Fill Out Your Xnx Universal Transmitter Form

The XNX Universal Transmitter Quick Start Guide serves as a concise reference for users tasked with the installation, operation, and maintenance of this versatile transmitter. It outlines crucial steps and best practices necessary for ensuring optimal performance and safety. The document includes essential information about mounting and wiring the transmitter, as well as considerations for power source selection. Users will find detailed instructions on calibration procedures and sensor data, which are integral to the transmitter's functionality. Additionally, the guide presents key options, such as local HART® interface and Modbus compatibility, allowing customization to meet specific needs. With sections dedicated to warning messages, fault messages, and control drawings, the guide provides comprehensive support for troubleshooting and compliance with various standards. Whether you are a seasoned technician or a newcomer to the system, this guide aims to facilitate your understanding and enhance your workflow.

Xnx Universal Transmitter Example

Quick Start Guide

XNX Universal Transmitter

Table of Contents

1 |

Introduction |

5 |

|

2 |

Warnings |

6 |

|

3 |

Mounting and Location of Detectors |

8 |

|

|

3.1 |

Mounting the XNX Universal Transmitter |

8 |

4 |

Wiring the XNX transmitter |

11 |

|

|

4.1 |

General Wiring Considerations |

11 |

|

|

Loading��������������������������������������������������������������������������� |

11 |

|

|

Isolation �������������������������������������������������������������������������� |

12 |

|

|

Circuit Protection����������������������������������������������������������� |

12 |

|

|

Loads ������������������������������������������������������������������������������ |

12 |

|

4.2 |

Distance Considerations for Installation |

12 |

Types of Installations ���������������������������������������������������� 12 Power Source Selection������������������������������������������������ 12 Wire Selection ���������������������������������������������������������������� 12 Single Transmitter Distances ��������������������������������������� 13

4.3 |

POD Connections |

16 |

4.4 |

16 |

Setting

4.5 |

Terminal Block Connections |

19 |

4.6 |

EC Personality Wiring |

20 |

|

4�6�1 XNX Electrochemical (EC) Sensor Installation ��������� |

22 |

|

4�6�2 XNX EC Sensor Remote Mounting Kit ����������������������� |

23 |

4.7 mV Personality Wiring |

24 |

|

|

4�7�1 mV Remote Sensor Mounting������������������������������ |

27 |

4.8 |

IR Personality Wiring |

29 |

4�8�1 Connecting a Searchpoint Optima Plus or Searchline Excel ���������������������������������������������������������������������� 30

Attaching the Searchpoint Optima Plus to the XNX Universal Transmitter���������������������������������������������������� 30

Searchline Excel and Searchpoint Optima Plus Re- mote Installation ������������������������������������������������������������ 30

Searchpoint Optima Plus or Searchline Excel Wiring Recommendations��������������������������������������������������������� 31

4�8�2 Connecting Generic mA Device ��������������������������������� 32

XNX Universal Transmitter Quick Start Guide |

3 |

Table of Contents (cont’d) |

|

|

5 Options |

36 |

|

5.1 |

Local HART® Interface |

36 |

5.2 |

Relays |

36 |

5.3 Modbus |

37 |

|

5.4 |

Foundation Fieldbus |

38 |

6 Powering the XNX for the First Time |

39 |

|

6.1 |

XNX Units Configured for EC, mV, and IR (except Searchline |

|

Excel) |

39 |

|

6.2 |

XNX IR Units Configured for Searchline Excel |

40 |

6.3 |

Configuring the XNX Universal Transmitter |

42 |

7 The XNX Front Panel |

43 |

|

7.1 |

Controls and Navigation |

43 |

7.2 |

The General Status Screen |

43 |

7.3 |

Entering the Menu Structure |

45 |

7.4 |

Displaying Transmitter Information |

46 |

8 Gas Calibration Menu |

46 |

|

8.1 |

Calibration |

47 |

|

8.1.1 Calibration Procedure |

47 |

|

8.1.2 Zero and Span Calibration for XNX EC Sensors |

49 |

|

8.1.3 Zero and Span Calibration of XNX EC Hydrogen Sulfide (H2S) |

|

|

Sensors |

49 |

|

8.1.4 XNX EC Sensor Operational Life |

50 |

|

8.1.5 Zero and Span Calibration for MPD Sensors |

50 |

|

8.1.6 MPD Flammable Sensor |

52 |

|

8.1.7 Cross Calibration procedure for |

52 |

|

8.1.8 Calibrating the 705/705HT |

55 |

|

8.1.9 Calibrating the Sensepoint/Sensepoint HT |

55 |

8.2 |

Functional Gas Testing (Bump Test) |

56 |

9 Sensor Data |

57 |

|

9.1 |

Operating and Storage Conditions for Performance Tested |

|

EC Cartridges |

57 |

|

9.2 |

EC Sensor Performance Data, Factory Mutual Verified |

58 |

9.3 |

EC Sensor Performance Data, DEKRA EXAM Verified |

59 |

9.4 |

Other EC Sensors |

60 |

10 XNX Catalytic Bead and IR Replacement Sensor Cartridges |

62 |

|

11 Warning Messages |

63 |

|

12 Fault Messages |

70 |

|

13 Informational Messages |

82 |

|

14 Control Drawings |

84 |

|

15 Certification Labels |

91 |

|

16 Specifications |

94 |

|

17 EC Declaration of Conformity |

96 |

|

4 |

XNX Universal Transmitter Quick Start Guide |

1 Introduction

The XNX Quick Start Guide is an abbreviated print reference for the installation, operation, and maintenance of the XNX® Universal Transmitter. Refer to the XNX Universal Transmitter Resource CD (Honeywell part number

Manuals

XNX Technical Manual (1998M0738)

XNX Quick Start Guide

MPD Operating Manual

XNX Safety Manual

XNX Foundation Field bus Technical Manual

Control Drawings

1226E0402 XNX Control Drawing- UL,CSA, XM Approved Model

1226E0454 XNX Control Drawing- UL, INMETRO Approved Models

3000E3159 XNX ECC Cartridge Control Drawing- XNXX***** Series EC Cartridges and Remote Mount Kit.

For other sensor types such as Sensepoint Optima Plus, Searchline Excel, model 705 HT, or Sensepoint sensors, refer to their respective manuals for installation and ordering information.

XNX Universal Transmitter Quick Start Guide |

5 |

2 Warnings

High

•Installation must be in accordance with the recognized standards of the appropriate authority in the country concerned.

•Any work on the interior of the detector must be conducted only by trained personnel.

•Ensure that local regulations and site procedures are followed when carrying out any work. Appropriate standards must be followed to maintain the overall certiication of the detector.

•To reduce the risk of ignition of hazardous atmosphere, disconnect the equipment

from the supply circuit before opening the detector enclosure. Conduit runs must have a seal itting connected within 18 inches (45 cm) of the enclosures. Keep the assembly tightly closed during operation.

•Never open the XNX enclosure under power unless the area is known to be non

•The detector must be earthed/grounded for Intrinsic Safety, electrical safety, and to limit the effects of radio frequency interference. Earth/ground points are provided inside and outside the unit. EMI note for applications using shielded cable: Cable shield terminations must be made at the cable glands with suitable EMI type glands. Avoid terminating cable shields at the Earth ground lug inside the XNX enclosure. In cases where wiring is in pipe, a shielded cable is not required. The external terminal is only a supplemental bonding connection where local authorities permit or require such a connection.

•Take care when handling EC sensor cells as they may contain corrosive solutions.

•Do not tamper with or in any way disassemble the sensor cells.

•Do not expose the transmitter or sensor cells to temperatures outside the recommended range.

•Do not expose the sensor to organic solvents or lammable liquids.

•At the end of their working lives, sensors must be disposed of in an environmentally safe manner. Disposal should be according to local waste management requirements and environmental legislation.

•Alternatively, sensors may be securely packaged, clearly marked for environmental disposal, and returned to Honeywell Analytics.

•Do NOT incinerate electrochemical cells as they may emit toxic fumes.

•Verify all outputs, including display, after installation, after service events, and periodically to ensure the safety and integrity of the system.

•Delays resulting from transmission errors between sensor and transmitter extend response times T90 by more than

•As some test gases are hazardous, exhaust the low housing outlet to a safe area. Do not use the XNX Universal Transmitter in

6 |

XNX Universal Transmitter Quick Start Guide |

Hazardous Locations instaLLation requirements (uL/csa/Fm)

•To reduce the risk of ignition of hazardous atmospheres, conduit runs must have a pour gland installed within 18 inches (457mm) of enclosure.

•All ¾ inch NPT conduit, stopping plugs and adapters must be installed with 5 ¼ threads (minimum) engaged to Maintain Explosion Proof rating.

•The XNX Cover Assembly must be fully seated to enclosure 9 threads (minimum) to maintain Explosion Proof rating.

•Stopping Plugs supplied (Honeywell Part Number

•For units itted with the optional relay module: Relay contact ratings are 250 VAC 5A, 24 VDC 5A Resistive Loads Only.

•Use copper conductors only, 60/75°C. Terminal block screws should be tightened to 4.5 lb/in maximum.

•For models

•

•XNX Universal Transmitters carrying UL/CSA/FM approvals that are conigured

for devices measuring %LEL will not allow adjustments to the full scale value. The range is ixed at 100%.

Hazardous Locations instaLLation requirements (ateX)

•Read and understand Technical Manual 1998M0738 before installation and use.

•Use only Certiied M25 cable glands for installation.

•Shielded armoured cable is required for CE compliance.

•special conditions for safe use

•The following applies to the HART Barrier intrinsically safe circuits: For

installations in which both the Ci and Li of the intrinsically safe apparatus exceeds 1% of the Co and Lo parameters of the associated apparatus (excluding the cable), then 50% of Co and Lo parameters are applicable and

shall not be exceeded, i.e. the Ci of the device plus the C of the cable must be less than or equal to 50% of the Co of the associated apparatus, and the Li of the device plus the L of the cable must be less than or equal to 50% of the Lo of the associated apparatus.

•For circuits connected to the EC barrier in which the capacitance and inductance exceed 1% of the permitted values, then the maximum permitted capacitance is limited to 600nF for group IIC and 1uF for group IIIC.

•The connection to the HART circuit shall be rated a minimum of IP 6X.

XNX Universal Transmitter Quick Start Guide |

7 |

3 Mounting and Location of Detectors

caution

caution

The location of the transmitters and sensors should be made in accordance with any relevant local and national legislation, standards or codes of practice. Always replace detectors with a detector of the same type. The detector should be mounted where the gas is most likely to be present. The following points should be noted when locating gas detectors.

•Consider the possible damage caused by natural events e.g. rain or looding when locating detectors.

•Consider ease of access for functional testing and servicing.

•Consider how escaping gas may behave due to natural or forced air currents.

notes:

The placement of detectors should be determined following the advice of experts having specialist knowledge of gas dispersion, experts having knowledge of the process plant system and equipment involved, safety and engineering personnel. The agreement reached on the location of detectors should be recorded.

CSA certiication does not cover XNX EC cartridges or XNX EC cartridge remote mounting kit,

use of HART®, Modbus, or Foundation Fieldbus used for combustible gas performance. HART®, Modbus, or Foundation Fieldbus may be used only for

data collection or record keeping with regards to combustible gas detection.

FM approved conigurations (see the XNX Universal Transmitter Technical Manual, section 6.3 XNX Certiications by Part Number Series) also limit the

use of HART®, Modbus, or Foundation Fieldbus to use for diagnostics, data collection, or record keeping.

The XNX Universal Transmitter is certiied and designed for installation and use worldwide in hazardous areas.

3.1 Mounting the XNX Universal Transmitter

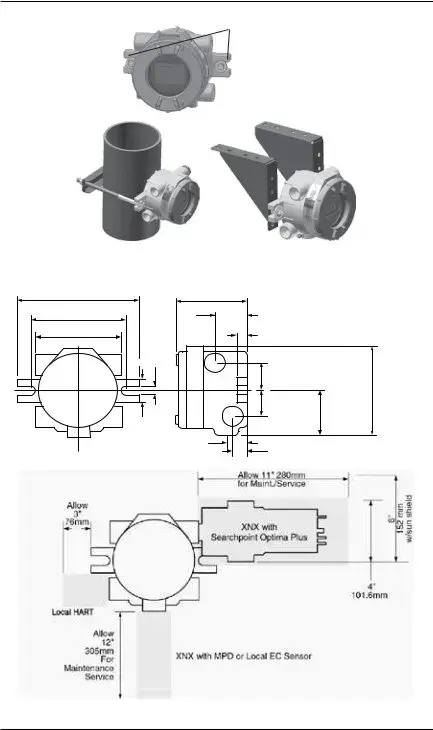

The XNX Universal Transmitter can be mounted in a number of different methods using the integral mounting tabs.

Using the mounting tabs, the XNX can be attached to:

•Flat wall surface

•Unistrut®

With the optional Pipe Mount kit, the XNX can be mounted to pipe of diameter 2 to 6 in (50 to 150mm).

A ceiling mount bracket kit (1226A0358) is also available.

notes:

Agency certiications require that EC and mV sensors face down. Optima sensors must be mounted horizontally.

8 |

XNX Universal Transmitter Quick Start Guide |

Integral Mounting Lugs

Figure 1. Integral mounting lugs and optional pipe and ceiling mounts

7.75"

196.85 mm

6.00"

15.4mm

5.6"

124.24 mm

4.48" |

|

|

113.8 mm |

2.054" |

|

|

|

|

|

52.18mm |

|

|

0.625" |

|

|

15.88mm |

|

0.55" |

|

|

14.35 mm |

|

|

|

1.768" |

|

|

44.90 mm |

|

|

1.768" |

|

|

44.90 mm |

3.176" |

1.67" |

|

80.67 mm |

|

|

|

42.41 mm |

|

|

1.2" |

|

|

31.75mm |

0.945" |

|

|

24mm |

|

6.138"

158.75mm

Figure 2. XNX Universal Transmitter mounting dimensions and clearances

XNX Universal Transmitter Quick Start Guide |

9 |

Warning

Warning

When the XNX is equipped with the optional Remote Mount Kit, the remote sensor MUST be securely mounted to a ixed position. The Remote Sensor Kit is not intended to be used as a

detector.

The XNX is conigured with 5 cable/conduit entries built into the housing for wiring and mounting sensors. Figure 3 provides the guidelines to proper installation of the XNX.

A

note

E

While relay wiring can use any available cable/conduit entry in the XNX enclosure, do not use the same cable/ conduit entry for both relay reset and relay signal lines to

D*

avoid electrical noise.

B

C

* Limited access due to IS barrier if equipped with electrochemical cell.

Option |

Position |

|

|

Local HART® Option |

B |

MPD, 705 Series, Sensepoint Series |

C |

|

|

Catalytic Bead Sensor |

C |

|

|

Searchpoint Optima Plus |

A or E |

|

|

Searchline Excel |

Typically C |

|

|

Remote Sensor Connection (except EC ) |

Any remaining |

|

|

Searchpoint Optima Plus - Remote |

Any remaining |

|

|

Modbus® |

Any remaining |

Relays |

Any remaining |

|

|

Foundation Fieldbus |

Any remaining |

|

|

Power |

Any remaining |

|

|

Figure 3. XNX Universal Transmitter cable/conduit entry assignments

10 |

XNX Universal Transmitter Quick Start Guide |

Form Characteristics

| Fact Name | Description |

|---|---|

| Introduction Purpose | The XNX Universal Transmitter Quick Start Guide provides essential information for installation, operation, and maintenance. |

| Mounting Location | Proper mounting and location of detectors are crucial for optimal performance, as specified in the guide. |

| Wiring Considerations | Every aspect of wiring, including general wiring considerations and circuit protection, is thoroughly outlined. |

| Powering the XNX | The guide includes specific instructions for powering the XNX Universal Transmitter for the first time. |

| Calibration Procedures | Calibration procedures, including zero and span calibration for various sensor types, are detailed to ensure accuracy. |

| Gas Calibration Menu | A dedicated menu for gas calibration is included, facilitating easy access to calibration functions. |

| EC Sensor Information | EC sensor data, including performance specifications and operational conditions, is provided for users' reference. |

| HART® Communications | Instruction for setting up HART® communications and supported modes is clearly laid out. |

| Relays and Options | The guide discusses optional features such as relays and Modbus communication for enhanced functionality. |

| Certification and Compliance | Each transmitter's certification labels and declarations of conformity are available for verification of compliance. |

Guidelines on Utilizing Xnx Universal Transmitter

The next steps will guide you through filling out the Xnx Universal Transmitter form accurately. Following these instructions will help ensure a smooth installation and operation process. Make sure to have all relevant information at hand as you fill out the form.

- Start with your personal information. Fill in your name, address, and contact details at the top of the form.

- Proceed to the section regarding the installation site. Include the location address, type of environment (indoor/outdoor), and any specific installation conditions.

- In the next section, indicate the type of transmitter you are installing. Choose from the available options on the form.

- Provide details about the power source. Specify the type of power source that will be used and its voltage rating.

- Complete the wiring specifications. Outline the wiring gauge and any special considerations necessary for the installation.

- Move to the sensor information section. Include the model numbers and specifications for any sensors that will be connected to the transmitter.

- Finally, review all filled-out sections for accuracy. Make adjustments as needed before submitting the form.

What You Should Know About This Form

What is the XNX Universal Transmitter?

The XNX Universal Transmitter is a versatile device used for detecting hazardous gases in various environments. It serves industries such as oil and gas, chemical processing, and wastewater management by ensuring safety through continuous monitoring of gas levels.

Where should I mount the XNX Universal Transmitter?

Choosing the right mounting location for the XNX Universal Transmitter is crucial. It should be positioned in areas where gas accumulation is likely and away from direct interference such as heavy machinery. Settings should comply with manufacturer's guidelines concerning environmental conditions such as temperature and humidity.

How do I wire the XNX Universal Transmitter?

Wiring the transmitter requires careful attention to detail. Use the provided wiring diagram to connect the power source, outputs, and any additional devices. Always ensure that the power is turned off when connecting or disconnecting wires. The transmitter supports several wiring configurations depending on your specific setup requirements.

Can the XNX Universal Transmitter be configured for different types of sensors?

Yes, the XNX Universal Transmitter can accommodate different types of sensors, including electrochemical (EC), catalytic bead, and infrared (IR) sensors. Refer to the specific sensor manual for installation instructions and compatibility details.

What is the process for gas calibration with the XNX Transmitter?

Calibrating the gas sensors involves following a systematic procedure outlined in the user guide. This includes performing zero and span calibrations to ensure that the readings are accurate. Regular calibration is necessary for maintaining compliance and safety standards.

What types of power sources are compatible with the XNX Universal Transmitter?

The XNX Universal Transmitter is compatible with various power sources, including typical AC power and specific DC options. Always refer to the specifications in the manual to confirm power requirements compatible with your setup.

What options are available for connecting to external systems?

There are multiple connection options including HART® Communications, Modbus, and Foundation Fieldbus. These interfaces allow the XNX Universal Transmitter to integrate seamlessly with existing safety and monitoring systems.

What should I do if I receive a warning message from the transmitter?

If warning messages appear on the XNX Universal Transmitter, it is essential to address them promptly. Refer to the troubleshooting section of the manual for specific messages and suggested actions. Always ensure safety protocols are followed, and if uncertain, consult a professional.

How can I access the user interface on the XNX Universal Transmitter?

The user interface can be accessed through the front panel of the XNX Universal Transmitter. By navigating through the controls, you can view the general status screen, access menu options, and gather information about the device’s performance.

Common mistakes

Filling out the XNX Universal Transmitter form can seem straightforward, but many individuals make critical mistakes in the process. Understanding these common errors can help ensure that the form is completed accurately and efficiently.

One prevalent mistake occurs when users overlook the mounting and location specifications. These specifications are vital for the proper operation of the transmitter. Improper placement can lead to inaccurate readings or even device failure. Be sure to check the guidelines carefully and ensure that all locations are appropriate as per the manufacturer’s recommendations.

Another frequent error is failing to consider wiring requirements. Incorrect wiring can not only damage the transmitter but also create safety hazards. Ensure that you are familiar with the general wiring considerations and terminal block connections provided in the documentation before proceeding. Using the wrong wire type or gauge can result in poor performance or risk of malfunction.

Many people also skip over the section on power source selection. This can have serious implications for device functionality. Using an inadequate power source could lead to intermittent operational issues. Make sure to verify that the power supply meets the necessary specifications outlined in the quick start guide.

In addition, users often neglect to follow the calibration procedures. Calibration is essential for ensuring that the transmitter provides accurate measurements. Ignoring this step can lead to significant discrepancies in data over time. It is important to consult the calibration section in the guide and perform the necessary procedures before regular use.

A fifth error is misunderstanding the communication protocols such as HART® or Modbus. Each protocol has specific setup requirements and incompatibility issues could arise if not correctly configured. Take time to read through the relevant sections to ensure you have the right settings for your application.

Lastly, many people fail to check for warnings and error messages during or after setup. It is crucial to remain alert for any alerts or messages provided by the device. Ignoring these warnings can lead to operating issues that compromise safety and efficiency. Regular monitoring of the status and performance messages can provide early indicators of potential issues.

By being mindful of these common mistakes—focusing on mounting, wiring, power sourcing, calibration, communication protocols, and warnings—users can significantly improve their experience with the XNX Universal Transmitter. Taking the time to review each section of the documentation thoroughly will yield better performance and reliability from this vital device.

Documents used along the form

The XNX Universal Transmitter form is often accompanied by various supplementary documents that serve to provide comprehensive information for installation, operation, and maintenance. Each of these documents plays a specific role in ensuring the effective use of the transmitter in various applications.

- XNX Technical Manual: This document offers detailed information on the technical specifications, features, and operational guidelines for the XNX Universal Transmitter. It serves as a thorough reference for engineers and technicians.

- XNX Quick Start Guide: A streamlined version of the technical manual, this guide presents essential information in a user-friendly format. It is particularly useful for those preparing for immediate installation and initial setup.

- MPD Operating Manual: This manual addresses the operational aspects of the Multi-Gas Detector (MPD), providing instructions on usage, calibration, and maintenance that are crucial for safety and functionality.

- XNX Safety Manual: Focusing on safety protocols, this document outlines precautions, operational safety measures, and troubleshooting tips to mitigate risks associated with using the XNX equipment.

- XNX Foundation Fieldbus Technical Manual: This technical manual elaborates on how to integrate the XNX Universal Transmitter with Foundation Fieldbus systems, detailing communication protocols and wiring configurations.

- Control Drawings: These diagrams include essential wiring schemes and component layouts. They help technicians visualize the installation process and ensure accurate connections during setup.

- Certification Labels: These labels provide information regarding the compliance of the XNX Universal Transmitter with industry regulations and standards, confirming its operational safety and reliability.

- Specifications: This document consists of specific performance parameters and technical details of the XNX Universal Transmitter, serving as a critical resource for selection and installation processes.

- EC Declaration of Conformity: This declaration certifies that the XNX Universal Transmitter meets the essential health and safety requirements set forth by regulatory bodies for electronic products.

Understanding these documents enhances effective use and maintenance of the XNX Universal Transmitter. Having access to a range of resources ensures that users can easily find the information necessary for successful implementation and compliance with safety standards.

Similar forms

-

Quick Start Guide for Other Devices: Similar to the XNX Universal Transmitter, other devices like the Quick Start Guide for the HART Communication Protocol provide straightforward instructions for installation and operational setup. These guides simplify complex procedures into easy steps, helping users get started quickly without overwhelming details.

-

Installation Manual for HVAC Systems: Just as the XNX guide includes detailed mounting and wiring suggestions, an HVAC installation manual features specific installation and operational directives. Both documents prioritize safety concerns and offer troubleshooting advice to ensure effective usage.

-

Owner's Manual for Home Appliances: An owner's manual often parallels the XNX guide in that it contains a blend of safety warnings, installation tips, and user maintenance information. Both documents serve as essential resources to enhance user understanding and appliance longevity.

-

Service Manual for Industrial Equipment: A service manual outlines the operational requirements and troubleshooting steps just like the XNX guide. Both types of documents help users maintain safe and effective equipment operation by addressing common issues and operational best practices.

-

Calibration Guide for Scientific Instruments: This type of guide is comparable to the XNX Universal Transmitter in that it shares procedures for calibrating devices to ensure accuracy. Both guides stress the importance of regular calibration and provide specific steps to attain optimal performance.

Dos and Don'ts

When filling out the XNX Universal Transmitter form, there are essential guidelines to follow. Below is a list of things you should and shouldn't do to ensure a smooth process.

- Do: Carefully read the accompanying Quick Start Guide for detailed instructions.

- Do: Double-check all entries for accuracy before submission.

- Do: Use clear and legible handwriting if completing the form by hand.

- Do: Refer to the specific manuals for additional guidance on sensor types.

- Do: Make sure to calibrate the device as instructed before initial use.

- Don't: Leave any mandatory fields blank; this may delay processing.

- Don't: Overwrite or use correction fluid on the form. This creates confusion.

- Don't: Ignore the warnings section in the Quick Start Guide.

- Don't: Submit documents that are illegible or difficult to read.

- Don't: Skip the review process. Always have someone else verify the filled form.

Misconceptions

The XNX Universal Transmitter is a complex device often misunderstood. Below are ten common misconceptions about this transmitter, along with clarifications for each.

- Misconception 1: The XNX Universal Transmitter can only be used with specific sensors.

- Misconception 2: The installation process is overly complicated.

- Misconception 3: Once installed, the transmitter requires constant manual calibration.

- Misconception 4: All XNX transmitters function the same way.

- Misconception 5: The XNX is only suitable for one type of gas detection.

- Misconception 6: It cannot communicate with other devices.

- Misconception 7: The XNX requires special wiring that is difficult to handle.

- Misconception 8: Fault messages indicate a defective unit.

- Misconception 9: You need to be a trained technician to operate the XNX.

- Misconception 10: The transmitter cannot perform self-diagnostics.

This is not true. The XNX is versatile and can read inputs from a variety of sensors, including Electrochemical (EC), mV, and Infrared (IR) sensors.

While the installation does require careful attention to wiring and mounting, the Quick Start Guide provides clear instructions to simplify the process.

Although periodic calibration is necessary, many users can perform these calibrations efficiently, and the device can maintain accuracy for extended periods between adjustments.

Different models are designed for various applications. Features and capabilities can vary significantly based on the specific sensor types and configurations chosen.

The device is designed for multi-gas detection, providing flexibility depending on the safety needs of an environment.

The XNX supports communication protocols like HART, Modbus, and Foundation Fieldbus, allowing integration with other systems.

While proper wiring is critical for safety and functionality, the guidelines provided in the Quick Start Guide help users make appropriate choices without specialist training.

Not necessarily. Fault messages can be triggered by various issues, including sensor malfunctions or environmental factors, and many can be resolved with troubleshooting.

Though training is beneficial, the XNX is designed with user-friendly features. A well-informed operator can effectively monitor and maintain the device.

In fact, the XNX is equipped with diagnostic capabilities that help identify issues and ensure proper functioning, making it more reliable for users.

Key takeaways

When using the XNX Universal Transmitter form, there are several essential points to keep in mind.

- Understand the Purpose: This form is crucial for the installation, operation, and maintenance of the XNX Universal Transmitter.

- Follow the Quick Start Guide: The guide serves as a condensed reference, aiding you through the process with ease.

- Familiarize with Wiring Considerations: Proper wiring is essential. Be attentive to the specific details regarding distance, power source selection, and wiring types.

- Calibration Matters: Calibration is a critical step that needs careful execution to ensure accurate sensor readings.

- Utilize the Right Resources: Refer to the digital resource CD and comprehensive manuals for in-depth guidance.

- Check Compatibility: Ensure that the XNX is compatible with various sensor types to avoid any integration issues.

- Pay Attention to Warnings: The warnings section outlines important safety precautions you shouldn't overlook.

- Monitor Powering Up: The initial powering of the device requires particular attention to set it up correctly the first time.

- Maintain Regular Testing: Conduct functional gas testing or bump tests to ensure the system's reliability.

By keeping these takeaways in mind, you’ll set yourself up for success when filling out and using the XNX Universal Transmitter form. It’s an intricate process, but with the right knowledge, it becomes much more manageable.

Browse Other Templates

T Accounts Accounting - Can be applied to any type of financial account.

What Does Dismissed Without Prejudice Mean - Failure to submit the CIV-120 may lead to misunderstandings regarding a case's status.