needing retraining.

- Check for supervisor availability. Confirm if the supervisor reviewed the project and was informed of audit results.

- Provide any additional comments or observations in the designated section.

- Finally, obtain the safety officer's signature and date to finalize the audit.

What You Should Know About This Form

What is the purpose of the Safety Construction Audit form?

The Safety Construction Audit form is designed to evaluate safety practices and conditions at a construction site. It helps ensure compliance with safety regulations and identifies areas for improvement. By assessing various safety aspects, the form promotes a safer work environment for all stakeholders involved in the project.

Who completes the Safety Construction Audit form?

The audit form is typically completed by a designated Safety Officer or a qualified professional trained in safety regulations. Their role is to inspect the site, gather observations, and document findings. This process is crucial for effective oversight of construction safety standards.

What criteria are evaluated on the Safety Construction Audit form?

Several key criteria are assessed, including personal protective equipment (PPE) use, work area conditions, electrical safety, lifting and stacking practices, scaffold safety, hazardous materials presence, ladder usage, hot work safety, and worker training compliance. Each section contains specific criteria that must be marked as "Yes," "No," or "N/A" based on observations.

What should be done if safety issues are identified during the audit?

If safety issues are identified, the Safety Officer should document them in the comments section of the form. It’s important to communicate these findings to the project supervisor and take corrective measures. Immediate action may be required to address the hazards and prevent accidents.

Are there specific qualifications needed to perform the audit?

Yes, individuals conducting the audit should have a clear understanding of construction safety standards and practices. Training in occupational safety and health regulations is recommended. Prior experience in safety inspections is also beneficial to effectively identify potential hazards.

How often should the Safety Construction Audit be conducted?

The frequency of audits can vary based on project scope, size, and complexity. Generally, audits should be conducted regularly, such as weekly or bi-weekly, or whenever significant changes occur on-site. Consistent audits help maintain safety standards and accountability throughout the construction process.

What happens to the audit results after they are completed?

After completion, the audit results should be reviewed by the project supervisor and the Safety Officer. The findings will guide necessary safety improvements and corrective actions. Copies of the completed form should be kept in the project file for future reference and compliance verification.

Common mistakes

When filling out the Safety Construction Audit form, many people tend to make errors that can impact the effectiveness of the evaluation. One common mistake is not properly identifying the Job Location. The job site is essential information, as it helps track safety compliance across different locations. Failing to specify the site can lead to confusion and hinder follow-ups.

Another frequent issue arises with the section on Personal Protective Equipment. Individuals often neglect to check all relevant boxes or mistakenly assume equipment is available without verifying it. This oversight can result in unsafe working conditions, as workers may not be adequately protected.

In the section for Electrical Safety, people sometimes fail to indicate whether GFI and machine guards are in use. Especially in environments with electrical hazards, noting these details is crucial. Not doing so could lead to complacency in addressing significant risks.

Inadequate comments on Worker Training and Performance can also pose a problem. Simply stating "yes" or "no" without elaboration does not provide enough context for future audits. If there are issues such as workers not following safety practices, it is important to clearly list those problems.

Another mistake occurs in the Hazardous Materials section. Individuals sometimes forget to list specific chemicals used on site, which may lead to insufficient safety measures being implemented. Identifying all materials, including their characteristics, can prevent serious accidents.

When assessing Ladders, users might overlook comments on whether the ladders are appropriate for the job. Even if a ladder is reported as "in use," it still requires commentary on its suitability, as using the wrong ladder can lead to accidents.

People also frequently miss out on checking the Supervisor Informed of Audit Results box. Communicating the results of the audit helps ensure accountability at all levels. If supervisors are not informed, they may be unaware of ongoing issues that need addressing.

Finally, individuals often ignore the importance of the Safety Officer Signature and date. This step is crucial for maintaining the integrity of the audit. Including this information legitimizes the document and marks when the assessment took place, which is essential for record-keeping and future reference.

Documents used along the form

When conducting a Safety Construction Audit, several other forms and documents may be utilized to ensure a comprehensive approach to safety in construction environments. Below are some commonly used documents that complement the Safety Construction Audit form. Each provides critical information or serves a specific purpose in promoting workplace safety.

- Incident Report Form: This document captures details of any accidents or incidents that occur on the construction site. It typically includes information about the involved parties, circumstances surrounding the event, and any injuries sustained.

- Daily Safety Inspection Checklist: Maintained on a daily basis, this checklist helps supervisors identify potential hazards and safety compliance issues on-site at a glance. Its regular use fosters ongoing vigilance.

- PPE (Personal Protective Equipment) Log: This log tracks the distribution and use of necessary protective gear among workers. It ensures that all employees have the appropriate PPE for their tasks and helps in maintaining compliance with safety regulations.

- Job Hazard Analysis (JHA): This analysis identifies hazards associated with specific tasks or jobs, recommending safety measures to mitigate those risks effectively. Understanding job-specific hazards is essential for worker safety.

- Safety Training Record: Documentation of completed safety training sessions is vital. This record details who has received training, when it occurred, and its content, ensuring compliance and awareness among the workforce.

- Construction Safety Plan: This comprehensive plan outlines the safety policies and procedures that must be followed throughout the project. It serves as a guide for supervisors and employees to understand their roles regarding safety.

- Emergency Action Plan (EAP): The EAP provides a clear protocol for responding to emergencies, including evacuation procedures and communication strategies. Its preparation helps ensure that all workers know how to act in a crisis.

- Safety Meeting Minutes: These notes record discussions and decisions made during safety meetings. Keeping a record of safety meetings helps reinforce a culture of safety and ensures ongoing communication among team members.

- Environmental Safety Assessment: This assessment reviews potential environmental risks associated with the project and outlines measures to mitigate negative impacts. It ensures that safety considerations extend beyond the immediate construction zone.

Incorporating these documents alongside the Safety Construction Audit form fosters a holistic approach to workplace safety, improving overall compliance and safeguarding the well-being of all workers on the job site.

Similar forms

- Job Hazard Analysis (JHA): Like the Safety Construction Audit form, a Job Hazard Analysis identifies potential hazards associated with specific tasks. Both documents serve to evaluate safety measures, ensuring that workers are informed of risks and protective equipment is adequate.

- Safety Inspection Report: A Safety Inspection Report captures the conditions of a job site at a specific moment, much like the audit form. Both aim to identify safety practices and hazardous situations, helping maintain a safe working environment.

- Incident Report Form: An Incident Report Form is used after an accident occurs. While the audit form proactively evaluates safety measures before incidents happen, both documents focus on improving workplace safety through detailed observations.

- Safety Procedures Manual: Similar to the Safety Construction Audit form, a Safety Procedures Manual outlines safety protocols and practices. Both share the objective of enforcing safety guidelines to mitigate risks throughout a project.

- Personal Protective Equipment (PPE) Assessment: A PPE Assessment reviews the use and adequacy of protective gear on-site. Both documents ensure that appropriate equipment is available and that workers understand its importance for their safety.

- Environmental Safety Audit: An Environmental Safety Audit examines how construction activities impact the surrounding environment, similar to how the audit form assesses safety measures on-site. Both documents aim for compliance with safety regulations and standards.

- Workplace Safety Training Records: These records track training sessions attended by workers regarding safety protocols. Like the Safety Construction Audit form, they emphasize the importance of ongoing education to mitigate hazards and promote safety in the workplace.

Dos and Don'ts

When filling out the Safety Construction Audit form, keep in mind the following important tips. These guidelines will help you ensure clarity, accuracy, and safety compliance.

- Do read each section carefully before answering. Understanding what is being asked will lead to better responses.

- Don’t skip questions. Every item is vital for a comprehensive safety audit.

- Do be honest in your assessments. If something is lacking or not up to standard, it’s crucial to report it.

- Don’t use vague language. Provide specific details, particularly when noting hazardous conditions or issues.

- Do have necessary documentation ready, such as the Material Safety Data Sheets (MSDS), when noting chemicals used.

- Don’t forget to involve supervisors in the process. Their insights can help identify potential safety issues.

- Do sign and date the audit form. This helps maintain accountability and provides a clear record of your findings.

Misconceptions

Here are six common misconceptions about the Safety Construction Audit form, along with clarifications to help better understand its purpose and use.

- The form is only necessary for major construction projects. In reality, the Safety Construction Audit form is beneficial for any construction-related work, regardless of size. It helps ensure safety standards are met on every job site.

- A completed form guarantees a safe work environment. While the audit form identifies safety protocols in place, it is not a foolproof guarantee. Continuous observation and active safety measures are essential to maintain a safe environment.

- Only safety officers need to fill out the form. Many people can participate in the audit process. Workers, supervisors, and safety officers should all contribute to ensure a comprehensive assessment of the work site.

- The form is a one-time requirement. The audit form should be used regularly, especially at various stages of a project. Consistent assessments help identify new hazards and ensure compliance with safety standards throughout the duration of the construction.

- Any issues found during the audit must be immediately resolved. While it is crucial to address safety concerns, not every finding requires immediate rectification. Some may need long-term planning or a strategic approach to resolve effectively.

- Filling out the form is a bureaucratic hassle with no real benefit. This perception overlooks the value of the form in promoting worker safety. The audit serves as a critical tool for identifying safety gaps and fostering a culture of safety on the job site.

Understanding these misconceptions can help promote a safer work environment and ensure that everyone involved is committed to adhering to safety protocols.

Key takeaways

Filling out the Safety Construction Audit form is a crucial step in ensuring a safe work environment on construction sites. Here are key takeaways for effectively using this tool:

- Complete the Form Thoroughly: Each section of the audit form should be filled out with attention to detail. Make sure to indicate whether each item has been checked off as "Yes," "No," or "N/A." This helps in maintaining comprehensive oversight.

- Prioritize Personal Protective Equipment (PPE): Ensure that compliance with PPE protocols is always monitored. Check for essential items like hard hats, gloves, and safety glasses, and confirm their availability and proper usage.

- Evaluate the Work Area Conditions: Assess conditions such as cleanliness, lighting, and any hazardous situations. If hazardous conditions do exist, it's important to document them and outline how they will be addressed.

- Verify Training and Supervision: Assess whether workers are adhering to safety practices and if they require any retraining. Document any concerns and inform supervisors to take necessary actions promptly.

- Conduct Health and Safety Reviews: Make sure to review each critical area, such as electrical safety, lifting techniques, and the use of scaffolds. Checking for fire safety measures, especially during hot work operations, is essential to prevent accidents.

Utilizing this audit form diligently can greatly enhance safety awareness and compliance on the construction site, ultimately contributing to a safer working environment for all involved.

Browse Other Templates

Transcript Delivery Request,Academic Record Release Form,Student Academic Transcript Application,GTCC Official Transcript Form,Transcript Release Authorization,Educational Record Request,GTCC Transcript Submission Form,Student Transcript Order Form,T - Requests can include multiple copies but must specify the number needed.

Nc Divorce Papers - Be aware that laws may change, affecting the forms and process.

Dhsh - Food assistance benefits can be expedited if you fill in specific questions and provide necessary proof.