Fill Out Your Tractor Checklist Form

The Tractor Checklist form serves as an essential tool for ensuring safety and operational readiness before a tractor is put to use. Designed for thorough inspections, this form encompasses various critical components that require verification, such as tire condition, engine oil levels, and the functionality of the three-point hitch assembly. Specific attention is directed towards the fuel supply and the safety features of the vehicle, including the proper functioning of the PTO master shield and the visibility of the Slow Moving Vehicle (SMV) sign when operating on the road. Moreover, it addresses operator safety through checks on the tractor's seat adjustment and seatbelt security. The process begins with a visual inspection while the key is off, assessing aspects such as signs of coolant leaks, the status of all lights, and the presence of any obstructions in the vicinity of the tractor. When the key is on, operators must ensure that critical gauges, including those for oil and temperature, are functioning correctly. Ultimately, if any part of the tractor is deemed unsafe, immediate reporting to a supervisor is mandated, reinforcing the form’s role not just as a checklist, but as a vital mechanism for maintaining workplace safety and operational efficiency.

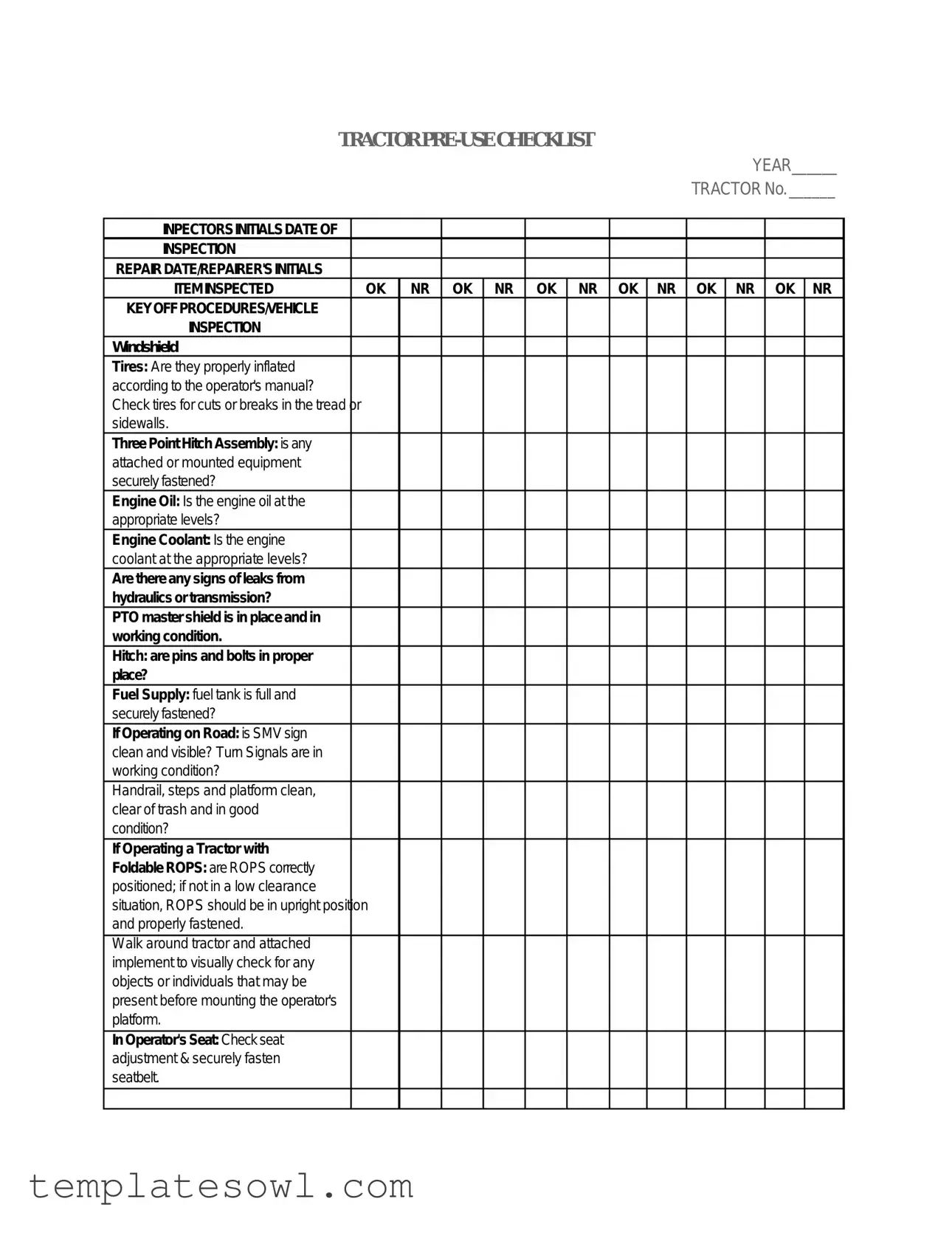

Tractor Checklist Example

TRACTOR

|

YEAR______ |

|

TRACTORNo.______ |

INPECTORSINITIALSDATEOF |

|

INSPECTION |

|

REPAIRDATE/REPAIRER'SINITIALS |

|

ITEMINSPECTED |

OK NR OK NR OK NR OK NR OK NR OK NR |

KEYOFFPROCEDURES/VEHICLE |

|

INSPECTION |

|

Windshield

Tires: Are they properly inflated according to the operator's manual?

Check tires for cuts or breaks in the tread or sidewalls.

Three Point Hitch Assembly: is any attached or mounted equipment securely fastened?

Engine Oil: Is the engine oil at the appropriate levels?

Engine Coolant: Is the engine coolant at the appropriate levels?

Are there any signs of leaks from hydraulicsortransmission?

PTO master shield is in place and in working condition.

Hitch: are pins and bolts in proper place?

Fuel Supply: fuel tank is full and securely fastened?

If Operating on Road: is SMV sign clean and visible? Turn Signals are in working condition?

Handrail, steps and platform clean, clear of trash and in good condition?

If Operating a Tractor with Foldable ROPS: are ROPS correctly positioned; if not in a low clearance situation, ROPS should be in upright position and properly fastened.

Walk around tractor and attached implement to visually check for any objects or individuals that may be present before mounting the operator's platform.

In Operator's Seat: Check seat adjustment & securely fasten seatbelt.

KEYONPROCEDURES

Checkgaugesandinstruments: Oil and battery lights are working properly?

Engine Temperature gauge is in working condition?

Hour Meter is in working condition?

StandardEquipment:

Steering is in working condition? Front, Tail, Brake, and Turn signal lights are in working condition? Horn is working properly?

ENGINERUNNINGPROCEDURES

StandardEquipment: Windshield wiper is working properly?

Brakes are working properly? Parking Brake is in working condition?

Hoist Operation is in working Condition?

Check all other items listed in operator'smanualas recommended.

NR= Needs Repair

If the tractor is found to be unsafe, the condition must be reported immediately to the supervisor and get repaired.

Form Characteristics

| Fact Name | Description |

|---|---|

| Form Purpose | The Tractor Checklist form is designed to ensure all safety and operational checks are conducted before using a tractor. |

| Year and Number | Each form includes a space for the year of inspection and the tractor number to track specific equipment and inspections. |

| Inspection Initials | Inspectors are required to provide their initials and the date of inspection, ensuring accountability and record-keeping. |

| OK/NR Options | The checklist features OK (satisfactory) and NR (needs repair) options for each item inspected, facilitating easy assessment of tractor condition. |

| Pre-Use and Running Checks | Both pre-use and running procedures are included to provide a comprehensive framework for tractor safety checks. |

| Repair Reporting | If the tractor is found to be unsafe, the form mandates that the condition must be reported immediately. |

| Governing Laws | State-specific forms fall under various agricultural safety regulations, including OSHA standards and state department of agriculture requirements. |

| Key Safety Items | Key items to check include tire condition, engine oil levels, and the presence of safety equipment like ROPS and SMV signs. |

| Importance of Visibility | Inspection includes visual checks for objects or individuals around the tractor to ensure safety before operation. |

Guidelines on Utilizing Tractor Checklist

Filling out the Tractor Checklist form is essential for ensuring safe and efficient operation. By systematically reviewing each item, you help maintain the tractor’s functionality and identify any necessary repairs. It provides a clear way to document inspection results, making it easier to track maintenance needs over time.

- Begin by entering the year and tractor number at the top of the form.

- Initial the inspector's initials and date of inspection.

- For each item in the inspection list, check the appropriate box under OK (if everything is fine) or NR (if repairs are needed).

- Start with the key off procedures/vehicle inspection section:

- Inspect the windshield.

- Check tire inflation and look for any damage.

- Verify the security of the three-point hitch assembly and any mounted equipment.

- Ensure engine oil and coolant levels are appropriate.

- Look for leaks in hydraulics or transmission.

- Confirm that the PTO master shield is in place.

- Check hitch pins and bolts.

- Ensure that the fuel tank is full and securely fastened.

- If operating on the road, confirm that the SMV sign is clean and visible, and that turn signals are working.

- Inspect handrails, steps, and platform for cleanliness and condition.

- If applicable, check the positioning of foldable ROPS.

- Conduct a walk-around to ensure no objects or individuals are present before mounting.

- Adjust the seat and fasten the seatbelt while seated.

- Next, move on to the key on procedures section:

- Check all gauges and instruments: oil and battery lights, engine temperature gauge, and hour meter.

- Test the steering and light functionality (front, tail, brake, and turn signals).

- Ensure the horn is operational.

- Finally, assess the engine running procedures:

- Confirm that the windshield wiper and brakes are working properly.

- Verify the parking brake functionality.

- Ensure hoist operation is in working condition.

- Review all other items listed in the operator's manual as recommended.

- If any item is marked as NR (needs repair), report the unsafe condition immediately to a supervisor for repair.

What You Should Know About This Form

What is the purpose of the Tractor Checklist form?

The Tractor Checklist form is designed to ensure that a tractor is safe and operational before use. It provides a systematic approach to inspect vital components and systems of the tractor, helping to identify any issues that may need attention.

How often should the Tractor Checklist be completed?

The Tractor Checklist should be completed before each use of the tractor. Regular inspections help to maintain safety and functionality, reducing the risk of accidents or breakdowns during operation.

What does 'NR' mean on the checklist?

'NR' stands for 'Needs Repair.' This indicates that the inspected item is not functioning properly and requires attention. Items marked as NR should be reported to a supervisor for immediate repairs.

What items are inspected in the Tractor Checklist?

The checklist covers various items, including tires, engine oil levels, coolant levels, fuel supply, signals, and operational controls. It ensures that all essential aspects of the tractor are checked before use.

Who is responsible for completing the Tractor Checklist?

The individual operating or inspecting the tractor is typically responsible for completing the checklist. This person needs to initial the form to indicate that the inspection has been performed.

What should be done if a problem is found during inspection?

If any issues are detected during the inspection, they must be reported immediately to the supervisor. The tractor should not be used until all necessary repairs have been made and the equipment is deemed safe for operation.

Why is it important to check the fuel supply before operation?

Ensuring the fuel tank is full and securely fastened is essential for uninterrupted operation. Running out of fuel could lead to unexpected downtime or operational hazards.

What specific aspects of the tires are checked?

During the inspection, check that the tires are properly inflated according to the operator's manual. Look for any cuts, breaks, or signs of wear in the tread or sidewalls that could compromise safety.

What are ROPS, and why is their position important?

ROPS stands for Roll Over Protection Structure. It's crucial to ensure that ROPS are correctly positioned, especially if the tractor is being used in areas with low clearance. Properly fastening and adjusting ROPS can enhance operator safety in case of an overturn.

What should be checked when starting the tractor?

When starting the tractor, check gauges and instruments, including oil lights and engine temperature gauge. Ensure that all standard equipment, like brakes and lights, is functioning correctly before proceeding.

Common mistakes

Completing the Tractor Checklist form may seem straightforward, yet many individuals encounter difficulties that can lead to oversights. One common mistake is unintentionally skipping crucial items listed in the checklist. This often happens due to a hurried approach, where the inspector may overlook essential inspections— such as checking the tire's inflation or examining the fuel supply. Each item on the checklist has been included for a reason; neglecting to check even one can lead to serious safety concerns.

Another frequent error involves misreading or misinterpreting instructions. Clear understanding of what each item entails is important. For instance, the check for the windshield wiper may be misunderstood to include only a visual check instead of ensuring it actually functions when activated. When this occurs, it may lead to the operator being ill-equipped to handle adverse weather conditions effectively.

Moreover, many forget to record the date of inspection or the inspector's initials in the appropriate sections. This oversight can create confusion later regarding accountability and may prevent critical information from being traced back if repairs are necessary. It’s vital that each inspection be well documented to maintain an accurate record for future reference.

Another misstep stems from not reassessing the tractor’s condition after a repair has been made. Individuals sometimes fail to go back to the checklist to confirm whether the items previously marked as needing repair have been successfully addressed. Documentation of repairs is essential, as it directly impacts safety and operational efficiency.

As inspectors fill out the form, some may mistakenly assume that all indicators are functional based on their prior experience. This hasty judgment can lead them to miss necessary checks on gauges and instruments. A thorough examination— not just relying on past experiences— is crucial to ensure correctness.

In addition, personal biases can influence the checking process. For instance, if an inspector feels confident in a certain area, they might not give it the thorough inspection it deserves. Each aspect, be it the condition of the brakes or the functionality of the turn signals, should be given equal attention in order to uphold safety standards.

Another critical error involves ignoring the need for a walk-around inspection. Failing to visually scan the tractor and any attached implements before mounting can lead to dangerous situations. It is essential to ensure that the area around the vehicle is clear before engaging in any operational procedures.

Lastly, improper completion of the Not Ready (NR) statuses can lead to complications. Some inspectors may incorrectly mark a functional item as needing repair, while conversely, they might overlook persistent issues. Correctly indicating whether equipment is OK or NR is paramount for ensuring timely repairs and safe operations.

By being mindful of these common mistakes, individuals can enhance their adherence to the Tractor Checklist, ultimately ensuring better safety and operational success.

Documents used along the form

Ensuring tractor safety and functionality is crucial for effective operation in any agricultural setting. The Tractor Checklist form serves as a comprehensive guideline for pre-use inspections, but it is often accompanied by additional documents that further enhance operational safety and maintenance tracking. Below are some essential forms that work alongside the Tractor Checklist form.

- Maintenance Log: This document records all maintenance activities performed on the tractor. It includes details like dates of service, types of maintenance performed, and any parts replaced. Keeping this log updated provides valuable insights into the tractor's service history and helps anticipate future needs.

- Operator Training Certification: This form verifies that tractor operators have undergone the necessary training. It includes the operator's name, training date, and a signature from the trainer. This certification ensures that only qualified individuals are operating the machinery, promoting a safer work environment.

- Incident Report Form: In case of an accident or malfunction, this document is vital for documenting the details of the incident. It includes information such as date, time, description of the event, and parties involved. Completing this form promptly can aid in analyzing causes and preventing future occurrences.

- Inspection Report: This report is used to record the results of any periodic inspections conducted by professionals. It outlines the condition of vital components and highlights any areas needing attention. This document helps ensure compliance with safety regulations.

- Repair Authorization Form: If repairs are necessary, this form is required to seek approval before any work is done. It includes the nature of repairs needed and estimated costs. Obtaining authorization ensures that all repairs are properly documented and authorized before any expenditure occurs.

By utilizing these forms in conjunction with the Tractor Checklist, operators and supervisors can enhance accountability and safety, resulting in a more efficient working environment. Proper documentation not only helps comply with safety standards but also facilitates better maintenance and risk management practices.

Similar forms

-

Vehicle Inspection Checklist: Like the Tractor Checklist, a Vehicle Inspection Checklist helps ensure all essential components are checked for safety and functionality before use. It also covers items like lights, tires, and brakes.

-

Pre-Trip Inspection Form: This document, often used by commercial drivers, outlines a systematic approach to evaluate the vehicle's condition before a trip. It stresses crucial operational checks similar to those found on the Tractor Checklist.

-

Equipment Inspection Log: Similar to the Tractor Checklist, this log records the status of various types of equipment. It details what was inspected and whether items are satisfactory or require repairs.

-

Maintenance Checklist: This document ensures that routine maintenance tasks are performed correctly. It mirrors the Tractor Checklist by specifying necessary checks for fluids, brakes, and other operational elements.

-

Safety Inspection Report: This report evaluates a vehicle's compliance with safety regulations. Like the Tractor Checklist, it includes inspections of lights, safety equipment, and overall functionality.

-

Daily Vehicle Condition Report: Used primarily by fleet operators, this report captures the daily condition of vehicles. Similarities lie in the attention to critical items such as fluid levels and brakes, akin to the Tractor Checklist.

-

Forklift Safety Inspection Form: Like the Tractor Checklist, this form focuses on critical safety checks for forklifts, including operational components and safety features that must be verified before use.

-

Aircraft Pre-Flight Inspection Checklist: This checklist ensures safety checks are performed on aircraft before flight. It resembles the Tractor Checklist with its methodical approach to confirming operational readiness.

-

Safety Equipment Inspection Form: This document addresses the condition of safety gear. It shares parallels with the Tractor Checklist in reviewing the functionality of safety features before operation.

-

Construction Equipment Daily Checklist: Used to inspect machinery, this checklist mirrors the Tractor Checklist by focusing on essential checks like fluid levels, safety devices, and general operational health.

Dos and Don'ts

When filling out the Tractor Checklist form, it's important to ensure accuracy and thoroughness. Here are some do's and don’ts to keep in mind:

- Do check all listed items thoroughly before marking them as OK.

- Do make sure to enter the correct year, tractor number, and inspector's initials.

- Don't skip any steps in the inspection process. Every section is vital for safety.

- Don't hesitate to report any issues immediately. Unsafe conditions must be addressed right away.

Misconceptions

There are several misconceptions surrounding the Tractor Checklist form that can lead to misunderstandings. Here, we clarify these common myths.

- It’s Optional to Use the Checklist - Some believe using the checklist isn't mandatory. In reality, it's a crucial step to ensure safety and compliance before operating any tractor.

- Visual Inspections Aren’t Necessary - There's a misconception that visual inspections can be skipped. Every item listed requires a careful visual check for potential hazards.

- As Long as the Tractor Runs, It's Safe - Just because the tractor starts doesn’t mean it's in safe operating condition. Each component needs thorough inspection beyond just starting the engine.

- Only Trained Personnel Should Inspect - Some think that only certified mechanics can do the inspections. In fact, anyone responsible for operating the tractor can and should conduct these checks.

- The Checklist is the Same for All Tractors - Many assume that one checklist fits all models. Each tractor may have specific requirements, so always refer to the operator’s manual.

- It Covers All Possible Issues - A prevailing belief is that the checklist is exhaustive. While comprehensive, it’s still important to be vigilant about any unusual sounds or behaviors from the tractor.

- Repairs Don’t Need to be Documented - Some think there's no need for noting repairs. However, documenting repairs is essential for accountability and future reference.

- Inspection Can Be Done Quickly - Lastly, it’s a common misconception that completing the checklist is a quick process. Rushing through can lead to missed details; taking time ensures safety.

Understanding these misconceptions will help ensure that the Tractor Checklist form is used effectively, keeping operators and equipment safe.

Key takeaways

Here are key takeaways for filling out and using the Tractor Checklist form:

- Year and Tractor Number: Always fill in the year and tractor number at the top of the form. This helps maintain accurate records.

- Inspectors' Initials: Ensure the inspectors' initials and the date of inspection are clearly marked. This confirms who conducted the inspection and when it took place.

- OK/NR Designation: Use the 'OK' or 'NR' (Needs Repair) designation for each item inspected. This provides a clear status for each component on the checklist.

- Thoroughness is Crucial: Check all items thoroughly, including tires, engine oil, and fuel supply. Skipping any components can lead to safety hazards.

- Immediate Reporting: If an issue is identified, report it to the supervisor immediately. This ensures safety and prompt repairs.

- Operator’s Comfort: In the operator's seat, adjusting the seat and securing the seatbelt are essential for comfort and safety while operating the tractor.

- Standard Equipment Checks: During running procedures, check all standard equipment, such as brakes and lights. Proper functionality is key to safe operation.

Browse Other Templates

Secondary Dependent Navy - Some applicants may need assistance completing the form, especially if their child has unique needs.

Anthem 151 Form - Your clear communication via the Anthem 151 form can make all the difference.

Barro's Pizza Jobs - Providing a current address allows us to keep you informed about your application status.