Fill Out Your Wood Infestation Inspection Report Form

The Wood Infestation Inspection Report form serves as a crucial document in the management and assessment of wood-related issues, particularly concerning the presence of pests and the integrity of wooden structures. This form consists of a variety of sections, each designed to capture key information about the inspection process. Inspections begin with basic details, such as the name of the inspector, the date of the inspection, and pertinent reference numbers that help track the form through any necessary follow-up actions. Subsequently, the form dives into specific findings regarding wood infestation, detailing type of pest, extent of damage, and recommendations for treatment. Additionally, the report includes statements verifying the qualifications of the inspector, ensuring that the evaluation is carried out by a certified professional with expertise in identifying and managing wood issues. Moreover, the documentation captures any significant observations encountered during the inspection, which could affect the structural integrity of the wood involved. Overall, this comprehensive approach allows for a thorough evaluation, promoting safety and longevity of wooden structures.

Wood Infestation Inspection Report Example

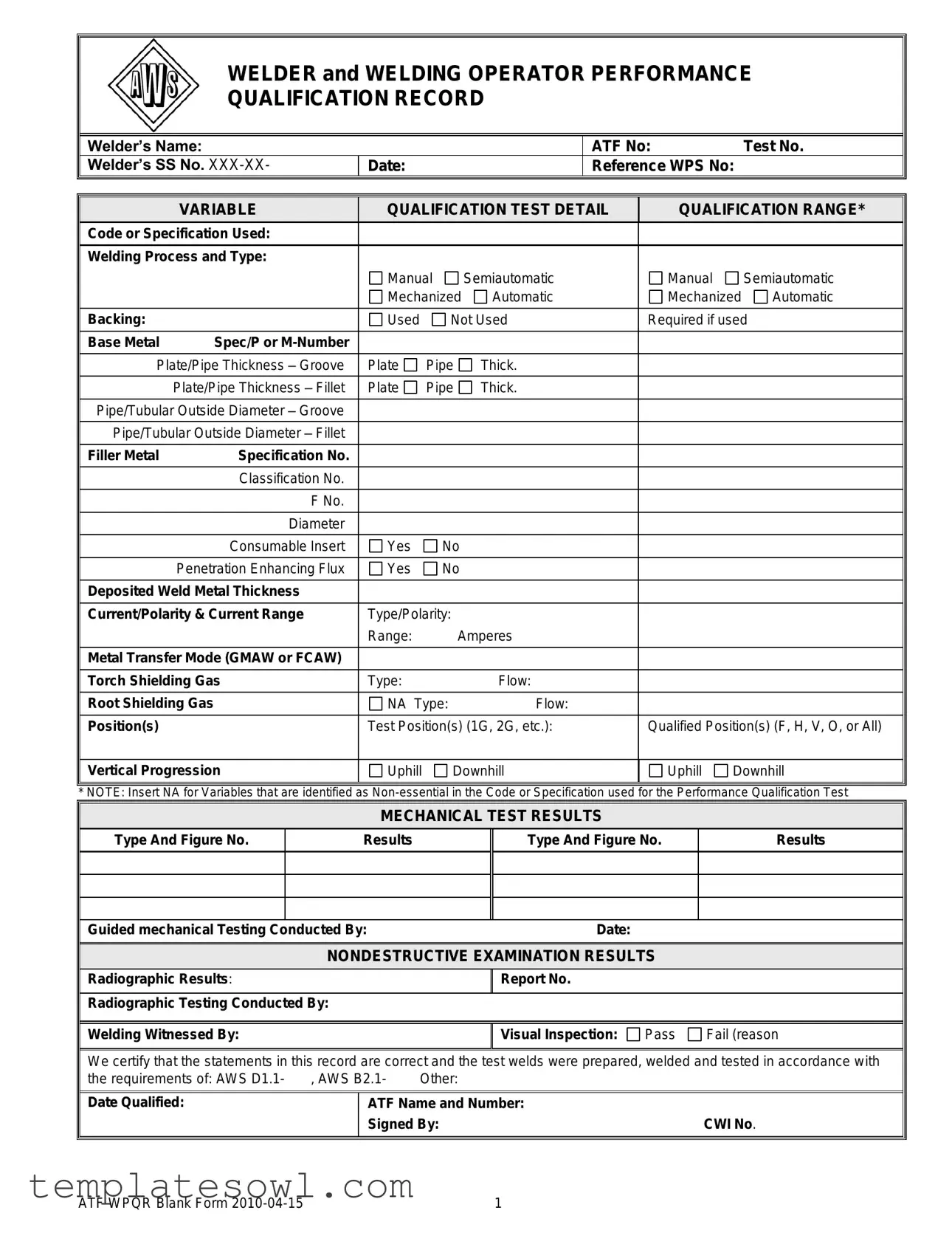

WELDER and WELDING OPERATOR PERFORMANCE

QUALIFICATION RECORD

|

Welder’s Name: |

|

|

|

|

ATF No: |

|

Test No. |

||||||

|

Welder’s SS No. |

|

Date: |

|

|

Reference WPS No: |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

VARIABLE |

|

|

QUALIFICATION TEST DETAIL |

|

|

QUALIFICATION RANGE* |

|

|||||

|

Code or Specification Used: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Welding Process and Type: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Manual |

Semiautomatic |

|

|

Manual |

|

Semiautomatic |

|||

|

|

|

|

|

Mechanized |

Automatic |

|

|

Mechanized |

Automatic |

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

Backing: |

|

|

|

Used |

Not Used |

|

|

Required if used |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Base Metal |

Spec/P or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Plate/Pipe Thickness – Groove |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Plate/Pipe Thickness – Fillet |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Groove |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Fillet |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filler Metal |

Specification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Classification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diameter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Consumable Insert |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Penetration Enhancing Flux |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Deposited Weld Metal Thickness |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Current/Polarity & Current Range |

|

Type/Polarity: |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Range: |

Amperes |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Metal Transfer Mode (GMAW or FCAW) |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Torch Shielding Gas |

|

Type: |

|

Flow: |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

|

Root Shielding Gas |

|

NA Type: |

Flow: |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||||

|

Position(s) |

|

|

|

Test Position(s) (1G, 2G, etc.): |

|

|

Qualified Position(s) (F, H, V, O, or All) |

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Vertical Progression |

|

Uphill |

Downhill |

|

|

Uphill |

Downhill |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* NOTE: Insert NA for Variables that are identified as

|

|

|

|

MECHANICAL TEST RESULTS |

|

|

||

|

Type And Figure No. |

|

|

Results |

|

Type And Figure No. |

Results |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Guided mechanical Testing Conducted By: |

|

Date: |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

NONDESTRUCTIVE EXAMINATION RESULTS |

|

|

|||

|

Radiographic Results: |

|

|

|

Report No. |

|

|

|

|

|

|

|

|

|

|

||

|

Radiographic Testing Conducted By: |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Welding Witnessed By: |

|

|

|

Visual Inspection: Pass |

Fail (reason |

) |

|

|

|

|

|

|||||

|

We certify that the statements in this record are correct and the test welds were prepared, welded and tested in accordance with |

|||||||

|

the requirements of: AWS D1.1- |

, AWS B2.1- |

Other: |

|

|

|||

|

|

|

|

|

|

|||

|

Date Qualified: |

|

ATF Name and Number: |

|

|

|||

|

|

|

|

Signed By: |

CWI No. |

|

||

|

|

|

|

|

|

|

||

ATF WPQR Blank Form |

|

|

1 |

|

|

|||

Form Characteristics

| Fact Name | Description |

|---|---|

| Purpose | The Wood Infestation Inspection Report form assesses the presence of wood-destroying insects and organisms. |

| Key Components | The form includes details such as inspector information, inspection date, and findings regarding wood infestation. |

| State-Specific Variations | Some states require a specific format or additional information based on local regulations. |

| Legal Authority | The governing laws for inspections in some states are derived from state pest control statutes. |

| Inspector Qualification | The inspector must typically be a licensed pest control operator to complete the report. |

| Findings Disclosure | Results from the inspection must be disclosed to any interested party, such as property buyers. |

| Validity Period | Typically, the inspection report is valid for a specific period, often ranging from 30 to 90 days. |

| Signature Requirement | The report must be signed by the certified inspector, indicating its authenticity and accuracy. |

| Usage | This report is commonly used in real estate transactions to inform buyers of any potential pest issues. |

Guidelines on Utilizing Wood Infestation Inspection Report

Completing the Wood Infestation Inspection Report form efficiently ensures a clear record of the wood inspection process. Follow these instructions closely to ensure accuracy and completeness before submission.

- Welder’s Name: Enter the full name of the welder performing the inspection.

- ATF No: Fill in the assigned ATF number associated with the welder.

- Test No: Record the specific test number for tracking purposes.

- Welder’s SS No: Input the welder’s Social Security number.

- Date: Write the date the report is being completed.

- Reference WPS No: Include the reference number for the Welding Procedure Specification used.

- Code or Specification Used: Specify the code or specification applicable to the inspection.

- Welding Process and Type: Indicate the type and method of welding performed, highlighting whether it was manual, semi-automatic, mechanized, or automatic.

- Backing: State whether backing was used, not used, or required if it was used.

- Base Metal Spec/P or M-Number: Enter the specification or material number of the base metal.

- Plate/Pipe Thickness: Provide the thickness measurements for groove and fillet welds, as necessary.

- Filler Metal Specification No: Record the specification number for the filler metal used.

- Classification No: Write down the classification number for the filler metal.

- Consumable Insert: Indicate if a consumable insert was used (Yes or No).

- PENETRATION ENHANCING FLUX: State whether penetration enhancing flux was used (Yes or No).

- Deposited Weld Metal Thickness: Provide the thickness of the deposited weld metal.

- Current/Polarity & Current Range: Specify the type/polarity and amperage used during welding.

- Metal Transfer Mode: Indicate whether GMAW or FCAW was used.

- Torch Shielding Gas Type: Document the type of shielding gas and its flow rate.

- Root Shielding Gas: Specify if applicable, noting the type and flow rate.

- Position(s): Indicate the testing and qualified positions, such as 1G, 2G, and others.

- Vertical Progression: State the direction of progression (uphill or downhill).

- MECHANICAL TEST RESULTS: Provide all relevant mechanical testing results and details.

- NONDESTRUCTIVE EXAMINATION RESULTS: Capture the results of radiographic testing and visual inspections, noting whether they passed or failed.

- Certification: Finally, certify that all statements are correct. Include the date qualified, ATF name and number, CWI number, and the signature of the authorized individual.

Once the form is completed accurately, ensure that it is reviewed for any potential errors. It is crucial to submit the report promptly to maintain compliance and facilitate any necessary follow-up actions.

What You Should Know About This Form

What is the Wood Infestation Inspection Report form?

The Wood Infestation Inspection Report form is a document used by pest control professionals to record findings from an inspection of structures for wood-destroying organisms. It details the presence of pests, such as termites or carpenter ants, and any applicable damage. This report is often necessary for real estate transactions or property management purposes.

Who needs to complete the Wood Infestation Inspection Report?

The report must be completed by a licensed pest control inspector or a qualified professional with expertise in identifying wood-destroying organisms. This ensures that the inspection is thorough and the findings are valid for legal or real estate purposes.

Why is a Wood Infestation Inspection important?

A Wood Infestation Inspection is critical because it helps property owners understand the condition of their structures. It identifies potential threats from pests that can cause severe damage if left unaddressed. In real estate transactions, the report provides peace of mind to buyers by revealing the wood’s condition and any necessary treatments.

What happens if wood-destroying organisms are found?

If wood-destroying organisms are detected during the inspection, the report will indicate the type and extent of the infestation. Recommendations for treatment will typically be included, guiding the property owner on the next steps to mitigate damage. Prompt action is usually advised to prevent further deterioration.

How often should a Wood Infestation Inspection be conducted?

It is recommended that property owners conduct a Wood Infestation Inspection at least once a year, especially in areas prone to pest infestations. However, additional inspections may be necessary if there are signs of wood damage or if a property is undergoing significant renovations.

Can I conduct my own inspection?

While homeowners can look for visible signs of pests, a professional inspection is strongly recommended. Trained inspectors have the experience and tools necessary to identify issues that may not be apparent. Relying on a professional reduces the risk of overlooking significant problems.

What information is included in the report?

The report includes details about the inspector's findings, types of pests found, the extent of damage, and any recommendations for treatment. It may also document the conditions of areas inspected, such as moisture levels, which can affect the possibility of infestations.

Is the report legally binding?

The Wood Infestation Inspection Report itself is not a legally binding document, but it is often required as part of legal transactions, such as selling or refinancing a home. Its findings can influence negotiations and should be taken seriously by all parties involved.

What should I do with the report once it's completed?

Once the inspection report is completed, property owners should keep it on record. If selling the property, the report can be shared with potential buyers, providing transparency about the property's condition. If treatment is needed, the report serves as a reference for pest control services.

Common mistakes

Filling out the Wood Infestation Inspection Report form can be straightforward, but mistakes often occur. One common error is failing to include all necessary information. It's crucial to complete every section fully. Omitting details can lead to confusion and delays when the report is reviewed.

Another frequent mistake is not accurately reporting the welder's identification details. People sometimes miswrite the Welder’s Name or ATF Number. These details must correspond correctly to ensure proper tracking and auditing of qualifications.

Errors in the Qualification Range section can also occur. Individuals may either misinterpret or fail to follow the guidelines of the relevant codes or specifications. This can compromise the report's integrity and the reliability of its findings.

Inconsistent use of welding process specifications is a notable pitfall. For example, selecting "Manual" when "Automatic" was actually employed can render the report invalid. Accuracy in detailing the welding process is non-negotiable.

Some individuals overlook the importance of specifying the Base Metal Specification when completing the report. Failing to include this information can confuse the material context for weld inspections and testing protocols.

Additionally, forgetting to document the results of non-destructive examinations is a serious misstep. These results, particularly from radiographic testing, are essential for assessing weld quality and structural integrity.

Filling out the deposited weld metal thickness is another area where mistakes are common. People may mistakenly record incorrect measurements, leading to further complications down the line. Correct data entry ensures that all engineering specifications are met.

Another significant mistake involves incorrect or incomplete certification signatures. The report must include the signature of a qualified individual, clearly denoting the authority behind the inspection. Missing this can jeopardize the report's validity.

Lastly, not keeping a copy of the completed form can lead to unnecessary issues. Retaining a record helps in any future inquiries regarding the inspection or in the case of disputes. Keeping paperwork organized is essential for effective project management.

Documents used along the form

The Wood Infestation Inspection Report form is a crucial document for assessing and documenting pest-related damage in wooden structures. Several other forms and documents often accompany this report to ensure a comprehensive evaluation and effective management of any identified issues. The following list outlines these documents and their significance.

- Pest Control Treatment Report: This document details the methods and materials used in the pest control treatment, including the date of application and any follow-up measures needed. It helps track the pest management history and effectiveness of treatments.

- Property Inspection Checklist: This checklist serves as a guideline for inspectors, ensuring that all necessary areas and components are evaluated during the property inspection. It aids in maintaining consistency and thoroughness in inspections.

- Maintenance and Repair Request Form: This form is used by property owners to request necessary repairs or maintenance based on findings from the inspection report. It facilitates prompt action to mitigate further damage.

- Claim Form for Property Damage: In case of significant structural damage due to infestation, this form is completed by property owners to initiate a claim with their insurance provider. It is essential for recovering losses related to pest damage.

- Follow-Up Inspection Report: This report is generated after the initial infestation inspection and any subsequent treatments. It assesses the effectiveness of the treatment and identifies any remaining issues that require attention.

- Environmental Impact Assessment: This document evaluates the ecological consequences of pest treatment methods used on the property. It ensures that the treatment complies with environmental regulations and maintains sustainability.

In summary, these accompanying documents are vital in providing a complete overview of the pest inspection process. They help property owners navigate the complexities of treatment and repair while ensuring that the integrity of the structures remains intact.

Similar forms

-

Home Inspection Report: This document provides a thorough evaluation of a home’s condition. Similar to the Wood Infestation Inspection Report, it assesses potential issues, including structural integrity and pest problems.

-

Termite Inspection Report: Like the Wood Infestation Inspection Report, this focuses specifically on termite infestations. Both documents serve to identify the presence of pests that can damage wooden structures.

-

Structural Engineering Report: This report examines the structural integrity of buildings. It parallels the Wood Infestation Inspection Report by ensuring that all components are sound and free from detrimental issues.

-

Building Inspection Report: Similar to the Wood Infestation Inspection Report, this document evaluates the general condition of a building. It often includes checks for pest infestations and structural problems.

-

Pest Control Report: This document outlines findings from pest assessments, much like the Wood Infestation Inspection Report. Both aim to confirm the absence or presence of harmful pests.

-

Environmental Assessment Report: This report addresses environmental conditions that might affect properties. It shares similarities with the Wood Infestation Inspection Report by evaluating impacts that could compromise property integrity.

-

Energy Audit Report: While primarily focused on a building's energy efficiency, this report also reviews potential issues that may arise from structural weaknesses, similar to concerns raised in a Wood Infestation Inspection Report.

Dos and Don'ts

Things to Do:

- Always provide accurate details in every field, including the welder's name and certification numbers.

- Make sure to sign and date the report when it is complete to validate the certification.

- Check the appropriate boxes for all applicable sections, including welding processes and metal specifications.

- Double-check the test results for any discrepancies before submitting the report.

Things to Avoid:

- Do not leave any fields blank; incomplete information can lead to rejection of the report.

- Avoid using abbreviations or unclear terms unless they are standard in the industry.

- Do not forget to verify the qualification range and ensure it aligns with required specifications.

- Do not submit the form without confirming that all necessary signatures are present.

Misconceptions

Misconceptions about the Wood Infestation Inspection Report form can lead to confusion or misinterpretations. Here are seven common misconceptions, explained:

- It's just a checklist. The report is more than a simple checklist; it requires detailed observations and necessary documentation about the wood infestation status, including specifics on any findings.

- It only covers termites. While termites are a common focus, the report addresses multiple wood-destroying organisms, including wood-boring beetles and fungi.

- All inspectors use the same criteria. Inspection criteria can vary significantly based on local regulations, specific property conditions, and the inspector's expertise.

- A clean report means no problems exist. A clean report indicates the absence of visible infestations at the time of inspection, but hidden issues may still be present.

- The report is unnecessary for new constructions. Even new buildings can harbor hidden infestations, making the inspection report important for verifying wood integrity.

- It’s only useful during real estate transactions. The report is valuable at any point to monitor wood health, especially in maintenance planning.

- All reports are the same. Inspection reports can vary in format and detail. This variation can affect the comprehensiveness and clarity of information provided.

Key takeaways

When utilizing the Wood Infestation Inspection Report form, keep the following key takeaways in mind:

- Accurate Information: Ensure that all details, including the welder's name and test number, are filled out accurately to avoid issues later.

- Relevance of Specifications: Use the appropriate code or specifications relevant to the inspection. This provides clarity and ensures compliance with industry standards.

- Testing Procedures: Clearly indicate the welding processes, positions, and any mechanical tests conducted. This helps document the qualification range effectively.

- Certification: Have the form signed by a qualified individual. This verifies that the inspection meets all stated standards and guidelines.

- Thorough Review: Before submission, review the form for completeness and accuracy. A well-filled report satisfies regulatory requirements and supports your credibility.

Browse Other Templates

Real Property Tax Credit Claim Form,Homeowners and Renters Tax Credit Application,New York Tax Credit Claim,IT-214 Tax Credit Application,Residential Property Tax Rebate Form,New York Homeowner and Renter Credit Form,Tax Savings Application for Homeo - Applicants must indicate whether they can be claimed as a dependent on another taxpayer's federal return.

California Sales Tax Exemption - This certificate is associated with section 6356.5.1 of the Tax Code.

Sales and Use Tax Certificate - Specific instructions are provided to clarify complex sections for taxpayers.