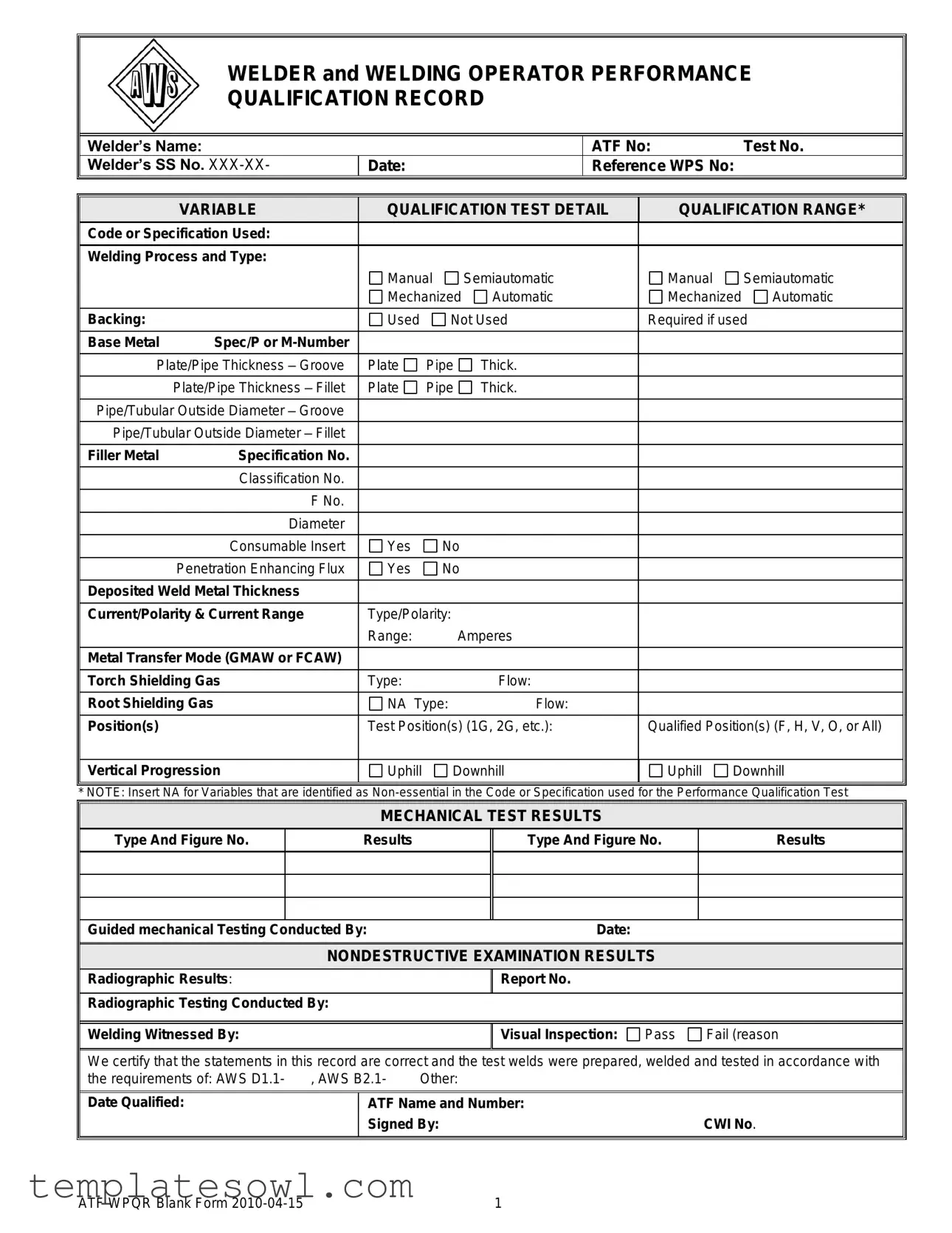

Fill Out Your Welder Performance Qualification Record Form

The Welder Performance Qualification Record form plays a crucial role in documenting a welder's skills and qualifications, ensuring that they meet industry standards. This comprehensive record captures essential information, including the welder’s name, reference WPS number, and various test details. Specific qualifications for different welding processes and types, whether manual or automatic, are clearly outlined. The form includes critical variables such as base metal specifications, thickness of materials, and filler metal classifications. Furthermore, it records the results of mechanical tests and non-destructive examinations, including radiographic testing and visual inspections, which confirm the quality of the welds produced. By detailing aspects like current polarity, metal transfer modes, and qualification ranges, this form serves as a reliable indicator of a welder’s competency in different positions and applications. Overall, the Welder Performance Qualification Record is integral to maintaining industry safety and performance standards, reflecting the welder's adherence to the required regulations.

Welder Performance Qualification Record Example

WELDER and WELDING OPERATOR PERFORMANCE

QUALIFICATION RECORD

|

Welder’s Name: |

|

|

|

|

ATF No: |

|

Test No. |

||||||

|

Welder’s SS No. |

|

Date: |

|

|

Reference WPS No: |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

VARIABLE |

|

|

QUALIFICATION TEST DETAIL |

|

|

QUALIFICATION RANGE* |

|

|||||

|

Code or Specification Used: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Welding Process and Type: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Manual |

Semiautomatic |

|

|

Manual |

|

Semiautomatic |

|||

|

|

|

|

|

Mechanized |

Automatic |

|

|

Mechanized |

Automatic |

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

Backing: |

|

|

|

Used |

Not Used |

|

|

Required if used |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Base Metal |

Spec/P or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Plate/Pipe Thickness – Groove |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Plate/Pipe Thickness – Fillet |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Groove |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Fillet |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filler Metal |

Specification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Classification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diameter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Consumable Insert |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Penetration Enhancing Flux |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Deposited Weld Metal Thickness |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Current/Polarity & Current Range |

|

Type/Polarity: |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Range: |

Amperes |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Metal Transfer Mode (GMAW or FCAW) |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Torch Shielding Gas |

|

Type: |

|

Flow: |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

|

Root Shielding Gas |

|

NA Type: |

Flow: |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||||

|

Position(s) |

|

|

|

Test Position(s) (1G, 2G, etc.): |

|

|

Qualified Position(s) (F, H, V, O, or All) |

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Vertical Progression |

|

Uphill |

Downhill |

|

|

Uphill |

Downhill |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* NOTE: Insert NA for Variables that are identified as

|

|

|

|

MECHANICAL TEST RESULTS |

|

|

||

|

Type And Figure No. |

|

|

Results |

|

Type And Figure No. |

Results |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Guided mechanical Testing Conducted By: |

|

Date: |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

NONDESTRUCTIVE EXAMINATION RESULTS |

|

|

|||

|

Radiographic Results: |

|

|

|

Report No. |

|

|

|

|

|

|

|

|

|

|

||

|

Radiographic Testing Conducted By: |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Welding Witnessed By: |

|

|

|

Visual Inspection: Pass |

Fail (reason |

) |

|

|

|

|

|

|||||

|

We certify that the statements in this record are correct and the test welds were prepared, welded and tested in accordance with |

|||||||

|

the requirements of: AWS D1.1- |

, AWS B2.1- |

Other: |

|

|

|||

|

|

|

|

|

|

|||

|

Date Qualified: |

|

ATF Name and Number: |

|

|

|||

|

|

|

|

Signed By: |

CWI No. |

|

||

|

|

|

|

|

|

|

||

ATF WPQR Blank Form |

|

|

1 |

|

|

|||

Form Characteristics

| Fact Name | Details |

|---|---|

| Purpose | The Welder Performance Qualification Record form verifies a welder's capability to produce sound welds according to industry standards. |

| Welder's Information | The form requires essential details about the welder, including the name, SSN, and ATF number. |

| Weld Process Details | The form specifies the welding processes used, such as manual, semiautomatic, or automatic methods. |

| Base Metal Information | Welders must indicate the specifications, thickness, and diameter of the base metal being used. |

| Filler Metal | The record includes details about the filler metal, such as classification and diameter. |

| Test Results | The form captures results from mechanical tests and nondestructive examinations, ensuring weld integrity. |

| Certification | Certification statements are included, affirming that the records are accurate and tests were conducted to standards. |

| Governing Codes | The performance qualifications align with various codes, notably AWS D1.1 and AWS B2.1, which set industry benchmarks. |

| Date Qualified | The form requires the date on which the welder was qualified, providing a clear timeline for records. |

Guidelines on Utilizing Welder Performance Qualification Record

Filling out the Welder Performance Qualification Record is an important step in documenting a welder’s skills and qualifications. Make sure to gather all necessary information before you begin. This includes details about the welder, the testing process, and results from mechanical and non-destructive examinations. Accurate completion of the form can help streamline the qualification process and demonstrate compliance with industry standards.

- Welder’s Information: Enter the welder’s full name, ATF number, test number, and social security number.

- Date: Write the date when the qualification test was conducted.

- Reference WPS No: Fill in the appropriate welding procedure specification number.

- Qualification Range: Identify the code or specification used for the qualification. This may include noting the welding processes—manual, semiautomatic, mechanized, or automatic.

- Backing: Indicate whether backing was used or not. Include additional information if required.

- Base Metal Specifications: Fill out specifications related to base metal used, including P or M-numbers, plate/pipe thickness for both groove and fillet welds, and tubular outside diameters.

- Filler Metal Information: Enter the specification number and classification number for the filler metal, including its diameter.

- Consumables: Mark whether consumable inserts or penetration-enhancing flux were used.

- Deposited Weld Metal Thickness: Provide the thickness measurement of the deposited weld metal.

- Current Settings: Note the type and polarity of current used for welding as well as the amperes range.

- Metal Transfer Mode: Specify the metal transfer mode utilized (such as GMAW or FCAW).

- Torch and Shielding Gas: Fill in the type and flow rate for both the torch shielding gas and root shielding gas, if applicable.

- Position(s) Testing: Indicate the test positions (like 1G, 2G, etc.) and corresponding qualifications (F, H, V, O, or All).

- Vertical Progression: Note whether the welding was done in an uphill or downhill progression.

- Mechanical Test Results: Document the type and figure number along with the results of guided mechanical testing.

- Non-Destructive Examination Results: Enter the radiographic results and report number, along with the names of those who conducted radiographic testing and witnessed the welding.

- Visual Inspection: Record whether the weld passed or failed visual inspection and provide reasons if it failed.

- Certification: State that all information is correct, and note the requirements that were followed during the testing. Include the date qualified, the ATF name and number, and the signature of the Certified Welding Inspector (CWI).

What You Should Know About This Form

What is the purpose of the Welder Performance Qualification Record form?

The Welder Performance Qualification Record (WPQR) form is a crucial document used to verify that a welder has the necessary skills and qualifications to perform specific welding processes. It serves as an official record of a welder’s abilities, detailing the different types of welding processes they can perform, the materials they are qualified to work with, and the test positions in which they can weld. By documenting this information, the WPQR helps ensure that welders meet industry standards and comply with safety regulations.

Who needs to complete the WPQR form?

The WPQR form must be completed by welders and welding operators who want to demonstrate their qualifications. It is typically filled out after the welder successfully completes a performance qualification test. Employers, welding inspectors, or certified welding personnel often oversee this process to ensure that the welders meet the necessary criteria set forth by industry standards and specifications.

What information is recorded on the WPQR form?

The WPQR form includes essential personal information about the welder, such as their name and identification numbers. It also details the qualifications based on specific welding processes, materials, and the testing methods used. Key fields encompass the level of welding processes (manual, semiautomatic, automatic), base metal specifications, the positions in which the welder is qualified to work, and results from both mechanical tests and nondestructive examination results.

How long does the qualification last?

The qualification period typically depends on the governing body and the specific regulations or codes being followed. Most certifications, including those conducted under AWS guidelines, require periodic requalification or have specific time frames for validity. It is essential for welders and employers to keep track of these requirements to maintain compliance and ensure ongoing qualification.

What is the significance of non-destructive examination results in the WPQR?

Non-destructive examination (NDE) results hold significant value in the WPQR. These results provide assurance that the welds meet quality and safety standards without affecting the integrity of the welded material. The inclusion of NDE results enhances the reliability of the welder’s qualifications by demonstrating that their work has been inspected and passes required quality assessments.

Can the WPQR be modified after it is completed?

Once the WPQR form is completed and signed, it should not be modified without proper authorization. Any changes could compromise the integrity of the document. If corrections or updates are necessary, it is recommended to create an official amendment or supplementary documentation that outlines the changes, ensuring that the integrity of the original record remains intact.

Common mistakes

Filling out the Welder Performance Qualification Record form accurately is essential for ensuring compliance and validating a welder's qualifications. However, there are common mistakes that individuals often make during this process. One frequent error is failing to complete all required fields. Each section, from the welder's name to the test specifications, must be filled out thoroughly. Omissions can result in delays and may even invalidate the qualification, as the absence of information raises questions about the validity of the records.

Another mistake involves misunderstanding the specifications and codes used. It is crucial to clearly understand the relevant code or specification, such as AWS standards, being applied to the qualifications. Without clarity, individuals may incorrectly fill in sections related to welding processes or metal specifications. Misunderstandings like these can lead to serious implications, including re-testing of welds that were otherwise acceptable.

Typos and poor handwriting are also significant issues. When forms are filled out by hand, legibility matters. Illegible entries can cause confusion down the line, as important details may be misinterpreted. Similarly, typographical errors in key data fields can compromise the integrity of the document. It is advisable to double-check all written information or, if possible, to use digital methods to ensure clarity.

Inconsistencies in the test conditions and results can pose serious issues as well. This includes discrepancies between the welding process noted on the form and what was actually used during the performance qualification test. It's important to ensure that the variables accurately reflect the conditions under which the welder qualified. Consistency builds credibility in the qualification process.

Finally, individuals often overlook the importance of signatures and certifications. The form must be signed by the appropriate personnel, including certified weld inspectors. An unsigned qualification record can lead to questions of authenticity and compliance with standards. Therefore, ensuring all necessary signatures are present is crucial at the conclusion of the record-keeping process.

Documents used along the form

The Welder Performance Qualification Record is an essential document used in the welding industry, highlighting a welder's skills and qualifications. When applying for jobs or certifications, several other forms and documents may accompany this record. Each of these documents serves a specific purpose, supporting the overall assessment and validation of a welder’s capabilities.

- Weld Procedure Specification (WPS): A detailed document outlining the welding process, including filler materials, types of joints, and essential variables. The WPS ensures consistency and quality during welding operations.

- Certificate of Compliance: This document certifies that the welding work complies with specific standards or codes. It often accompanies construction projects to ensure quality control.

- Welder Certification Card: This card verifies that a welder has been tested and certified according to industry standards. It serves as proof of qualification and may be required for job applications.

- Non-Destructive Testing (NDT) Reports: These reports provide results of testing methods designed to evaluate weld integrity without damaging the finished product. They are crucial for ensuring that welds meet quality standards.

- Guided Bend Test Results: A specific type of mechanical test where welded samples are bent to assess their ductility and quality. Results from these tests are often documented for official records.

- Visual Inspection Reports: These reports detail the findings from visual inspections of welded joints. They evaluate surface conditions and structural integrity, contributing to the overall quality assessment.

- Welding Logs: These logs record details of each welding operation, including materials used, conditions during welding, and any issues encountered. They are useful for tracking performance over time.

- Material Test Reports (MTR): These reports provide detailed information about the materials used in welding, including their mechanical properties. MTRs are vital for quality assurance.

- Quality Assurance Audit Reports: Conducted internally or by third parties, these documents assess the effectiveness of quality control processes within a welding operation, ensuring compliance with industry standards.

Understanding these documents can significantly enhance a welder's prospects in the field. Collectively, they form a comprehensive picture of competence and reliability, crucial in a competitive job market. Familiarity with these documents not only supports career advancement but also promotes adherence to high industry standards.

Similar forms

The Welder Performance Qualification Record (WPQR) form is an essential document in the welding industry, primarily used to validate a welder's skills and qualifications. Several other documents share similarities with the WPQR in terms of their purpose, structure, and the information they convey. Below is a list of eight documents that are similar to the WPQR, along with a brief explanation of how they are alike:

- Welding Procedure Specification (WPS): This document outlines the specific welding parameters and procedures to be followed during a welding project, similar to how the WPQR details the qualifications and performance tests of the welder.

- Welder Certification: Like the WPQR, a welder certification verifies a welder's skills after they have passed required tests. Both documents serve as proof of a welder's competence and adherence to industry standards.

- Procedure Qualification Record (PQR): The PQR provides documentation of the welding variables and test results for a specific welding procedure. This is akin to the WPQR, which focuses on the welder’s performance within those specified parameters.

- Non-Destructive Testing (NDT) Report: NDT reports detail the results of inspections that verify the integrity of welds. Similar to the WPQR, they confirm compliance with standards and assess quality through testing.

- Inspection Report: These reports summarize the findings of inspections conducted by certified personnel. Both the inspection report and the WPQR ensure that welding practices meet the required specifications and regulations.

- Quality Assurance Plan: A quality assurance plan outlines procedures and standards for maintaining quality in welding. Similar to the WPQR, it emphasizes the importance of compliance and skill verification.

- Certification of Compliance: This document certifies that certain specifications and industry standards have been met, mirroring the objective of the WPQR in establishing welder qualifications and process adherence.

- Material Certificate: A material certificate provides evidence of the material properties, similar to how the WPQR includes details about the specific welding materials used and their compliance with relevant standards.

Each of these documents plays a crucial role in ensuring that welding operations are performed safely and effectively. They contribute to the overall quality assurance processes in the welding industry.

Dos and Don'ts

When filling out the Welder Performance Qualification Record form, it's important to be careful and thorough. Here’s a list of things to keep in mind:

- Do enter all required personal information, such as the welder's name and ATF number.

- Don't leave any fields blank unless specified as optional.

- Do clearly indicate the welding process and type used during the qualification.

- Don't use abbreviations that may confuse others reviewing the document.

- Do ensure all test results are filled out accurately and legibly.

- Don't forget to have the necessary signatures, especially from the CWI.

Following these steps will help make the process smoother and ensure that the record is valid and compliant.

Misconceptions

Misconceptions about the Welder Performance Qualification Record (WPQR) form can lead to confusion and errors in the qualification process. Below are ten common misconceptions, along with clarifications.

- Misconception 1: The WPQR is only necessary for certification.

- Misconception 2: The form is only applicable to one type of welding process.

- Misconception 3: A signed WPQR guarantees a welder's ability to perform all types of welds.

- Misconception 4: Non-destructive testing is optional and doesn’t need to be reported.

- Misconception 5: WPQR forms are only needed for new welders.

- Misconception 6: All records associated with the WPQR must be kept indefinitely.

- Misconception 7: Only a certified inspector can complete the WPQR.

- Misconception 8: The welding witness needs to be present for all aspects of the qualification.

- Misconception 9: The WPQR is the same as the Procedure Qualification Record (PQR).

- Misconception 10: Detailed test results are optional on the WPQR.

In reality, the WPQR serves as both a record of a welder’s skills and a documentation tool to ensure compliance with industry standards. It is a vital component in various qualification processes.

The WPQR accommodates various welding processes, including manual, semiautomatic, and automatic methods. This flexibility allows for a broader range of qualifications.

A WPQR only certifies the specific tests and parameters documented. Welders must undergo separate qualifications for different processes or materials.

Non-destructive examination results are critical. They must be clearly documented in the WPQR, as they validate the integrity of the welds performed.

Established welders may also be required to complete a WPQR to validate their ongoing skills or when qualifying for new processes or materials.

While it's important to maintain these records, retention periods can vary depending on company policy and applicable regulations. It's essential to verify specific requirements.

While a qualified individual must verify the information, the initial completion of the WPQR can be performed by the welder or welding operator themselves.

The witness is crucial for specific stages, especially during testing. However, not all parts of the qualification process require their presence.

Although related, they serve different purposes. A WPQR focuses on the welder’s skills, while a PQR outlines the welding procedure and parameters.

Comprehensive test results are mandatory. They provide essential validation for the qualifications and must be accurately filled out to meet compliance.

Key takeaways

Here are key takeaways for filling out and using the Welder Performance Qualification Record form:

- Complete Identification Information: Ensure all personal details are accurate, including the welder's name, ATF number, and social security number. This information is critical for record-keeping.

- Document Welding Details: Specify the welding processes utilized, ensuring to note whether they are manual, semiautomatic, or automatic. Include information about the base metals and filler metals used.

- Test Position Clarity: Clearly indicate the test positions (such as 1G or 2G) and any qualified positions. This is vital for validating the welder’s ability to perform in various orientations.

- Record Mechanical Test Results: Document the results of mechanical testing thoroughly. Include any necessary certifications, who conducted the tests, and the date of testing.

- Final Certification: Ensure all sections are signed off by the appropriate personnel. This includes certifying the accuracy of the information and the acceptance of the tests conducted.

Browse Other Templates

Dmas 99 Form - The DMAS 99 form is an essential tool for the Medicaid EDCD Waiver process.

Are Usda Grants Taxable - It highlights the importance of thorough auditing and review processes.