Fill Out Your Sample Receiving Form

The Sample Receiving form is an essential tool for accurately documenting the receipt of materials and ensuring that they meet the necessary quality and quantity standards. Designed specifically for use by departments within the County of Tennessee, this form captures critical details such as the purchase order number, requisition number, and item specifics. It includes sections for the description of items received, their respective quantities, unit prices, and any additional freight charges, ultimately aggregating into a total cost. Moreover, the form emphasizes the importance of inspection by requiring a certification statement from the inspector, who must confirm that the materials received were examined and deemed satisfactory for their intended purpose. This process not only helps maintain accountability and transparency but also supports effective inventory management and resource allocation.

Sample Receiving Example

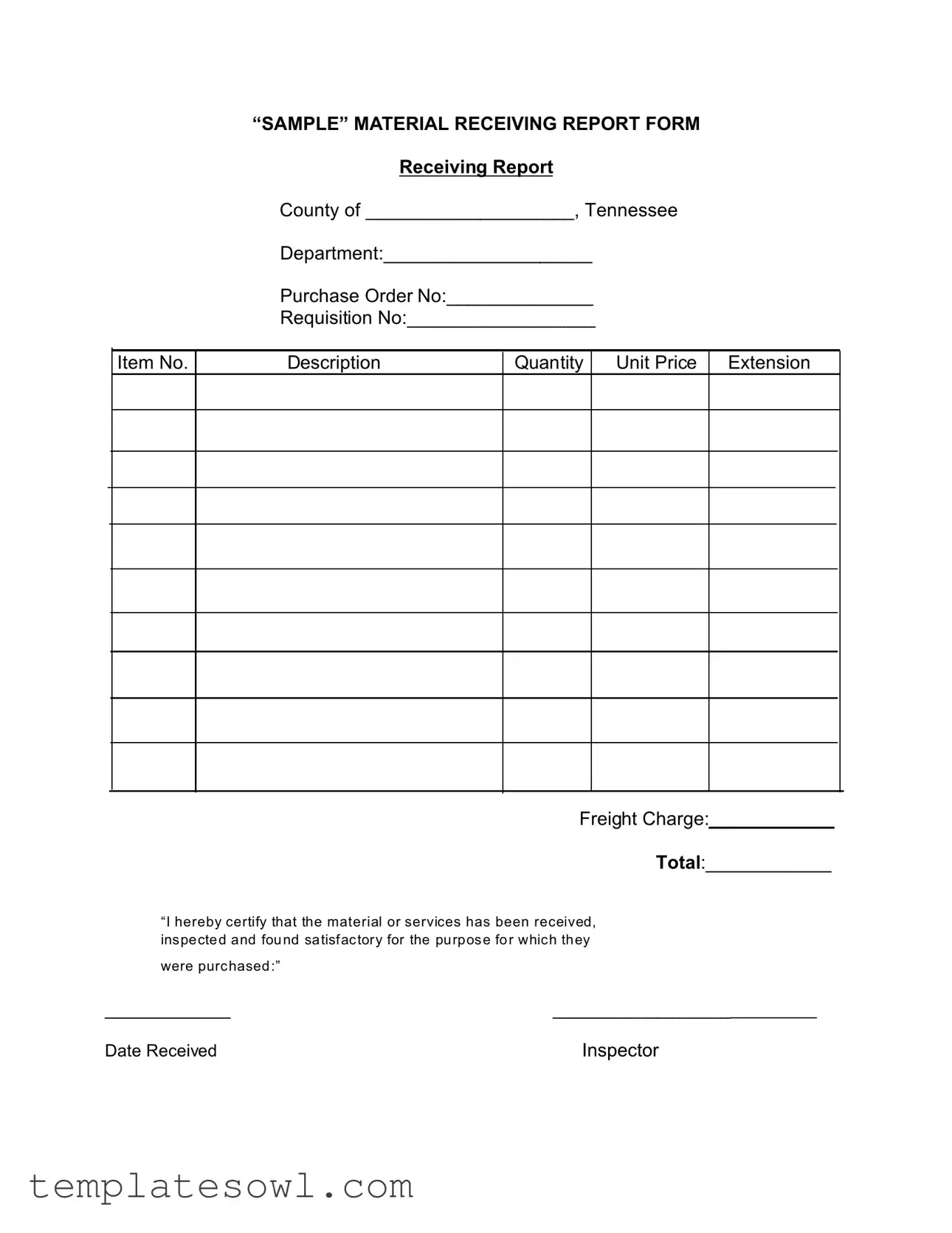

“SAMPLE” MATERIAL RECEIVING REPORT FORM

Receiving Report

County of ____________________, Tennessee

Department:____________________

Purchase Order No:______________

Requisition No:__________________

Item No.

Description

Quantity

Unit Price

Extension

Freight Charge:____________

Total:____________

“I hereby certify that the material or services has been received, ins pe cte d a nd fou nd sa tisf ac tor y for the pu rpos e fo r whic h th ey

were purc hased :”

____________ |

__________________________ |

Date Received |

Inspector |

Form Characteristics

| Fact Name | Detail |

|---|---|

| Form Purpose | This form documents the receipt of materials or services, ensuring they meet the required standards. |

| Governing Law | The form falls under Tennessee state procurement laws, including T.C.A. § 12-3-101. |

| Department Identification | The form requires the name of the department that received the materials, promoting accountability. |

| Purchase Order Reference | An area for the purchase order number ensures consistency between orders and received items. |

| Inspection Certification | The inspector must certify that the materials or services received have been checked and are satisfactory. |

| Cost Breakdown | The form includes sections for item price, freight charge, and total expenses for transparency. |

| Date of Receipt | The inspector's signature and date confirm when the items were received, which is critical for record-keeping. |

Guidelines on Utilizing Sample Receiving

Once you have gathered all necessary information, you are ready to proceed with filling out the Sample Receiving form. This form is essential in documenting the details of materials or services received, ensuring everything matches your order. Follow these steps to complete the form accurately.

- County: Write the name of the county in Tennessee where the receiving report is being created.

- Department: Specify the name of the department that is receiving the items.

- Purchase Order No: Enter the purchase order number associated with the order.

- Requisition No: Fill in the requisition number if applicable.

- Item No: List the item number for each product or service received.

- Description: Provide a brief description of each item.

- Quantity: Indicate the number of units received.

- Unit Price: Write the price per individual unit.

- Extension: Multiply the quantity by the unit price to calculate the extension, and enter that total.

- Freight Charge: If applicable, record any freight or shipping charges incurred.

- Total: Sum up the extension and freight charges and write the total amount.

- Inspector: The person who inspected the materials should sign and print their name in the appropriate space.

- Date Received: Indicate the date when the materials were received.

What You Should Know About This Form

What is the purpose of the Sample Receiving form?

The Sample Receiving form serves as an official document to confirm the receipt of materials or services in a specific county or department. It ensures accountability in the procurement process by recording essential details, such as purchase order numbers, item descriptions, quantities, and associated costs. This form helps facilitate proper inventory management and compliance with local regulations.

What information is required to complete the Sample Receiving form?

To effectively complete the Sample Receiving form, several key pieces of information are necessary. These include the county name, the department receiving the materials, the purchase order number, the requisition number, item descriptions, quantities, unit prices, total costs, and any freight charges. Additionally, the inspector must provide their signature and date to certify that the materials have been received and inspected satisfactorily.

Who is responsible for completing the Sample Receiving form?

The responsibility for completing the Sample Receiving form typically falls on the designated inspector within the department receiving the materials. This individual is tasked with ensuring that the items match the specifications outlined in the purchase order and that they are in satisfactory condition upon receipt.

What should be done if there are discrepancies on the Sample Receiving form?

If discrepancies arise, such as damaged items or differences in quantity, it is crucial to address them immediately. The inspector should document any issues directly on the Sample Receiving form and report these findings to the purchasing department. Prompt reporting allows for resolutions to be sought, whether through returns, replacements, or adjustments to invoices.

How does the Sample Receiving form contribute to inventory management?

The Sample Receiving form plays a key role in effective inventory management by providing a clear record of what has been received, including specific details about each item. This documentation helps prevent inventory discrepancies, aids in tracking usage and storage, and contributes to accurate accounting practices. A well-maintained inventory is crucial for ensuring that departments operate smoothly and efficiently.

Is there a need for electronic versions of the Sample Receiving form?

Yes, electronic versions of the Sample Receiving form can enhance efficiency and accessibility. Digital records can be easily stored, retrieved, and shared among departments. Additionally, electronic forms can help streamline the reporting process, reduce the risk of lost paperwork, and facilitate data analysis for inventory and procurement purposes.

What should be done after the Sample Receiving form is completed?

Once the Sample Receiving form is completed and signed, it should be submitted to the appropriate departmental personnel for record-keeping. It is also advisable to create copies for both the receiving department and purchasing department to ensure all parties have the necessary documentation. Records should be maintained in accordance with local policies and regulations to support both accountability and transparency.

Common mistakes

When individuals fill out the Sample Receiving form, numerous mistakes can occur that may lead to administrative delays or inaccuracies. One common error is failing to complete the County field accurately. Omitting or inaccurately entering the county name can cause significant disruptions in tracking and processing the materials.

Another frequent mistake involves the Purchase Order Number. If this specific field is left blank or filled out incorrectly, it complicates the linkage between the receipt of materials and the respective accounts payable, potentially leading to payment issues.

Completing the Requisition Number is equally crucial. Neglecting to enter this number can result in miscommunication between departments, which may hinder future material requests and create confusion.

The Item No. may seem straightforward, yet many people either duplicate numbers or assign them incorrectly. This inconsistency can cause mismatches in inventories and complicate record-keeping processes.

In the Description section, participants may use vague wording or abbreviations that are not universally understood. Clear descriptions ensure that all parties involved know precisely what materials have been received.

An error in the Quantity field can lead to either overstocking or understocking issues. Double-checking this quantity is essential for maintaining accurate records and ensuring that departments have adequate supplies.

Misstating the Unit Price can result in financial discrepancies. If this information is grossly inaccurate, it can lead not only to payment errors but also to budgeting issues in the future.

The Freight Charge section is often overlooked or filled out incorrectly. This oversight can lead to unexpected costs that are not accounted for in budget planning, impacting overall financial management.

After all the details have been filled out, the signature of the inspector must be added along with the Date Received. Failing to provide this certification means that the report isn't officially recognized, which can render it void.

Lastly, the entire form must be reviewed before submission. Errors overlooked or omitted at this stage can multiply, making it imperative to ensure accuracy throughout the completion process.

Documents used along the form

When managing the receiving process for materials, a variety of forms and documents play essential roles alongside the Sample Receiving Form. These documents help ensure accuracy, accountability, and compliance throughout the procurement process. Below is a detailed list of other important forms often utilized in tandem with the Sample Receiving Form.

- Purchase Order: This document is issued by the buyer to the seller, detailing the types, quantities, and agreed prices for products or services. It serves as a formal agreement and helps to prevent misunderstandings regarding the order.

- Requisition Form: This internal document requests approval to purchase goods or services. It often contains details about the items needed, the purpose of the purchase, and the budget account to be charged, streamlining communication within departments.

- Invoice: Typically sent by the vendor, an invoice bills the buyer for the goods delivered or services rendered. It includes crucial information such as item description, quantities, prices, and payment terms, making it vital for financial tracking.

- Receipt: After payment is made, a receipt serves as proof of transaction. It provides confirmation that the buyer has received the goods or services and often includes details like date, total amount, and payment method.

- Delivery Note: Accompanying goods during transit, a delivery note lists the items delivered. It’s used to verify that the correct items have been received in the correct quantities, aiding in inventory management.

- Inspection Report: After receiving materials, an inspection report documents the condition and quality of the goods. This report helps identify any discrepancies or problems with the received materials, providing a basis for further actions if necessary.

- Inventory Management Sheet: This document tracks the quantities and status of materials in storage. It aids in maintaining accurate records of stock levels and helps prevent over-ordering or stockouts.

- Return Authorization Form: If materials need to be returned, this form outlines the reasons for the return and serves as a formal request to process it. It ensures that the return process is documented and approved.

- Supplier Assessment Form: Evaluating suppliers for their performance and quality assurance, this form gathers essential feedback. It helps companies maintain strong relationships with vendors and ensure adherence to standards.

Utilizing these forms and documents effectively creates a comprehensive procurement system that enhances operational efficiency. Ensuring that all necessary paperwork is in order not only streamlines the receiving process but also contributes to better resource management and accountability.

Similar forms

-

Delivery Receipt: Similar to the Sample Receiving form, a Delivery Receipt documents the receipt of goods. It typically includes details such as the item description, quantity received, and signatures to confirm that the items were delivered and inspected. Both documents serve to verify that the order was fulfilled and received in acceptable condition.

-

Purchase Order Acknowledgment: This document provides formal confirmation from the supplier that they have received a purchase order. It outlines the items, prices, and any special requests. Like the Sample Receiving form, it functions to confirm the details of an order but does so from the vendor's perspective.

-

Inspection Report: This report details the evaluation of materials received, often focusing on their quality and compliance with specifications. The Sample Receiving form includes a certification of satisfactory inspection, which aligns it closely with Inspection Reports that also confirm whether the received materials meet the required standards.

-

Inventory Receipt: An Inventory Receipt is used to record the addition of goods to a company's inventory. It includes information about item descriptions, quantities, and receiving dates. Similar to the Sample Receiving form, it tracks the flow of materials into an organization and ensures proper inventory control.

Dos and Don'ts

When filling out the Sample Receiving form, there are several important practices to follow. Here’s a list of six dos and don’ts that can help ensure accurate and efficient completion of the form.

- Do fill in all required fields completely, as missing information can cause delays.

- Do double-check the Purchase Order and Requisition numbers for accuracy.

- Do list the quantity received matching the description to avoid discrepancies.

- Don't leave any fields blank, particularly the date received and the inspector's signature.

- Don't use abbreviations unless they are widely understood within the department.

- Don't forget to include any applicable freight charges in the total calculation.

Misconceptions

Understanding the Sample Receiving form is essential for smooth operations within a department. However, several misconceptions exist about this form that can lead to confusion. Here are eight of those misconceptions:

- It's only for large shipments. Many believe this form is necessary only for bulky deliveries. In reality, it applies to all types of materials or services received, regardless of size.

- You don’t need it for services. Some people think this form is only for physical items. However, it is also used to confirm the receipt of services that were ordered.

- Once submitted, it’s final. A common myth is that the form can’t be modified after submission. Corrections can and should be made if errors are found post-submission.

- Freight charges don’t need to be listed. There is a perception that freight charges are optional. Actually, included freight charges are important for calculating the total cost and do need to be reported.

- Any employee can sign it. Some believe any department member can certify the receipt. However, only designated inspectors should sign to ensure accountability and proper oversight.

- The date of receipt is irrelevant. There's a misconception that the date when items were received doesn’t matter. In fact, documenting this date is crucial for tracking and compliance purposes.

- It’s redundant if you have a purchase order. Many think that having a purchase order makes the Sample Receiving form unnecessary. However, the form serves a different purpose by confirming actual receipt and inspection.

- It's a one-time form. People often assume this form is used only once for each purchase. In fact, multiple instances may be documented for ongoing shipments or recurring services.

Awareness of these misconceptions helps ensure proper use of the Sample Receiving form, fostering more efficient and accountable purchasing processes in departments.

Key takeaways

Ensure that you fill in the County name accurately at the beginning of the form to reflect the correct jurisdiction.

Specify the Department clearly to facilitate proper record-keeping and accountability within the organization.

Enter the Purchase Order No and Requisition No in their designated fields. This information is crucial for financial tracking and inventory management.

List each item under the Description section in detail, as this will help in confirming the materials received match what was ordered.

Make sure to record the Quantity received accurately. This helps prevent discrepancies in inventory counts.

Note the Unit Price next to each item so that you can calculate costs effectively.

Total up the Extension for each item by multiplying the quantity by unit price. This figure contributes to the overall order amount.

If applicable, include any Freight Charge in the designated space. Transport fees can significantly affect overall costs.

Calculate the Total amount owed, including all items and freight charges. Double-check this figure for accuracy.

Certification section must be completed by an inspector. This person's signature verifies that the received materials were satisfactory.

Document the Date Received to create an accurate timeline for inventory records and to satisfy audit requirements.

Browse Other Templates

Daf Form 594 - It reinforces responsible financial practices within military life by addressing dependents' welfare.

Stoichiometry Review Worksheet - Determine how many moles of H2O are necessary to produce 55.7 moles of H2.

Commercial Rental Application Form - The Federal Tax ID Number is collected, ensuring the business is recognized for tax purposes.